In metal cutting operations, the proper selection of cutting fluid has a direct impact on cutting forces, cutting temperature, tool wear, workpiece thermal deformation, and overall machining quality.

An appropriate metal cutting fluid not only extends tool life but also improves machining efficiency and surface finish, making it a critical element in process planning and optimization.

1.0What Are the Main Functions of Metal Cutting Fluids?

1.1Cooling:

During machining, plastic deformation of the material and friction between the tool, workpiece, and chips generate a large amount of heat. Metal cutting fluids remove this heat from the cutting zone through continuous flow, reducing cutting temperatures, minimizing tool wear, and limiting thermal deformation of the workpiece.The cooling performance of a cutting fluid mainly depends on its fluidity, specific heat capacity, heat transfer coefficient, and latent heat of vaporization.

1.2Lubrication:

Cutting fluids form a lubricating film between the tool rake face, flank face, and the workpiece or chips, reducing direct contact, friction, and material adhesion. This improves cutting conditions and enhances surface quality.To ensure effective lubrication, the fluid should have good penetration ability and sufficient oil film strength so that the lubricating film remains stable under high temperature, high pressure, and severe friction.

1.3Cleaning:

Machining processes generate chips, metal particles, and fine debris. In grinding operations in particular, abrasive grains continuously detach from the wheel. Metal cutting fluids help flush these contaminants away from the tool and workpiece surfaces, preventing chip adhesion, clogging of chip evacuation paths, or scratching of the finished surface.For this reason, cutting fluids must have good flow characteristics and be supplied at adequate pressure and flow rates.

1.4Corrosion Protection:

Metal cutting fluids should also provide rust and corrosion protection for the workpiece, cutting tools, and machine components. Their anti-rust performance depends on the base fluid composition and the type and concentration of corrosion inhibitors used.

2.0Common Types of Metal Cutting Fluids

2.1Aqueous Solutions:

Aqueous solutions use water as the primary component and offer excellent heat dissipation and cooling performance. However, water alone has poor lubricating properties and can easily cause corrosion.In practical applications, rust inhibitors, surfactants, and lubricating additives are added to water to retain cooling efficiency while providing basic lubrication and corrosion protection.

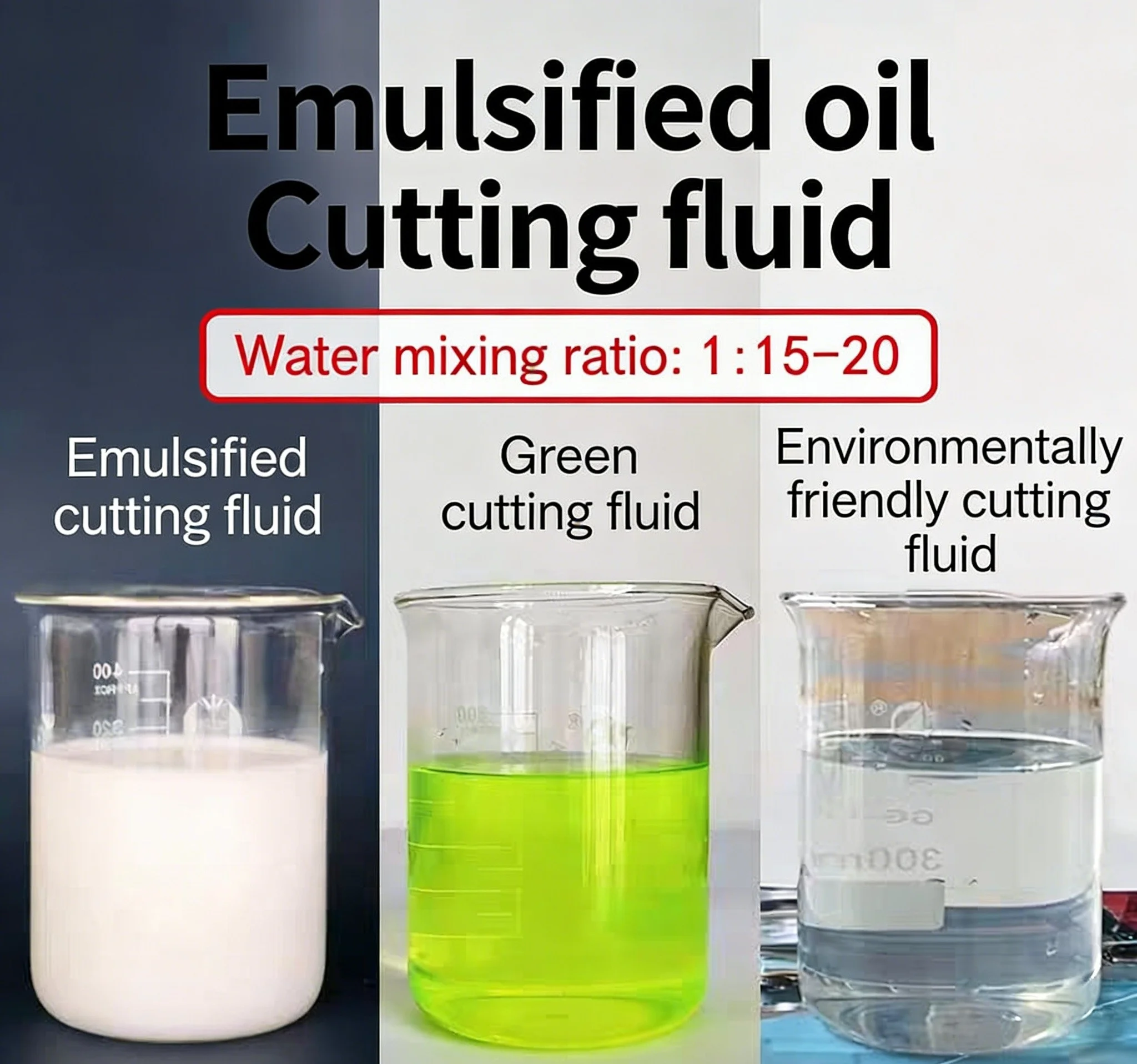

2.2Emulsions:

Emulsions are produced by diluting emulsifiable oils with approximately 95%–98% water, resulting in a milky or semi-transparent appearance. They provide good cooling performance but relatively limited lubrication and corrosion resistance.By incorporating lubricity agents, extreme-pressure additives, and corrosion inhibitors, emulsions can be formulated into EP emulsions or rust-resistant emulsions to meet more demanding machining conditions.

2.3Cutting Oils:

Cutting oils are primarily based on mineral oils, with some formulations using vegetable oils, animal oils, or blended base stocks. Pure mineral oils offer limited lubricity, so oiliness agents, extreme-pressure additives, and corrosion inhibitors are commonly added to enhance lubrication and wear resistance.Cutting oils are especially suitable for heavy-duty machining operations and applications involving boundary lubrication conditions.

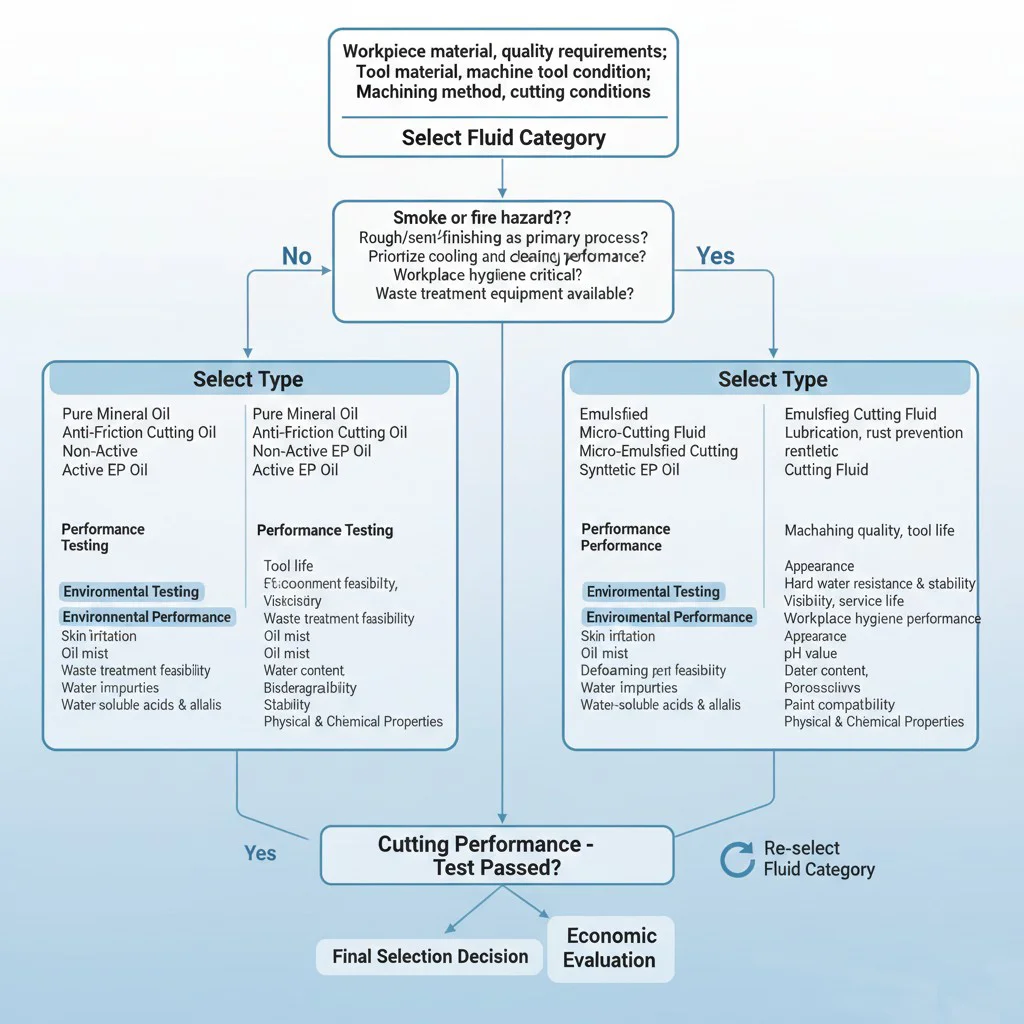

3.0Principles for Selecting Metal Cutting Fluids

3.1Selection Based on Workpiece Material:

When machining ductile materials such as steel, metal cutting fluids are generally required.When machining brittle materials such as cast iron or bronze, dry cutting can often be used.For difficult-to-machine materials such as high-strength steels and high-temperature alloys, extreme-pressure cutting oils or EP emulsions are recommended.When machining copper, aluminum, and aluminum alloys, 10%–20% emulsions or kerosene can be used to achieve better surface finish.When machining magnesium alloys, water-based cutting fluids should be avoided to prevent the risk of combustion.

3.2Selection Based on Tool Material:

High-speed steel tools have relatively low heat resistance and should be used with cutting fluids.

- Rough machining: cooling should be the primary focus.

- Finish machining: lubrication should be the primary focus.Carbide tools have better heat resistance and can often be used without cutting fluids.

- When cutting fluids are required, water-based solutions or low-concentration emulsions are preferred.

- Cutting fluids should be applied continuously to avoid thermal shock and potential tool cracking caused by alternating heating and cooling.

3.3Selection Based on Machining Method:

Operations with severe friction, such as drilling, reaming, tapping, and broaching, are best performed using emulsions, EP emulsions, or EP cutting oils.High-value tools with strict service life requirements, such as form tools and gear cutting tools, are better matched with EP cutting oils.Grinding operations generate high temperatures and fine debris, placing greater demands on cooling and cleaning; emulsions are typically used.

3.4Selection Based on Machining Requirements:

Rough machining involves high cutting parameters and significant heat generation; cooling should dominate, and low-concentration emulsions of 3%–5% are recommended.Finish machining prioritizes dimensional accuracy and surface quality; lubrication is more important, and EP cutting oils or high-concentration EP emulsions are preferred to suppress built-up edge formation.

4.0Methods of Applying Metal Cutting Fluids

In practical machining, metal cutting fluids are commonly applied using the following methods:

- Flood cooling

- High-pressure cooling

- Mist cooling

The specific application method should be determined based on machine tool structure, machining process, and cutting parameters.

5.0Frequently Asked Questions (FAQ)

Is it always necessary to use metal cutting fluids?

Not all machining operations require cutting fluids. When machining ductile materials such as steel, cutting fluids help reduce cutting temperature and tool wear. For brittle materials such as cast iron and bronze, dry cutting is often feasible. However, for high-precision machining or difficult-to-machine materials, the proper use of cutting fluids remains essential.

How should metal cutting fluids be selected based on workpiece material?

Selection should be based on the material’s machining characteristics. High-strength steels and high-temperature alloys are best machined with EP cutting oils or EP emulsions. Aluminum, copper, and their alloys typically use medium- to high-concentration emulsions. Water-based cutting fluids should be avoided when machining magnesium alloys.

How do metal cutting fluids affect tool life?

Properly selected cutting fluids reduce cutting temperature and friction, minimize wear and adhesion, and significantly extend tool life. Inappropriate cutting fluids can accelerate wear and may even cause premature tool failure.

What is the main difference between cutting oils and emulsions?

Cutting oils primarily provide lubrication and are suitable for high-load and boundary lubrication conditions. Emulsions emphasize cooling performance and are more suitable for high-speed cutting and grinding operations. The final choice should be based on specific machining conditions.

Is a higher cutting fluid concentration always better?

No. If the concentration is too low, lubrication and corrosion protection may be insufficient. If the concentration is too high, costs increase, cooling performance may be reduced, and environmental impact may worsen. An appropriate concentration range should be selected according to the machining process and technical requirements.