- 1.0Core Concepts of IEC 61508

- 2.0What is IEC 61508 and SIL (Safety Integrity Level)?

- 3.0What is Functional Safety

- 4.0Why IEC 61508 is a Key Standard for Industry 4.0

- 5.0Recommended Resources on 《IEC 61508 IEC 61508:2010 PDF》

- 6.0IEC 61508 & SIL – Frequently Asked Questions (FAQ)

- 6.1What is IEC 61508 and which industries does it apply to?

- 6.2What is SIL (Safety Integrity Level) and how many levels are there?

- 6.3How is the required SIL level determined?

- 6.4What is Functional Safety and how is it different from general safety?

- 6.5Why pursue SIL certification?

- 6.6Why is IEC 61508 important in the context of Industry 4.0?

IEC 61508 is an international standard for functional safety published by the International Electrotechnical Commission (IEC). Its full title is “Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems” (often abbreviated as E/E/PE or E/E/PES). The standard provides a systematic framework to ensure the functional safety and reliability of systems throughout the entire safety lifecycle.

IEC 61508 serves as the foundational standard for many industry-specific functional safety standards, such as IEC 61511 and IEC 62061. It is widely applied in sectors including industrial automation, process control, and machinery manufacturing.

1.0Core Concepts of IEC 61508

IEC 61508 covers the following key aspects:

- Functional Safety: The standard emphasizes that systems or equipment must correctly perform their safety functions under defined conditions. If they fail, the failure must occur in a predictable and safe manner.

- Safety Lifecycle: It introduces a comprehensive lifecycle approach, covering all phases from initial concept, design and development, operation and maintenance, to decommissioning—ensuring continuous compliance with safety requirements.

- Risk-Based Approach: By identifying hazards, assessing associated risks, and applying appropriate control measures, the standard helps reduce risk to a level that is As Low As Reasonably Practicable (ALARP).

- Safety Integrity Level (SIL): SIL is a quantitative measure of the reliability of safety functions, ranging from SIL 1 (lowest) to SIL 4 (highest). Each SIL level is determined based on three main criteria:

- System Capability: Reliability of hardware and software design

- Architectural Constraints: Limitations imposed by system architecture

- PFDavg / PFH: The probability of dangerous failure, either on demand (PFDavg) or per hour (PFH)

The final SIL level is defined by the lowest level among these three criteria.

1.1Structure and Scope of IEC 61508

IEC 61508 consists of eight parts. Parts 1 to 7 were released between 1998 and 2000, and IEC/TR 61508-0 was added in 2005. The standard underwent a comprehensive review process starting in 2002, leading to the publication of Edition 2 in April 2010.

The full title of the standard is “Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems (E/E/PE systems)”, and its structure includes:

- Part 0: Functional safety and IEC 61508

- Part 1: General requirements

- Part 2: Requirements for E/E/PE safety-related systems

- Part 3: Software requirements

- Part 4: Definitions and abbreviations

- Part 5: Examples of methods for the determination of safety integrity levels

- Part 6: Guidelines on the application of Parts 2 and 3

- Part 7: Overview of techniques and measures

In addition, several industry-specific standards have been derived from IEC 61508, adapting its principles for particular domains:

- IEC 61511– For the process industry (e.g., chemical and petrochemical plants)

- IEC 62061– For machinery safety

- ISO 26262– For automotive electronic systems

- DO-178C– For avionics software systems

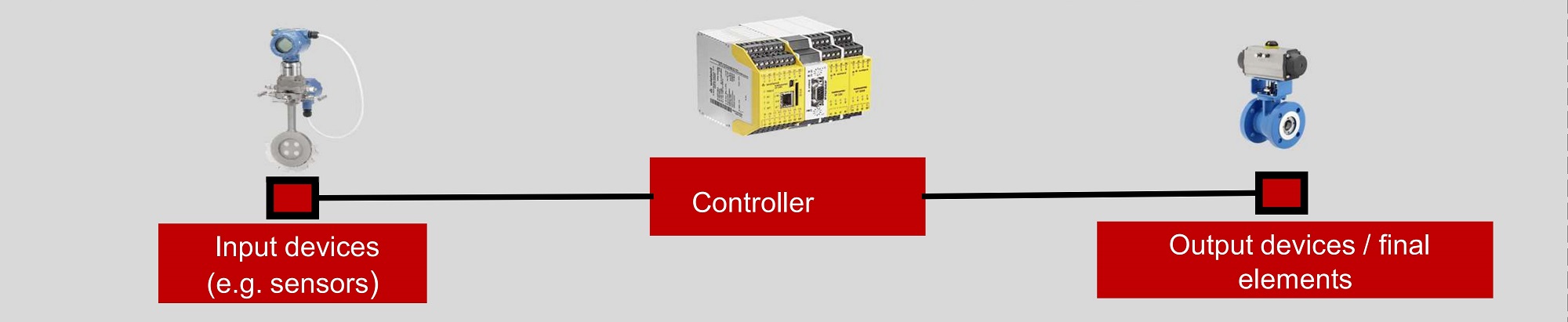

The example shows a typical Electrical, Electronic & Programmable Electronic safety-rated system usually referred to as an E/E/PE safety -related system.

1.2Implementation and Compliance

To achieve compliance with IEC 61508, organizations must:

- Understand and follow the prescribed validation and verification processes

- Identify and mitigate critical failure modes

- Ensure that hardware and software systems operate within the constraints of the applicable SIL level

- Manage complexity during system design to reduce the risk of failure

- Apply appropriate safety strategies for components used frequently or activated only during hazardous events

1.3Practical Applications of IEC 61508

IEC 61508 is widely used across safety-critical electrical, electronic, and programmable electronic systems. Common application examples include:

- Machinery Industry: Press brakes, laser cutters, stamping machines, industrial robot safety systems

- Process Industry: Emergency shutdown systems (ESD), safety valves, pressure relief devices

- Power Sector: Protective relays, fault isolation devices, intelligent circuit breakers

- Transportation: Railway signaling systems, automatic train control (ATC) units, automotive safety modules

- Medical Devices: Life support systems, safety monitoring modules

By following IEC 61508, these systems are designed with functional safety principles that help prevent accidents and protect both human life and the environment in the event of a failure.

1.4Why IEC 61508 Was Developed

In the 1990s, an increasing number of safety functions were being implemented through electronic or programmable electronic systems. These systems often exhibit high complexity, making it practically impossible to identify every possible failure mode or test every operational scenario.

The key challenge was to design systems that could either prevent hazardous failures or manage them safely if they occurred. Such failures could stem from:

- Incorrect specifications for safety-related control systems

- Incomplete safety requirement definitions (e.g., failure to define functions across all operating modes)

- Random hardware failures

- System-level hardware faults

- Software design errors

- Common cause failures

- Human errors

- Environmental factors (e.g., electromagnetic interference, temperature extremes, mechanical stress)

2.0What is IEC 61508 and SIL (Safety Integrity Level)?

IEC 61508 is an internationally recognized functional safety standard applicable to electrical, electronic, and programmable electronic safety-related systems. It provides systematic safety guidance for the design, development, operation, and maintenance of such systems. One of its key components is the Safety Integrity Level (SIL), a critical measure of a safety function’s ability to reduce risk under hazardous conditions.

2.1Definition and Role of SIL

IEC 61508 defines safety integrity as:

“The probability of a safety-related system successfully performing the required safety function under all specified conditions and within a specified time.”

SIL levels indicate the degree of risk reduction provided by a safety function when a hazardous event occurs. There are four SIL levels, from SIL 1 to SIL 4, with higher levels corresponding to stricter safety requirements and more complex development and verification processes.

| SIL Level | Probability of Hazard | Corresponding Development Requirements |

| SIL 1 | Highest probability | Minimum requirements |

| SIL 2 | Medium | Recommended measures |

| SIL 3 | Low | Strict measures |

| SIL 4 | Lowest probability | Most stringent controls |

2.2How SIL is Determined

IEC 61508 provides both qualitative and quantitative methods for determining SIL, including the following:

1. Hazard and Risk Assessment (Part 5)

- Identify potential hazards

- Assess the frequency and severity of the risk

- Determine the required level of risk reduction (Annex A)

2. Failure Probability Assessment

SIL can be quantitatively assessed using:

- PFDavg (Average Probability of Dangerous Failure on Demand)for low-demand modes

- PFH (Probability of Dangerous Failure per Hour)for continuous modes

PFDavg – Low Demand Mode:

| SIL Level | PFDavg Range |

| SIL 4 | ≥ 10⁻⁵ to < 10⁻⁴ |

| SIL 3 | ≥ 10⁻⁴ to < 10⁻³ |

| SIL 2 | ≥ 10⁻³ to < 10⁻² |

| SIL 1 | ≥ 10⁻² to < 10⁻¹ |

PFH – Continuous Mode:

| SIL Level | PFH [1/h] Range |

| SIL 4 | ≥ 10⁻⁹ to < 10⁻⁸ |

| SIL 3 | ≥ 10⁻⁸ to < 10⁻⁷ |

| SIL 2 | ≥ 10⁻⁷ to < 10⁻⁶ |

| SIL 1 | ≥ 10⁻⁶ to < 10⁻⁵ |

2.3System Capability and Architectural Constraints

The system must meet specific design, testing, and verification capabilities (e.g., FMEDA, SFF).

SFF (Safe Failure Fraction) = (Safe Failures + Detected Dangerous Failures) / Total Failures

2.4Comparison of Safety Integrity Levels Across Standards

While SIL is part of the IEC 61508 framework, other industry standards define similar safety levels that are not directly interchangeable:

| Standard | Safety Levels (Low → High) |

| IEC 61508 | SIL 1, SIL 2, SIL 3, SIL 4 |

| ISO 26262 | ASIL A, ASIL B, ASIL C, ASIL D |

| DO-178C | Level E, D, C, B, A |

| IEC 62304 | Class A, B, C |

| EN 50128 | SSIL 0, 1, 2, 3, 4 |

2.5SIL and Software Development

IEC 61508 Part 3 (“Software Requirements”) specifies development measures for embedded software depending on the SIL level. Common practices and their recommendation levels include:

| Technique/Practice | SIL 1 | SIL 2 | SIL 3 | SIL 4 |

| Use of coding standards | R | HR | HR | HR |

| Forward traceability | R | R | HR | HR |

| FMEA / FMEDA analysis | Optional | Recommended | Strongly Recommended | Mandatory |

Note: HR = Highly Recommended, R = Recommended, — = Not Recommended

2.6How to Evaluate and Calculate SIL?

According to IEC 61508, three core criteria must be considered to determine the appropriate SIL:

- System Capability– Whether the design meets functional requirements

- Architectural Constraints– Whether the design meets redundancy and structural requirements (e.g., SFF)

- Random Hardware Failure Probability– Quantified using PFDavg or PFH

Recommended Evaluation Tools:

- Hazard Analysis (HAZOP)

- Risk Matrix or Requirements Traceability Matrix

- Failure Mode and Effects Analysis (FMEA)

- Failure Modes, Effects and Diagnostic Analysis (FMEDA)

3.0What is Functional Safety

Key Concepts of Functional Safety:

To effectively understand IEC 61508 and its application, it is necessary to grasp the following fundamental concepts and core terms:

Functional Safety

Definition:

Functional safety is a part of overall system safety, focusing on whether the system operates correctly upon receiving specified inputs, thereby preventing hazardous events or reducing risks to an acceptable level in case of failures.

Objective:

To proactively control the system to respond upon detecting potential hazards, ensuring the safety of people, equipment, and the environment. For example:

A smoke detector triggering an automatic sprinkler system;

Industrial heating equipment automatically shutting down when overheating occurs.

Safety Integrity Level (SIL)

SIL is a quantitative measure of the performance and reliability of a safety function, indicating the system’s ability to reliably perform safety functions when required.

There are four SIL levels (SIL 1 to SIL 4), with higher levels indicating more stringent safety requirements and more rigorous software development and verification.

| SIL Level | Average Probability of Dangerous Failure on Demand (PFDavg) – Low Demand Mode | Probability of Dangerous Failure per Hour (PFH) – Continuous Mode |

| SIL 1 | ≥ 10⁻² to < 10⁻¹ | ≥ 10⁻⁶ to < 10⁻⁵ |

| SIL 2 | ≥ 10⁻³ to < 10⁻² | ≥ 10⁻⁷ to < 10⁻⁶ |

| SIL 3 | ≥ 10⁻⁴ to < 10⁻³ | ≥ 10⁻⁸ to < 10⁻⁷ |

| SIL 4 | ≥ 10⁻⁵ to < 10⁻⁴ | ≥ 10⁻⁹ to < 10⁻⁸ |

⚠ Note: SIL levels defined in IEC 61508 should not be confused with those in other standards such as ISO 26262 or IEC 61511.

Safety Lifecycle

IEC 61508 defines a structured process for managing functional safety issues throughout the entire project lifecycle—from initial concept to system decommissioning.

The safety lifecycle emphasizes:

Hazard identification and risk assessment

Definition of safety requirements;

Safety design implementation;

Verification and validation;

Maintenance and continuous improvement.

This process ensures that the system continuously meets safety requirements throughout its entire lifecycle.

3.1Importance of Functional Safety

Why is functional safety critical?

With increasing system complexity, especially in high-risk environments like industry, transportation, and energy, the potential hazards also increase. The goal of functional safety is to proactively identify and mitigate failure risks to ensure:

- Safety of personnel and users;

- Reliable operation of equipment;

- Minimization of economic losses for enterprises.

In manufacturing, functional safety systems help factories better control equipment, improve efficiency, and reduce downtime, thus enhancing overall productivity.

Why pursue certification?

- Legal requirements:Some industries and regions mandate functional safety certification by law.

- Market access:Products without certification may be barred from certain markets.

- Customer trust:End users and system integrators often require independent third-party certification from suppliers.

- Insurance compliance:Many insurers require functional safety certification as a condition for coverage.

Certification standards are typically based on IEC 61508 or its industry-specific derivatives.

3.2IEC 61508: The Fundamental Functional Safety Standard

IEC 61508 is the “mother standard” for functional safety, applicable to all industries without specific standards. It is based on risk assessment methodology and provides comprehensive guidance from system design and implementation to verification.

IEC 61508 covers safety-related system components including:

- Sensors (signal detection);

- Control logic units (such as PLCs or embedded controllers);

- Actuators (e.g., relays, brakes, alarm systems);

- Software components (including firmware and application logic).

The standard sets SIL requirements based on quantitative risk assessment addressing:

- System failures;

- Random hardware failures;

- Software logic or systemic failures.

3.3Industry-Specific Functional Safety Standards (Derived from IEC 61508)

| Industry | Derived Standard | Description |

| Process Industry | IEC 61511 | For continuous control processes like chemical and petrochemical plants |

| Machinery | IEC 62061 | For machinery equipment and robotic systems |

| Automotive Electronics | ISO 26262 | For road vehicle electronic/electrical systems |

| Aerospace | DO-178C / DO-254 | For civil aviation software/hardware development and verification |

| Medical Devices | IEC 62304 | Covers medical software lifecycle management |

| Nuclear Industry | IEC 61513 | For nuclear power plant instrumentation and control systems |

| Household Appliances/Consumer Goods | IEC 60730 | Focus on safety of automatic control devices |

4.0Why IEC 61508 is a Key Standard for Industry 4.0

With the development of Industry 4.0 and increasing automation and connectivity, IEC 61508 has become a critical standard for ensuring functional safety. It is particularly important for:

- Managing System Complexity:IEC 61508 offers a structured approach to handle the increasingly complex architectures of Industry 4.0 systems, including coordinated operation of sensors, actuators, and control systems, ensuring complexity does not compromise safety.

- Risk Mitigation:As automation rises, so does the risk of system failures. IEC 61508 provides guidance for risk identification and mitigation throughout the system lifecycle—from design to decommissioning—ensuring continuous and reliable safety.

- Ensuring Interoperability:Industry 4.0 requires seamless integration of diverse systems and devices. IEC 61508 provides a unified safety framework, ensuring that different vendors and platforms can interoperate without compromising safety.

- Enhancing Reliability of Autonomous Systems:With widespread adoption of software-controlled industrial systems, software reliability is critical. IEC 61508 defines explicit requirements for safety-critical software development, helping enterprises build stable and reliable intelligent systems.

- Demonstrating Compliance:Following IEC 61508 not only helps enterprises meet regulatory and industry standards but also demonstrates their commitment to safety to markets and regulators, boosting brand reputation and competitive edge.This is especially important when bidding for safety-critical contracts or entering regulated markets.

IEC 61508 not only sets the foundation for functional safety across industries but also provides a roadmap for building resilient, reliable, and certifiable systems in the age of digital transformation.

5.0Recommended Resources on 《IEC 61508 IEC 61508:2010 PDF》

🔗 IEC 61508 & Functional Safety-2022

6.0IEC 61508 & SIL – Frequently Asked Questions (FAQ)

6.1What is IEC 61508 and which industries does it apply to?

IEC 61508 is an international functional safety standard for electrical, electronic, and programmable electronic (E/E/PE) safety-related systems. It serves as the foundational or “parent” standard for many sector-specific standards and is applicable across industries such as industrial automation, process control, energy, transportation, and medical devices.

6.2What is SIL (Safety Integrity Level) and how many levels are there?

SIL is a measure of the performance required of a safety function to maintain or reduce risk. It is categorized into four levels:

- SIL 1(Lowest integrity)

- SIL 2

- SIL 3

- SIL 4(Highest integrity)

Each level corresponds to a specific range of failure probability and increasingly rigorous development and verification requirements.

6.3How is the required SIL level determined?

According to IEC 61508, SIL determination is based on three core criteria:

- System Capability– Functional compliance with safety requirements

- Architectural Constraints– Structural integrity and redundancy (e.g., SFF)

- Random Hardware Failure Probability– Quantified using PFDavg or PFH

Common evaluation tools include HAZOP, FMEA, FMEDA, and Risk Matrices.

6.4What is Functional Safety and how is it different from general safety?

Functional Safety is the part of system safety that ensures automatic responses to hazardous conditions through proper system behavior. It focuses on:

- Preventing or mitigating risks upon failure

- Automatically activating safety mechanisms (e.g., emergency shutdown, fire suppression)

Passive safety (e.g., fire doors, warning labels) is not considered part of functional safety.

6.5Why pursue SIL certification?

- Legal compliance: Mandatory in some industries or countries

- Market access: Non-certified products may be restricted from entering critical sectors

- Customer trust: Clients and integrators often require third-party certified components

- Insurance requirements: Many insurers mandate functional safety compliance

6.6Why is IEC 61508 important in the context of Industry 4.0?

IEC 61508 plays a vital role in ensuring safe automation and system interoperability in modern smart factories. It helps by:

- Structuring complex system safety design

- Mitigating risks throughout the lifecycle

- Defining software reliability expectations

- Supporting vendor-neutral system integration

- Demonstrating safety compliance and building trust

References

dra.com/iec-61508/#61508-1

www.tuvsud.com/en-sg/services/functional-safety/iec-61508

www.perforce.com/blog/qac/what-iec-61508-safety-integrity-levels-sils

www.gt-engineering.it/en/insights/functional-safety-300321/iec-61508-all-parts/