- 1.0Overview of ISO 12100:2010 – Core Principles of Machinery Safety Design

- 2.0Why Use ISO 12100?

- 3.0Who Should Use ISO 12100?

- 4.0Legal Responsibilities of Employers

- 5.0What Does a Risk Assessment Include?

- 6.0The Five Steps of Risk Assessment (Based on EN ISO 12100)

- 7.0ISO 12100 and Risk Assessment

- 8.0ISO 12100 VS ANSI B11.0 –Differences and Equivalence Between ISO and ANSI Standards

1.0Overview of ISO 12100:2010 – Core Principles of Machinery Safety Design

ISO 12100:2010 (equivalent to ANSI-adopted ISO 12100:2010 in the United States) is an internationally recognized Type-A safety standard intended to guide the design of machinery toward inherent safety. This standard defines the fundamental terminology, principles, and methodology required to achieve safety in machinery and is applicable to the risk management process for all industrial machinery.

1.1The core elements of the standard include:

- Principles of Risk Assessment:Based on experience related to machinery design, use, incidents, and associated hazards, the standard outlines principles for hazard identification, risk estimation, and risk evaluation.

- Lifecycle Management:The standard specifies the process for identifying hazards and evaluating risks throughout the entire life cycle of the machinery, including design, manufacturing, operation, and maintenance stages.

- Risk Reduction Measures:It prescribes procedures to eliminate hazards or reduce risks to an acceptable level through inherently safe design measures, safeguarding and protective devices, and the provision of user information.

- Documentation and Validation:Specific guidance is provided for recording and verifying the processes of risk assessment and risk reduction to ensure compliance and traceability.

- Foundation for the Standards System:ISO 12100:2010 serves as the foundational framework for the development of Type-B (generic safety requirements) and Type-C (machine-specific safety requirements) standards.

For manufacturers, installers, and employers aiming to comply with current legal regulations and protect operator safety, understanding and implementing the requirements of ISO 12100:2010 is a critical step toward ensuring equipment safety and regulatory accountability.

1.2Resource Downloads

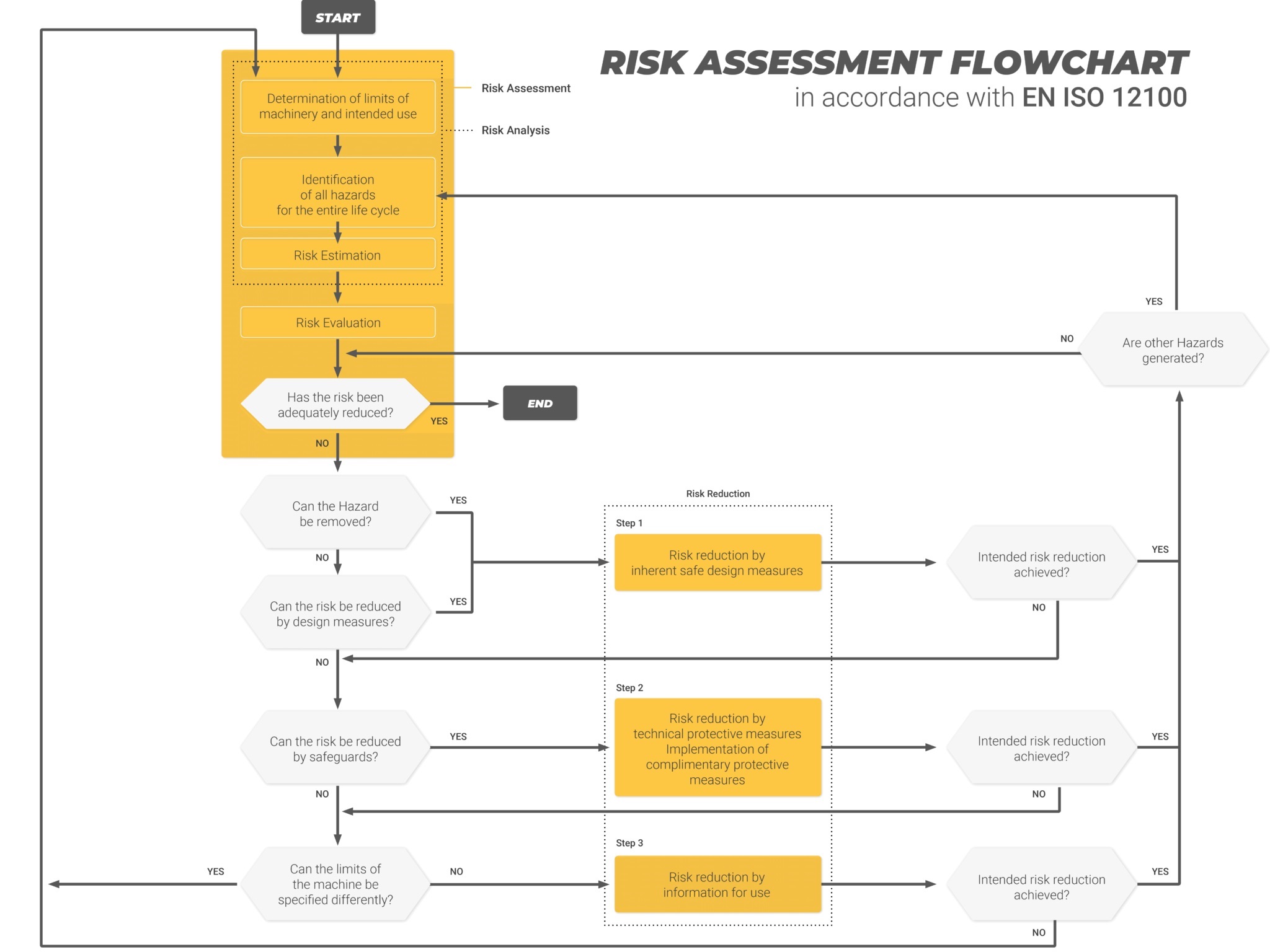

1.3EN-ISO-12100-Flow of risk assessment and risk reduction

2.0Why Use ISO 12100?

The main reasons for adopting ISO 12100 include:

- Enhancing the inherent safety of machinery and reducing operational risk

- Meeting international legal requirements, CE marking, or other market access regulations

- Standardizing the risk assessment process to reduce liability and accident-related costs

- Assisting manufacturers and designers in systematically identifying and managing machinery-related risks

- Improving safety performance and traceability in complex and highly automated equipment scenarios

In particular, for precision machinery and automated systems, timely identification of potential hazards and corrective measures is essential to safeguarding personnel and property.

3.0Who Should Use ISO 12100?

The ISO 12100 standard is relevant to the following roles and organizations:

- Mechanical engineers and machinery manufacturers

- Machine designers, developers, and automation system integrators

- Safety, Environmental, Health (EHS), and risk management professionals

- Industrial equipment purchasers, users, and installers

- Employers (to ensure compliance with occupational safety regulations)

This standard works in conjunction with harmonized standards such as EN ISO 13849 (Safety of control systems) and EN IEC 62061 (Functional safety), forming the foundational framework for machinery safety compliance and serving as a key technical reference for meeting the EU Machinery Directive and the new Machinery Regulation.

4.0Legal Responsibilities of Employers

For employers who use or install industrial machinery, conducting a risk assessment is not only a technical requirement—it is a legal obligation. Occupational safety regulations in various countries, along with international machinery safety directives, mandate systematic risk assessments to be carried out prior to equipment commissioning or whenever changes are made to the machinery or its operation.

5.0What Does a Risk Assessment Include?

According to ANSI/ISO 12100:2012, a comprehensive risk assessment typically includes the following elements:

Determination of the Limits of the Machinery:Define the operating conditions, methods of use, involved personnel, environmental factors, and product characteristics across the entire life cycle of the machinery.

Hazard Identification:Identify all reasonably foreseeable sources of hazards, hazardous situations, or hazardous events that may occur during transportation, installation, commissioning, operation, maintenance, and decommissioning phases.

Risk Analysis and Evaluation

- Assess the severity of potential harm and the number of individuals exposed

- Determine the probability and frequency of exposure to each identified hazard

- Evaluate the level of risk and decide whether further risk reduction measures are necessary

Risk Reduction Strategies:Implement inherently safe design measures, add protective devices, and provide warnings and user information as supplementary measures when residual risks remain.. Ensure that these measures are properly documented and validated to confirm their effectiveness.

Importance of Risk Assessment:Conducting systematic risk assessments not only enhances worker safety and reduces legal liabilities but also minimizes equipment downtime caused by failures, ensuring production continuity and operational efficiency.

6.0The Five Steps of Risk Assessment (Based on EN ISO 12100)

- Hazard Identification:Inspect the workplace and operational processes to identify potential sources of mechanical, electrical, thermal, and other hazards. Evaluate the operational limits of the machine by referring to manufacturer manuals and incident records.

- Risk Evaluation:Analyze how, when, where, and how frequently workers may be exposed to each hazard. Use a risk matrix to determine the risk level of each identified hazard, including residual risks.

- Establishment of Control Measures:Based on the risk level, implement effective control systems or protective strategies to ensure the safety of personnel, equipment, and the environment.

- Documentation of Results:Record the entire assessment process, including identified risks and corresponding mitigation measures, to create a traceable risk assessment record.

- Review and Updating:Periodically review the effectiveness of implemented measures. Update the risk assessment as needed—especially in cases of equipment commissioning, structural modifications, or changes in operation.

7.0ISO 12100 and Risk Assessment

ISO 12100:2010 replaces ISO 12100-1:2003, ISO 12100-2:2003, and ISO 14121:2007, consolidating them into a single international standard.

It provides a systematic approach to help designers determine machinery limits and assess a wide range of hazards—including shearing, crushing, electric shock, and fatigue—as well as their sources, such as equipment malfunction or human error.

As a globally recognized general standard for machinery safety, ISO 12100 complies with legislative requirements in many countries and is particularly applicable to machine designers and equipment manufacturers.

8.0ISO 12100 VS ANSI B11.0 –Differences and Equivalence Between ISO and ANSI Standards

Before implementing machinery safety practices, manufacturers must identify the applicable safety standards. While ISO 12100:2010 (international) and ANSI B11.0-2010 (North American) are closely aligned in their approaches to risk assessment, they differ in scope and terminology.

8.1Scope of Application

- ISO 12100: Primarily intended for original equipment manufacturers (OEMs), focusing on risk identification and control during the machinery design phase.

- ANSI B11.0: Applies to new, rebuilt, or modified powered machinery. It is not limited to manufacturers and also includes end users. This standard typically covers machinery not intended to be hand-held and used for forming processes involving metals or other materials, such as cutting, punching, pressing, electrical processing, or combinations thereof.

8.2Terminological Differences

As ANSI B11.0 addresses both manufacturers and end users, it may include certain terms or guidance that do not have direct equivalents in ISO standards.

8.3Consistency in Risk Assessment Principles

Despite differences in wording and structure, both standards are fundamentally aligned in hazard identification, risk assessment processes, and documentation requirements.

ANSI B11.0 adopts a methodology harmonized with ISO and EN standards, emphasizing risk assessment as a core element for hazard control and achieving acceptable risk levels.

8.4Standard Integration

ANSI B11.0 incorporates elements from:

- ANSI/ISO 12100 Parts 1 and 2

- ISO 14121(now fully integrated into ISO 12100)

- Various related U.S. national standards

Manufacturers who comply with ANSI B11.0 generally also meet the requirements of ISO 12100.

8.5Global Applicability and Standards Equivalence

- Machinery designed in accordance with ANSI B11.0can typically be exported to Europe or other ISO-compliant regions, as it satisfies the requirements of ISO 12100 or EN ISO 12100.

- Similarly, machines developed based on ISO 12100 are usually accepted in the North American market.

- Both standards enjoy broad international recognition, providing a common compliance foundation that supports the global trade of industrial machinery.

References:

us.idec.com/RD/safety/law/iso-iec/iso12100

blog.ansi.org/ansi-iso-12100-2012-machine-safety-risk-assessments/