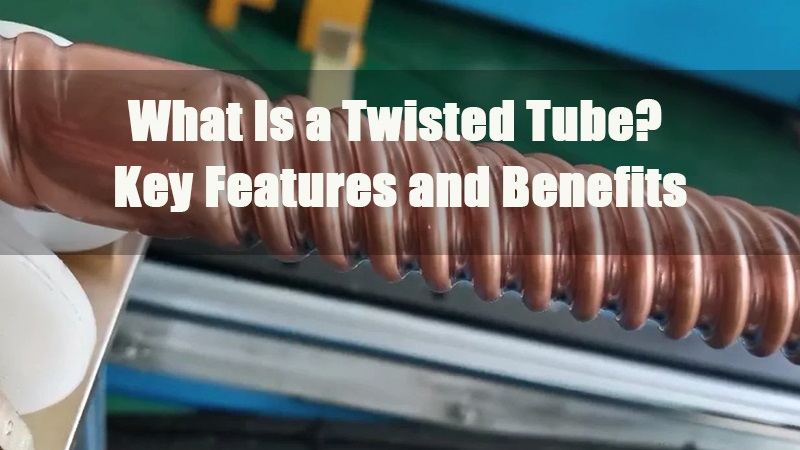

1.0What Is a Twisted Tube?

A Twisted Tube is a type of heat transfer tube formed by applying a controlled axial twist along the tube’s length, resulting in a continuous helical geometry. This design generates strong internal turbulence and flow disruption, significantly enhancing heat transfer efficiency while reducing fouling tendencies. Twisted Tubes are widely used in high-performance heat exchanger applications.

1.1Structural Features

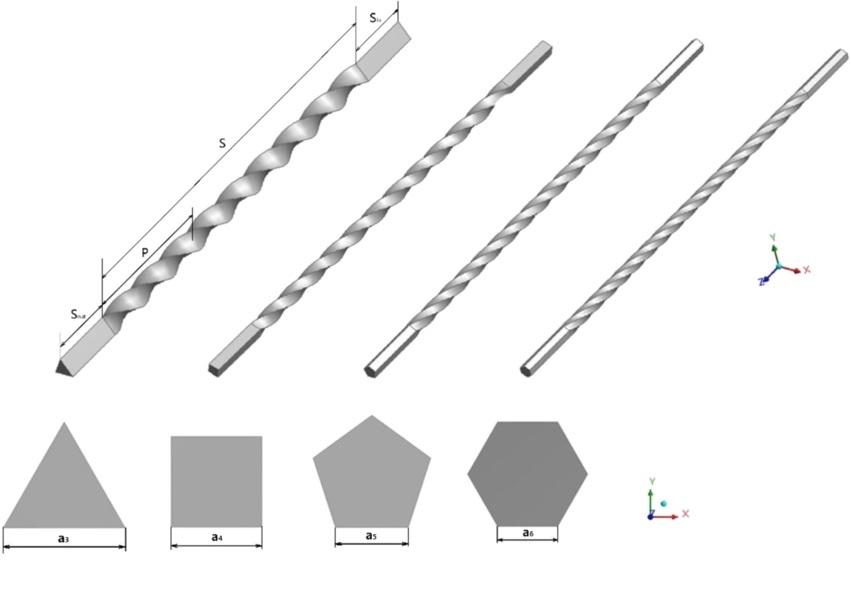

- Helical Twist Design:

The tube wall is periodically twisted along its axis, forming a spiral-shaped surface. - Cross-Section Shape:

Typically features a closed circular cross-section, offering high mechanical strength and uniform fluid distribution. - Internal Flow Disruptors:

The internal helical contour induces turbulent flow and breaks the boundary layer for enhanced thermal performance. - Outer Surface Treatment:

Available with polished or textured finishes to improve thermal conductivity or fouling resistance, depending on service needs. - Customizable Parameters:

- Twist angle: 30° to 90°

- Twist pitch: Number of twists per unit length

1.2Material Options

Twisted Tubes can be fabricated from various corrosion- and heat-resistant metals to suit demanding process environments:

- Stainless Steel: Grades such as 304 and 316L

- Copper Alloys: Including red copper, brass, and copper-nickel alloys

- High-Performance Alloys: Such as Inconel, titanium alloys, and other specialty metals

2.0How Are Twisted Tubes Manufactured?

The manufacturing of Twisted Tubes involves a combination of forming techniques, precision parameter control, and surface treatments, aiming to deliver high thermal efficiency, mechanical integrity, and long-term operational reliability.

2.1Cold Roll Forming

Principle:

Metal strip is continuously fed into a spiral-shaped die, roll-formed into a twisted profile, and then welded into a tube.

Features:

- Cost-effective for high-volume production

- Can be integrated with online welding systems

- Commonly used for stainless steel and copper alloy strips

2.2Hydraulic Torsion Forming

Principle:

A prefabricated straight tube is clamped and subjected to axial torque via a hydraulic system, inducing localized plastic deformation to form a uniform spiral twist.

Features:

- High torsional precision with controllable angle and pitch

- Suitable for low-to-medium batch customization

- Capable of producing complex or variable-pitch geometries

2.3Laser-Assisted Twisting

Principle:

Localized laser heating is applied to the tube surface while rotating, inducing thermoplastic deformation and forming the twisted structure incrementally.

Features:

- High accuracy for small-diameter or thin-walled tubes

- Common in aerospace and medical-grade manufacturing

- Higher cost; ideal for precision-critical applications

2.4Torsion Drawing

Principle:

The tube is held in a rotating fixture while being axially drawn, enabling continuous and uniform helical twisting.

Features:

- Excellent structural stability

- Flexible control over process parameters

- Suitable for typical tube sizes (10–50 mm OD)

2.5Rotary Rolling Forming

Principle:

The rotating tube is progressively pressed by forming rollers to imprint the spiral contour.

Features:

- Superior surface finish

- Ideal for designs requiring specific surface turbulence

- Common for ductile materials like stainless steel, copper, and aluminum

2.6Die Pressing

Principle:

The tube is placed in a pre-shaped helical die and rapidly formed using mechanical or hydraulic presses.

Features:

- High efficiency and repeatability

- Suitable for standardized mass production

- Cost-effective but less flexible for customization

2.7Key Process Parameters

| Parameter | Control Range | Impact & Design Trade-offs |

| Twist Angle | 30°–90° | Greater angles increase turbulence and heat transfer but also pressure drop |

| Twist Pitch | 10–100 mm | Shorter pitch enhances fluid disruption for high-performance applications |

| Outer Diameter | 6–60 mm | Customizable based on equipment space and flow requirements |

| Wall Thickness | 0.3–3.0 mm | Thin walls improve heat transfer; thicker walls boost pressure resistance |

| Tube Length | Up to 30 meters | Suitable for large heat exchangers and coil winding |

| Surface Roughness | As per design spec | Smooth surfaces reduce fouling; textured finishes enhance turbulence |

2.8Heat and Surface Treatment Options

To enhance corrosion resistance, cleanliness, and service life, Twisted Tubes are commonly subjected to the following treatments:

- Annealing:

Relieves residual stress, improves ductility and flexibility - Pickling and Passivation:

Removes oxide layers and enhances corrosion resistance, especially in food and pharmaceutical systems - Electropolishing:

Improves internal and external surface smoothness, minimizing fouling and bacterial adhesion - Shot Peening / Micro-Texturing (Optional):

Promotes turbulence formation, enhancing thermal performance

2.9Complete Manufacturing Workflow (Overview)

Raw Material Preparation:

Select high-grade tube materials such as stainless steel, copper alloys, or titanium; define outer diameter, wall thickness, and other specs.

Forming Process:

Choose from cold roll forming, hydraulic torsion, rotary rolling, or laser-based methods based on design requirements.

Welding & Assembly (If Required):

Automatically weld multi-segment tubes or bundle assemblies into full components.

Heat Treatment (Optional):

Used to relieve stress or refine microstructure, improving consistency and performance.

Surface Treatment:

Apply pickling, polishing, or passivation per industry and environmental standards.

Quality Inspection:

Includes dimensional checks, tolerance verification, spiral uniformity, pressure testing, surface finish, and leak testing.

3.0Comparison: Twisted Tubes vs. Other Tube Types

| Criteria | Twisted Tube | Smooth Tube | Finned Tube | Spiral/Corrugated Tube |

| Heat Transfer Efficiency | ⭐⭐⭐⭐⭐ — Excellent | ⭐⭐ — Low | ⭐⭐⭐ — Moderate | ⭐⭐⭐⭐ — High |

| Fouling Resistance | ⭐⭐⭐⭐ — Good | ⭐ — Poor | ⭐⭐ — Fair | ⭐⭐⭐ — Moderate |

| Manufacturing Complexity | ⭐⭐⭐ — Medium | ⭐ — Low | ⭐⭐⭐ — High | ⭐⭐ — Moderate |

| Ease of Cleaning & Maintenance | ⭐⭐⭐⭐ — Easy | ⭐⭐⭐⭐⭐ — Very Easy | ⭐⭐ — Difficult | ⭐⭐⭐ — Moderate |

| Cost | Medium to High | Low | Medium | Medium |

4.0Typical Applications of Twisted Tubes

An ideal choice for high-efficiency heat exchange in industrial sectors:

- Petrochemical Industry:

Shell-and-tube heat exchangers, reactor cooling bundles - Power Generation Equipment:

Steam condensers, boiler reboilers, regenerative heat exchangers - Food and Pharmaceutical Processing:

Pasteurizers, cooling coils, steam heating units - Precision Cooling Systems:

Laser cooling units, thermal components in medical devices - HVAC Systems:

Air-source heat pumps, water-cooled air conditioning heat exchangers