- 1.0What Is Thread Rolling? Definition, Process, and Key Benefits

- 2.06 Key Advantages of Rolled Threads in Modern Manufacturing

- 2.1Higher Thread Strength: Fatigue life 5–10 times longer than cut threads

- 2.2Stable Accuracy: Consistent tolerances over long runs

- 2.3Material Savings of 15%–27%: Visible cost reduction

- 2.4Higher Productivity: Fastest thread-forming process

- 2.5Superior Surface Finish: Comparable to ground threads

- 2.6Broad Application Range: More than just threads

- 3.0What Can Be Rolled? Thread Types, Materials, and Product Applications

- 4.0How to Choose a Thread Rolling Machine? 3 Main Types + Selection Guide

- 4.1Reciprocating (Flat Die) Thread Rolling Machines: For Small Diameters and Low Volumes

- 4.2Planetary Rotary Thread Rolling Machines: For Small to Medium Diameters in Mass Production

- 4.3Cylindrical Die Thread Rolling Machines: For Large Diameters and Complex Parts

- 4.4Thread Rolling Machine Selection: 3-Step Guide

- 5.0How to Use Thread Rolling Dies? Key Tips for Longer Life and Higher Accuracy

- 6.0Frequently Asked Questions (FAQ): Thread Rolling Explained

- 7.0Conclusion: Thread Rolling — A Proven Method for Lower Cost and Higher Efficiency

In industries such as fasteners, aerospace components, and automotive parts, the precision and efficiency of thread production directly affect product quality and overall cost. Traditional thread cutting methods often result in excessive material waste, lower thread strength, and poor surface finish. In contrast, thread rolling—an advanced cold-forming process—has become the preferred choice in modern manufacturing due to its core advantages: chip-free production, superior strength, and high accuracy.

1.0What Is Thread Rolling? Definition, Process, and Key Benefits

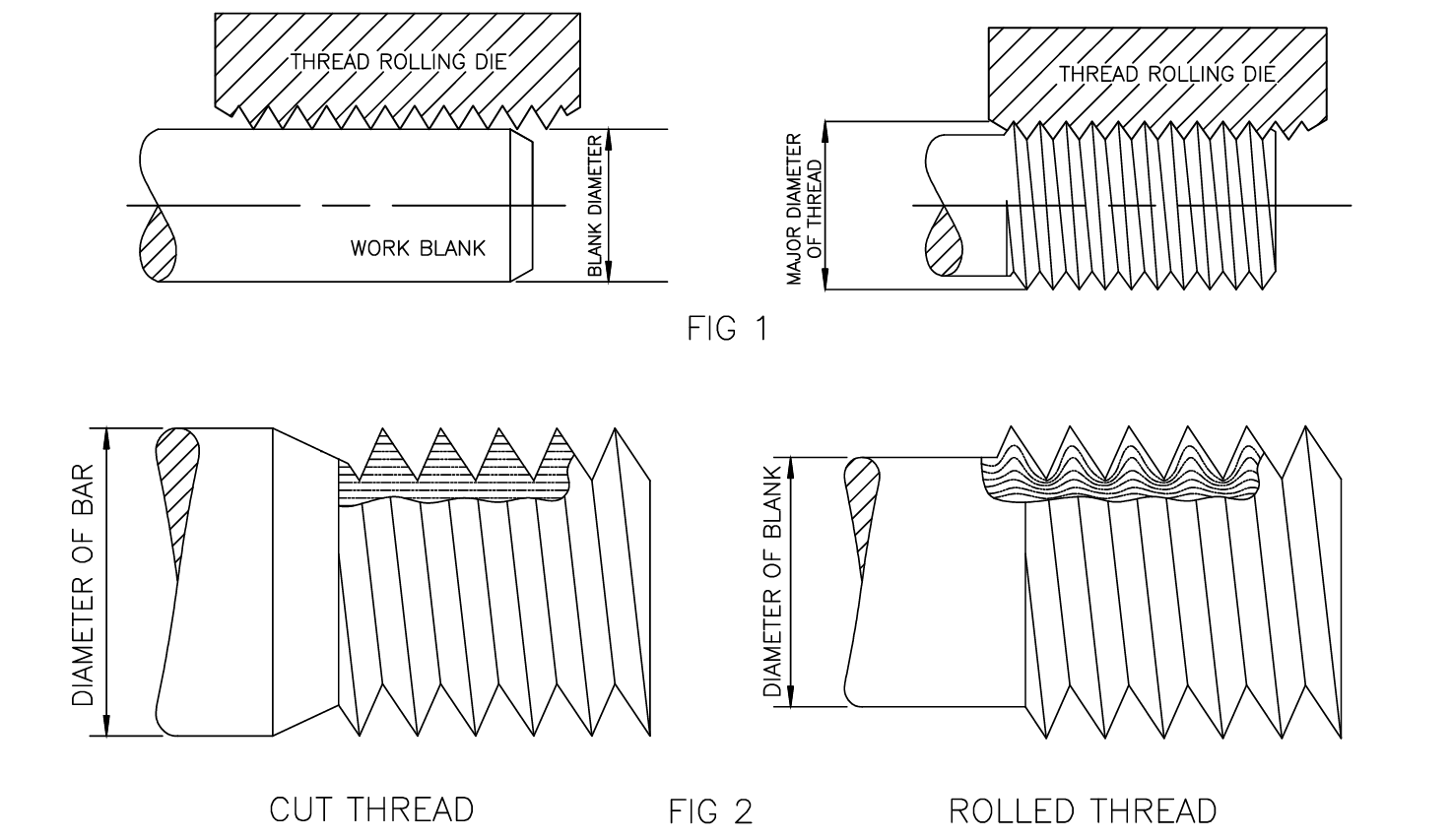

Many professionals in manufacturing often search for “What is thread rolling?” or “How are rolled threads made?”. The core principle is straightforward: instead of cutting away material, thread rolling uses cold forming to displace and shape the metal.

1.1Definition of Thread Rolling:

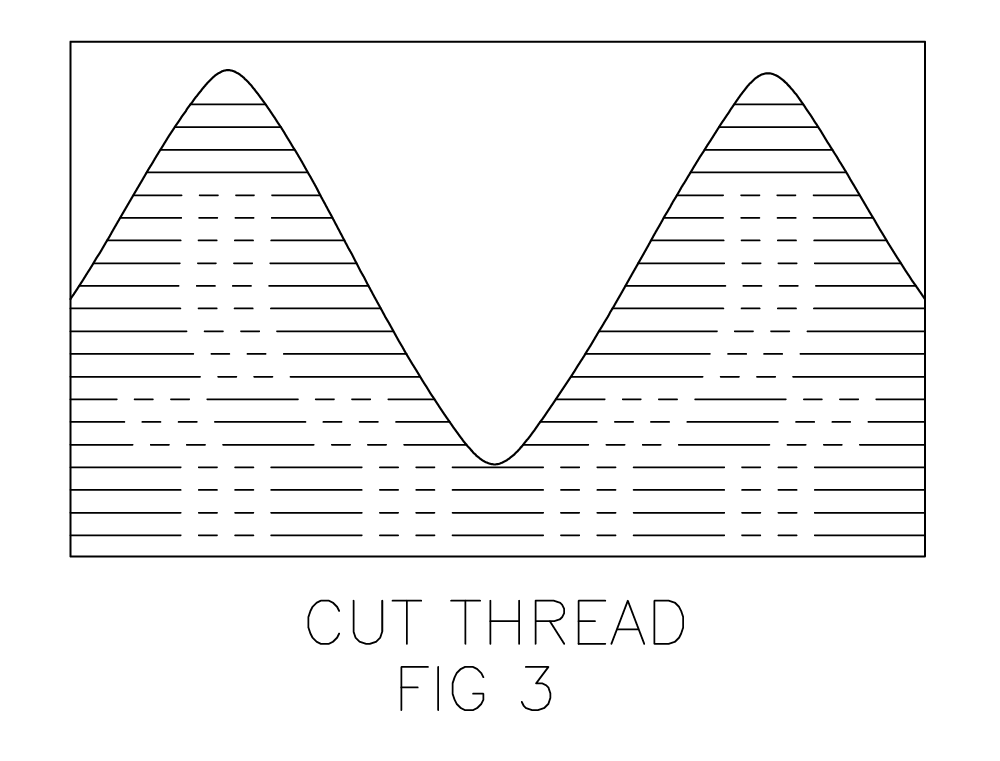

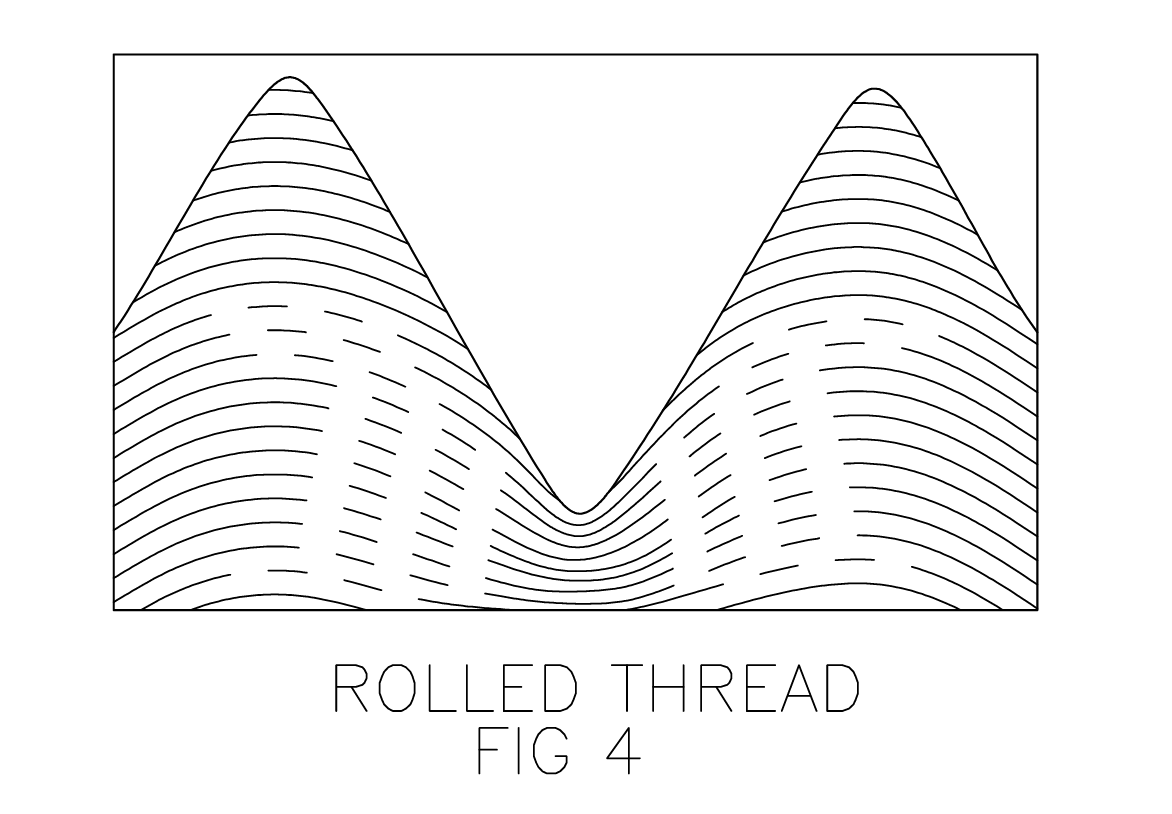

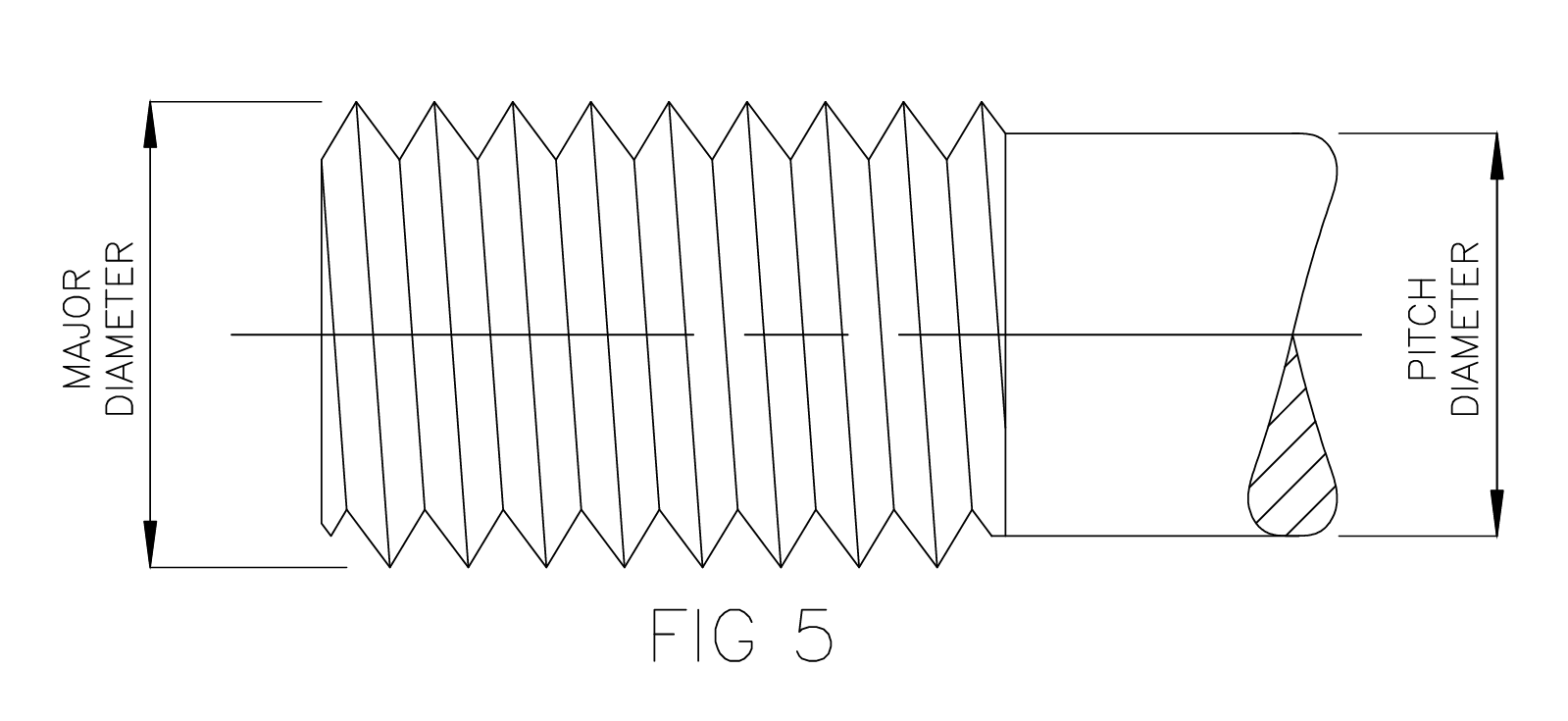

Thread rolling is a cold-forming process primarily used to produce external threads, usually on metal blanks at room temperature (with the option of heated blanks in special cases). Using hardened steel dies with reverse thread profiles, the process applies pressure as the blank rotates. This forces the material to plastically flow: the die impression forms the thread root while displaced metal flows outward to create the crest, resulting in uniform and smooth threads.

1.2Thread Rolling vs. Thread Cutting: Key Differences

| Comparison Aspect | Thread Rolling | Thread Cutting |

| Forming Method | Plastic displacement of material (chip-free) | Material removal (chip-producing) |

| Thread Strength | Cold-worked for enhanced tensile and fatigue strength | Grain structure cut, resulting in lower strength |

| Surface Finish | Polished by rolling, smoother surface | Tool marks and burrs more common |

| Material Utilization | Saves 15%–27% (no waste) | Wastes over 15% as chips |

| Production Efficiency | High-speed, continuous forming | Slower, single-pass cutting |

In short: Thread cutting is subtractive—wasting material and weakening strength—while thread rolling is formative, saving material and producing stronger threads.

2.06 Key Advantages of Rolled Threads in Modern Manufacturing

When searching for terms like “advantages of thread rolling” or “why rolled threads are better than cut threads,” manufacturers are usually focused on the real value it brings. Based on production data and industry feedback, the benefits of rolled threads can be summarized into six key points across strength, accuracy, cost, and efficiency.

2.1Higher Thread Strength: Fatigue life 5–10 times longer than cut threads

During rolling, the cold-forming process causes the grain structure to “flow continuously” instead of being cut. At the same time, residual compressive stresses are formed at the thread root. These two effects significantly enhance the mechanical properties of rolled threads:

- Tensile strength +10%:Cold work hardening increases surface density, improving fracture resistance in static tensile tests.

- Improved shear resistance: Continuous grain flow resists thread slippage; shear failure requires cutting across grains instead of following grain boundaries.

- Superior fatigue performance: Rolled roots are smooth and free of tool marks, avoiding stress risers. Residual compressive stress delays crack initiation. Even at 260 °C (500 °F), fatigue strength remains intact (cut threads lose ~25% strength after heating).

2.2Stable Accuracy: Consistent tolerances over long runs

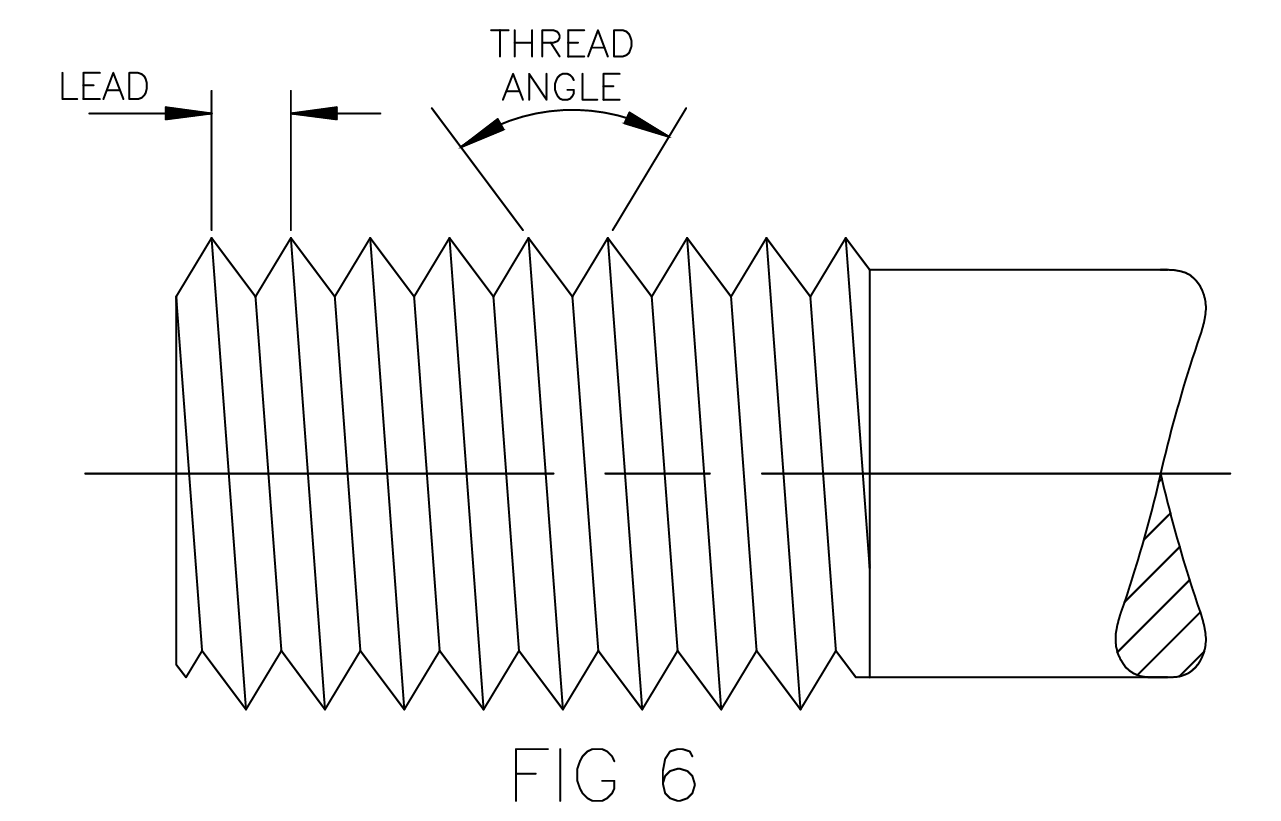

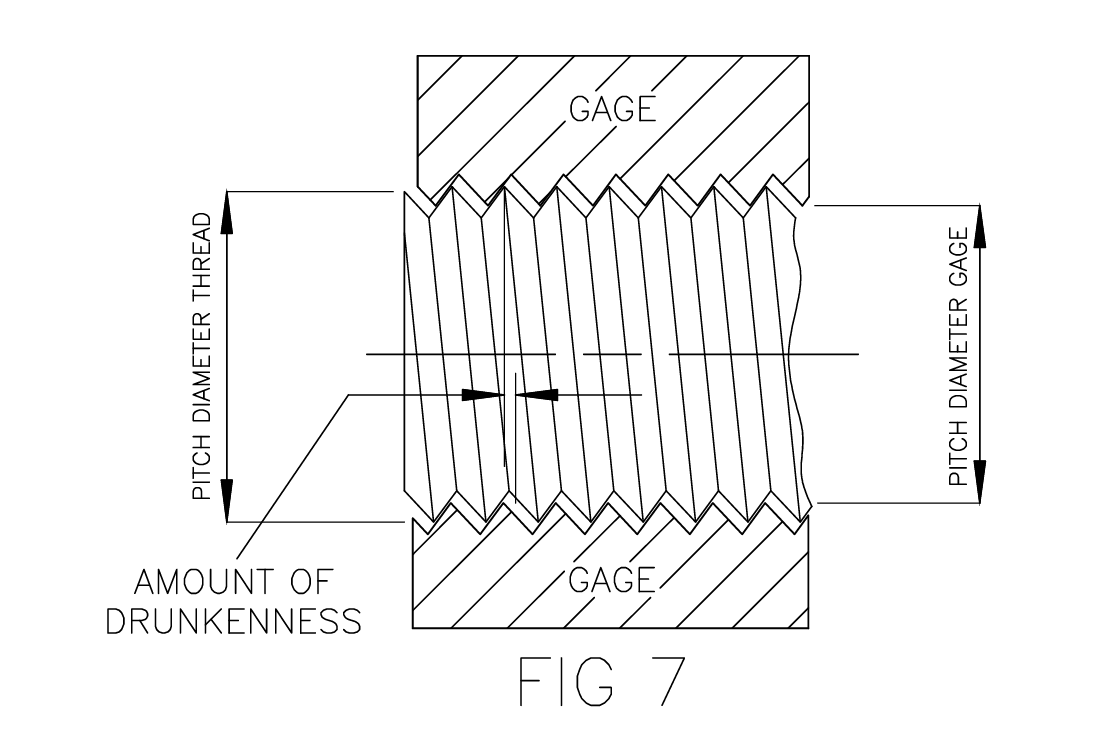

Thread accuracy in rolling is defined by the dies, which distribute wear across wide surfaces instead of sharp cutting edges, reducing the need for frequent resharpening. This ensures stable precision over time. Key controlled parameters include:

- Diameters: Major, pitch, and minor diameters are governed by blank size and die profile; tolerances can remain within ±0.01 mm.

- Thread angle & lead: Die accuracy transfers directly to the thread; slight elastic recovery in hard materials can be compensated with modified lead dies.

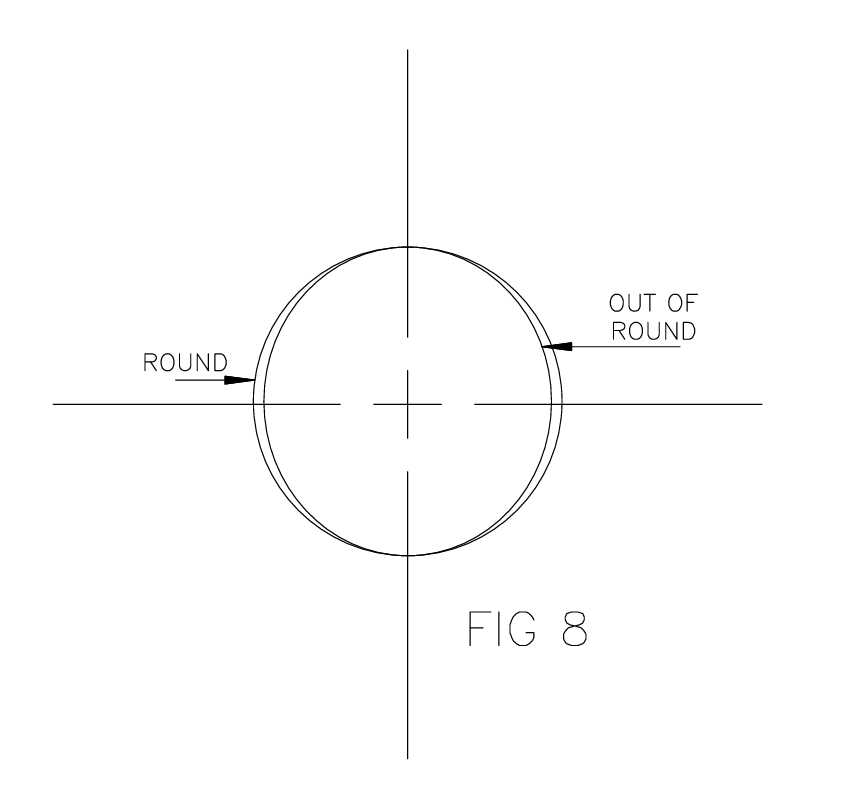

- Roundness & runout: Uniform blanks and progressive die pressure maintain roundness; runout can be controlled via lead angle adjustments.

2.3Material Savings of 15%–27%: Visible cost reduction

Because no chips are generated, thread rolling displaces material instead of removing it. Industry test data shows material savings by thread size:

| Thread Size | Material Saved | Thread Size | Material Saved |

| 8-32 | 24% | ¾-10 | 16% |

| 4-20 | 25% | 1-8 | 18% |

| ⅜-16 | 27% | 1½-6 | 16% |

For stamped parts, thread rolling allows the use of thinner stock (only requiring blank diameter close to pitch diameter rather than minor diameter), further reducing material waste.

2.4Higher Productivity: Fastest thread-forming process

Thread rolling is the most rapid method available for thread production, offering clear efficiency gains:

- Versatile equipment: Suitable for manual, semi-automatic, and fully automated machines. With automatic feeders, one operator can run multiple machines, producing dozens to hundreds of parts per minute.

- Eliminates secondary operations:Rolled threads near shoulders can be produced directly, eliminating deburring, chamfering, or polishing steps.

- Cost-effective even in small batches: Setup is quick and simple, making rolling competitive even for runs of a few hundred parts.

2.5Superior Surface Finish: Comparable to ground threads

The die surface finish directly transfers onto the thread, while the rolling action provides a polishing effect. This results in surface roughness as low as Ra 0.8 μm, comparable to ground threads. Regardless of whether processing carbon steel, stainless steel, brass, or aluminum, rolling produces a uniform polished appearance without additional finishing.

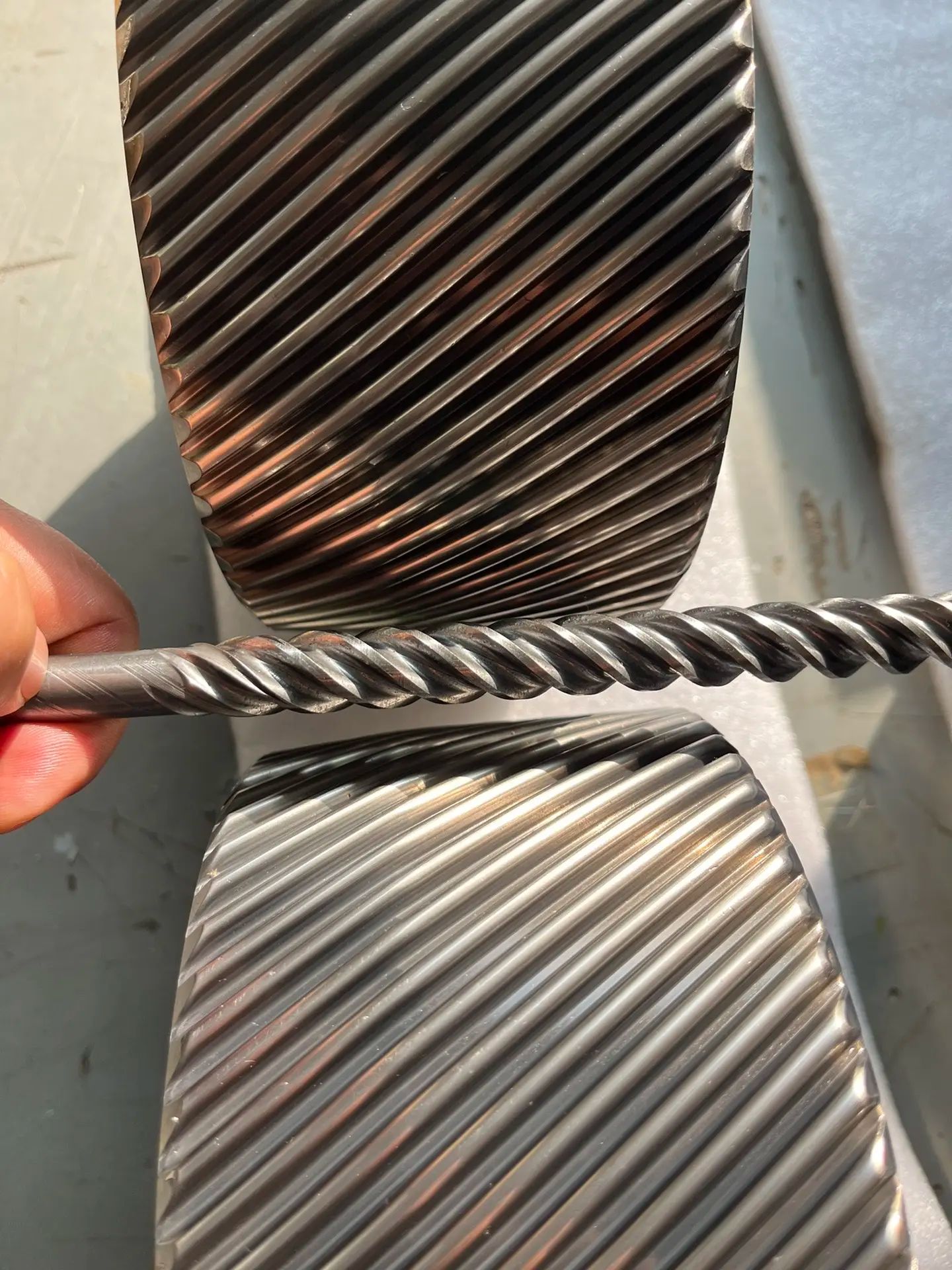

2.6Broad Application Range: More than just threads

Thread rolling is not limited to threads. It can also form knurls, splines, serrations, oil grooves, and polished shafts. For example, automotive shafts with oil grooves can be rolled in a single pass, producing smooth channels at 30% lower cost than milling.

3.0What Can Be Rolled? Thread Types, Materials, and Product Applications

When searching for “thread rolling applications” or “which threads can be rolled,” manufacturers typically want to confirm whether their specific products are suitable. The adaptability of thread rolling is extremely broad—covering nearly all thread types, materials, and product categories used in modern manufacturing.

3.1Thread Types Compatible with Rolling: Over 20 Standard Specifications

Thread rolling can produce almost any common or specialized thread form, including:

- S. Standards: NPT (taper pipe), NPTF (dryseal pipe), ANPT (aerospace pipe), NPSM/NPSL (straight pipe).

- International Standards: ISO metric, British Association threads.

- Special Threads: Buttress threads, Lok-Thred® forms, self-tapping screw threads (Types A / B / C), power screw threads.

- Others: Left-hand, multiple-start, annular, and tapered threads for fittings.

Size range: Diameters from 0.060 in. (1.52 mm) to 5 in. (127 mm), with pitches from 2–80 TPI. Larger or smaller threads can be accommodated with specialized equipment.

3.2Suitable Materials: Any ductile metal ≤ Rockwell C40 hardness

The key requirement for thread rolling is ductility. Any metal with hardness up to Rc 40 (sometimes higher under specific conditions) can be rolled, including:

- Steels: Carbon steels (1010/1112), alloy steels (2330/3140/6150), stainless steels, tool steels.

- Nonferrous Metals: Brass, bronze, aluminum, copper, beryllium copper, titanium, nickel, Monel alloys.

- Others: Selected die-cast alloys, silver, and gold (used in precision parts).

3.3Typical Applications: From Fasteners to Aerospace Components

- Fasteners: Bolts, screws, studs, nuts (particularly high-strength bolts where fatigue resistance is critical).

- Automotive: Shafts (splined or grooved), gears, radiator fittings.

- Aerospace: ANPT threaded fittings, high-precision sensor housings.

- Electronics & Electrical: Lamp bases, connector terminals.

- Special Components: Hollow tubes (with sufficient wall thickness), stamped parts with threads, integrated screw-washer assemblies.

4.0How to Choose a Thread Rolling Machine? 3 Main Types + Selection Guide

“Thread rolling machine selection” is one of the most common questions for procurement and engineering teams. Choosing the right equipment directly impacts production efficiency and cost. Today’s market offers three primary types of thread rolling machines, each suited to different applications. In practice, these categories have evolved into specialized solutions such as automatic 2-roll thread rolling machines, hydraulic 3-roller machines, CNC 3-die thread rolling machines, and automatic CNC screw thread rolling machines, providing a wide range of options for different industries.

4.1Reciprocating (Flat Die) Thread Rolling Machines: For Small Diameters and Low Volumes

- Structure: One stationary die and one moving die with flat working surfaces; each stroke produces one part.

- Advantages: Simple setup, low cost, ideal for threads up to 1 in. diameter.

- Applications: Small-batch fasteners (e.g., small screws), tapered-end threads, simple rolled parts.

- Limitations: Long threads require higher blank rotation; efficiency decreases with hard materials.

Modern automatic 2-roll thread rolling machines extend the capabilities of traditional flat-die designs, offering better handling of slightly larger diameters while maintaining simple operation and low production cost. They are particularly useful for workshops that need to move from small-batch to flexible medium-batch production.

4.2Planetary Rotary Thread Rolling Machines: For Small to Medium Diameters in Mass Production

- Structure: One central rotating die and multiple fixed segment dies; no axial movement of the blank.

- Advantages: High speed (hundreds of parts per minute), stable accuracy, suitable for small- to medium-diameter parts.

- Applications: Large-volume production of small screws (e.g., electronic screws), standard fasteners.

- Limitations: Restricted diameter range; not suitable for large parts.

For manufacturers focused on high output and automation, automatic CNC screw thread rolling machines integrate the planetary principle with digital control, ensuring both speed and consistency. This type is widely used for electronics screws, micro fasteners, and other high-volume standard components.

4.3Cylindrical Die Thread Rolling Machines: For Large Diameters and Complex Parts

- Structure: Two- or three-die systems with parallel-axis arrangement; supports infeed or through-feed rolling.

- Advantages: Wide processing range (up to 5 in. diameter), capable of processing hollow parts, long bars, and harder materials.

- Applications: Large bolts, hollow fittings, continuous threads on bars (e.g., lead screws), heat-treated components.

- Variants: Three-die machines offer greater support than two-die versions, making them better suited for hollow or high-precision parts.

Advanced hydraulic 3-roller machines are especially effective for hollow tubes and large-diameter bolts, providing extra stability during rolling. Meanwhile, CNC 3-die thread rolling machines push cylindrical technology further, delivering precise alignment and repeatability for complex or heat-treated parts where accuracy is critical.

4.4Thread Rolling Machine Selection: 3-Step Guide

- By Production Volume: Small batches (hundreds to a few thousand) → Reciprocating or automatic 2-roll machines; large batches (tens of thousands or more) → Planetary or automatic CNC screw thread rolling machines.

- By Part Size: Small diameters (≤1 in.) → Reciprocating or planetary; larger diameters (>1 in.) or long bars → Cylindrical, hydraulic 3-roller, or CNC 3-die machines.

- By Part Type: Hollow or complex components → Three-die cylindrical or CNC 3-die machines; standard fasteners → Planetary or automatic CNC screw thread rolling machines.

5.0How to Use Thread Rolling Dies? Key Tips for Longer Life and Higher Accuracy

Many users search for “thread rolling die life” or “how to maintain thread rolling dies.” As the primary consumable in rolling operations, die life directly impacts overall cost. Below are three essential practices:

Choose the Right Die Material: Match to the Workpiece Material

- Soft materials (aluminum, brass): Use Cr12MoV tool steel; cost-effective and long-lasting.

- Hard materials (stainless steel, alloy steel): Use high-speed steel (W18Cr4V) or carbide dies for superior wear resistance and fracture toughness.

Extend Die Life with Three Operating Practices:

- Control penetration speed: Use slower speeds for hard materials or hollow parts (to prevent die chipping), and higher speeds for soft materials (to avoid material sticking).

- Inspect dies regularly: Replace promptly when crest wear or chipping is detected to prevent excessive scrap.

- Optimize die stations: Multi-station dies (e.g., double or four-station setups) distribute wear across multiple surfaces, extending service life by 2–4 times.

Select Proper Die Width:

- Infeed rolling: Die width should equal thread length + 2–3 pitches, preventing end breakage.

- Through-feed rolling: Follow the manufacturer’s recommended width; for threads near shoulders, reserve 3–5 lead pitches of clearance.

6.0Frequently Asked Questions (FAQ): Thread Rolling Explained

Can internal threads be rolled?

No. Thread rolling is almost exclusively for external threads. Internal threads require tapping or roll tapping processes.

Can high-hardness materials (e.g., Rockwell C45) be rolled?

Partially. With carbide dies and slow penetration speeds, some high-hardness materials can be rolled. However, ductility must be tested in advance to avoid die fracture.

What accuracy levels can rolled threads achieve?

Standard thread rolling can achieve Class 6g tolerances. With ground dies and high-precision machines, accuracy can reach Class 4h, meeting aerospace requirements.

Is thread rolling more expensive than cutting for small batches?

No. Setup time for a thread rolling machine is short (about 30 minutes). Even for small runs of ~500 pieces, the combined savings in material and higher productivity make rolling 10%–15% more cost-efficient than cutting.

7.0Conclusion: Thread Rolling — A Proven Method for Lower Cost and Higher Efficiency

Whether in the fastener industry demanding high-strength threads or aerospace applications requiring precision and material savings, thread rolling consistently delivers with its chip-free process, superior strength, and cost efficiency.

By selecting the right machine type (reciprocating, planetary, or cylindrical) and matching dies with materials, manufacturers can increase threading productivity by 3–5 times while reducing material waste by 15%–27%.

If you are wondering whether your parts are suitable for rolling—or which machine to choose—refer to the selection guide provided or evaluate your specific part dimensions to optimize the process.