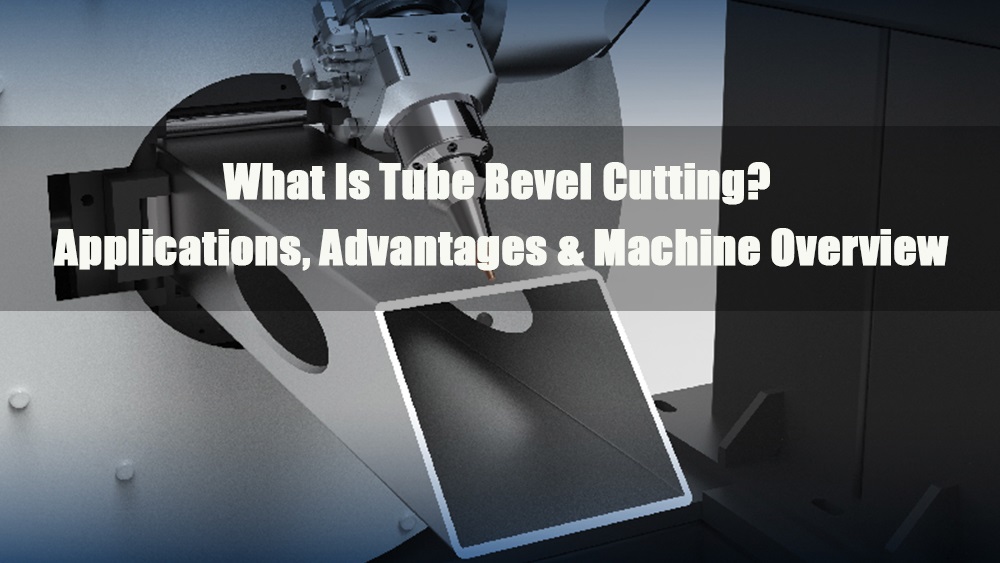

- 1.0What Is Tube Bevel Cutting?

- 2.0Bevel Cutting Capabilities of Tube Laser Cutting Machines

- 3.0Technical Principles of Bevel Cutting

- 4.0Importance and Advantages of Tube Bevel Cutting

- 5.0Challenges with Traditional Tube Bevel Cutting Methods

- 6.0How to Choose a Tube Laser Cutting Machine with Beveling Capability

- 7.0Step-by-Step Guide to Operating a Tube Laser Bevel Cutting Machine

- 8.0Common Advanced Tube Cutting Processes

- 9.0Common Issues and Solutions in Tube Bevel Laser Cutting

- 10.0Typical Applications of Laser Bevel Cutting for Tubes

- 11.0Conclusion & Operational Recommendations

Tube laser cutting technology has seen widespread adoption in the manufacturing industry, particularly in the field of precision processing. Beyond conventional perpendicular cuts, bevel cutting has emerged as a higher-level technique that significantly improves welding quality and supports the creation of high-strength structural joints.

1.0What Is Tube Bevel Cutting?

Tube bevel cutting refers to the process of removing material from the edge of a tube at a specific angle. This angle is critical for ensuring proper joint fit-up, especially when two tubes need to be connected at a defined angle. Common bevel angles include 15°, 30°, 45°, and 60°, which can be adjusted based on structural requirements.

Compared with a standard perpendicular cut, a bevel cut creates an angled cutting surface, enabling precise weld preparation, smoother assembly, and stronger mechanical connections.

Typical Applications Include:

- Bevel preparation prior to welding

- Mitered joints for non-standard tube profiles

- 3D structural tube connections

- High-stress joint design in load-bearing assemblies

2.0Bevel Cutting Capabilities of Tube Laser Cutting Machines

A bevel tube laser cutting machine is a specialized fiber laser system designed for cutting metal tubes with angled or sloped edges. Unlike standard laser cutters that perform only straight cuts perpendicular to the tube surface, bevel cutting systems allow for angled cutting paths, typically within a range of 0° to 45°, depending on the model.

Modern machines integrate multiple bevel cutting features, such as:

- Fixed-angle cutting: Standard bevels like 45° for consistent weld seams

- Variable-angle cutting: Dynamic path adjustments for complex 3D chamfers

- Single-side beveling: Angled cuts on one face of the tube

- Multi-face beveling: Four- or six-face angled cuts for intricate joint designs

Compatible Materials:

Carbon steel, stainless steel, aluminum alloy, titanium alloy, and other standard industrial tube materials.

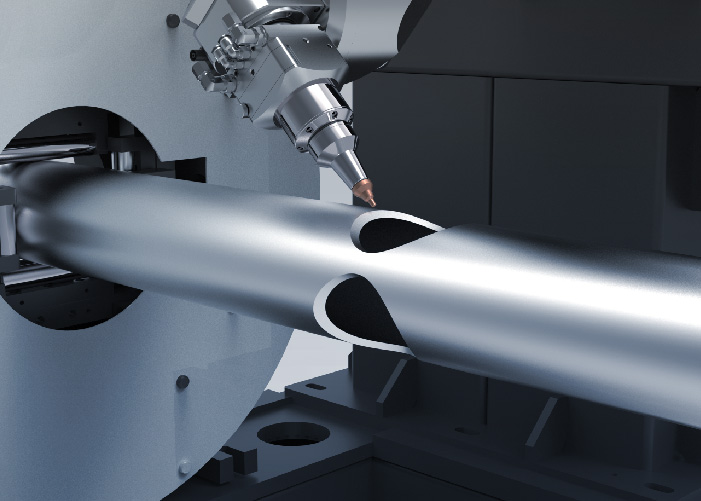

3.0Technical Principles of Bevel Cutting

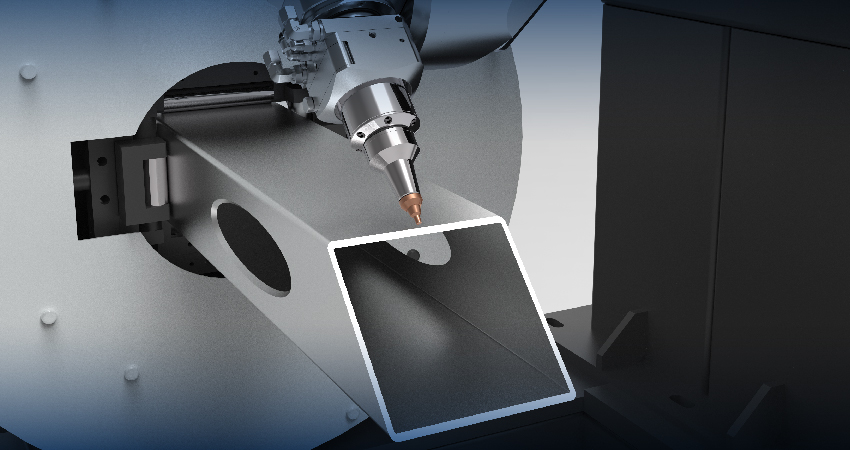

The core of bevel cutting lies in the multi-axis control of the laser head. Typically, machines must be equipped with five-axis motion (X/Y/Z + rotary axis + tilt axis) or dynamic 3D adjustment capabilities.

Key Technical Components:

- Tilting laser head mechanism: Controlled by motors or mechanical systems, the laser head tilts at a preset angle away from the tube’s normal, enabling precise angled cuts.

- Path algorithm support: The CAD/CAM system must generate G-code that supports tilted toolpaths to ensure accurate and controllable cutting paths.

- Incidence angle compensation: Adjustments are made for focus offset and kerf width changes on inclined surfaces, maintaining cutting precision.

- Assist gas adjustment: Larger bevel angles require higher assist gas flow and pressure to prevent slag buildup and ensure smooth edges.

4.0Importance and Advantages of Tube Bevel Cutting

- Weld preparation step: Bevel cutting is a critical part of welding preparation, ensuring joint strength and stability.

- Improved weld quality: Produces V-, K-, or X-shaped bevels that increase penetration depth and weld area, reducing risks of incomplete fusion, cracking, and stress concentration.

- Enhanced joint strength: Especially beneficial in high-reliability applications such as pressure pipelines, structural components, and heavy equipment frameworks.

- Higher welding efficiency: Reduces the need for post-weld grinding and touch-ups, shortening the overall production cycle.

- Integrated in automated systems: Bevel cutting has become a standard process in automated laser systems for high-consistency and high-precision weld joints.

- Support for smart manufacturing: Enables design-driven structural optimization and precision manufacturing, aligning with intelligent fabrication goals.

5.0Challenges with Traditional Tube Bevel Cutting Methods

- Welding difficulties: Conventional methods often result in oversized gaps or incorrect bevel angles, complicating the welding process and requiring manual rework.

- Precision limitations: Flame or plasma cutting struggles with maintaining accuracy on complex angles and can lead to heat-induced deformation.

- Slow processing speed: Traditional cutting is time-consuming, often requiring multiple adjustments to achieve the desired bevel.

- Material waste: Lower precision and the need for secondary processing result in higher material consumption and added costs.

- Limited flexibility: Mechanical and thermal methods lack adaptability across different materials and wall thicknesses, often requiring tool changes and setup modifications.

6.0How to Choose a Tube Laser Cutting Machine with Beveling Capability

Not all tube laser cutting systems are equipped for bevel cutting. When selecting a machine, pay close attention to the following features:

- Five-axis laser cutting head: Enables dynamic adjustment with rotary and tilt motion.

- Smart control system: Supports bevel path programming and simulation preview.

- Rotary chuck system: Automatically clamps and rotates the tube to ensure stable bevel cutting trajectories.

- Automatic support system: Provides dynamic support for long tubes to prevent deflection and vibration.

- Auxiliary functions: Features like auto-focus, cooling units, and dust extraction help improve precision and operational safety.

7.0Step-by-Step Guide to Operating a Tube Laser Bevel Cutting Machine

7.1Preparation Stage

- Material setup: Confirm tube material, outer diameter, and wall thickness.

- Chuck installation: Mount the tube in the automatic chuck and align it with the central axis.

- Model import: Load a 3D cutting model with bevel paths, such as a STEP file.

7.2Parameter Configuration

- Angle settings: Set the cutting angle according to the design (e.g., 45° bevel).

- Laser parameters: Adjust laser power (typically 1500W–3000W) and assist gas pressure.

- Cutting path setup: Define the piercing point and cutting route to avoid thermal distortion zones.

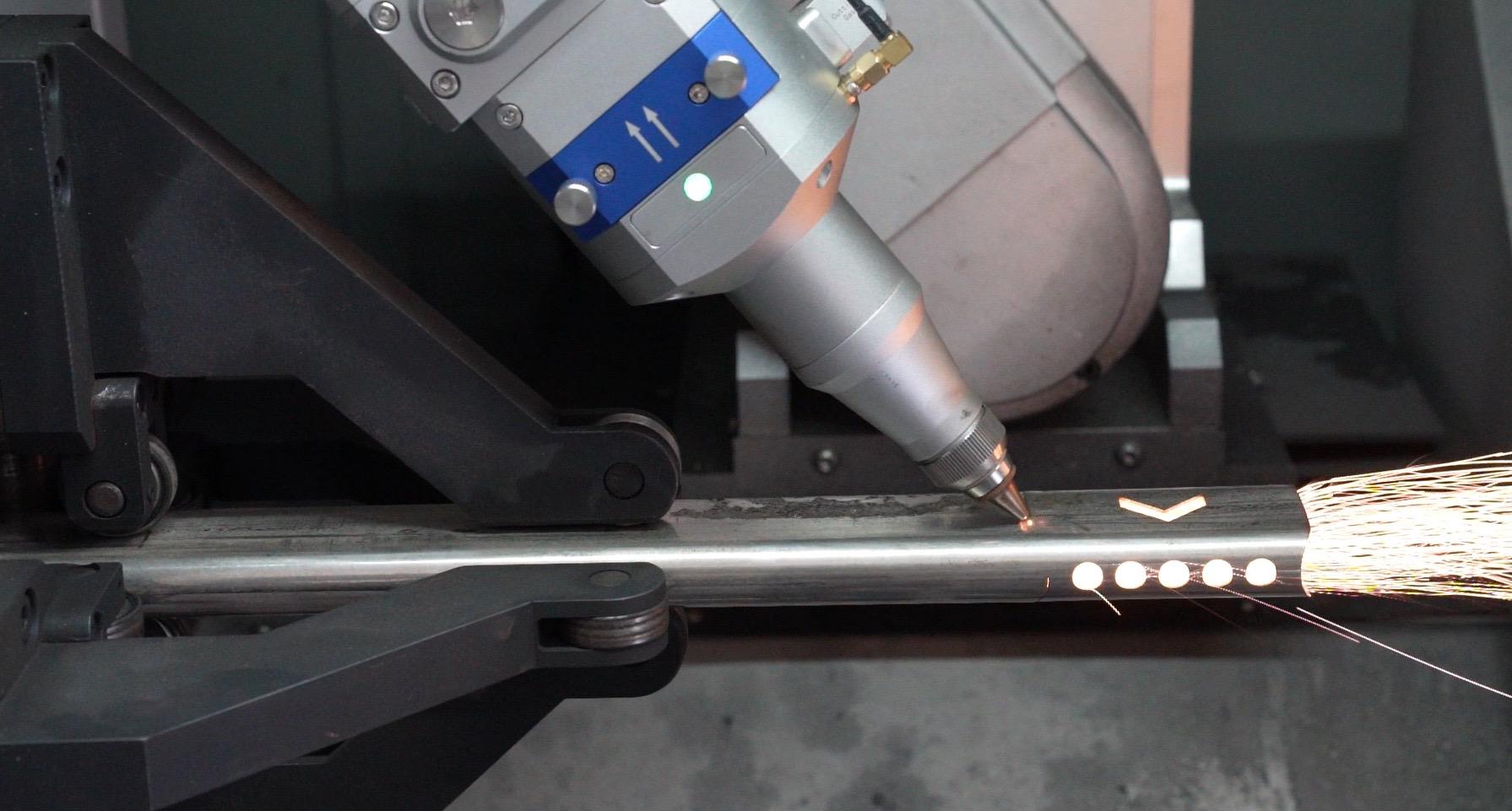

7.3Cutting Process

- The laser head tilts to the preset angle and synchronizes with chuck rotation.

- Cutting path and incidence angle are dynamically adjusted for bevel accuracy.

- The entire process is monitored in real-time to prevent angle deviations or vibration interference.

7.4Post-Cutting Procedures

- Deburring: Use a grinding wheel or deburring tool to clean the edges.

- Angle verification: Check bevel accuracy using a protractor or 3D scanner.

- Quality inspection: Evaluate surface finish, perpendicularity deviation, and bevel geometry.

8.0Common Advanced Tube Cutting Processes

As structural designs become more complex and manufacturing standards continue to rise, a variety of specialized tube cutting techniques have been developed. These processes not only fulfill diverse assembly requirements but also significantly improve weld quality and structural performance.

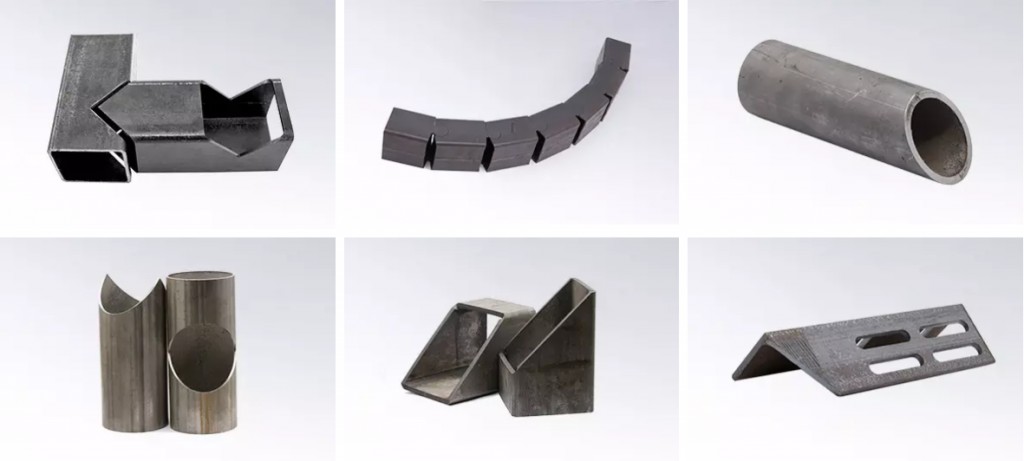

8.1Bevel Cutting

Bevel cutting involves trimming the tube end or plate edge at a specified angle, primarily for weld preparation. By creating a bevel, this process enhances weld strength and joint integrity. It is widely used in pipeline and structural fabrication.

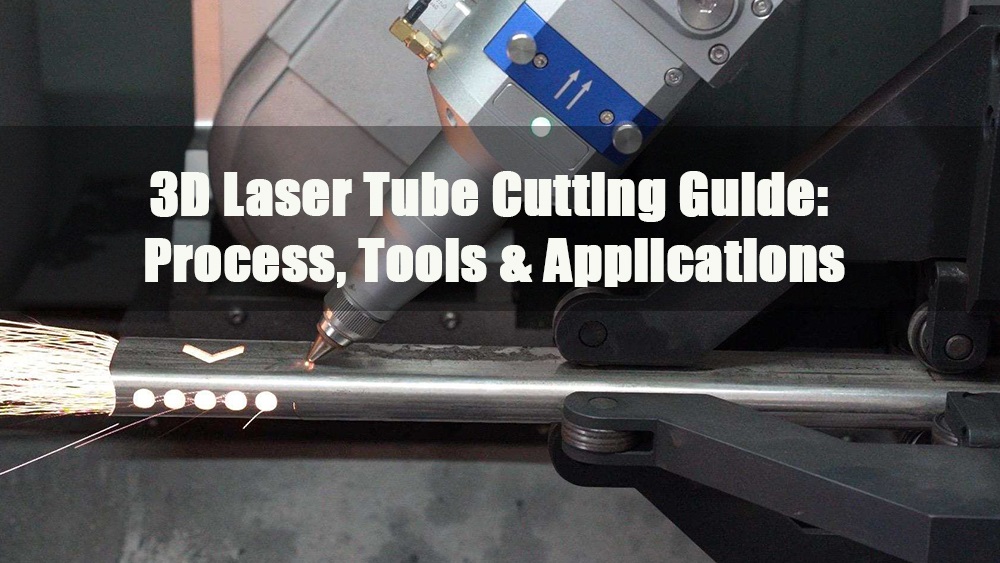

8.23D Contour Cutting

3D contour cutting utilizes multi-axis laser systems to follow complex three-dimensional profiles. Ideal for non-standard tube shapes and intricate components, this method ensures precise contour cuts that meet detailed assembly specifications.

8.3Tube End Forming Cutting

This includes processes such as flaring, tapering, and flange-end cutting to facilitate effective connections at the tube ends. It is commonly applied in piping systems and mechanical assemblies to ensure sealing reliability and joint strength.

8.4Branch Cutting

Branch cutting is used to create outlet openings on a main pipe, often in combination with intersection (or saddle) cuts. This process is essential for pipe network design and ensures smooth layout and assembly of complex piping systems.

8.5Multi-face Cutting

This technique targets multiple sides of a tube or profile, allowing for simultaneous or sequential cuts to prepare precise joining interfaces. It is especially suitable for high-precision, multi-angle tube connections.

8.6Joint Bevel Cutting

Joint bevel cutting forms specific bevel shapes on connecting surfaces to ensure tight sealing and mechanical strength when joining multiple pipe sections. It plays a critical role in the long-term reliability of pipeline installations.

9.0Common Issues and Solutions in Tube Bevel Laser Cutting

| Issue | Possible Cause | Recommended Solution |

| Inaccurate bevel angle | Laser head not calibrated; worn or loose guide rails | Perform recalibration; inspect and secure guide rails |

| Rough kerf or heavy slag | Insufficient gas pressure or focus misalignment | Increase oxygen/nitrogen pressure; refocus laser beam |

| Laser head collision with tube wall | Inadequate path clearance in programming | Optimize bevel path; adjust start point or add clearance moves |

| Cutting accuracy affected by vibration | Insufficient tube support or unstable chuck clamping | Use automatic support system; ensure reliable chuck clamping |

| Burn marks on cutting surface | Excessive laser power or low cutting speed | Reduce laser power or increase cutting speed; fine-tune parameters |

| Uneven cut edge | Deviation between preset path and actual cut | Regularly inspect and calibrate equipment; improve path precision |

| Bevel mismatch during welding | Inconsistent bevel angles or low cutting accuracy | Use high-precision laser system; ensure consistent path output |

| Material deformation | Excessive heat-affected zone or high thermal input | Optimize cutting parameters; apply suitable assist gas to reduce heat |

| Slow cutting speed | Insufficient laser power or defocused beam | Increase power; adjust focus to optimal point |

| Heavy oxidation on cut surface | Inadequate gas flow or poor gas purity | Increase gas flow; use higher-purity gas to prevent oxidation |

10.0Typical Applications of Laser Bevel Cutting for Tubes

Weld Preparation

Purpose: To create bevels at weld joints for full penetration welding or high-strength connections.

Common Bevel Types:

- V-type bevel (single side 30°/45°)

- Y-type bevel

- K-type bevel (symmetrical 45° on both sides)

- X-type bevel (used for thick-walled tube butt joints)

Typical Scenarios:

- Oil and gas pipeline welding

- Pressure vessel assembly

- Truss connections with thick-walled tubes

- Stainless steel storage tank fabrication

Structural Fitting & Framing

Purpose: Multi-angle tube joining at structural nodes to improve fit-up accuracy and load-bearing performance.

Typical Components:

- 3D space frames (triangular trusses, bridge structures)

- Fitness equipment frames (multi-directional tube joints)

- Smart home or metal furniture structures (e.g., table legs)

Advantages:

- No need for manual bevel grinding

- High angular accuracy with minimal joint gaps

- Enhanced weld appearance and structural stability

Automotive Manufacturing

Applications:

- Exhaust system weld joints (stainless steel or titanium elbows)

- Chassis piping (anti-vibration or reinforcement connections)

- Battery tray frame joining (for EVs and hybrid vehicles)

Technical Highlights:

- Thin-wall bevel cutting without deformation

- High consistency in welding gaps

- Suitable for large-scale automated production

Rail Transit and Aerospace

Applications:

- Lightweight tubular structural components

- Beveled joints for stress distribution optimization

- Weld groove preparation for fatigue-resistant design

Materials: High-strength steel, titanium alloys, aluminum-magnesium alloys

Key Features:

- Tight angle tolerance (within ±0.2°)

- Clean-cut surfaces (no need for secondary finishing)

Steel Structures and Curtain Wall Systems

Applications:

- Prefabricated beveling of angle irons and round tubes for node connections

- Optimized weld seams for both aesthetics and structural integrity

- Diagonal joining of curtain wall aluminum profiles

Advantages:

- Replaces the traditional sawing + beveling process

- Improves on-site assembly precision and efficiency

- Supports BIM-integrated modeling and toolpath programming

Pipeline and Pressure System Fabrication

Applicable Industries: Energy, power, chemical, food and pharmaceutical sectors

Key Applications:

- Beveled welding of pressure pipelines

- Clean bevel cutting of stainless steel sanitary tubing

- Sloped openings for Y- and T-branch tube connections

Technical Requirements:

- High-precision bevel angles with burr-free edges

- Clean inner walls with no slag or oxidation (compliant with GMP and ASME standards)

11.0Conclusion & Operational Recommendations

The integration of bevel cutting technology marks a new era in tube laser processing, enabling higher precision and more complex geometries. To achieve stable and efficient bevel cutting, manufacturers should:

- Choose tube laser cutters with 5-axis simultaneous motion capability

- Utilize specialized bevel path design software

- Provide operator training on machine functions and process parameters

- Maintain the system regularly to ensure motion accuracy and repeatability

With the right equipment and process management, bevel cutting not only improves product quality but also reduces manual labor costs and enhances overall manufacturing competitiveness.

References

https://en.wikipedia.org/wiki/Pipe_Cutting