1.0What Is Swaging?

1.1Origin and Development of Swaging

The swaging process originated in Germany and was initially developed for shaping hollow cylindrical workpieces into complex profiles. Extensive research has been conducted to understand the material flow and wall thickness variation during the process. As early as 1964, Kegg proposed a mechanical model of the swaging process, predicting the relative rotational movement between the die and the workpiece, especially under different spindle configurations that influence motion patterns and speed variations.

1.2Difference Between Swaging and Conventional Forging

Forging processes can generally be divided into two categories:

- Tube Drawing: Reduces the diameter of metal tubes by pulling or extruding them through a reducing die. Similar to wire drawing, this method is used for downsizing tubular workpieces.

- Swaging / Radial Forging: Involves two or more dies that hammer the workpiece through continuous or high-frequency reciprocating motion, inducing localized plastic deformation. This method is widely used for diameter reduction, taper forming, pointing, and shaping of internal cavities in hollow parts.

One key advantage of swaging is its ability to perform complex forming at room temperature while maintaining high dimensional accuracy and conserving material. This makes it especially favorable in the processing of precious metals.

1.3Working Principle

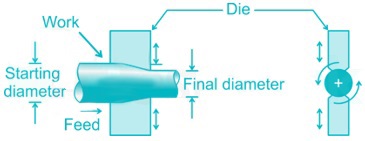

Swaging processes are typically performed in the following two modes:

- Axial Swaging: The metal flows laterally under the radial blows of the dies, effectively changing its diameter or creating a tapered profile.

- Rotary Swaging with Rollers: Uses a set of rollers that orbit around the part to flare or expand the edges in a controlled manner—commonly used in assembling components such as press-fitting bearings into housings. This method often involves lubricants to reduce friction and wear and is ideal for applications requiring high concentricity and tight fit.

Swaging can also be performed with a mandrel to control the internal shape of hollow workpieces, provided that the deformation zone maintains a constant cross-sectional area.

2.0What Is a Swaging Machine?

A swaging machine is a metal forming device used to alter the shape and dimensions of metal workpieces, typically rods or tubes, by means of high-speed radial hammering with two or four split dies. Common applications include diameter reduction, taper formation, tip forming, and shaping the inner profiles of hollow components. It is primarily used in cold-working operations.

Working Principle of a Swaging Machine

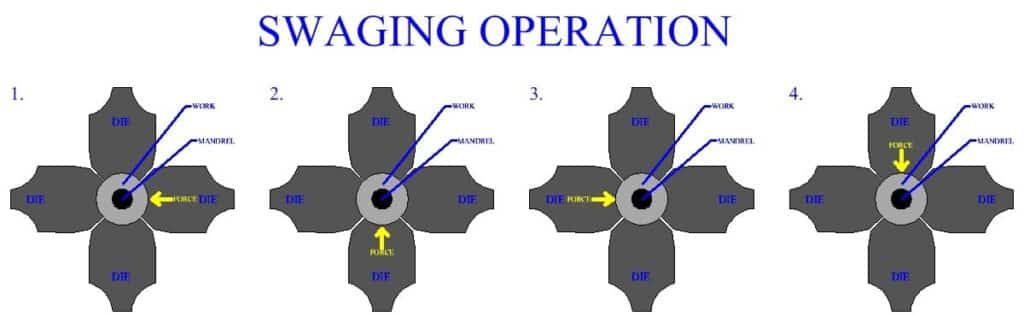

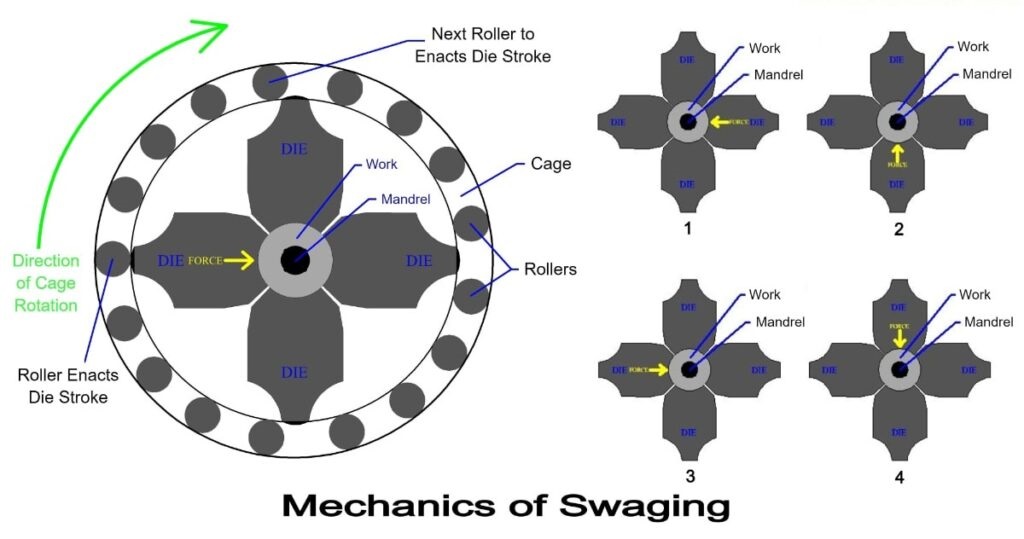

The core components of a swaging machine include:

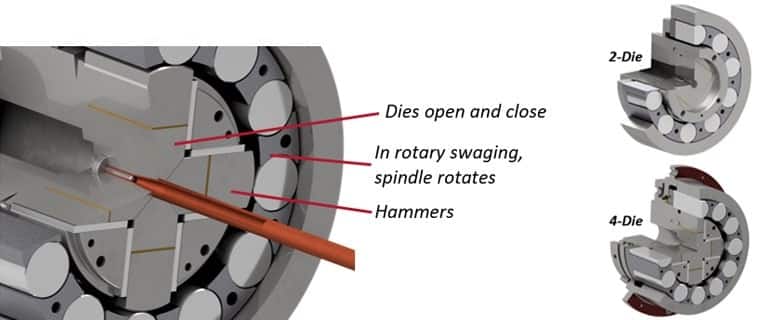

- Spindle and Die System: The dies are mounted on a motor-driven spindle, which is enclosed in a roller cage, similar in design to a roller bearing.

- Die Motion: As the spindle rotates, centrifugal force throws the dies outward to ride on the cage. When the dies pass over large rollers, they are forced to close momentarily, delivering impact force to the workpiece.

- Operating Frequency: The dies open and close at extremely high frequencies—up to 2,000 times per minute—enabling fast and efficient forming.

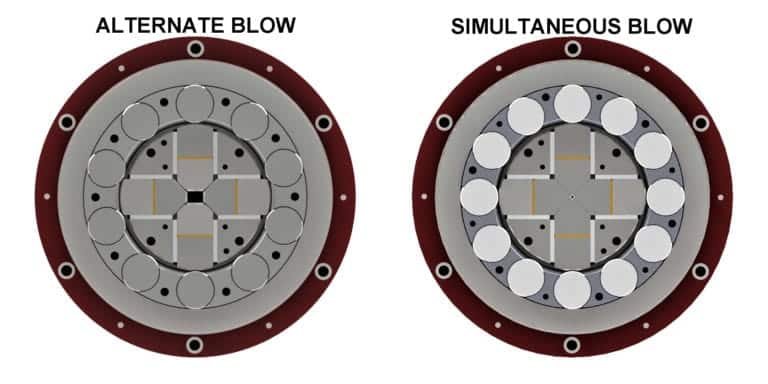

Depending on the roller arrangement, the dies may close simultaneously (in standard swaging machines) or sequentially (a configuration often referred to as rotary forging, though it is fundamentally still a swaging process).

2.1Types of Swaging Machines

Swaging machines can be classified into the following basic types:

- Marking Swager: Also known as an automatic swaging machine, it features motor-driven continuous die motion and is ideal for high-speed, high-volume production.

- Tapering Swager: Utilizes a wedge mechanism to engage the dies with the rollers. Typically foot-operated, this design allows insertion of long workpieces while the dies remain open and enables localized forming, especially for tapered ends.

2.2Special Swaging Configuration: Oscillating-Spindle Swaging Machine

A variation of rotary swaging, this design features counter-rotating spindles and cages, which helps eliminate the formation of unwanted metal “fins” between dies. This results in improved edge quality and concentricity of the finished parts.

Forming Principle and Process Details

- Forming Method: Dies deliver rapid radial blows to a stationary workpiece, striking at a rate of 10–20 times per second.

- Workpiece Types: Typically bars or tubes, ideal for end tapering, tip forming, or internal shaping of hollow parts.

- Forming Procedure: A mandrel can be used to control the internal dimensions of hollow workpieces. Dies may operate in an in-and-out motion or rotate around the part.

- Typical Applications: Press-fitting bearings into housings, reducing or flaring tube ends, forming pointed tips, or imparting internal geometries.

- Lubrication: Grease lubrication is commonly applied to reduce die wear and improve forming quality.

2.3Process Classification Comparison

| Category | Description | Alternate Name(s) |

| Type I | The workpiece is forced through a reducing die to decrease diameter | Tube Swaging, Tube Drawing |

| Type II | Two or more dies hammer the workpiece to reduce diameter | Swaging, Radial Forging |

Swaging is widely used in the precious metal processing industry due to its cold-forming nature, minimal material loss, and high efficiency in shaping complex geometries.

3.0Principle of Rotary Swaging for Metal Tubes

Rotary swaging of metal tubes is a plastic forming process that combines high-frequency radial impact with rotational motion. It typically involves multiple forging dies—commonly three, four, or eight—uniformly arranged around the circumference of the tube. Through synchronized short-stroke radial reciprocation, the process enables precise shaping such as end reduction, mid-section necking, and taper forming.

3.1Process Characteristics and Workflow

- Die Arrangement: Multiple forging dies are evenly distributed around the tube. As they rotate, the dies deliver high-frequency, short-distance radial blows to the tube surface, causing continuous plastic deformation.

- Process Types:

- Progressive Swaging: The tube is gradually necked down from one end while slowly advancing axially, allowing continuous deformation along its length.

- Groove Swaging: The workpiece remains stationary while the dies perform localized diameter reduction or recessed contour forming at specific positions, suitable for precise structural shaping.

- Deformation Mechanism: Multidirectional impacts and rapid cyclic loading promote grain refinement and densification in the material, while ensuring high forming accuracy and superior surface finish.

3.2Advantages of the Process

- Efficient plastic deformation with minimal material waste and no chip generation

- Improved structural strength and durability

- Capability to form complex geometries for diverse industrial applications

- Cold-forming operation eliminates issues associated with heat treatment

4.0What Is Forging?

Forging is a metal forming process in which a workpiece undergoes plastic deformation under external force, typically through hammering or pressing. The material is shaped inside a die, improving its internal structure and enhancing mechanical properties and strength. Forging is one of the most fundamental and widely used metal forming techniques in industrial manufacturing.

5.0What Is the Forging Process?

Working Principle: In closed-die forging, a metal workpiece—either a rod or a tube—is inserted into a die cavity of a defined shape. Multiple hammer heads then strike the material in high-frequency radial motion, driving it inward to progressively fill the cavity. Die movement can take the form of:

- Reciprocating (axial in-and-out) motion

- Rotary motion (often achieved via a roller cage system similar to a roller bearing)

In rotary swaging, the dies rotate at high speed, delivering 10–20 blows per second while the workpiece remains stationary. For tubular components, a mandrel can be used to control inner diameter and wall thickness. Shaped mandrels allow the creation of complex internal geometries.

5.1Forming Capacity and Precision:

- Workpiece size range: diameters from 0.5 mm to 150 mm

- Production rate: up to 30 parts per minute (depending on complexity and automation)

- Dimensional tolerance: as tight as ±0.05 mm to ±0.5 mm

- Material compatibility: suitable for a wide range of metals from aluminum, copper, and stainless steel to hard-to-deform metals like tungsten and molybdenum; hot forging is typically used for low-ductility materials

- Lubricants are often applied to reduce tool wear and improve surface finish during processing.

5.2Applications of Forging :

Forging is widely applied across industries due to its efficiency and versatility, particularly for:

- Closed-end tubular components

- Tube end reduction and tapering

- Electrical cable assemblies and structural supports

- Punches, chisels, handles, and pliers components

- Exhaust systems and automotive connection tubes

- Tool shafts, segmented cones, and clamping elements

6.0What Is Rotary Swaging?

Rotary swaging is a specialized forging technique involving rapid, continuous radial impacts combined with rotary motion to reduce, shape, or taper round bars, tubes, or wires without cutting. A rotary swaging machine uses multiple hammer heads (typically 3 or 4) that rotate around the workpiece while delivering synchronized radial blows, causing localized plastic deformation that gradually forms the desired profile.

Compared to conventional forging, rotary swaging offers greater dimensional accuracy, reduced material waste, and improved grain structure uniformity. It is an energy-efficient, chipless metal forming process.

6.1Types of Rotary Swaging

| Type | Description |

| Cold Swaging | Performed at room temperature, suitable for ductile materials such as copper and aluminum |

| Hot Swaging | Performed after heating high-strength materials to reduce hardness; used for alloy steels, stainless steels, etc. |

| Solid Swaging | Used for reducing or tapering solid bars and wires |

| Hollow Swaging | Primarily for tubes; used for reducing, expanding, or tapering hollow profiles |

| External Swaging | Deformation applied from the outside; typical in standard rotary swaging machines |

| Internal Swaging | Uses internal mandrels or support rods to control inner contours, ideal for precision hollow parts |

6.2Rotary Swaging Process Steps

- Workpiece Preparation: Select appropriate bar or tube material

- Clamping and Positioning: Secure the workpiece in the machine fixture

- Die Rotation and Hammering: Dies rotate at high speed and deliver synchronized radial blows

- Incremental Forming: Continuous impact gradually reduces the outer diameter and changes the shape

- Part Removal: Once the final size or shape is achieved, the part is removed manually or automatically

7.0Types of Swaging Machines: A Complete Guide from Fixed to Rotary Systems

Swaging machines are widely used in metal forming, diameter reduction, and tapering applications. Based on their structure and forming mechanisms, they can be categorized into the following main types:

7.1Fixed Die Swaging Machine

Also known as stationary swaging machines, these are highly versatile devices suitable for both hot and cold forging. During operation, the spindle assembly remains stationary while the outer roller cage rotates, driving the dies to close and compress the workpiece.

Features and Benefits:

- Capable of processing various cross-sectional shapes (round, square, rectangular);

- High flexibility for forming complex geometries;

- Compatible with both hot and cold working processes.

Variants:

- Synchronous Blowing Type: Suitable for producing round and grooved tubes.

- Alternating Blowing Type: Ideal for square, rectangular, or hexagonal profiles.

Applications: Aerospace tubing, fluid control piping, and other industries require high-precision tubular components.

7.2Rotary Die Swaging Machine

Also known as rotary swaging machines, these are high-efficiency, high-consistency tools commonly used in modern swaging applications. The dies are mounted on multiple hammer blocks that rotate around the workpiece. As the spindle rotates, centrifugal force drives the hammer blocks to strike the rollers, which causes the dies to close periodically and perform radial forging.

Die Configurations:

- Two-Die System: Ideal for small parts with excellent surface finish;

- Four-Die System: Suitable for larger components requiring heavy compression and tip forming.

Applications: Cartridge heaters, hypodermic needles, firearm components, forestry tools, and various tube-based products.

7.3Hydraulic Swaging Machine

Hydraulic swaging machines combine rotary die motion with hydraulic control and are mainly used for cable fitting assembly, shoulder reduction, and corrugated tube forming. During operation, the workpiece is inserted through the opened dies, which are then closed by the rotating spindle and wedge mechanism. After swaging, the system automatically reopens the dies.

Key Advantages:

- Greater flexibility for part handling;

- Easy clamping and removal, ideal for assembly-oriented tasks.

Typical Applications: Architectural cable railings, marine rigging, outdoor rope courses, and maintenance tools.

7.4Long Die Swaging Machine

Designed for manufacturing extra-long tapered tubes, this machine operates similarly to rotary swaging but is equipped with extended-length dies to overcome the length limitations of standard swaging machines. It can form tapered parts up to 24 inches long, making it suitable for applications in furniture, sporting goods, and aerospace components.

Material Compatibility: Applicable to both ferrous and non-ferrous metals, including stainless steel, aluminum, welded and seamless tubes.

Applications :Tapered furniture legs, sports equipment, and aerospace tubing where extended length and shape consistency are required.

7.5Summary

| Machine Type | Forming Applications | Advantages | Typical Uses |

| Fixed Die Swaging | Various cross-sections | Versatile forming, stable structure | Aerospace tubing, shaped profiles |

| Rotary Die Swaging | Round profiles | High speed, high precision, continuous | Needles, heaters, gun barrels, steel tubing |

| Hydraulic Swaging | Cables and tubing | Easy handling, suited for assemblies | Cable fittings, railings, rope course gear |

| Long Die Swaging | Long tapered components | Extended part length, multi-metal support | Furniture legs, aerospace tapers, sports gear |

References

https://en.wikipedia.org/wiki/Swaging

https://thelibraryofmanufacturing.com/swagging.html

https://www.researchgate.net/publication/275540272_Rotary_Swaging_Forming_Process_of_Tube_Workpieces