- 1.0What is ISO 2859?

- 2.0Core Principles of ISO 2859

- 3.0The Role of ISO 2859 in the Mechanical Manufacturing Industry

- 4.0Application of ISO 2859-1 in Machining and Manufacturing

- 5.0Common Misconceptions When Using ISO 2859

- 6.0How to Implement an ISO 2859 Inspection Process

- 7.0ISO 2859 in Relation to Other Quality Management Standards

- 8.0Conclusion: ISO 2859 as a Strategic Tool for Mechanical Quality Control

In practical quality control operations, 100% inspection is often costly and inefficient—especially in mass production environments. Striking a balance between inspection efficiency and product quality becomes a key challenge for manufacturers. ISO 2859 was developed precisely for this purpose. As a globally recognized standard for sampling inspection, it is widely used across industries and serves as a critical reference in the quality inspection processes of manufacturing plants, particularly in the field of mechanical engineering.

1.0What is ISO 2859?

ISO 2859, officially titled Sampling Procedures for Inspection by Attributes, is a set of standardized procedures developed by the International Organization for Standardization (ISO) for attribute-based inspection of product lots.

Attribute inspection refers to the binary evaluation of items as either “conforming” or “nonconforming” (e.g., dimensionally acceptable, free from surface defects), rather than the measurement of quantitative values—which is addressed by ISO 3951. The ISO 2859 standard is commonly applied in incoming inspection, in-process inspection, and final inspection scenarios.

1.1ISO 2859-1 Version History

ISO 2859-1 is a key standard from the International Organization for Standardization (ISO) for sampling inspection of product batches. It has been revised several times to align with industrial changes and evolving quality systems.

- ISO 2859-1:1989: An early widely used version that established the core framework of AQL, inspection levels, sample size codes, and switching rules. It was broadly adopted in industries like machinery, electronics, and consumer goods, and supported systems like ISO 9001:1994.

[Download ISO 2859-1:1989 PDF]

- ISO 2859-1:1999: A major update improving terminology, switching rules, and usability. It enhanced clarity and better supported integration with automated inspection and ISO 9001:2000 systems.

[Download ISO 2859-1:1989 PDF]

2.0Core Principles of ISO 2859

The ISO 2859 series consists of several parts, the most commonly used are:

| Standard Number | Simplified Title | Application |

|---|---|---|

| ISO 2859-1 | General sampling procedures for inspection by attributes | Most commonly used, provides AQL inspection tables |

| ISO 2859-2 | Procedures for tighter quality limits | Used in high-reliability sectors (e.g., military, medical) |

| ISO 2859-3 | Procedures for validating sampling plans | For verifying the effectiveness of inspection schemes |

| ISO 2859-4 | Multiple sampling procedures | More complex but cost-efficient sampling methods |

| ISO 2859-5 | Sequential sampling for continuous production | Suitable for ongoing production processes |

Sampling inspection based on ISO 2859 involves several key concepts:

2.1AQL (Acceptable Quality Limit)

AQL refers to the maximum percentage of defective items in a batch that can be considered acceptable as a process average. Common AQL values include 1.0%, 1.5%, 2.5%, and 4.0%. Importantly, an AQL does not imply that defective items are permissible, but rather that the batch should be accepted statistically if the defect rate is below the specified limit.

2.2Inspection Level

The standard provides three general inspection levels (General Levels I, II, III) and four special levels (S-1 to S-4). These levels determine the sample size. General Level II is the default and most commonly used level in practice.

2.3Sampling Plans

ISO 2859 defines three types of sampling plans:

Single sampling: A decision is made after inspecting one sample;

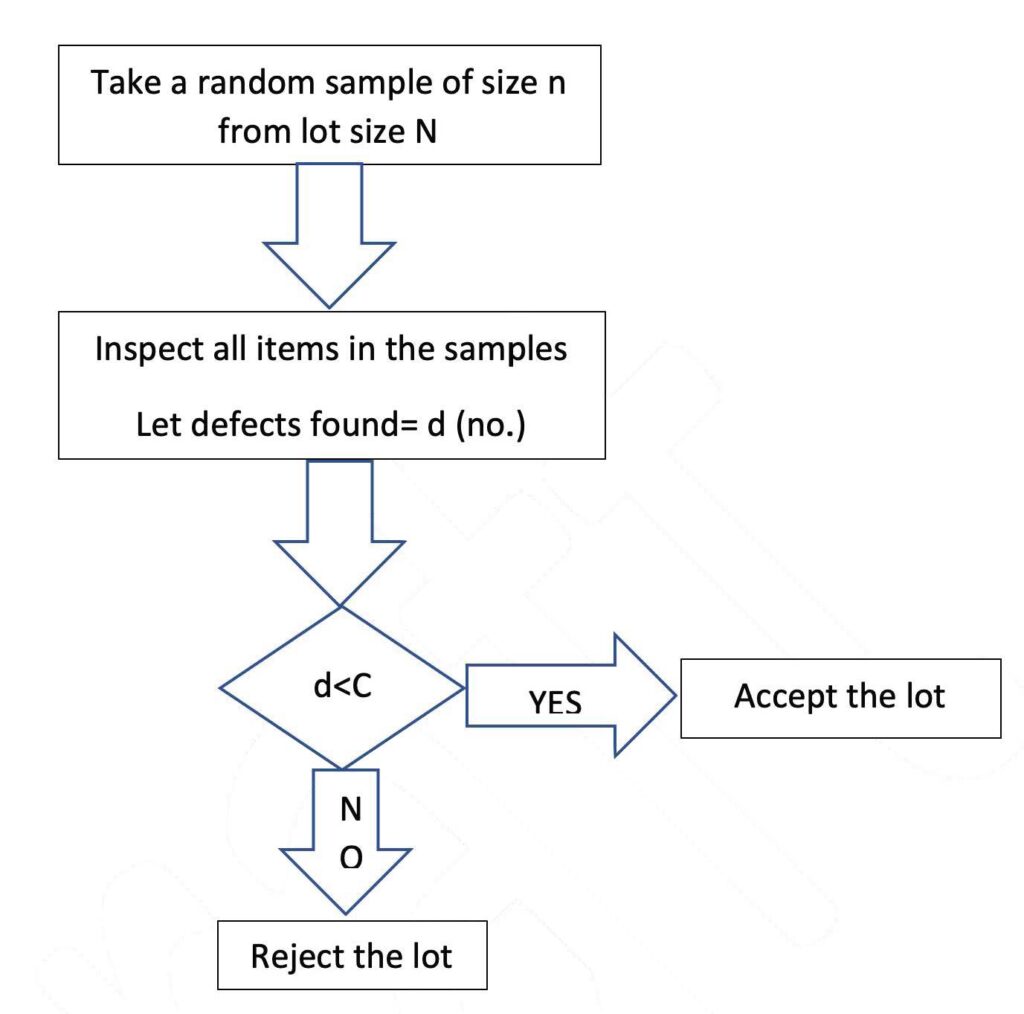

Single Sampling Plan (ISO 2859)

Let:

-

N = lot size

-

n = sample size

-

C = acceptance number

-

d = number of defective items found in the sample

Rule:

-

If d < C, accept the lot.

-

If d ≥ C, reject the lot.

This is the simplest and most commonly used inspection rule in ISO 2859, suitable for general quality control scenarios.

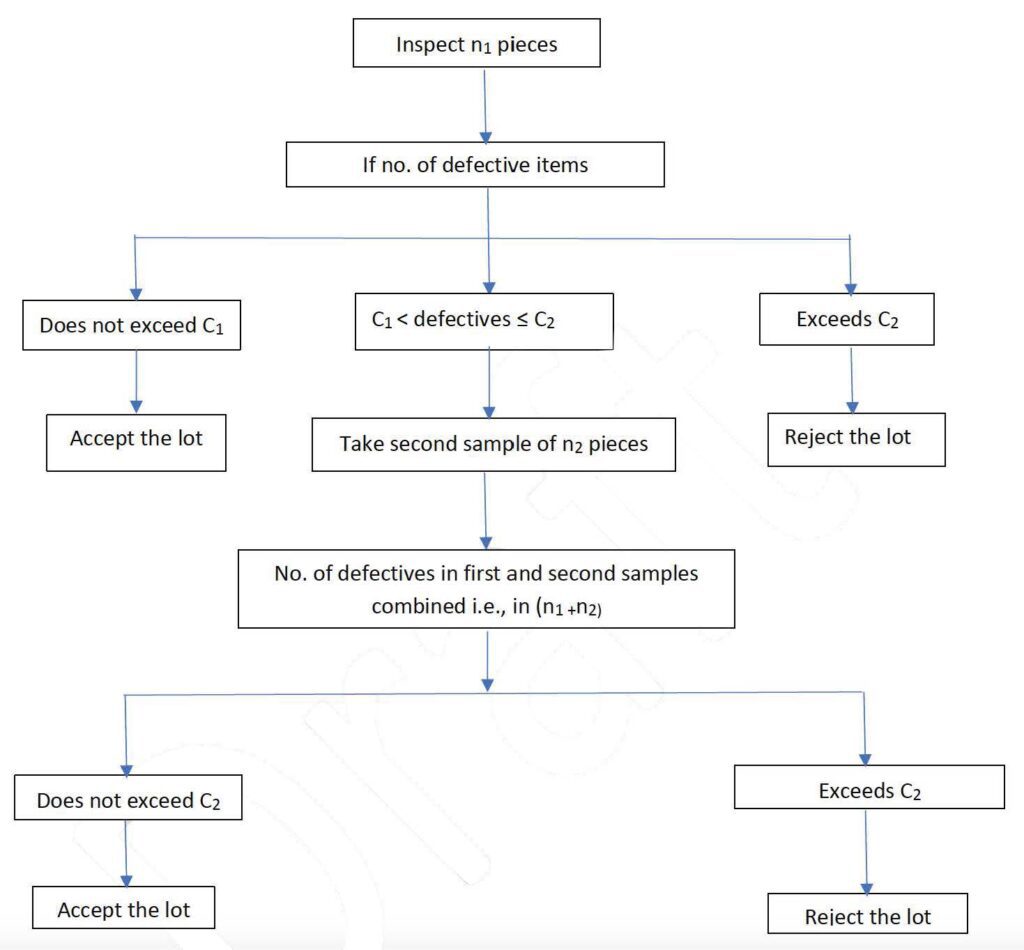

Double sampling: A second sample is drawn if the first is inconclusive;

Let:

-

N = lot size

-

n₁ = number of pieces in the first sample

-

C₁ = acceptance number for the first sample

-

d₁ = number of defectives in the first sample

-

n₂ = number of pieces in the second sample

-

n₁ + n₂ = total number of inspected items

-

C₂ = acceptance number for the combined samples

-

d₂ = total number of defectives in both samples

Rule:

-

If d₁ ≤ C₁, accept the lot.

-

If d₁ > C₂, reject the lot.

-

If C₁ < d₁ ≤ C₂, take a second sample and inspect:

-

If d₂ ≤ C₂, accept the lot.

-

If d₂ > C₂, reject the lot.

-

This approach helps reduce inspection effort when the lot quality is clearly good or bad after the first sample, while allowing further evaluation when results are borderline.

Multiple sampling: Further subdivides the inspection process to enhance efficiency.

2.4Sample Size Code Letters

This is a central tool in ISO 2859. Based on lot size and the selected inspection level, a code letter (e.g., K, L, M) is determined from the lookup table. The letter is then used to find the corresponding sample size and the acceptance/rejection criteria according to the selected AQL.

2.5Industry Applications of ISO 2859

ISO 2859 is applicable to virtually any batch production process where quality control is essential. It is especially relevant in the following sectors:

- Electronics manufacturing: e.g., capacitors, resistors, PCBs;

- Food and pharmaceutical industries: for visual inspection of packaging, sealing, etc.;

- Medical devices: where zero-defect delivery is critical;

3.0The Role of ISO 2859 in the Mechanical Manufacturing Industry

ISO 2859 finds broad and direct application in the field of mechanical manufacturing, including but not limited to the following areas:

3.1Sampling Inspection of Components

Parts such as milled, turned, stamped, and sheet metal components—especially those outsourced or purchased externally—are typically inspected upon receipt using ISO 2859-based sampling plans as part of the Incoming Quality Control (IQC) process.

3.2In-Process or Intermediate Inspection (IPQC)

During production steps such as welding, painting, or polishing, sampling inspection is used to monitor process stability within a batch. This helps prevent further processing of large quantities of defective products, thereby reducing waste.

3.3Final Product Inspection (FQC/OQC)

Before packaging, final products undergo sampling inspection to ensure that they meet the Acceptable Quality Limit (AQL) agreed upon with the customer. This reduces the risk of returns and post-delivery quality claims.

3.4Automated Line Quality Control

In smart manufacturing environments, ISO 2859 is integrated into MES (Manufacturing Execution Systems) or QMS (Quality Management Systems), allowing real-time sampling, decision-making, and feedback within automated inspection workflows.

4.0Application of ISO 2859-1 in Machining and Manufacturing

In the mechanical industry, products often require high precision and strength. In key processes such as turning, stamping, and bending, product consistency and safety directly affect assembly quality and operational reliability. ISO 2859-1 offers an efficient quality control framework and is widely adopted in both in-process and final inspections of these critical operations.

4.1Application in Turning Processes

Turned parts—such as shafts, threaded components, and sleeves—require strict control over dimensional accuracy and surface finish. By applying ISO 2859-1, the quality team can set an appropriate AQL (e.g., 1.0%) based on lot size and define sampling plans for “go/no-go” inspection of key characteristics such as diameter, concentricity, and thread pitch. This approach reduces inspection time and effectively filters out machining defects.

4.2Application in Stamping Processes

Stamped parts (e.g., metal housings, brackets, perforated plates) often involve geometric and edge-quality criteria. Under ISO 2859-1, different AQLs can be assigned to various defect types:

- Critical defects(e.g., cracks, severe deformation): AQL = 0.0%

- Major defects(e.g., incomplete punching, burrs): AQL = 1.0%

- Minor defects(e.g., light scratches): AQL = 2.5% Using General Inspection Level II or III, a statistically determined number of units is inspected to assess batch acceptability.

4.3Application in Sheet Metal Bending Processes

Common issues in sheet metal bending include angular deviation, cracking, and surface indentation. ISO 2859-1 allows manufacturers to tailor inspection criteria to customer-specific appearance and functional requirements.

For instance, aesthetic enclosures may require stricter visual inspection using special levels like S-4, while structural brackets may prioritize dimensional and load-bearing attributes.

4.4Standardization and Efficiency Gains

By implementing ISO 2859-1, manufacturers can establish standardized quality control procedures. Sampling plans can be documented in quality manuals or work instructions and consistently executed by inspection personnel. This minimizes subjective judgment and enables rapid adaptation of inspection strategies across multiple lines and processes, enhancing overall inspection efficiency.

5.0Common Misconceptions When Using ISO 2859

Despite being a mature and widely used standard, ISO 2859 is sometimes misapplied due to the following misconceptions:

- Treating AQL as a Quality Goal

AQL defines the statistical acceptance limit—not the actual target for product quality. A lower defect rate should remain the manufacturing goal. - Ignoring Sample Representativeness

Samples must be randomly and representatively selected. Choosing only “good-looking” items compromises statistical validity. - Misaligning Inspection Frequency with Production Rhythm

Sampling must be synchronized with actual production cycles. Otherwise, it may cause inspection bottlenecks or missed batches.

6.0How to Implement an ISO 2859 Inspection Process

- Step 1:Define AQL and Inspection Level

Set appropriate AQLs based on product type, customer requirements, and historical defect rates (e.g., 1.0% for key dimensions, 2.5% for cosmetic defects). - Step 2:Determine Lot Size

Refer to the actual quantity in the batch—whether in production or procurement. - Step 3:Refer to the Sampling Table

For example:- Lot size: 500 units

- Inspection level: General II

- AQL: 1.5%

- Sample size: 50 units

- Acceptance criteria: Accept if ≤ 2 defects; reject if ≥ 3 defects

- Step 4:Conduct On-Site Inspection and Record Results

Inspectors perform sampling and make batch disposition decisions based on standard-defined thresholds.

7.0ISO 2859 in Relation to Other Quality Management Standards

Relation to ISO 9001: ISO 2859 serves as a key tool in the implementation of ISO 9001, enabling organizations to validate process outputs for conformity.

Difference from ISO 3951: ISO 2859 is attribute-based (pass/fail), while ISO 3951 is variable-based (quantitative). The latter is typically used for continuous data like dimensions.

8.0Conclusion: ISO 2859 as a Strategic Tool for Mechanical Quality Control

In the mechanical sector, quality impacts not just performance but also brand reputation. ISO 2859 offers a scientific, efficient, and repeatable method for managing inspection under resource constraints.

For manufacturers focused on lean management and process control, ISO 2859 is more than a tool—it embodies a philosophy of proactive, data-driven quality management.

References

blog.ansi.org/2020/07/iso-2859-4-2020-declared-quality-levels/

www.testcoo.com/en/blog/understanding-iso-2859-a-comprehensive-guide-to-sampling-for-quality-inspection

qualityinspection.org/inspection-level/