1.0What Is Hot Rolled Coil (HRC)? Definition, Production Process, and Uses

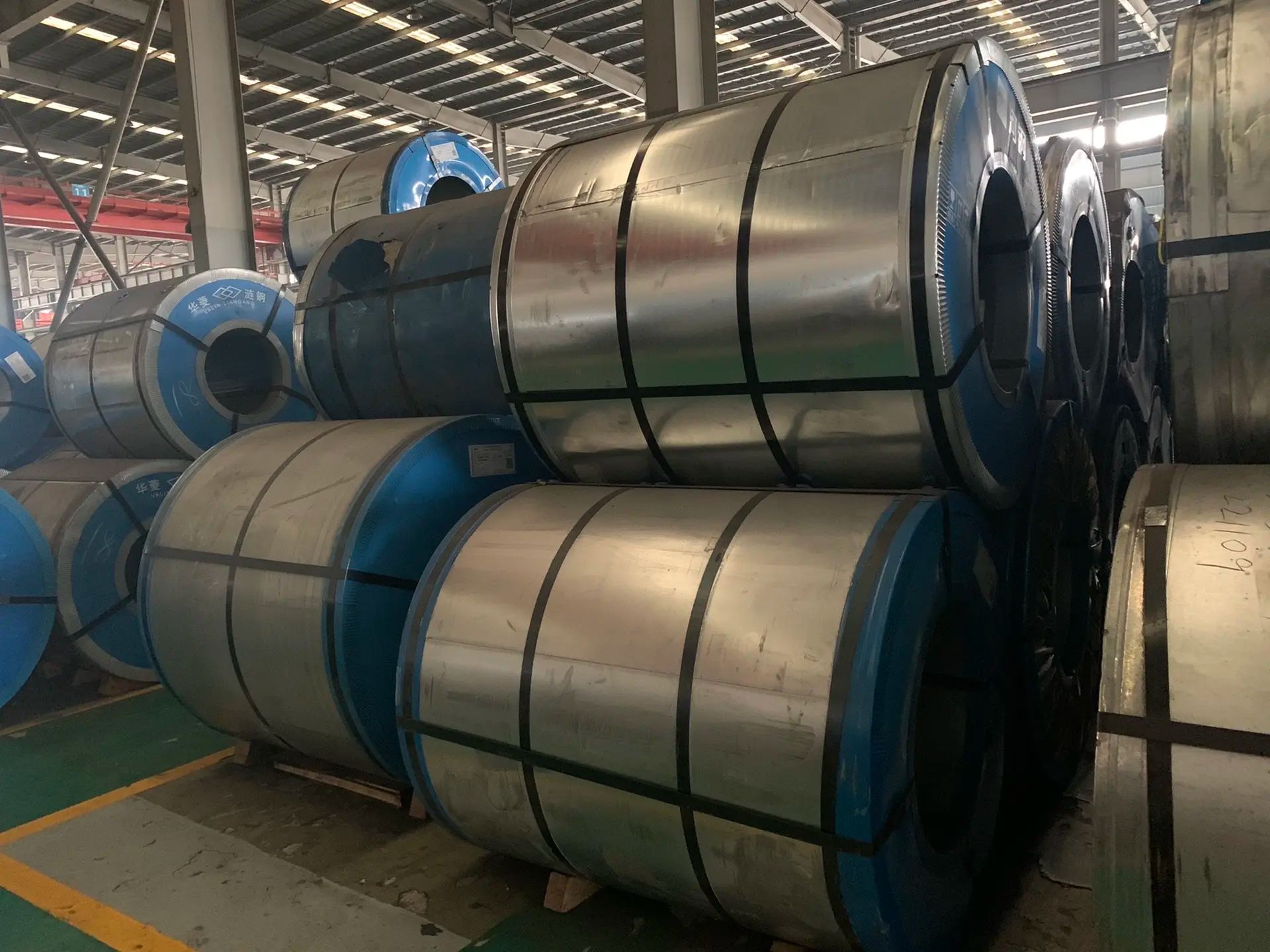

Hot Rolled Coil (HRC) is a flat steel product made by continuously rolling heated steel slabs through a hot rolling mill. It is typically supplied in coil form and widely used across industries such as construction, machinery, automotive, shipbuilding, and pressure vessel manufacturing.

Hot rolled steel is a fundamental material in the steel industry due to its low cost, good formability, and high production efficiency. It is suitable for structural applications that require strength but not high surface precision. For improved dimensional accuracy or surface finish, further processing like cold rolling or surface treatment is often needed.

- Surface: A rough, oxidized finish caused by high-temperature scaling (not as smooth as cold-rolled steel).

- Mechanical Properties: Relatively low strength but excellent ductility, making it suitable for secondary processing like cold rolling or stamping.

- Size Range: Common thickness ranges from 1.2 mm to 25.4 mm, with widths exceeding 2000 mm.

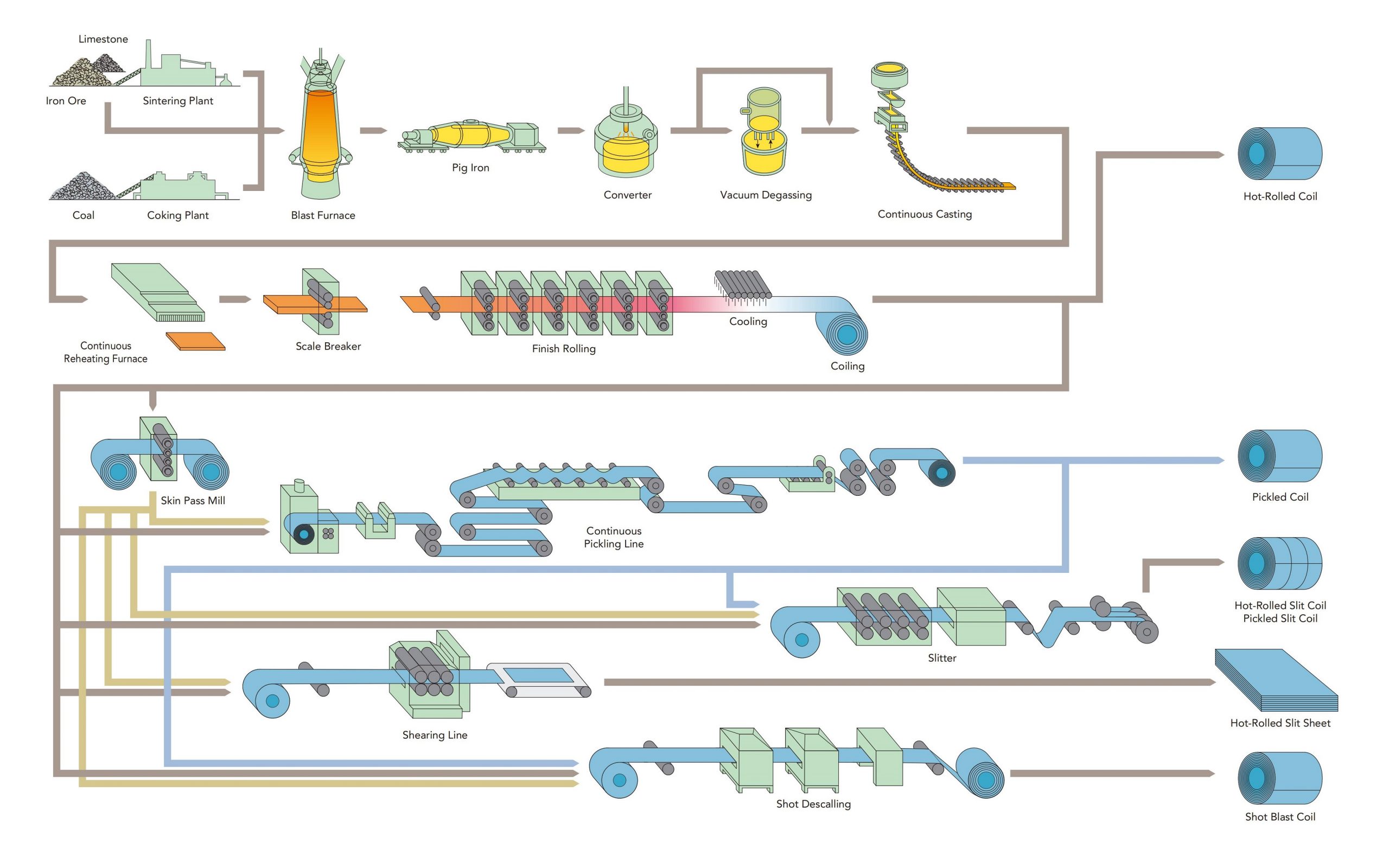

1.1Production Process of Hot Rolled Coil (HRC)

- Slab Preparation and Heating: Production begins with thick or thin slabs (typically from continuous casting) fed into a reheating furnace.The slabs are heated above their recrystallization temperature—typically around 1700°F (927°C)—to ensure sufficient plasticity for rolling.

- Descaling: After heating, the slab surface is covered with mill scale (iron oxide). High-pressure water jets are used to remove the scale and ensure proper surface quality for rolling.

- Rough Rolling: The slabs pass through a roughing mill (often multiple stands), reducing thickness and extending length while breaking down the cast structure.Some mills use a reversing mill, where slabs are passed back and forth through a single stand to achieve thickness reduction.

- Finish Rolling: The strip is then processed through five to seven finishing stands for precise thickness reduction. Additional descaling may occur during this stage.Finishing rolling plays a critical role in determining final shape, thickness uniformity, and internal mechanical properties.

- Controlled Cooling: The rolled strip is rapidly cooled by water sprays along the run-out table. This controls the grain structure and enhances mechanical performance.

- Coiling and Packaging: After cooling, the strip is coiled into a roll using a coiler.The finished coils are strapped, labeled, and packaged, ready for storage or shipment.

1.2Types of Hot Rolled Coil (HRC) and Key Advantages

Hot rolled coils (HRC) are typically categorized into three main types:

- Commercial Quality (CQ): The most widely used type, suitable for general-purpose applications such as pipes, tubing, and automotive components.

- Structural Quality (SQ): Designed for structural applications like beams, plates, and load-bearing parts where higher strength is required.

- Draw Quality (DQ): Used in applications that require good formability, such as deep-drawn or stamped components.

1.3Key Advantages of HRC Compared to Other Steel Products:

- High Yield Strength:Ideal for high-stress environments and heavy-duty applications.

- Excellent Abrasion Resistance:Suitable for operations involving high wear and surface friction.

- Good Weldability and Formability:Easy to fabricate and shape into various industrial parts and components.

1.4Processing and Performance Characteristics of Hot Rolled Steel

- Good Formability:Suitable for bending, stamping, and drawing processes.

- Excellent Weldability:Compatible with various welding techniques and methods.

- Moderate Strength with Good Toughness:Capable of bearing significant loads; suitable for structural applications.

- Surface Scale:The surface may contain mill scale from high-temperature oxidation, typically removed by pickling or further processing.

- Lower Dimensional Precision:Shrinkage during cooling can lead to looser tolerances than cold-rolled products.

- Irregular Edges:Edges may be slightly dull or uneven compared to cold-rolled steel.

- Low Internal Stress:Minimal residual stress, reducing the risk of warping or distortion during fabrication.

- Coarse Grains, Uniform Structure:Stable and consistent performance, though not as refined as cold-rolled steel.

- Cost-Effective:Offers high production efficiency and lower manufacturing costs, making it ideal for large-volume structural steel applications.

1.5Typical Industry Applications of Hot-Rolled Steel

| Industry | Application | Details |

| Construction | Beams, columns, structural frames | Used in buildings, bridges, warehouses, civil engineering |

| Base plates and angle iron | Load-bearing support and structural framing | |

| Automotive | Chassis, frames, wheels | Used in trucks, trailers, buses, and passenger vehicles |

| Reinforcement panels | Applied to high-strength and impact-resistant body structures | |

| Shipbuilding | Hull and deck plates | Large-format plates for vessels and barges |

| Oil & Gas | Pipe and tubing (low-pressure) | Welded pipes, platform supports |

| Tank shells and linings | Storage of oil, gas, and chemical products | |

| Heavy Equipment | Crane and excavator components | Boom arms, frames, load-bearing parts |

| Manufacturing | Substrate for cold-rolled products | HRC often pickled and oiled before further processing |

| Steel drums and barrels | Used for liquid storage and transport | |

| Railway | Rail car frames and wheel bases | Structural, load-bearing elements |

| Energy | Wind tower segments | Thick hot-rolled steel used for towers and nacelles |

| General Fabrication | Guardrails, fences, gates | Road safety and structural use |

| Storage Systems | Warehouse racking and shelving | Medium-strength HRC for logistics and storage |

| Shipping Containers | Wall panels and frames | High-strength steel for container structures |

2.0Hot Rolled Steel Coil (HRC): Manufacturing, Properties, and Applications

2.1Common Performance Indicators of Hot Rolled Steel

(Typical values for carbon structural steel)

| Property | Typical Range |

| Yield Strength (MPa) | 235–355 |

| Tensile Strength (MPa) | 370–550 |

| Elongation (%) | 20–35 |

| Hardness (HB) | 100–170 |

| Working Temperature Range | Room temperature to ~400°C |

2.2Key Features of Hot Rolled Steel

| Feature | Description |

| High-Temperature Rolling | Rolled above the recrystallization temperature, providing excellent ductility and workability. |

| Surface Scale | Oxide scale forms during cooling, affecting appearance but removable via pickling. |

| Lower Dimensional Accuracy | Due to thermal expansion and natural cooling, tolerances are looser than cold-rolled steel. |

| Slight Deformation | Minor shrinkage may occur; corners and edges may be rounded or slightly irregular. |

| Ideal for Structural Use | Widely used in applications where high strength is needed but dimensional precision is secondary (e.g., buildings, bridges). |

2.3Delivery Conditions of Hot Rolled Coil

| Condition | Description |

| Black Surface (HR) | Untreated surface with mill scale; cost-effective and ideal for further processing. |

| Pickled and Oiled (HRPO) | Scale removed and coated with anti-rust oil; offers cleaner surface for downstream processes. |

2.4Common ASTM Standards for Hot-Rolled Steel – Application-Oriented Overview

The following table summarizes widely used ASTM standards for hot-rolled steel sheets, strips, and structural products, focusing on their application scenarios:

| Standard No. | Abbreviated Name | Material Type | Typical Applications |

| ASTM A1011 | Hot-Rolled Carbon, Structural, HSLA, UHSS Steel Sheet/Strip | Carbon Steel, Structural Steel, HSLA, UHSS | Automotive, construction structures, mechanical components |

| ASTM A36 | Carbon Structural Steel | General hot-rolled structural steel plate | Beams, columns, brackets, bridges |

| ASTM A569 | Commercial Quality Hot-Rolled Carbon Steel Sheet and Strip | Commercial carbon steel (obsolete, replaced by A1011) | General stamping, welding (non-structural) |

| ASTM A572 | HSLA Structural Steel | High-strength low-alloy structural steel | Bridges, high-rise buildings, heavy-duty components |

| ASTM A992 | Structural Steel Shapes | Hot-rolled H-beams and I-beams | Structural beams and columns in modern buildings |

| ASTM A715 | Hot-Rolled, High-Strength, Cold Forming Sheet/Strip | High-strength, cold-formable hot-rolled steel | Stamped parts, frames, reinforcements |

| ASTM A606 | HSLA Steel with Atmospheric Corrosion Resistance | Weathering steel (e.g., Cor-Ten) | Outdoor structures, railway cars, containers |

| ASTM A635 | Hot-Rolled Strip, Carbon and HSLA, Wide Width | Wide-strip carbon and HSLA steel | Applications requiring thicker hot-rolled plate |

| ASTM A1008 | Cold-Rolled Steel Sheet and Strip (for comparison) | Cold-rolled steel (compared to A1011) | Parts requiring high surface finish |

2.5Mechanical Property Comparison of Common Hot-Rolled ASTM Grades

This table presents a comparison of typical mechanical properties for commonly used hot-rolled ASTM steel grades, including yield strength, tensile strength, and elongation:

| ASTM Grade | Type | Yield Strength | Tensile Strength | Elongation (%) | Remarks |

| A36 | Carbon Structural Steel | ≥ 250 MPa | 400–550 MPa | ≥ 20% | Common structural steel for construction |

| A1011 CS Type B | Commercial Steel | ≥ 170 MPa | ≥ 270 MPa | ≥ 28% | General forming, non-structural |

| A1011 SS Grade 36 | Structural Steel | ≥ 250 MPa | ≥ 400 MPa | ≥ 20% | A36 substitute, widely used in construction |

| A1011 SS Grade 50 | High-Strength Structural Steel | ≥ 345 MPa | ≥ 450 MPa | ≥ 18% | Higher strength, used in bridges, heavy equipment |

| A1011 HSLAS Grade 50 | HSLA Steel | ≥ 345 MPa | ≥ 450 MPa | ≥ 20% | Better formability than SS grades, suitable for automotive frames |

| A1011 HSLAS-F Grade 50 | HSLA – Improved Formability | ≥ 345 MPa | ≥ 450 MPa | ≥ 22% | Enhanced for stamping performance |

| A1011 Grade 100 (UHSS) | Ultra High Strength Steel | ≥ 690 MPa | ≥ 830 MPa | ≥ 10% | Automotive structural parts, safety shells |

| A572 Grade 50 | HSLA Structural Steel | ≥ 345 MPa | ≥ 450 MPa | ≥ 18% | Bridges, lifting equipment, construction machinery |

| A992 | Structural Steel for H-Shapes | ≥ 345 MPa | 450–620 MPa | ≥ 18% | Replaces A572 for I-beams and H-beams |