- 1.0What Is Metal Spinning?

- 2.0Materials Suitable for CNC Metal Spinning

- 3.0What Is a Metal Spinning Machine?

- 4.0Recommended Metal Spinning Machine Manufacturers

- 5.0How to Choose the Right Metal Spinning Machines?

- 6.0When to Use Metal Spinning

- 7.0Types of Metal Spinning Processes

- 8.0Why Choose Metal Spinning

- 9.0Frequently Asked Questions (FAQ) about Metal Spinning

Originally introduced to North America in the early 19th century, manual metal spinning has since evolved into a highly advanced and automated manufacturing process. Technological advancements have improved production speed, repeatability, and overall efficiency, making metal spinning a reliable and cost-effective solution for many manufacturers.

1.0What Is Metal Spinning?

1.1Introduction

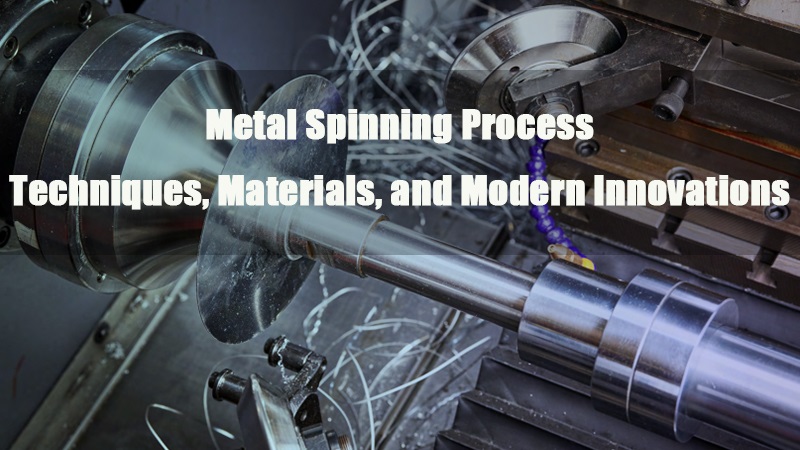

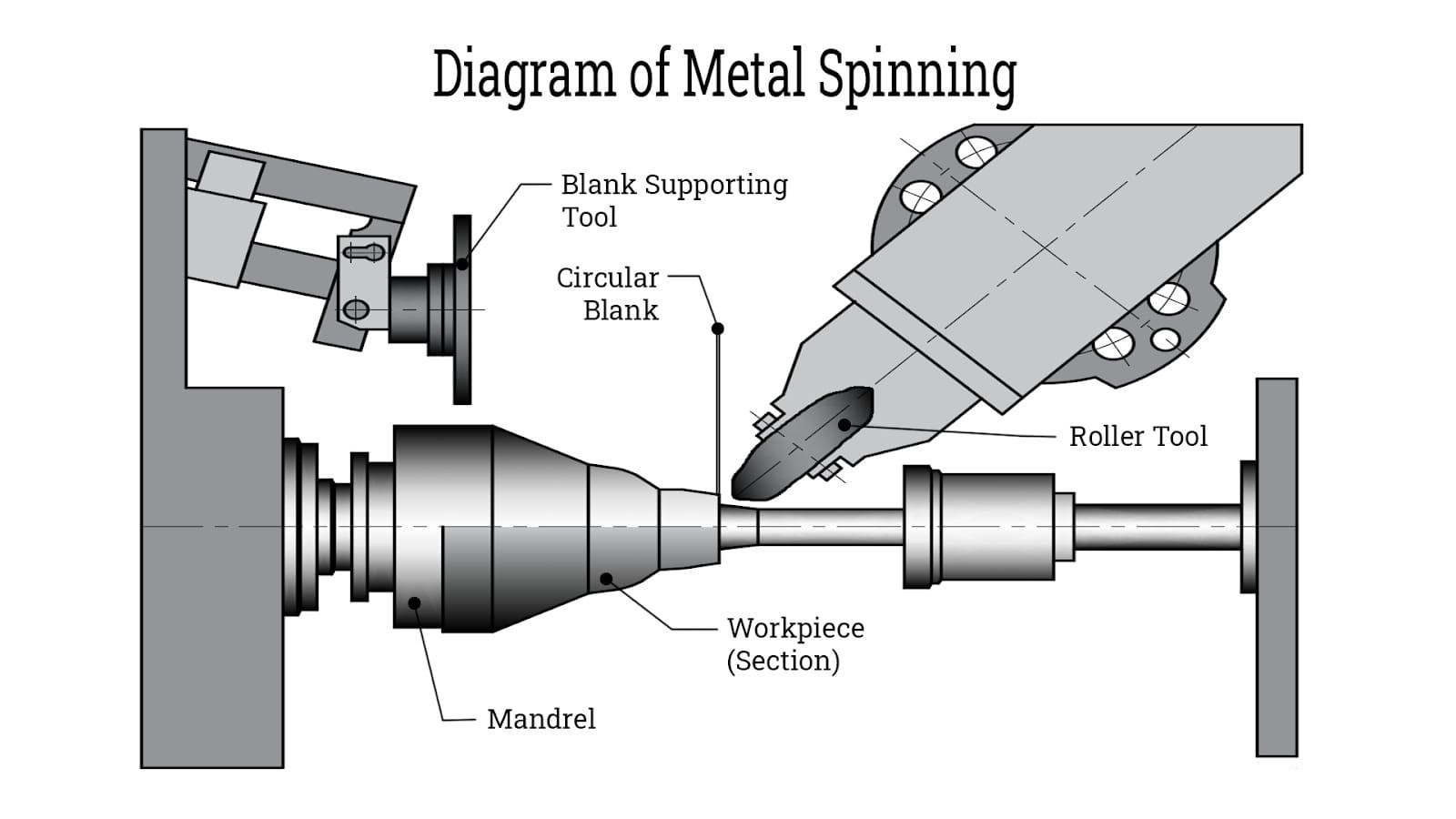

According to the DIN 8584 classification, metal spinning is a chipless forming process in which a rotating mandrel and roller are used to transform flat or tubular blanks into axially symmetric hollow parts. Often referred to as spin forming, flow turning, or simply spinning, the process involves high-speed rotation of a metal disc or tube to shape a circular cross-section hollow component.

1.2How Does Metal Spinning Work?

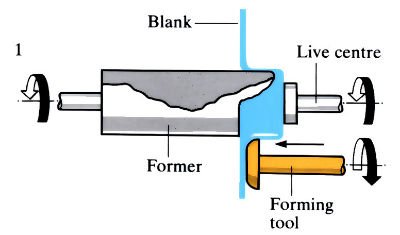

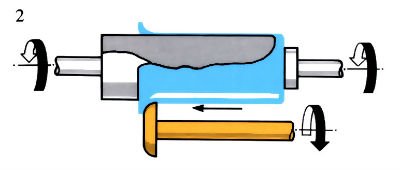

Metal spinning is a metal forming technique where a flat metal blank, tube, or cylindrical preform is mounted on a lathe and rotated at high speeds. A forming roller applies localized pressure to the rotating workpiece, gradually shaping it into a symmetric form—typically cones, cylinders, or hemispheres—without the need for welding or seams.

This process is compatible with a wide range of materials, including aluminum, stainless steel, and high-strength, heat-resistant alloys. Depending on production needs, metal spinning can be carried out manually or using CNC-controlled machinery.

Applications: Metal spinning is widely used in the production of automotive and motorcycle components, gas cylinders, cookware (such as frying pans), and in sectors like defense and aerospace where precision and strength are critical.

1.3Advantages of Metal Spinning

- Superior Structural Strength: The seamless design of spun parts allows them to withstand high internal and external pressure. Cold working also enhances tensile strength by refining the grain structure.

- Material Efficiency: Lighter and thinner metals can be used effectively, resulting in weight reduction and cost savings.

- Smooth Surface Finish: Parts often emerge with high-quality surfaces, minimizing the need for secondary processing.

- Cost-Effective Alternative: It can replace deep drawing or stamping processes, reducing the reliance on expensive tooling.

- Rapid Prototyping: Quick adjustments to design can be made without incurring major tooling costs.

- Fast Setup and Changeover: Ideal for low- to mid-volume production runs or when frequent design variations are required.

- Eco-Friendly: Generates minimal scrap, optimizing material usage.

1.4Basic Steps in the Spinning Process

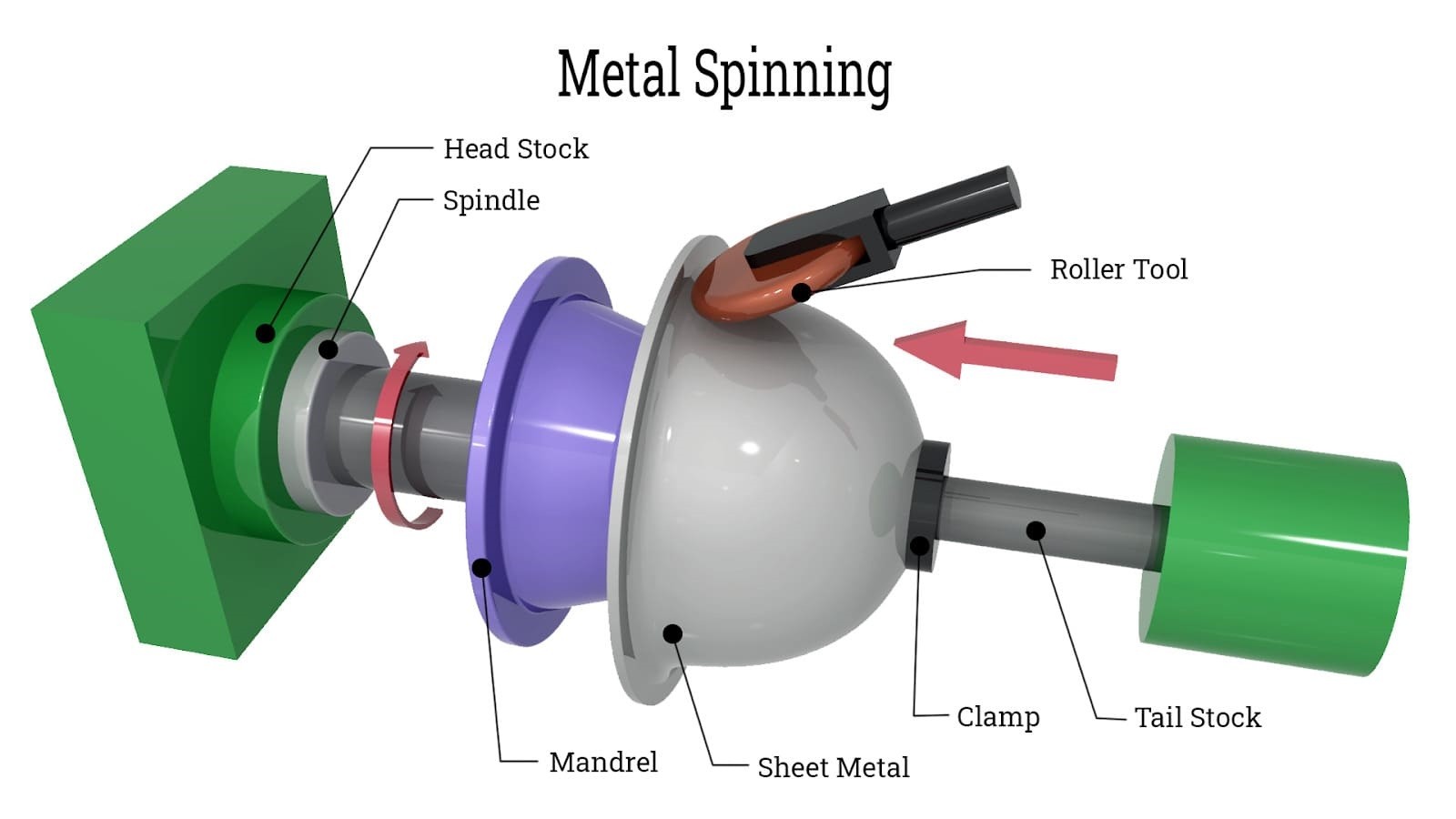

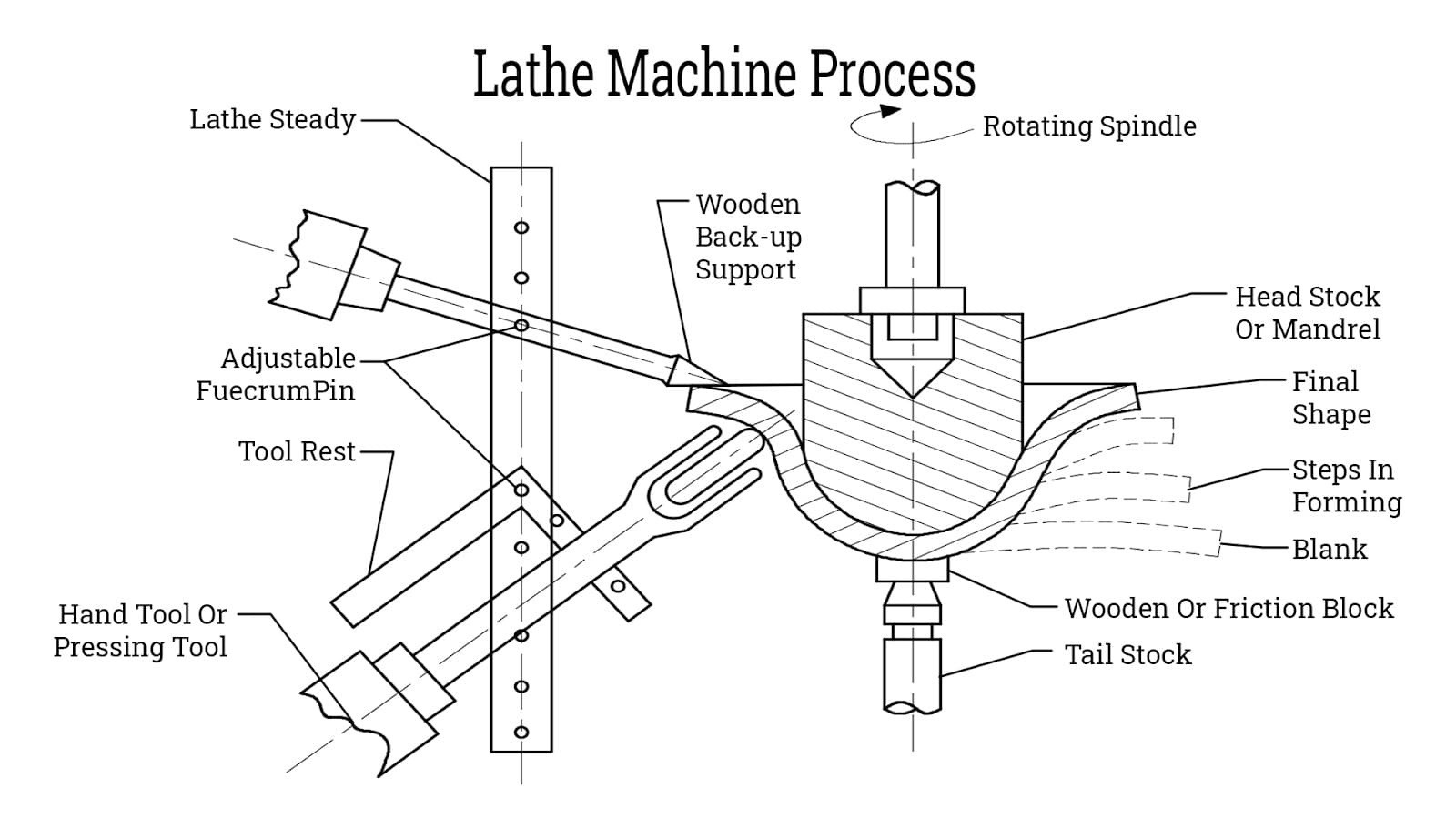

- The mandrel is mounted on the headstock of the spinning lathe.

- A follower block is installed on the tailstock side.

- The circular blank is clamped between the mandrel and follower using axial force.

- A roller tool, mounted on a lever arm, applies side pressure onto the blank. A scissor-like support structure stabilizes the forming arm.

- The roller traces a programmed path, progressively shaping the blank into the final part.

1.5Principle of Flow Forming

For thicker materials, pressure rollers induce plastic deformation, reducing wall thickness while maintaining part integrity. Flow forming achieves extended shapes with enhanced mechanical properties.

1.6A Hybrid of Bending and Stretching

Metal spinning involves a combination of bending and tensile deformation. As a result, the process produces components with excellent formability and strength.

2.0Materials Suitable for CNC Metal Spinning

Metal spinning is compatible with a wide range of ductile metals, including:

- Aluminum

- Stainless steel

- Carbon steel

- Copper

- Brass

- Hastelloy

- Inconel

- Titanium

- Cold-rolled steel

3.0What Is a Metal Spinning Machine?

A metal spinning machine, also known as a spinning lathe or flow-forming machine, is used to form round, hollow metal parts like cylinders, cones, and complex shapes.

These machines offer precise, repeatable results and support custom designs. In addition to spinning, they can perform tasks like cutting, CNC drilling, and sanding. A mandrel sets the internal shape, while coordinated tool movements form the final part with tight tolerances.

3.1Types of Metal Spinning Machines

| Type | Description |

| Manual Spinning Lathes | Operator-controlled rollers, ideal for prototypes, artistic work, and small production runs. |

| CNC Metal Spinning Lathes | Fully automated control of roller paths, pressure, and speed for industrial-scale production. |

| Hot Spinning Machines | Equipped with heating systems to work with hard-to-form or high-strength alloys. |

| Shear Spinning Machines | Designed for high torque and rigidity, suitable for precision thinning of wall thickness. |

3.2Key Spinning Technologies

CNC (Computer Numerical Control) Metal Spinning

CNC spinning uses CAD models and programmed tool paths to deliver high-precision, repeatable results. Key features include:

- Rapid setup and changeover

- Tight tolerances (up to ±01 mm)

- Excellent repeatability and consistency

- Ideal for medium to high-volume production

PNC (Playback Numerical Control) Spinning

PNC systems record an operator’s initial manual movement and replay it automatically for future production. This approach offers:

- High flexibility for complex geometries

- Scalability for batch manufacturing

- A balance between manual control and automation

Automated Metal Spinning with CNC

Automated spinning replaces manual effort with computer-controlled precision. CNC technology enables chipless, precise plastic forming by guiding tools along programmed paths. . Compared to manual spinning, CNC spinning offers:

- Greater accuracy and consistency throughout production

- Reduced human error through automation and minimized manual intervention

- Lower labor demands for large-scale production runs

- Continuous operation, lowering operational costs and increasing throughput

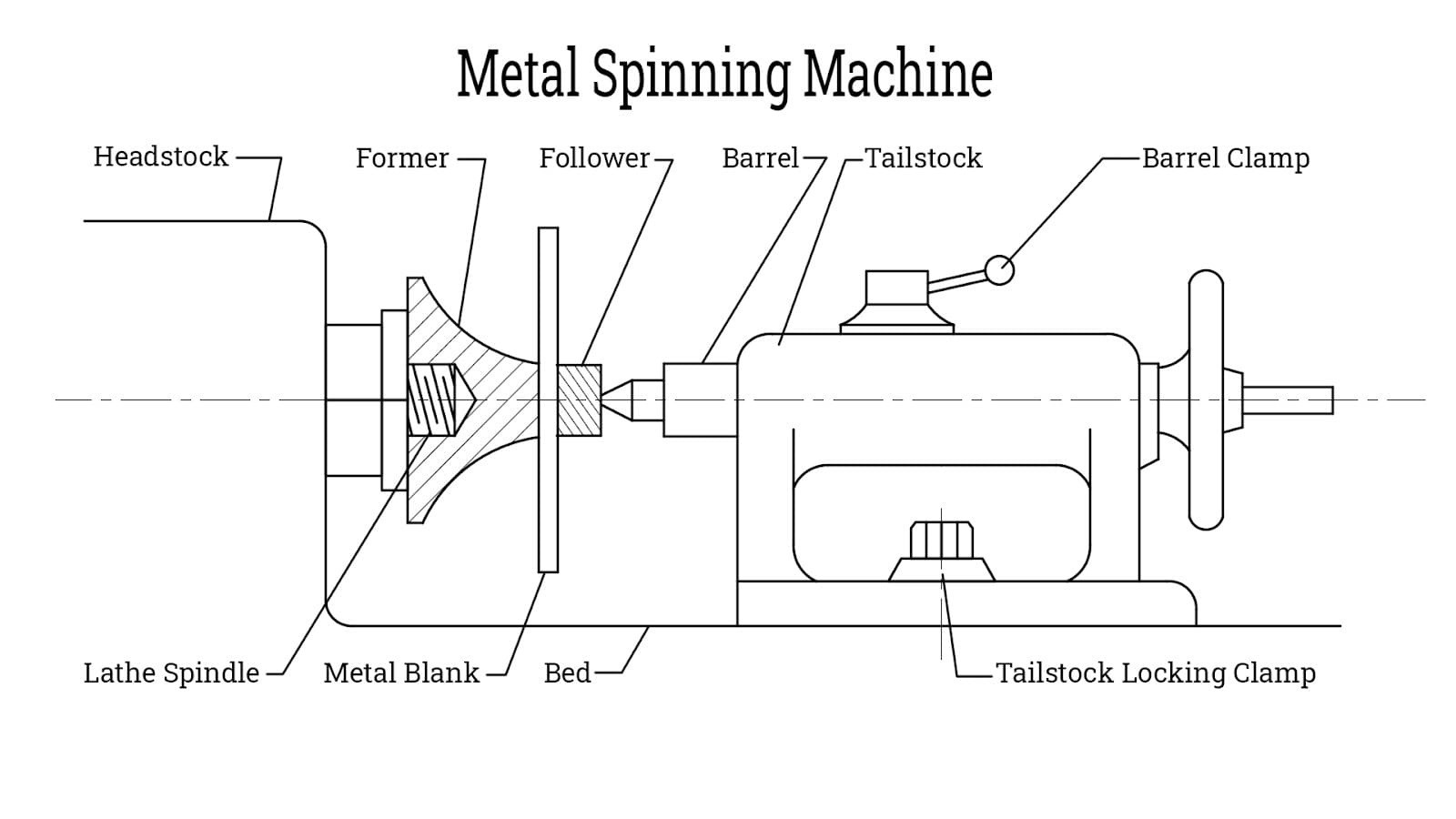

3.3Core Components of a Metal Spinning Machine

- Mandrel: The central die that defines the internal shape of the part. Made from hardened steel or aluminum alloys for strength and durability.

- Roller: The forming tool that applies pressure along the mandrel profile to shape the metal. Often equipped with ball bearings for smooth operation.

- Tailstock: Provides axial positioning and support for the workpiece during forming.

- Follower (Follower Block): Mounted on the tailstock to securely clamp the metal blank, ensuring precision and stability.

- Spindle: The rotating shaft that drives the workpiece, determining rotational speed and torque delivery.

- Headstock: Houses the motor and drive system, controlling the spindle’s power and stability.

- Bed: The machine’s foundation, providing structural rigidity, precise alignment, and vibration resistance

4.0Recommended Metal Spinning Machine Manufacturers

Leifeld Metal Spinning AG

Known for precision, automation, and large-diameter capabilities. Ideal for aerospace and automotive sectors requiring seamless spun parts.

MJC Engineering & Technology, Inc.

Recognized for heavy-duty spinning capacity and real-time quality control, serving industries like medical technology and renewable energy.

ALEKVS, Inc.

Offers a full line of small to heavy-duty spinning machines. Known globally for exceptional cost-performance ratio.

Baileigh Industrial, Inc.

Provides manual spinning machines suitable for small shops and prototyping tasks. Affordable and user-friendly.

PNC Engineering

Specializes in high-torque spindles and programmable roller systems. Tailored for automated production across diverse industries.

5.0How to Choose the Right Metal Spinning Machines?

Key factors to consider:

- Production volume: Manual machines are ideal for single or custom pieces; CNC and PNC systems are better for batch production.

- Material type: Stronger alloys require high-torque spindles and rigid machine frames.

- Part size and complexity: Large diameters or intricate profiles demand higher forming capacity and precision.

- Control system: CNC programming enables complex, multi-step operations with high accuracy.

- Automation: For loading, unloading, and in-process inspection, consider machines with automation integration.

- Supplier support: Choose vendors offering technical training, spare parts, and maintenance services.

6.0When to Use Metal Spinning

Metal spinning is ideal for producing hollow, round parts with shapes like cones, domes, flanges, hemispheres, elliptical forms, or trumpets. Unlike traditional machining, it forms parts without removing material. Instead, the operator shapes a spinning metal blank—called a preform—against a mandrel to create the final part.

This process can be done hot or cold, depending on the material. Metal spinning is also cost-effective, with tooling expenses typically just 10% of those in other forming methods. It offers faster turnaround—often just weeks—and is well-suited for evolving product designs thanks to its flexibility and short setup times.

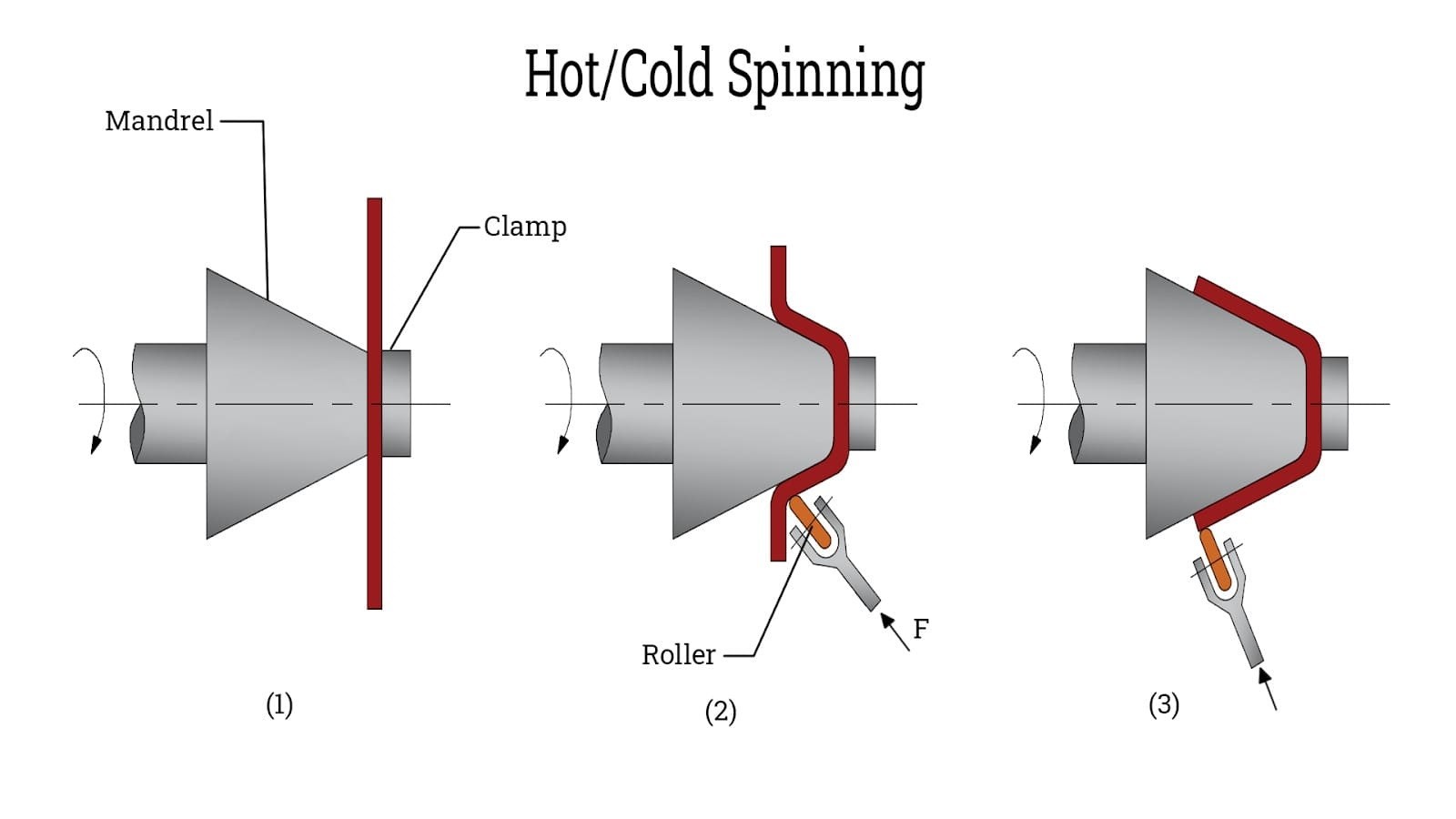

7.0Types of Metal Spinning Processes

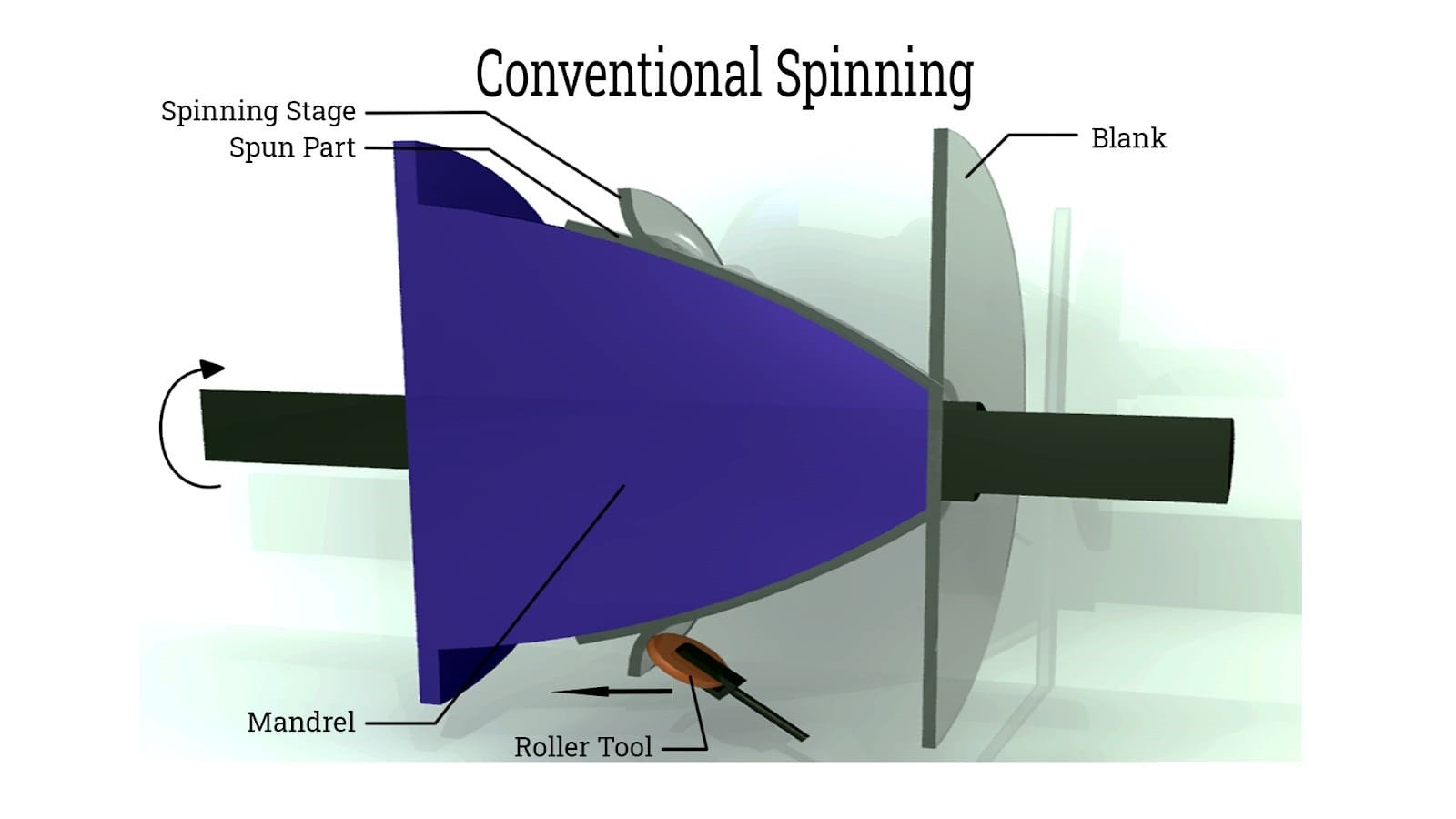

- Conventional Spinning: In this method, rollers guide the blank over the mandrel to form a part while maintaining its original thickness. It’s suitable for producing deep-shaped parts where thickness remains constant.

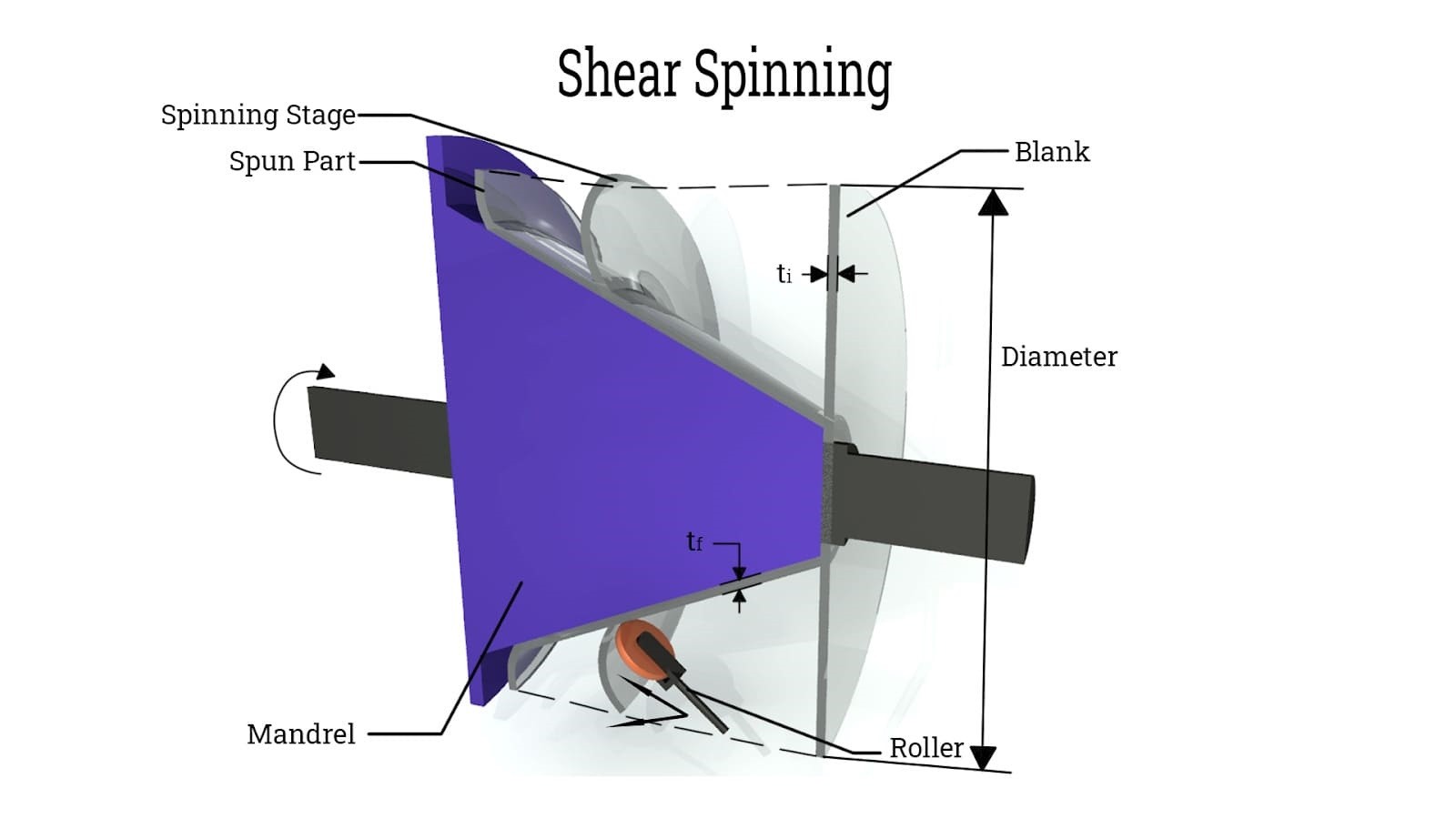

- Shear Spinning: Here, axial force is applied by the roller, reducing the material thickness while maintaining the original diameter. This process enhances part strength and hardness, ideal for precision, high-strength components.

- Hot Spinning: Uses flame or induction heating to increase material ductility during spinning. It’s effective for thick stock, hard-to-form metals, or parts requiring high deformation ratios. However, it involves higher cost and greater oxidation risk.

- Cold Spinning: Performed at room temperature, cold spinning offers high efficiency and wide material applicability. It’s the standard process for most general-purpose spinning operations.

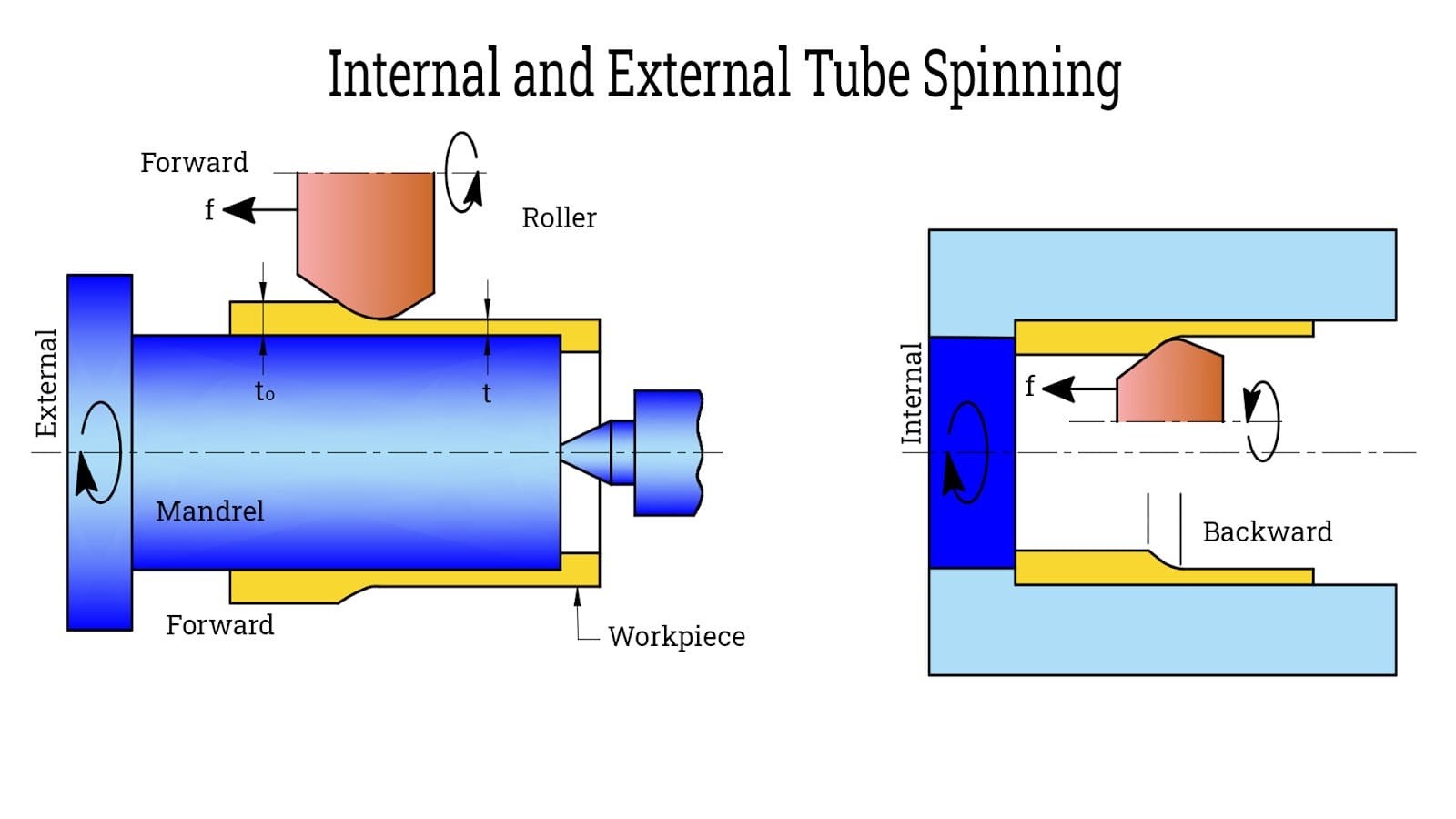

- Tube Spinning: Designed for hollow cylindrical parts, this process reduces wall thickness and elongates the part. It can be internal or external and is ideal for dimensional tuning and improving mechanical properties of metal tubes.

7.1Key Principles and Supporting Techniques in Spinning

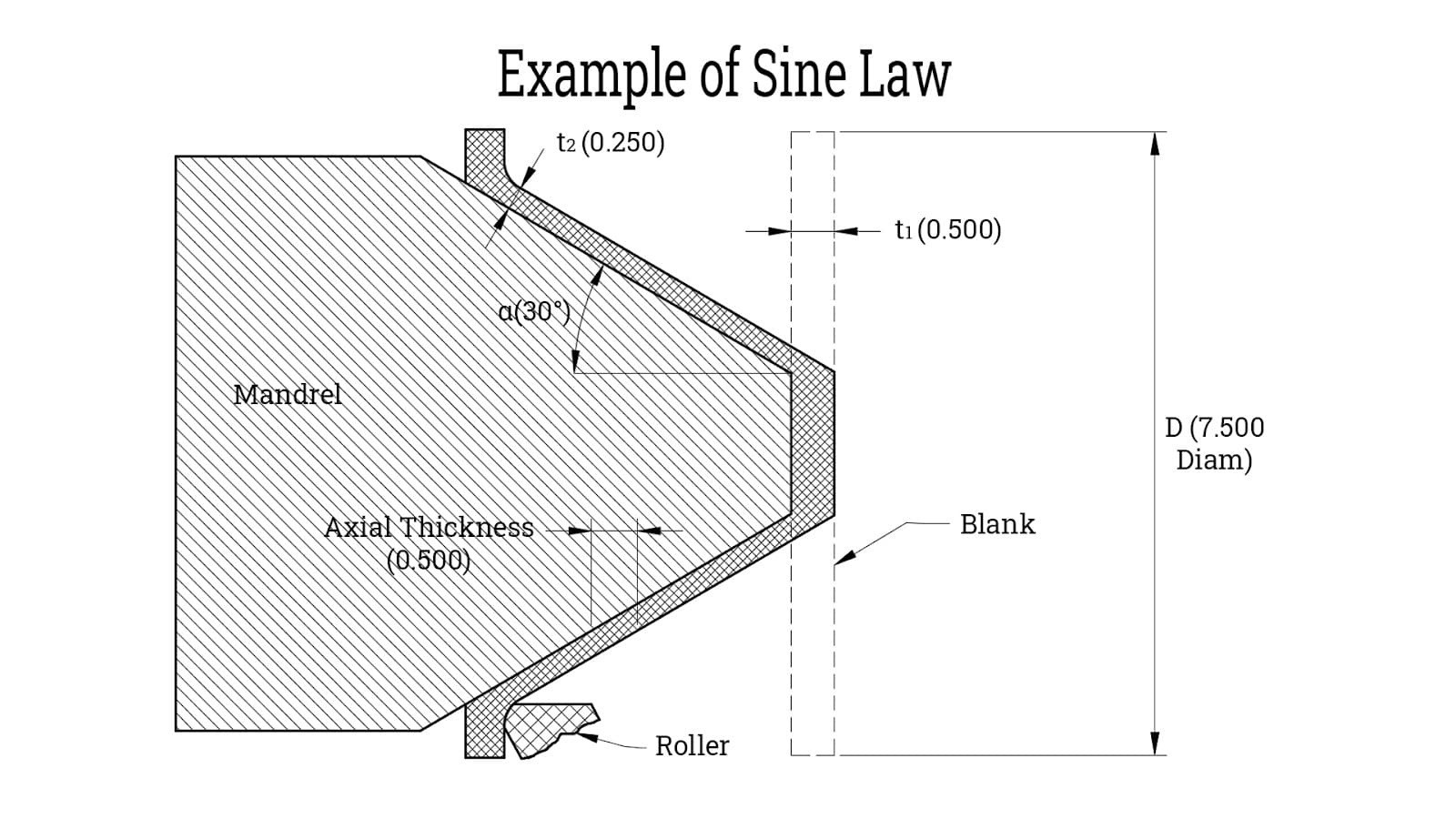

- Sine Law for Thickness Prediction: In shear spinning, the final thickness ≈ initial thickness × sine of the cone’s half-angle. This helps estimate wall thickness changes in conical parts.

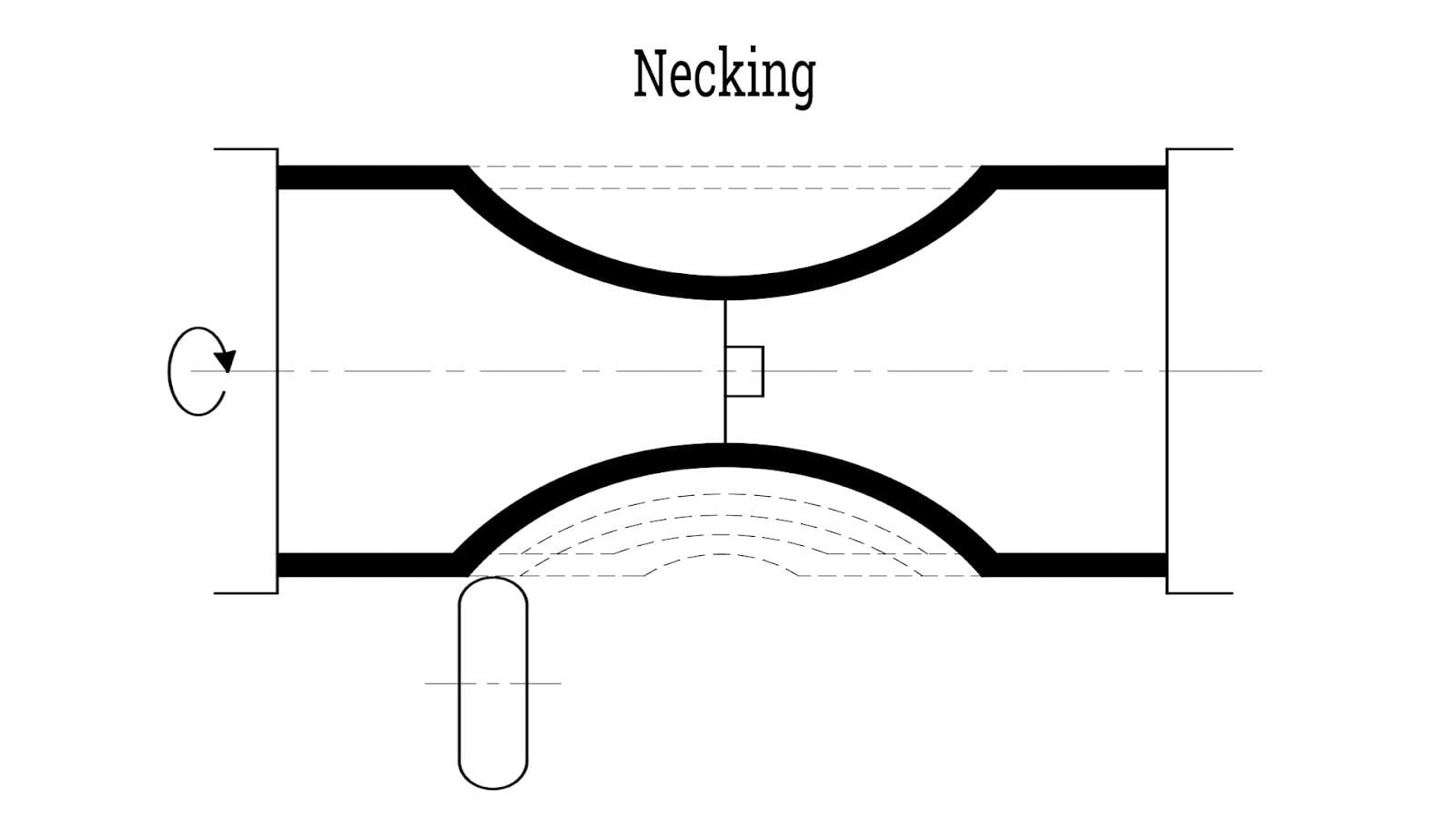

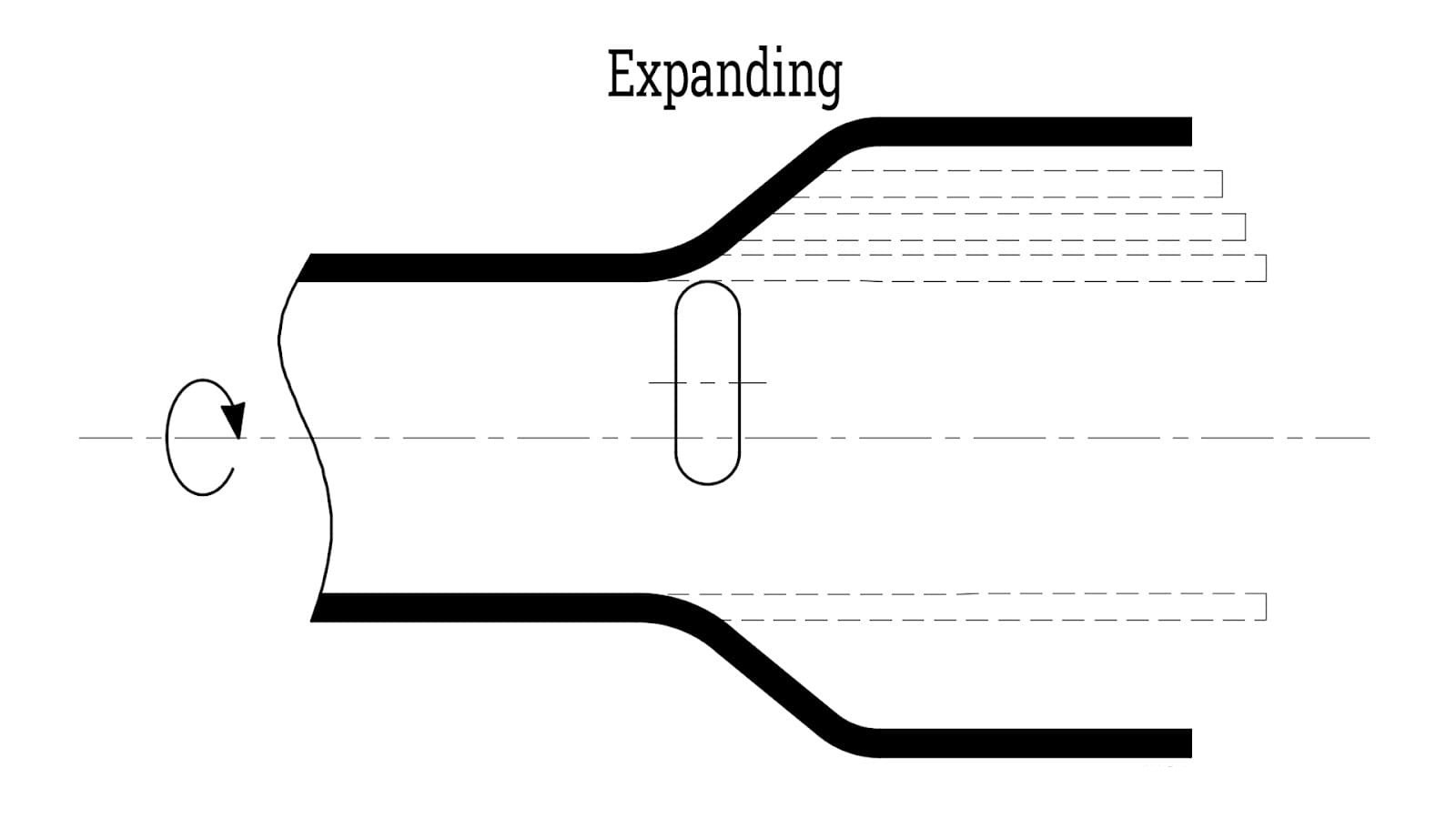

- Necking and Expanding: Necking reduces a section’s diameter, while expanding increases it—ideal for shaping complex profiles.

- Fine Tuning & Multi-Pass Spinning: Adjusting roller pressure, spindle speed, and feed angles, along with multiple passes, enhances dimensional accuracy and surface finish.

- Ironing and Trimming: Ironing smooths wrinkles for better surface quality; trimming removes excess edges for a clean final contour.

7.2Common Spinning Techniques

- Multi-Pass Conventional Spinning

A typical method is where the roller progressively sweeps over the blank to shape it on the mandrel. This can be performed manually or with CNC machines. Wall thickness usually remains constant unless altered by roller direction. Forward passes reduce thickness, while reverse passes control deformation and springback. CNC allows programmable control for consistent wall targets. - Shear Forming (Shear Spinning)

A single-pass method that shapes the part while significantly reducing thickness. The roller applies pressure at a defined shear angle, strengthening the thin material to match properties of thicker stock. This is widely used in aerospace and automotive where weight reduction is critical. Shear angles below 8° tend to induce wrinkling or cracking due to insufficient tangential force., as it causes wrinkling or tearing. Ideal for cones and curved shapes—not cylindrical parts. - Necking (Reduction Spinning)

Also known as “air spinning,” this method typically omits a mandrel. It’s used to neck down tubes and produce items like gas cylinders.

7.3Forming Principles and Influencing Factors

- Material Deformation Mechanism: Localized pressure from the roller causes plastic deformation and cold working. Grain structures are compressed and hardened, especially during shear forming.

- Wall Thickness Control: In multi-pass spinning, wall thickness depends on roller passes and direction. In shear spinning, thickness is governed by mandrel clearance and shear angle, following the sine law. Key parameters include initial thickness, target thickness, and forming angle.

- Stress Distribution: In shear forming, stress concentrates at the roller-contact zone, while the rest of the workpiece remains stress-free. No radial stress is induced; the part maintains a stable annular profile throughout the process.

- Applications of Metal Spinning

While metal stamping is often more cost-effective and faster for high-volume production, metal spinning remains the superior choice for parts with complex geometries and unique designs.

7.4Common Metal Spun Products and Applications

- Hemispherical Parts: Widely used in lighting reflectors, mixing bowls, satellite dishes, tank covers, domes, and caps. Materials include cold-rolled steel, stainless steel (grades 304, 316), aluminum, copper, and brass. Wall profiles can be straight or curved depending on functional and aesthetic requirements.

- Conical Forms: Ideal for producing funnels, hoppers, and cone-shaped pendant fixtures.

- Venturi Tubes: Utilized in dust collectors, fans, blowers, and air scrubbers to control fluid dynamics via the Venturi effect.

- Parabolic Shapes: Common in bell housings, satellite antenna reflectors, lighting components, and structural supports.

- Cylinders: Used for pipes, containers, external shells of tanks, and various gas cylinders.

- Hopper Covers and Bases: Often made through manual spinning from premium aluminum or other metals. These parts can be trimmed, pierced, or slotted after spinning to meet customized functional needs.

- Tank Heads (Pressure Vessel End Caps): Metal spinning is extensively applied to fabricate end caps for pressure vessels, storage tanks, and process equipment. These spun heads are seamless, structurally robust, and resilient to high-pressure environments. Typical forms include:

- Flanged only

- Dished only

- Flanged and dished

- Hemispherical

- High crown

- Quasi-spherical

- 2:1 semi-elliptical

8.0Why Choose Metal Spinning

Metal spinning provides manufacturers with unmatched flexibility to tailor production for various scales and design complexities.

At its core, the metal spinning process is simple:

A round blank (flat or preformed) is clamped onto a spinning lathe. As the blank rotates, a forming roller applies pressure—typically against a mandrel—forcing the material to flow and conform to the desired shape through plastic deformation. The result is a seamless part with a smooth surface, often eliminating the need for secondary machining.

This process dispels two common myths:

Metal spinning is not limited to skilled manual labor.

It is not only suitable for low-volume production.

While manual spinning is still used for prototypes and small batches, modern CNC metal spinning supports large-scale production. For instance, automated spinning lines are standard in the production of automotive wheels. High-volume spinning operations can be fully automated with robotic loading/unloading systems, enabling lights-out manufacturing that improves efficiency and reduces labor input.

8.1Advantages of Metal Spinning

- Superior Component Reliability: Metal spinning produces seamless parts that can withstand high internal and external pressures. Unlike welding or fabrication methods where seams are potential failure points, spinning eliminates this weakness by forming parts from a single piece of material.

- Enhanced Mechanical Properties: The spinning process refines the grain structure of the metal, improving tensile strength, toughness, and hardness. This allows lighter materials to handle the same loads, making spinning ideal for lightweight yet high-strength applications.

- Low Tooling Cost and Maintenance: Compared to stamping, casting, forging, or hydroforming, spinning requires simpler and more cost-effective tooling. For low-volume or one-off productions, even soft and inexpensive mandrels may be used. For mass production, more rigid tooling ensures consistent quality with minimal wear.

- Rapid Design Change Adaptability: Small design changes—especially reductions in dimensions—can be quickly implemented by adjusting the forming tool or mandrel, without needing to create entirely new dies. This makes metal spinning ideal for fast-paced product development or iterative design.

- Minimal Material Waste:The process yields low scrap rates, helping reduce raw material usage and improve material efficiency.

- Cost Efficiency and Versatility: Metal spinning is a highly economical process, combining low material waste with fast forming speeds and inexpensive tooling. It is often a competitive alternative to deep drawing or stamping for many part types.

- High Work Hardening Capability: The spinning process can significantly strengthen the material being formed, allowing the use of lower-cost base metals while still achieving high-performance parts. Final components exhibit superior mechanical characteristics.

- Support for Complex Geometries: The forming roller (spinning tool) faces minimal geometric restrictions. With simple CNC programming adjustments, the shape of the part can be altered along its length, offering high flexibility for forming complex axial-symmetric designs.

- Environmentally Friendly: Metal spinning consumes less energy and generates less waste than many other metal forming methods. It supports material recycling and contributes to sustainable manufacturing practices.

8.2Disadvantages of Metal Spinning

- Longer Processing Time: Compared to casting and other mass production processes, metal spinning typically takes more time per part, especially in larger volumes. It is best suited for small to medium production runs.

- Consistency Depends on Operator Skill: In manual spinning, the uniformity and quality of parts heavily rely on the operator’s experience and skill level. This can lead to variability in part dimensions and surface finish.

- Geometrical Limitations: Metal spinning is ideal for forming axisymmetric parts such as cones, hemispheres, and parabolas. However, it is not suitable for non-axisymmetric or highly irregular geometries.

- Low Error Tolerance: The process has little room for error. Any defect such as cracks, dents, or deformation typically results in scrapped parts, as repair is difficult or impractical. This demands strict quality control.

- Safety Concerns: During manual spinning, parts rotate at high speeds, posing safety risks. If the blank is not securely clamped between the tailstock and mandrel, it may dislodge. Operators must remain vigilant and follow stringent safety protocols.

- Conclusion: Why Metal Spinning Remains a Competitive Forming Method

Metal spinning stands out as a versatile, cost-effective, and mechanically advantageous process for producing high-performance, axially symmetric metal parts. Whether you’re developing prototypes, handling small production runs, or automating high-volume lines, metal spinning offers:

- Seamless parts with superior strength

- Minimal material waste and tooling cost

- Fast adaptability to design changes

- Strong support for complex, symmetrical geometries

Despite some limitations in processing time and part geometry, advancements in CNC automation and forming control have significantly expanded its industrial relevance—especially in aerospace, lighting, pressure vessel, and HVAC industries. For manufacturers seeking a balance between performance, flexibility, and cost, metal spinning is a process worth considering.

9.0Frequently Asked Questions (FAQ) about Metal Spinning

Q1: What materials are commonly used in metal spinning?

A: Common materials include aluminum alloys (e.g., 1100, 6061), stainless steels (e.g., 304, 316), carbon steels, copper, brass, and titanium. Material selection depends on formability, strength requirements, and final use conditions.

Q2: What shapes can be formed using metal spinning?

A: Typical shapes include cones, hemispheres, cylinders, parabolas, venturi tubes, tank heads, and other axially symmetric profiles. Complex curves can be achieved through multi-pass CNC spinning.

Q3: What is the difference between shear spinning and conventional spinning?

A: Conventional spinning maintains material thickness while shaping, whereas shear spinning reduces thickness as the roller applies axial force. Shear spinning increases material strength but requires tighter control.

Q4: Is CNC metal spinning suitable for high-volume production?

A: Yes. CNC metal spinning enables consistent, repeatable forming with minimal operator input. Fully automated cells with robotic loading/unloading are common in industries like automotive and cookware manufacturing.

Q5: How does metal spinning compare to deep drawing or stamping?

A: Metal spinning is more flexible and economical for low to medium volume runs and custom shapes. Stamping is better for flat or shallow parts at very high volumes. Spinning requires less tooling investment and allows quicker design changes.

Q6: Can I use metal spinning to make pressure vessel components?

A: Absolutely. Metal spinning is widely used to produce seamless tank heads and end caps with high structural integrity, such as hemispherical or elliptical heads for storage and process vessels.

Q7: Is metal spinning an environmentally friendly process?

A: Yes. It generates minimal scrap, consumes less energy than forging or casting, and supports sustainable practices by improving material yield and enabling use of recyclable alloys.

References:

https://www.iqsdirectory.com/articles/metal-spinning.html

https://www.open.edu/openlearn/science-maths-technology/engineering-technology/manupedia/metal-spinning/flow-turning

https://en.wikipedia.org/wiki/Metal_spinning