金属切割工业带锯出售

作为ALEKVS金属带锯的专业制造商,我们提供从通用型到专用型的各种工业带锯,旨在满足不同材料和工况的多样化切割需求。以下是我们常见的带锯类型:

- 卧式带锯

- 立式带锯

- 全自动带锯

- 数控带锯

- 半自动带锯

- 金属切割带锯

- 工业带锯

- 重型带锯

- 高速带锯

- 双柱带锯

- 龙门带锯

- 模具钢带锯

- 管道带锯

- 大型带锯

- 斜切/角向带锯

作为ALEKVS金属带锯的专业制造商,我们提供从通用型到专用型的各种工业带锯,旨在满足不同材料和工况的多样化切割需求。以下是我们常见的带锯类型:

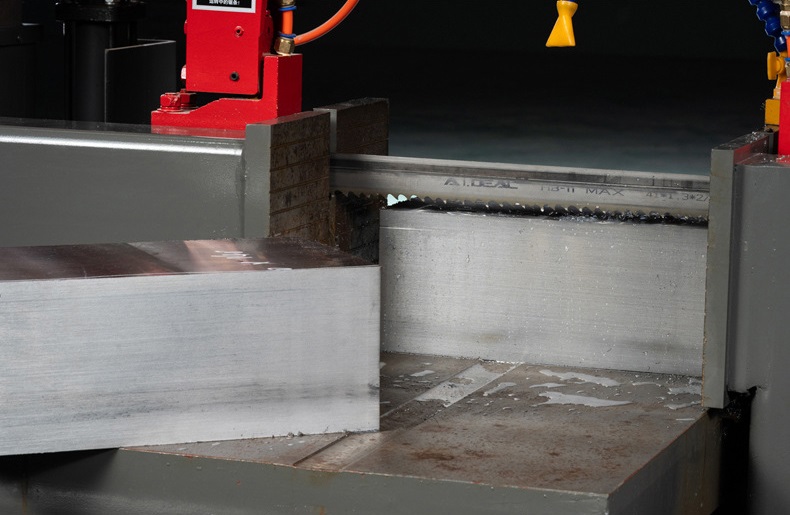

ALEKVS 工业金属带锯拥有卓越的切割性能,可精准处理厚结构钢和高韧性合金棒材。其设计注重精准度、速度和耐用性,可高效切割低碳钢、硬化合金和复杂的金属工件。

我们功能多样的产品系列包括用于精细加工的立式锯、用于控制切割的手动锯,以及用于大批量生产的半自动或全自动型号。ALEKVS 带锯为各种规模的车间提供可靠且经济高效的解决方案。

立式带锯非常适合 曲线切割、复杂形状加工、模具加工,精度高,操作灵活。

卧式带锯更适合 批量直切、棒材和型材切割,为大批量生产提供高效率。

ALEKVS 提供的不仅仅是带锯机,我们还提供完整的自动化切割解决方案。ALEKVS 全自动卧式带锯生产线专为高效、大批量金属加工而设计,集成了 装载、精准定位、智能检测、产品收集帮助制造商提高生产力、降低劳动力成本、实现智能制造。