1.0Differences Between Beveling and Chamfering

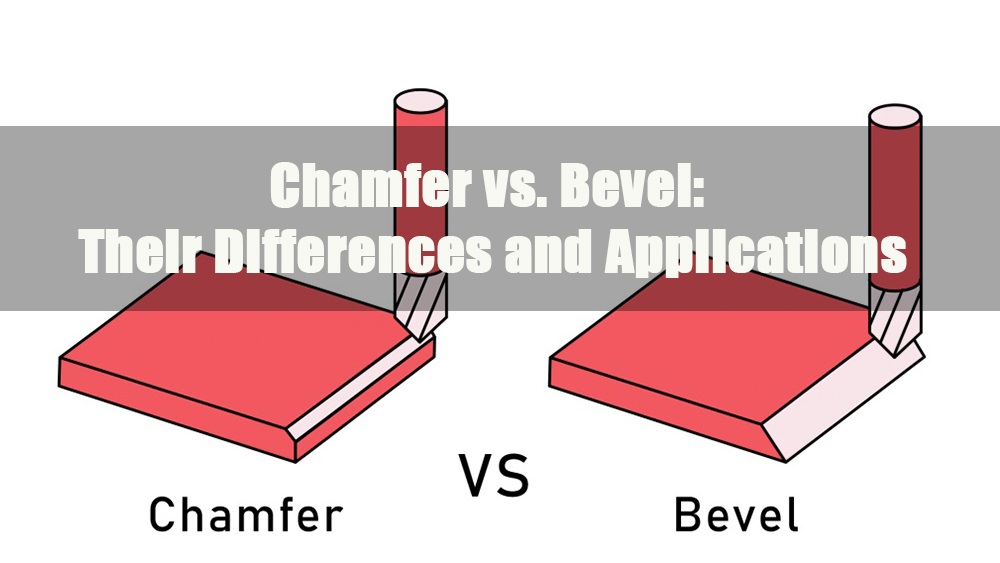

In pipe processing, metal fabrication, and welding preparation, both beveling and chamfering are common edge-finishing techniques. While they may appear similar, they differ significantly in purpose, angle design, application scope, and processing methods.

1.1Basic Definitions

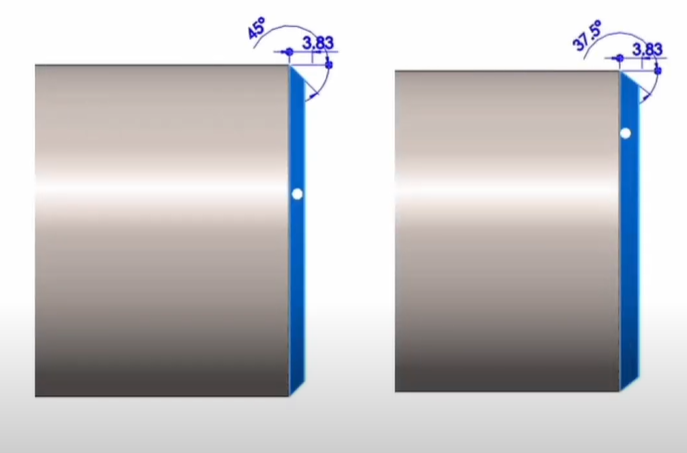

| Aspect | Chamfer | Bevel |

| Definition | A small angled cut—typically 45°—between two adjoining surfaces to remove sharp edges or guide assembly. | An angled surface machined at the material’s edge, primarily for welding prep or structural connections. |

| Typical Angle | 45° | Commonly 37.5°, but may also be 30°, 60°, etc. |

| Depth | Only affects the outermost edge | Can extend deeper into the material |

| Material Removal | Yes (usually minimal) | Yes (removes more material) |

| Edge Relation | Typically between perpendicular faces | Often between non-perpendicular or parallel surfaces |

1.2Purpose Comparison

| Process Type | Main Purpose |

| Chamfering | Removes sharp edges, improves assembly fit, enhances safety and aesthetics. |

| Beveling | Prepares pipe ends or edges for welding, increases weld penetration and joint strength. |

| Process Type | Main Purpose |

| Chamfering | Removes sharp edges, improves assembly fit, enhances safety and aesthetics. |

| Beveling | Prepares pipe ends or edges for welding, increases weld penetration and joint strength. |

1.3Processing Methods

Common Beveling Methods:

- Manual Grinding: Cost-effective, suitable for on-site use; lower consistency.

- Portable Beveling Machine: Higher efficiency, mobile, ideal for small- to medium-batch work.

- Stationary Beveling System: High precision, supports V-, U-, and J-grooves; suitable for automation.

- Plasma or Flame Cutting: Ideal for thick-wall pipes; enables simultaneous cutting and beveling.

Common Chamfering Methods:

- Chamfer Mill: Used on CNC mills or lathes; offers high accuracy.

- Chamfer Gauge / Ruler: Supports manual operation; suitable for low-volume or fieldwork.

- Deburring Tools / Grinding Wheels: For plastics, glass, or light edge treatment.

1.4Application Comparison

| Application Area | Chamfer | Bevel |

| Piping Systems | Removes sharp edges at pipe ends to ease assembly | Prepares ends for welding, improves penetration and strength |

| Mechanical Parts | Helps align screws, reduces stress concentration | Used in gear teeth and sealing interfaces |

| Architectural Hardware | Enhances safety and appearance of exposed edges | Enables angled joints or decorative transitions |

| Welded Structures | Rarely applied directly | Essential for butt joint preparation (e.g., pipes, plates) |

1.5 Is Chamfering a Type of Beveling?

Technically, a chamfer can be considered a specific type of bevel, typically at a fixed 45° angle. However, its intended function and processing depth are different:

- Chamfer: Used in precision machining, assembly fit improvement, and edge deburring.

- Bevel: Focused on structural joining and welding preparation.

2.0Common Pipe Beveling Methods

2.1Angle Grinder Beveling:

Using a handheld angle grinder to manually create a bevel at the pipe end. This is the most basic method of pipe beveling.

- Cost-effective: One of the least expensive options, ideal for small batches or repair jobs.

- Operator dependent: Requires skilled labor to maintain correct angle and depth.

- Inconsistent quality: Difficult to ensure uniform bevels across multiple pipes.

- Time-consuming: Not efficient for high-volume production.

- Dust and debris: Generates sparks and metal dust, increasing cleanup time and safety concerns.

2.2Portable Pipe Beveling Machine:

A more efficient, mechanized alternative for controlled beveling in field environments.

- Improved safety: Offers more stability and reduces risk compared to manual grinding.

- Higher efficiency: Suitable for medium-volume operations; reduces labor time.

- Field-friendly: Compact and portable, ideal for on-site work.

- Limited capacity: Not recommended for large-scale production due to lower continuous output.

2.3Stationary Pipe Beveling Machine:

Designed for industrial-scale operations and automation lines with a focus on consistency and speed.

- Versatile bevel profiles: Supports a range of weld bevel types, including V-, J-, and U-grooves.

- Stable processing: Delivers precise angle control and consistent feed depth.

- Automation-ready: Can be integrated into CNC lines for continuous operation.

- Clean and chip-free: Some models offer chipless processing for minimal cleanup.

- High productivity: Short cycle times and fast throughput.

- Higher upfront cost: Requires significant initial investment, suitable for fixed production lines.

2.4Plasma or Oxy-Fuel Bevel Cutting:

Uses thermal cutting technology to melt and bevel pipe ends, particularly effective for thick or high-strength materials.

- Ideal for heavy-wall pipes: Works well with stainless steel, carbon steel, and alloy piping.

- Flexible angles: Allows programmable multi-angle bevels such as X- and K-grooves.

- Fast cutting: Efficient for large-diameter or high-volume production.

- Heat-Affected Zone (HAZ): Careful temperature control is required to avoid thermal distortion or metallurgical changes.

- CNC-compatible: Often paired with automated positioning and cutting systems.

Method Comparison Summary

| Method | Cost | Efficiency | Consistency | Ideal Use | Bevel Quality |

| Angle Grinder | ★ | ★ | ★ | Small batches, repairs | Low (manual control) |

| Portable Machine | ★★ | ★★★ | ★★ | Field work, mid-volume | Moderate |

| Stationary System | ★★★★ | ★★★★★ | ★★★★★ | Automation, high-volume | Very high |

| Plasma/Oxy-Fuel | ★★★ | ★★★★ | ★★★★ | Thick-wall, large-diameter pipes | High (with thermal control) |