In today’s manufacturing landscape, fastening and assembly play a critical role in defining product stability, production efficiency, and cost management. The primary goal is to join individual components through precise and reliable connection methods, creating functional units or subassemblies.

While an ideal product design seeks to minimize the number of assembly parts through integrated engineering, in most complex manufacturing processes, multi-component fastening and assembly remain indispensable. These operations typically fall into three categories—manual, semi-automated, and fully automated—and may involve various techniques such as mechanical fastening and adhesive bonding.

1.0Mechanical Fastening: The Foundation of Industrial Assembly

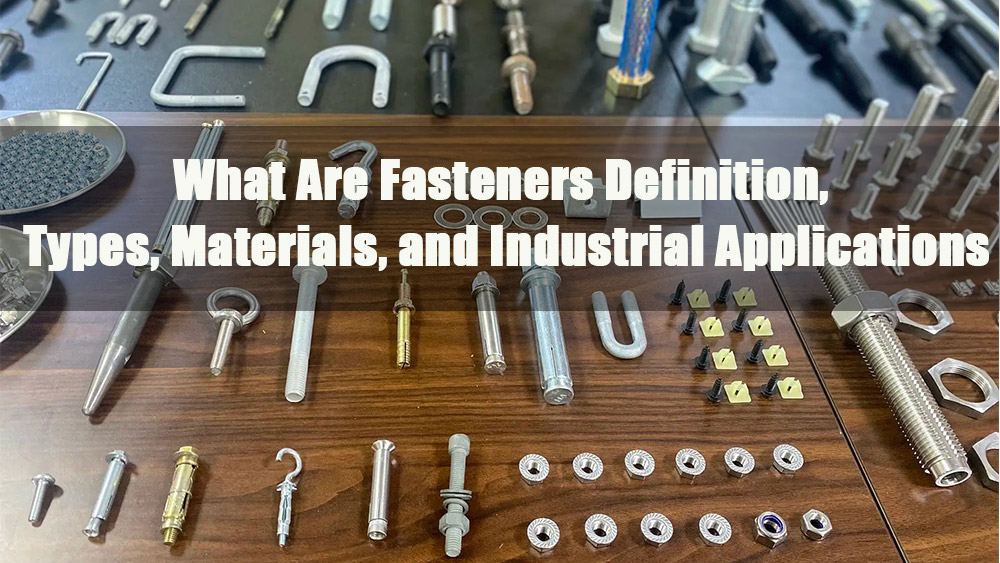

Mechanical fastening remains the most widely used joining method in manufacturing, known for its reliability and versatility. It can be divided into four main categories, with key details summarized below:

| Category | Key Types | Core Characteristics | Typical Applications |

| Integral Fasteners | Embossed protrusions, Edge seams, Hemming | Built into sheet metal; join via interlocking/interference; no separate parts needed. | Automotive body panels, appliance casings |

| Threaded Fasteners | Machine screws, Nuts, Bolts | Low-cost; detachable; supports maintenance/upgrades; available in imperial/metric. | Electronics, construction, machinery |

| Non-threaded Fasteners | Rivets, Pins, Washers | No threads; join via deformation/geometry; includes permanent and positioning types. | Aerospace components, precision machinery |

| Stapling | Chisel-point, Inside/outside bevel-point, Divergent-point staples | Permanent; low-cost; uses pre-bonded staple strips. | Automotive interiors, furniture production |

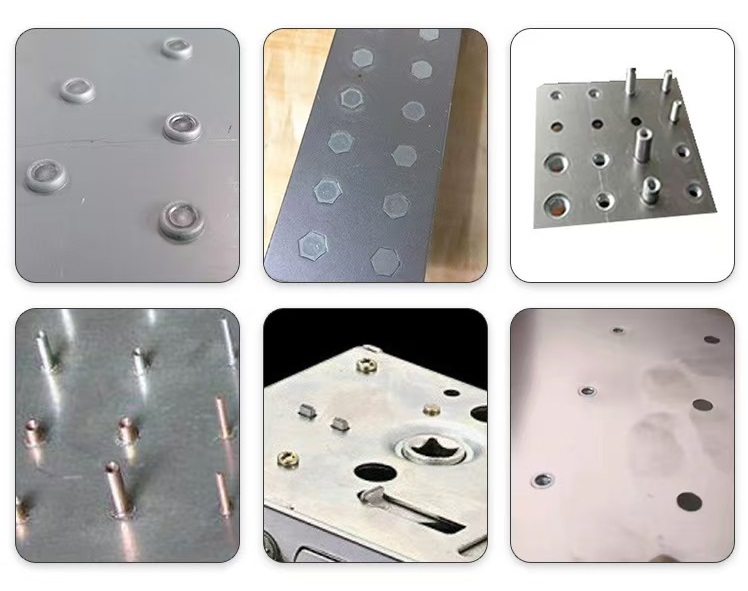

1.1Integral Fasteners: Built-in Connections for Sheet Metal Products

Integral fasteners are formed directly into sheet metal parts and achieve joining through interlocking or interference between components, eliminating the need for separate parts. Key types include:

- Embossed protrusions: Created by stamping two sheets of metal to form a cup-shaped structure. The metal expands under pressure to create an interlocked “button” larger than the punch diameter. This process, known asclinching, provides a permanent connection suitable for lightweight sheet metals.

- Edge seams: Involve folding and interlocking sheet edges to create a secure bond that strengthens the assembly while eliminating sharp edges for improved safety.

- Hemming: One sheet’s edge is folded over 180 degrees to tightly enclose another sheet, forming a strong and sealed connection. Commonly used in automotive body panels and appliance casings requiring rigidity and sealing.

1.2Threaded Fasteners: The Key to Detachable Assembly

Threaded fasteners provide a flexible, low-cost mechanical connection that supports disassembly and reassembly, making them ideal for products that require maintenance or upgrades.

- Types and specifications: Range from miniature screws for electronics to large-diameter bolts for structural applications in construction and bridges.

- Standardization and compatibility: Available in both imperial and metric systems, with customizable thread forms, pitches, and tolerances to meet different load and precision needs.

- Installation methods:

- Manual assembly: Uses wrenches or screwdrivers for small-scale operations.

- Automated assembly: Relies on fastener insertion machines with precise positioning/feeding mechanisms to insert specially headed screws. This minimizes human error and ensures high-speed, consistent installation.

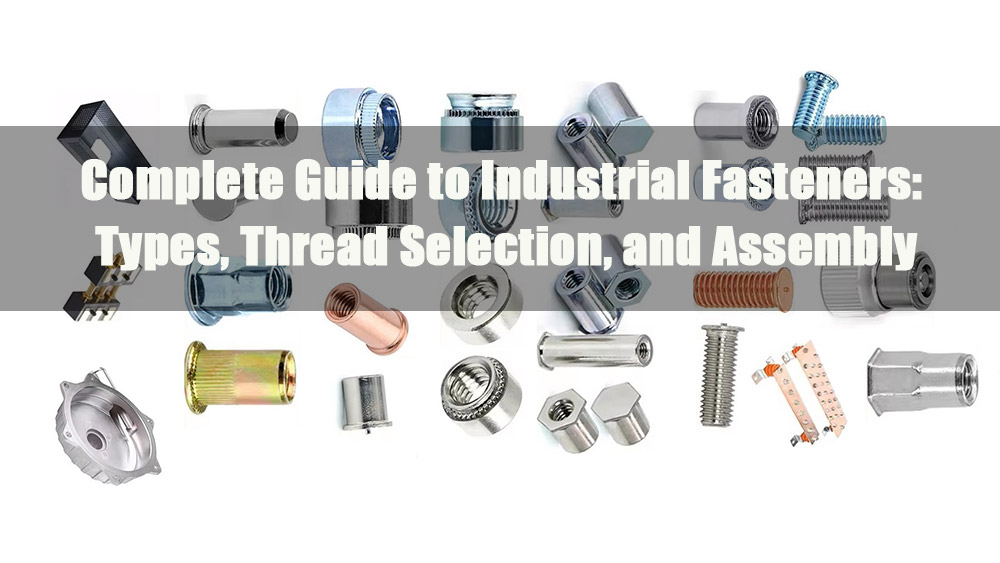

1.3Non-threaded Fasteners: Efficient Joining Without Threads

Non-threaded fasteners connect components through deformation or geometry rather than threads. Common examples include:

- Rivets: One-piece permanent fasteners inserted into aligned holes, then deformed at the tail end to lock parts together. Available in solid, semi-tubular, tubular, and split forms. Automated processes such asorbital riveting use a rotating head with a slight offset angle (3–6°), reducing noise compared to conventional riveting—ideal for noise-sensitive environments.

- Pins: Cost-effective, multifunctional fasteners serving as locking devices, pivots, or alignment tools.

- Clevis pins: Feature a hole for a cotter or spring pin.

- Dowel pins: Ensure precise alignment in high-accuracy assemblies.

- Washers: Complement bolts and screws by distributing loads and reducing surface stress. Lock washers with internal, external, or combined teeth prevent loosening under vibration or shock.

1.4Stapling: A Lightweight, High-efficiency Fastening Solution

Staple fastening is a cost-effective permanent joining method widely used in automotive interiors and furniture production. Semi-automatic staplers use pre-bonded staple strips for manual operation. Staples vary in:

- Length: Adapt to different material thicknesses.

- Point type: Chisel, inside chisel, outside chisel, or divergent points—selected based on material properties.

2.0Fastener Insertion Machines: The Core of Automated Threaded Assembly

With increasing automation across manufacturing, fastener insertion machines have become essential for large-scale threaded assembly—especially in automotive, electronics, and home appliance production. Their key features include:

| Feature | Details |

| Automated Feeding & Positioning | Dedicated feeding systems orient fasteners; vision/mechanical positioning ensures precise hole targeting. |

| Multi-type Compatibility | Adjustable tooling/parameters handle various fastener diameters, lengths, and head shapes. |

| Efficiency & Consistency | Manual assembly: ~10–15 pieces/min; automated systems: 30–60 pieces/min with controlled pressure/torque. |

| Production Line Integration | Synchronizes with robots, conveyors, and inspection systems for seamless “feeding → insertion → inspection” workflows. |

ALEKVS Fastener Insertion Machines

3.0Adhesive Bonding: An Innovative Path to Permanent Joining

Adhesive bonding achieves a molecular-level connection between different materials through cohesive forces, forming permanent joints that cannot be disassembled without damaging the parts. As a complementary alternative to mechanical fastening, it offers unique performance and design advantages.

3.1Material Versatility

Adhesives are available in multiple forms to meet diverse needs:

- Fluid forms: Liquid, paste, emulsion (for flexible application spaces).

- Solid forms: Film, tape, stick, pellet, powder (for precise, pre-cut applications).

3.2Flexible Application Methods

- Small-scale assembly: Manually applied using brushes.

- Medium-scale production: Semi-automated dispensing via extrusion or spray guns.

- High-volume manufacturing: Dedicated automated systems perform precise, repeatable application with programmable paths tailored to specific components or part families.

3.3Key Performance Advantages

Compared with traditional mechanical fastening, adhesive bonding offers:

- Even stress distribution: Spreads stress across large surfaces, minimizing localized failure risks.

- Dissimilar material compatibility: Joins metal-plastic, glass-ceramic, and other material pairs without drilling/welding.

- Sealing capability: Forms protective barriers against moisture, dust, and contaminants.

- Lightweight & cost efficiency: Reduces assembly weight and overall costs while improving structural integrity.

4.0Automated Assembly: The Core Driver of Cost Reduction and Efficiency

Assembly is one of the most labor-intensive stages in manufacturing, accounting for a significant portion of direct labor costs. Automation has therefore become a key strategy to reduce expenses, increase throughput, and ensure consistent quality.

Successful implementation requires:

- Part designs that prevent overlapping (shingling).

- Pre-oriented feeding via stacks, reels, bins, or trays.

- Robot-assisted part loading and finished-part unloading.

4.1Types of Automated Assembly Machines

| Machine Type | Structure | Suitable Components |

| Dial/Rotary Index Machines | Workstations/tooling around a central indexing dial/column; intermittent rotation. | Small, low-complexity parts (hardware fittings, miniature electronics). |

| In-line Indexing Machines | Components travel along oval/rectangular/square paths; intermittent pausing at stations. | Medium-sized parts with multiple steps (appliance subassemblies, small automotive modules). |

| Carousel Assembly Machines | Fixtures on chain/belt conveyors; horizontal part transport; reconfigurable stations. | Large, heavy components (industrial machinery, automotive body frames). |

4.2Key Factors in Equipment Selection

When selecting automated assembly systems, manufacturers should evaluate five critical aspects:

- Required production rate (output per time unit).

- Size and weight of the components.

- Proportion of automated operations versus manual support.

- Necessity of human-assisted processes.

- Complexity of assembly steps (multi-part coordination, precision alignment).

5.0Core Technology Summary

As manufacturing continues to advance toward greater intelligence, efficiency, and precision, fastening and assembly technologies are evolving along three main directions—automation, lightweighting, and accuracy.

- Mechanical fastening is upgraded via fastener insertion machines to boost batch production efficiency.

- Adhesive bonding expands in high-end sectors (new energy vehicles, aerospace) for its lightweight and sealing benefits.

- Automated assembly systems (dial, in-line, carousel) offer flexibility for diverse product needs.

By aligning fastening and assembly strategies with product characteristics, production scale, and cost objectives, manufacturers can achieve substantial gains in efficiency, quality, and overall competitiveness.