- 1.0Core Heating Types and Working Principles

- 2.0Key Characteristics of High-Frequency Heating

- 3.0Technical Differences Between RF and Microwave Heating (Dielectric Heating Only)

- 4.0Equipment Structure and Process Parameters

- 5.0Major Application Fields

- 6.0Conclusion

- 7.0Frequently Asked Questions (FAQ)

- 7.1Is high-frequency heating limited to metals?

- 7.2Can non-ferromagnetic metals (such as aluminum or copper) be effectively heated using induction heating?

- 7.3How should RF and microwave heating be selected?

- 7.4Is there a standardized frequency range for high-frequency heating?

- 7.5Why should the reserved hole for plastic insert applications be 0.3–0.6 mm smaller than the metal insert?

- 7.6How does high-frequency heating achieve better energy efficiency compared with traditional heating?

Overview of High-Frequency Heating (HF Heating)

Dielectric heating—also referred to as electronic heating, radio-frequency heating, or high-frequency heating—is the process of heating dielectric materials using radio-frequency (RF) alternating electric fields, radio waves, or microwave electromagnetic radiation. At high frequencies, heat is generated by the rotational motion of dipole molecules within the dielectric material.

High-frequency heating utilizes electromagnetic energy (radio waves or microwaves) to heat materials by generating alternating magnetic or electric fields that produce heat directly inside the workpiece. Since no physical contact with the heat source is required, this method offers fast, precise, efficient, and controllable thermal performance. HF heating generally includes two major mechanisms: induction heating for conductive metals (eddy-current effect) and dielectric heating for insulating materials (molecular friction).

1.0Core Heating Types and Working Principles

1.1Induction Heating: Suitable for Metallic Materials

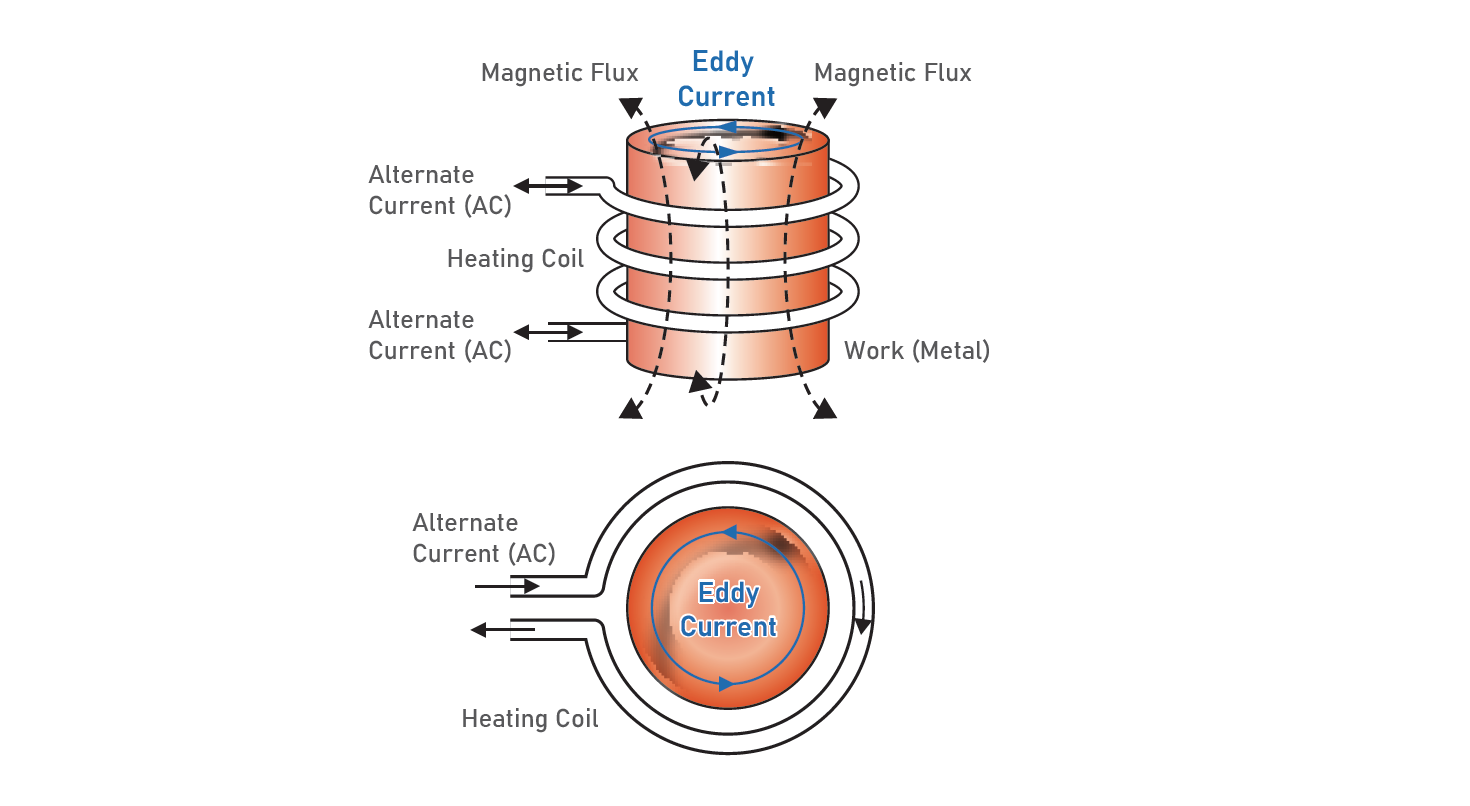

Induction heating is a non-contact method in which electromagnetic induction causes the metal to generate heat internally. Its fundamental mechanism is based on two loss components:

Eddy-Current Losses: High-frequency alternating current flowing through an induction coil generates a rapidly changing magnetic field. When a metal workpiece (such as tubing or machined parts) is placed inside this field, strong closed-loop currents—eddy currents—are induced within the metal, much like the secondary coil of a transformer. These currents produce Joule heat, enabling rapid and uniform heating. Tube-end sealing machines, for example, use this principle to heat and melt tube ends for clean sealing without internal contamination.

Hysteresis Losses:These occur only in ferromagnetic metals such as iron and some steels. As the alternating magnetic field repeatedly magnetizes and demagnetizes the material, magnetic domain realignment generates additional heat. Once the metal temperature exceeds approximately 700°C (Curie point), magnetic properties disappear; hysteresis losses cease, and heating continues purely through eddy-current effects.

In addition, induction heating is influenced by the skin effect, where high-frequency currents concentrate in a thin surface layer of the metal. This increases effective resistance and enhances surface heating. By adjusting frequency, operators can control heat penetration depth for applications such as surface hardening, uniform heating, or tube-end sealing.

1.2Dielectric Heating: Suitable for Non-Metallic Materials

Dielectric heating—also known as RF heating or electronic heating—uses RF alternating electric fields or microwave radiation to heat dielectric materials. The primary mechanism is dipole rotation:

Molecular Dipole Rotation: Under a high-frequency electric field, polar molecules within materials such as plastics, food products, wood, and textiles attempt to align with the alternating field. Their rapid rotation and internal friction generate substantial heat, producing volumetric heating (heat generated throughout the entire material rather than from the surface inward).

Heat Generation Factors: Heating performance depends on dielectric loss factor, frequency, and electric field intensity. Because heat is produced inside the material, efficiency is significantly higher compared with conductive or convective heating.

2.0Key Characteristics of High-Frequency Heating

2.1Non-Contact Heating

Heat is generated internally without direct contact with flames or heating elements, preventing contamination or surface damage. This is critical for equipment such as tube-end sealing machines where clean sealing is required.

2.2High Efficiency and Rapid Heating

Energy acts directly on the target material with minimal loss, enabling significantly faster temperature rise compared with conduction, convection, or infrared heating. This greatly improves productivity for applications such as tube sealing or metal hardening.

2.3Precision and Control

Adjusting frequency allows control over heat penetration (e.g., the skin effect in induction heating). This enables selective surface or core heating. Tube-end sealing systems can accurately control the molten zone, reducing tube deformation.

2.4Wide Applicability

Suitable for both metals (induction heating) and dielectric non-metals such as plastics, food, and textiles (dielectric heating).

2.5Environmentally Friendly

Since only the workpiece is heated, energy waste is minimized and no pollutants are emitted.

3.0Technical Differences Between RF and Microwave Heating (Dielectric Heating Only)

The operating frequency range for dielectric heating spans from 5 MHz to 5 GHz. Radio-frequency (RF) heating typically refers to frequencies below 100 MHz (commonly 13.56 MHz and 27.12 MHz), while microwave heating operates from 500 MHz to 5 GHz (commonly 900 MHz and 2.45 GHz). Both fall under designated ISM frequency bands to prevent interference with communication systems. The core differences are as follows:

| Characteristic | Radio Frequency (RF) | Microwave |

| Wavelength | Longer (11.2–22.4 m) | Shorter (0.13–0.35 m) |

| Dominant Polarization Mechanism | Space-charge polarization | Dipole orientation polarization |

| Equipment Compatibility | Suitable for wide-format or large workpieces | Suitable for medium-sized workpieces and continuous processing |

4.0Equipment Structure and Process Parameters

4.1Components of a High-Frequency Induction Heating System

A typical high-frequency induction heating system consists of three major units:

High-Frequency Power Generator: Produces the required high-frequency electrical energy.

Matching Network: Ensures efficient power transfer and impedance matching between the generator and the induction coil.

Induction Coil: Often manufactured using Litz wire to minimize high-frequency losses. This structure is highly adaptable for integration into automated production lines.

For tube-end closing machines, coils are customized based on tube diameter and material to focus the magnetic field on the tube end, enabling precise and localized heating.

These systems are compact, lightweight, require no preheating, and deliver instantaneous heating performance, making them suitable for industrial automation environments.

4.2Key Process Parameters

Plastic Insert Applications: When high-frequency induction heating is used for embedding metal inserts (such as nuts or bolts) into plastic components, the following parameters must be considered:

- Hole Diameter Design: The reserved hole in the plastic part should be 0.3–0.6 mm smaller than the metal insert diameter to provide fusion allowance.

- Auxiliary Structures: Screw-guiding features and melt-release channels should be incorporated.

- Operating Procedure: The metal insert is induction-heated and immediately pressed into the reserved hole using a punch, followed by controlled air cooling.

Tube-End Sealing Applications: Tube-end closing machines must adjust frequency according to the tube material. Ferromagnetic tubes benefit from both hysteresis and eddy-current heating, while non-ferromagnetic materials such as aluminum require higher frequencies to enhance the skin effect.

Heating duration must be controlled within the millisecond range to prevent excessive melting or incomplete sealing. Some systems incorporate air-cooling modules for rapid shaping and solidification.

5.0Major Application Fields

5.1Induction Heating Applications

- Metal Processing: Hardening, brazing, soldering, annealing of automotive and aerospace components; metal melting; surface hardening of gears, saw blades, and drive shafts; hardening of ammunition components; tube-end sealing for metal tubes such as hydraulic tubes and medical instrument tubing.

- Sealing and Purification: Aluminum-foil tamper-evident sealing for pharmaceutical and beverage bottles; degassing of getters in vacuum tubes, cathode-ray tubes, and gas-discharge lamps.

- Specialized Processing: Zone refining for semiconductor manufacturing; sterile heating and thermal sterilization of medical instruments.

- Everyday Applications: Induction cooktops and smart rice cookers.

5.2Dielectric Heating Applications

- Food Industry: Drying, baking, thawing, and cooking.

- Plastics and Textiles: Welding, drying, polymerization processes, and embedding metal inserts (nuts, bolts) into plastic components.

- Additional Fields: Paper drying, rubber vulcanization and preheating for molding, vacuum microwave drying in pharmaceutical production (especially for heat-sensitive high-value compounds), and therapeutic tissue repair in medical treatments.

6.0Conclusion

High-frequency heating technology leverages the fundamental advantage of internal heat generation, supporting both induction heating and dielectric heating to serve a wide range of metal and non-metal processing requirements. Its non-contact, efficient, and precisely controllable characteristics overcome common issues associated with conventional heating methods, including contamination, inefficiency, and unstable temperature control.

With strong compatibility for automated production lines, HF heating is widely used across automotive, food, pharmaceutical, and electronics industries. Whether for surface hardening of metal components, embedding inserts into plastic products, or rapid drying of food materials, high-frequency heating has become an indispensable core technology in modern manufacturing due to its flexible frequency adjustment, controllable heating depth, and environmentally friendly operation.

7.0Frequently Asked Questions (FAQ)

7.1Is high-frequency heating limited to metals?

No. High-frequency heating includes induction heating for metals and dielectric heating for non-metallic materials. Dielectric heating applies to plastics, food products, textiles, wood, and other dielectric materials through dipole rotation mechanisms.

7.2Can non-ferromagnetic metals (such as aluminum or copper) be effectively heated using induction heating?

Yes. Although non-ferromagnetic metals do not generate hysteresis losses, they can still be efficiently heated via eddy-current losses. Increasing the operating frequency strengthens the skin effect, improving heating efficiency.

7.3How should RF and microwave heating be selected?

Selection depends on material properties and production requirements. RF provides deeper penetration and is suitable for wide-format or large workpieces (e.g., large-scale paper drying). Microwave heating offers shallower penetration and is ideal for medium-sized, continuous processing (e.g., rapid food heating, pharmaceutical vacuum drying).

7.4Is there a standardized frequency range for high-frequency heating?

Dielectric heating generally ranges from 5 MHz to 5 GHz, where RF typically refers to frequencies below 100 MHz, and microwave heating ranges from 500 MHz to 5 GHz. Industrial use must follow designated ISM frequency bands such as 13.56 MHz or 2.45 GHz to avoid interference with communication systems.

7.5Why should the reserved hole for plastic insert applications be 0.3–0.6 mm smaller than the metal insert?

This gap provides fusion allowance. When the heated metal insert is pressed into the plastic hole, the slight size difference ensures proper melting, tight bonding, and enhanced mechanical strength and sealing performance.

7.6How does high-frequency heating achieve better energy efficiency compared with traditional heating?

Heat is generated directly inside the material, eliminating the need to heat surrounding air or equipment surfaces. This minimizes thermal losses during transfer. Additionally, the extremely fast heating rate shortens production cycles, reducing total energy consumption.

Reference

https://en.wikipedia.org/wiki/Dielectric_heating

https://www.thermopedia.com/de/content/850/

https://www.canroon.com/Industry-Insights/Understanding-High-Frequency-Induction-Heaters-and-Their-Working-Principles

https://avioweld.com/highfrequency/