- 1.0What Is IEC 61511?

- 2.0Understanding IEC 61511 and IEC 61508 in the Process Industry

- 2.1What Is Process Safety?

- 2.2Why Is Functional Safety Critical in the Process Industry?

- 2.3Relationship Between IEC 61511 and IEC 61508

- 2.4Safety Instrumented Systems (SIS) and Safety Instrumented Functions (SIF)

- 2.5Safety Integrity Levels (SILs) and Risk Reduction

- 2.6Structure of IEC 61511

- 2.7The Safety Lifecycle: A Closed-Loop Approach from Analysis to Decommissioning

- 3.0IEC 61511 vs IEC 61508: Key Differences and Interdependencies

- 4.0Conclusion

1.0What Is IEC 61511?

1.1Introduction to the Process Industry

Unlike discrete manufacturing industries—such as those producing nuts, bolts, or automotive parts—the process industry deals with the transformation and handling of bulk materials. Typical sectors include:

- Oil and gas production

- Refining

- Chemical manufacturing

- Pharmaceuticals

- Other continuous processing operations

Due to the high-risk nature of these environments, functional safety is essential to ensuring the stable and reliable operation of safety control systems.

1.2Purpose and Definition of the Standard

IEC 61511 sets out a comprehensive set of requirements for achieving functional safety in the process sector. It addresses system architecture, hardware and software development, and application programming, with the overarching goal of ensuring that SIS can reduce risks reliably in the event of failures or abnormal conditions.

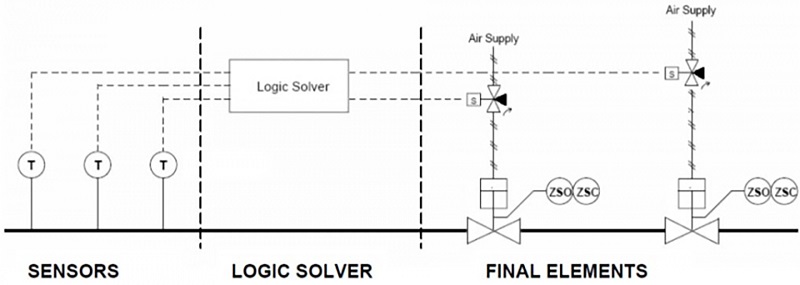

Under IEC 61511, a Safety Instrumented System (SIS) is defined as an automated system designed to carry out one or more Safety Instrumented Functions (SIF). It typically comprises three core elements:

- Sensors

- Logic solvers

- Final elements

1.3Scope of Application

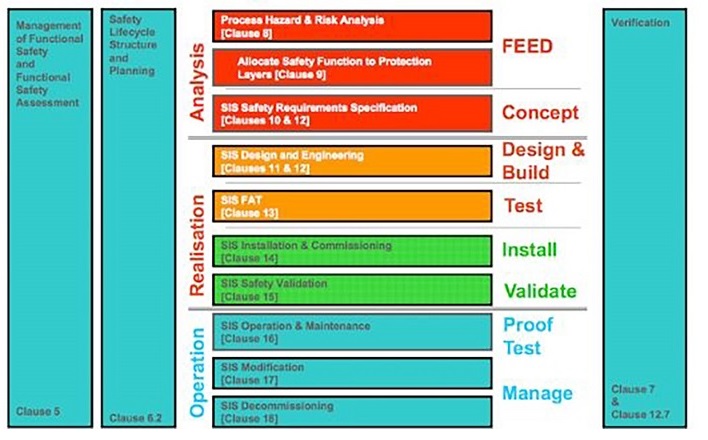

IEC 61511 covers the entire lifecycle of a Safety Instrumented System—from concept design and hazard analysis to detailed engineering, installation, commissioning, operation, maintenance, and eventual decommissioning. It also includes requirements for system modifications during operation.

1.4Structure of the Standard

IEC 61511 is structured into three main parts:

- IEC 61511-1: Functional Safety – System Requirements

Lays down the fundamental definitions, system structure, and technical requirements for hardware and software. - IEC 61511-2: Guidelines for the Application

Offers practical guidance on implementing the requirements from Part 1. - IEC 61511-3: Guidance for Determining Safety Integrity Levels (SILs)

Helps users determine the required SIL for each safety function based on risk analysis.

1.5Evolution of the Standard

Safety Instrumented Systems have been used for over half a century to mitigate industrial risks. Early SIS were based on pneumatic, hydraulic, or electrical circuits, characterized by simple architectures and well-understood failure modes.

In the 1970s, programmable electronic systems began to be used in SIS, offering greater flexibility but also introducing new complexities and uncertainties. These changes increased the difficulty of risk management, prompting the need for updated standards. IEC 61511 has evolved accordingly:

The first and second editions were released in 2003.

The second edition introduced nearly 200 updates, including requirements for Safety Requirements Specifications (SRS), performance monitoring, failure rate assessments, IT security, and Functional Safety Management (FSM).Summary of Key Elements in IEC 61511

1.6Standard Composition and Stakeholders

IEC 61511 is often referred to as the functional safety standard for the process industry, especially for Safety Instrumented Systems (SIS). It consists of:

- Part 1: Framework and requirements for hardware and software

- Part 2: Guidance on implementation

- Part 3: Methodology for determining SIL

It is relevant to all personnel involved with safety instrumented functions, including system suppliers, plant operators, maintenance teams, SIF designers, SIL analysts, and EPC contractors.

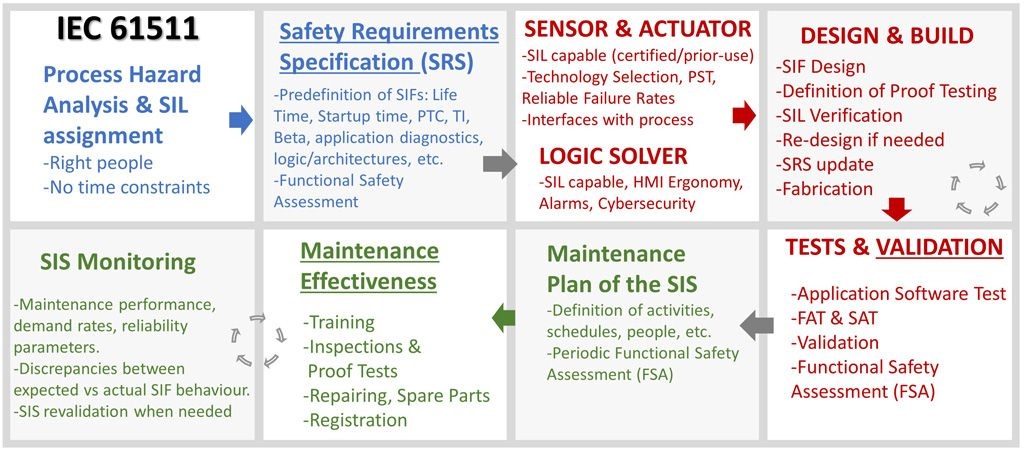

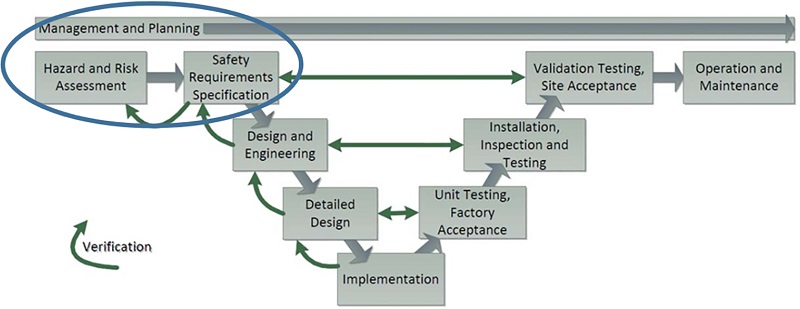

1.7Functional Safety Lifecycle

IEC 61511 defines a structured safety lifecycle to ensure that SIS consistently meets safety requirements. This includes:

Analyzing process hazards and documenting required SIFs

Implementing systems using suitable hardware, software, and design methods

Verifying system performance and modifying it as needed

Operating and maintaining the SIS using standardized procedures while monitoring its performance continuously

1.8SIS Management System Requirements

The standard mandates a systematic management approach to SIS, which is composed of sensors, logic solvers, final elements, and supporting components, all working together to implement one or more SIFs.

A compliant SIS management system must include:

A defined workflow across the SIS lifecycle: assessment, design, verification, installation, commissioning, validation, operation, maintenance, and continuous improvement

Clearly assigned responsibilities for all involved roles

Documented procedures supporting each responsibility

Performance monitoring and feedback loops to ensure ongoing compliance with the assigned SIL

1.9SIL and Performance Assessment

IEC 61511 uses the Safety Integrity Level (SIL) to quantify how effectively a SIS can reduce risk.

SIL levels are determined through hazard and risk analysis based on the required risk reduction for each SIF

SIS design and architecture are tailored to meet the allocated SIL

During operation, performance is evaluated through field data and mechanical integrity testing

If the actual performance falls short of the intended SIL, corrective actions must be taken to restore compliance

2.0Understanding IEC 61511 and IEC 61508 in the Process Industry

2.1What Is Process Safety?

Process safety is a systematic framework designed to ensure the integrity of systems and processes that handle hazardous materials. It combines engineering principles, design practices, and operational procedures to prevent the unintended release of dangerous substances or energy. The concept originated from the U.S. Occupational Safety and Health Administration (OSHA) and is widely applied in processes involving Highly Hazardous Chemicals (HHCs).

2.2Why Is Functional Safety Critical in the Process Industry?

As process systems grow in complexity, functional safety systems are increasingly relied upon to mitigate operational risks. In many countries—such as Singapore—safety case regimes have become mandatory. Organizations must establish functional safety management programs that comply with international standards in order to meet regulatory obligations.

2.3Relationship Between IEC 61511 and IEC 61508

- IEC 61511 is the process sector–specific standard for functional safety, focused on the entire safety lifecycle of Safety Instrumented Systems (SIS) in industries such as oil & gas and chemicals.

- IEC 61508 serves as the foundational standard for functional safety across all sectors that involve electrical, electronic, or programmable electronic (E/E/PE) systems. It acts as the parent standard guiding IEC 61511’s implementation.

2.4Safety Instrumented Systems (SIS) and Safety Instrumented Functions (SIF)

A Safety Instrumented System (SIS) typically comprises multiple Safety Instrumented Functions (SIFs). Each SIF includes the following key components:

- Sensors– detect deviations from normal operating conditions

- Logic solvers– process sensor inputs and execute the safety logic

- Final elements– initiate a safe response (e.g., actuate valves or shut down equipment)

2.5Safety Integrity Levels (SILs) and Risk Reduction

Safety Integrity Level (SIL) is the performance measure used to quantify the risk reduction capability of an SIS. Under IEC 61511, SIL requirements are determined through Hazard and Risk Analysis (H&RA) and are used to guide both system design and verification.

2.6Structure of IEC 61511

IEC 61511 is structured into four distinct parts:

| Part | Content |

| Part 1 | Normative requirements: terminology, system design, software development, validation, testing |

| Part 2 | Application guidance: practical recommendations for implementing Part 1 |

| Part 3 | Guidance on Hazard & Risk Assessment and determining SIL |

| Part 4 | Technical report: rationale and explanation of the updates introduced in the second edition |

2.7The Safety Lifecycle: A Closed-Loop Approach from Analysis to Decommissioning

IEC 61511 adopts a SIS safety lifecycle model, ensuring that functional safety is maintained throughout the system’s operational life.

Phase 1: Analysis (Blue Phase)

- PHA – Process Hazard Analysis: Identify risk sources, potential consequences, and event frequency.

- SIL Determination: Assign a Required Risk Reduction Factor (RRF) and corresponding SIL for each SIF.

- SRS – Safety Requirements Specification: Define each SIF’s parameters and functional objectives.

- FSA – Functional Safety Assessment: Independent verification of the analysis phase by a third party.

Phase 2: Design and Implementation (Red Phase)

- Device Selection: Choose components with appropriate SIL certification or proven-in-use history.

- System Design: Define logic structure, redundancy, and test strategies per the SRS.

- SIL Verification: Use tools such as exSILentia or SILcet to calculate reliability metrics.

- FAT/SAT and SIS Validation: Conduct Factory and Site Acceptance Tests to ensure SRS compliance.

- FSA Stage 2: Independent assessment of the design and implementation quality.

Phase 3: Operation and Maintenance (Green Phase)

- SIS Maintenance Plan: Ensure long-term reliability and regular proof testing of each SIF.

- Performance Monitoring and Failure Management: Track key performance indicators (KPIs) to evaluate real-world operation

- System Modifications and Change Management: Adhere to Clause 17 of IEC 61511 to prevent unintended risk introduction during modifications.

- Ongoing FSA: Conduct periodic audits to ensure continued compliance and effectiveness during O&M.

3.0IEC 61511 vs IEC 61508: Key Differences and Interdependencies

3.1Core Distinctions: Scope and Target Users

| Standard | Scope | Primary Users | Focus Area |

| IEC 61508 | Foundational standard for functional safety | Device manufacturers, system designers | Design and verification of safety-related functions in hardware and embedded software |

| IEC 61511 | Sector-specific standard for the process industry | System integrators, end users (e.g., chemical, petrochemical, pharmaceutical) | Lifecycle management of Safety Instrumented Systems (SIS) |

IEC 61511 is a sector-specific derivative of IEC 61508, customized for the needs of the process industry. While tailored in its application, both standards share a consistent framework in terms of lifecycle models, safety metrics (e.g., SIL, PFD/PFH), and functional safety management principles.

3.2Why IEC 61511 Is Crucial to the Process Industry

Even if a system uses components compliant with IEC 61508, overall functional safety in the process industry cannot rely solely on individual device compliance. IEC 61511 ensures system-level risk reduction through the following:

SIF performance assurance: Evaluates interdependencies between devices to confirm achievement of required Safety Integrity Levels (SIL).

Maintenance optimization: Defines strategies for proof test intervals and system reliability upkeep.

Operational phase requirements: Provides key guidance on installation, commissioning, operation, and maintenance.

Change management: As process systems evolve, IEC 61511 mandates that any modification must be assessed for its impact on functional safety.

Application software validation: While IEC 61508 governs embedded software, IEC 61511 outlines verification methods for application-level logic (e.g., Level/Flow control programs).

3.3Coordination Between the Standards in SIL Implementation

| Project Area | IEC 61511 Requirements | Relationship to IEC 61508 |

| SIS Design & Validation | Requires full lifecycle control, including SRS, verification, testing, maintenance | Devices used must comply with IEC 61508 |

| SIF SIL Determination | SIL 1–3 can be managed within IEC 61511 | SIL 4 requires IEC 61508 design and validation |

| Safety Performance Data | Allows use of proven-in-use operational history | Data must meet IEC 61508 integrity requirements |

IEC 61511 focuses on system-level implementation and lifecycle governance, whereas IEC 61508 ensures equipment-level design, certification, and embedded safety functionality. Together, they form a complementary functional safety framework.

3.4IEC 61511 Requirements for Mechanical Elements

Although IEC 61511 centers on electrical/programmable electronic systems, many final elements are mechanical (e.g., shut-off valves, pneumatic actuators, pressure relief valves). Mechanical failures can directly cause SIF failure. The standard therefore requires:

Reliability Data for Mechanical Components

Mechanical components must provide PFD/PFH data;

Compliance may be demonstrated via:

- Proven-in-use data (in line with IEC 61508 requirements);

- SIL suitability statements from manufacturers;

- Third-party certifications(e.g., from TÜV or Exida).

Periodic Proof Testing

Define appropriate proof test intervals;

Maintenance plans must include functional testing (e.g., valve actuation response);

Testing data must be fed back into risk assessments and lifecycle updates.

Inclusion in System Reliability Modeling

Incorporate mechanical elements into system-level FMEA or FTA models;

Calculate the PFD of the entire final control element loop (valve + actuator + logic);

System must meet the assigned SIL before entering operation.

3.5Coordinated Implementation Strategy

| Activity Area | Recommended Standard | Key Implementation Focus |

| Device Selection | IEC 61508 | Select components with SIL certification or proven-in-use data |

| System Architecture | IEC 61511 | Define SRS, configure safety architecture, plan validation strategy |

| O&M Practices | IEC 61511 | Perform proof tests, manage changes, monitor real-time performance |

| High SIL Requirements | IEC 61508 + 61511 | For SIL 4, both device- and system-level design and verification are mandatory |

4.0Conclusion

IEC 61508 and IEC 61511 together form the backbone of functional safety in the process industry. While IEC 61508 provides a generic, device-level framework for safety-related systems, IEC 61511 tailors these principles to the specific needs of real-world Safety Instrumented Systems (SIS) throughout their entire lifecycle—from risk assessment and system design to ongoing maintenance and modification.

In complex and high-risk industrial environments, device-level compliance alone is not sufficient. Only a comprehensive, lifecycle-based approach—covering SIF definition, SIL allocation, verification, and performance monitoring—can deliver demonstrable safety and operational reliability.

Understanding how these two standards complement each other is essential for engineers, integrators, and safety managers aiming to build and maintain robust SIS architectures. When applied together effectively, IEC 61508 and IEC 61511 enable a consistent, auditable path to risk reduction, regulatory compliance, and long-term plant safety.

References

www.wolterskluwer.com/en/expert-insights/functional-safety-the-next-edition-of-iec-61511

safetyandsis.com/compliance-with-iec-61511/

www.tuvsud.com/en-in/resource-centre/blogs/iec-61511-explained—all-you-need-to-know

www.abhisam.com/iec-61511-iec-61508/

https://www.alekvs.com/iec-61508-explained-functional-safety-and-safety-integrity-levels-sil-guide/