- 1.0Introduction to Tapered Pipes

- 2.0What Is Tube Tapering?

- 3.0Manufacturing Processes and Equipment Selection for Tapered Pipes

- 4.0Common Materials and Performance Requirements for Tapered Pipes

- 5.0Typical Application Areas for Tapered Pipes

- 6.0Tapered Tube Design Quick Reference

- 7.0Future Trends in Tapered Tube Development

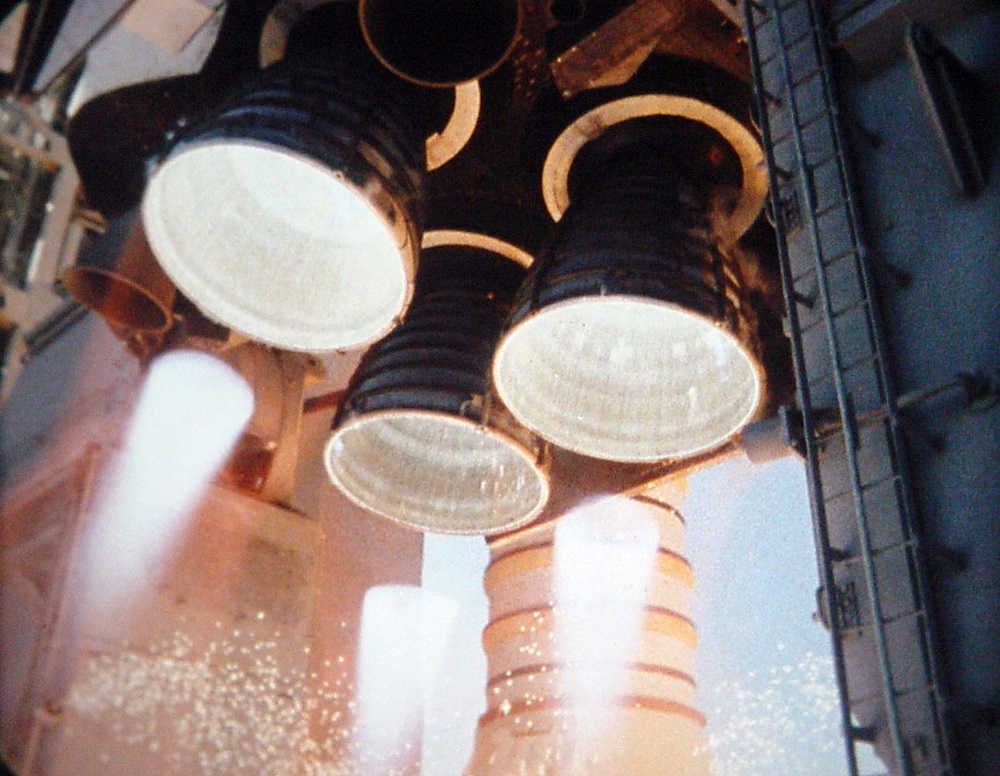

Imagine the blazing flame erupting from a rocket’s tail during launch — one of the key components behind this force is a tapered nozzle made from heat-resistant alloys.

Even in an automobile exhaust system, the smooth transition between pipes of different diameters often relies on one essential feature: the tapered tube.

1.0Introduction to Tapered Pipes

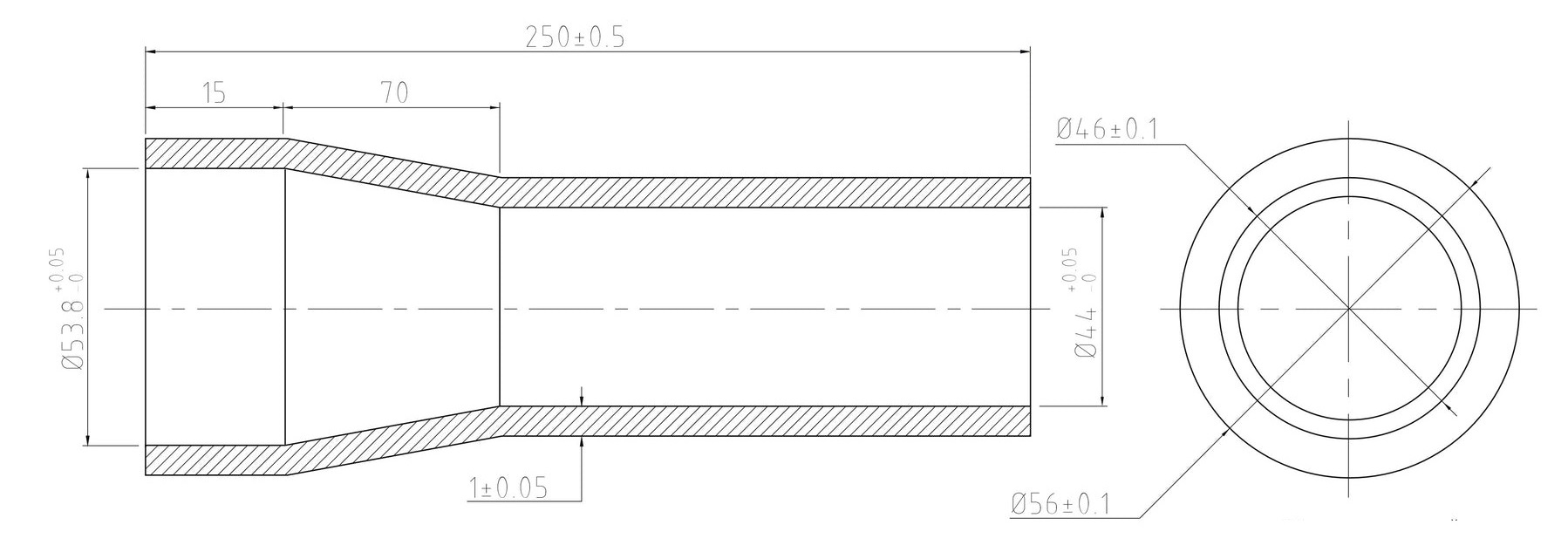

Geometric Characteristics and Key Design Factors

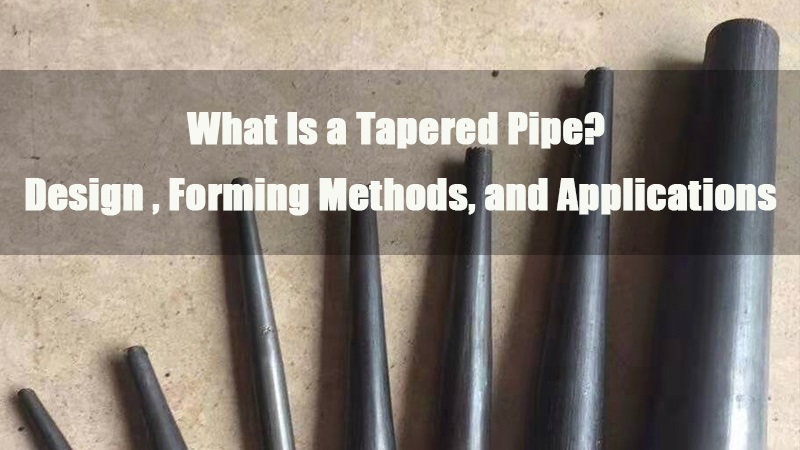

Tapered pipes can be categorized based on structure into:

- Concentric tapered pipes: The centerlines at both ends are aligned.

- Eccentric tapered pipes: The centerlines at both ends are offset.

Key design parameters include:

- Diameter range: Large-end diameter (D) and small-end diameter (d)

- Length and angle: Tube length (L) and taper angle (A)

- Wall thickness profile: Constant or gradually varying

- Cross-sectional shape: Primarily round, but can also be elliptical or transitional (e.g., square to round)

Design considerations: Maintaining concentricity, managing wall thickness distribution, avoiding stress concentration, and ensuring adequate joint strength (especially at welded sections).

Taper Specification

Taper is a core design feature and has a direct impact on function:

- Linear taper: T = (D₁ – D₂) / L (unit: mm/m)

-

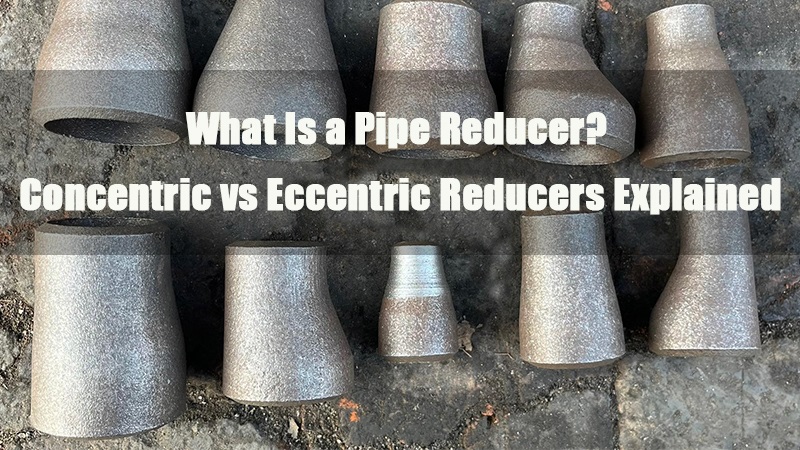

Angular taper: Defined by half cone angle θ/2 (see diagram)

Angular taper - Ratio taper: e.g., 1:10 (a 1-unit diameter change per 10 units of length)

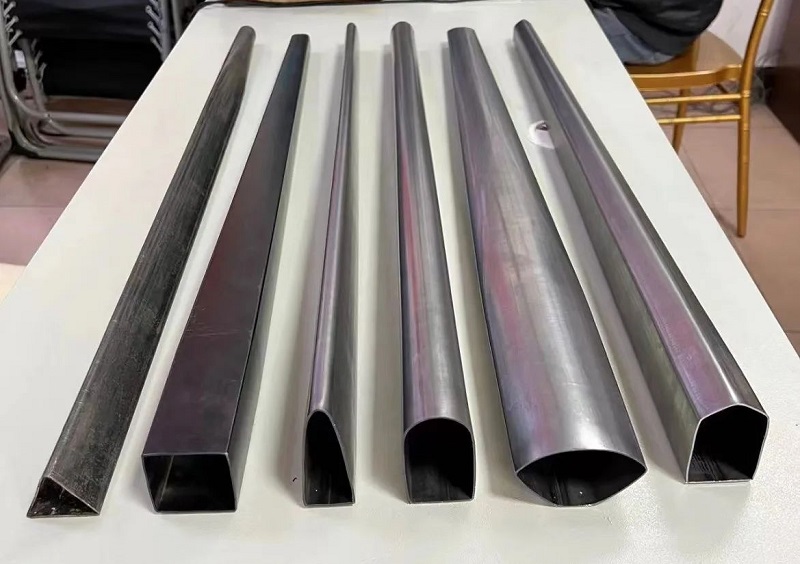

Shape Variations

| Type | Characteristics | Typical Applications |

| Circular tapered pipe | Most common; supports symmetric flow | Piping connections, rocket nozzles |

| Rectangular tapered pipe | Easy to integrate; high space efficiency | HVAC ducts, lighting trusses |

| Custom-shaped tapered pipe | Complex cross-sections for specialized use | Aerodynamic components |

2.0What Is Tube Tapering?

Tube tapering refers to a structural feature where the outer or inner diameter of a tube gradually increases or decreases along its axial direction, typically forming a conical transition. This shaping process enables versatile applications in connection, transition, decoration, or functional performance.

A tapered tube features a gradually changing cross-section, improving fluid dynamics, enhancing connection precision, and offering both structural and aesthetic advantages.

2.1Basic Process of Tapering

The core principle of tube tapering is to apply axial force—physically or mechanically—to reshape the tube material along a tapered die or forming tool.

- In most cases, tube tapering is performed as a cold-forming process.

- Molds, extrusion heads, or rotary hammers apply controlled friction and pressure to reduce or expand the tube diameter progressively.

- Once the tapered section is formed, the remaining segment maintains a constant diameter, resulting in a “bottleneck” structure.

2.2Common Tube Tapering Methods

| Method | Working Principle | Key Features |

| Rotary Swaging | High-speed radial hammering of the tube end via dies | Cold forming, suitable for long tapers, smooth finish, high precision |

| Tapered Drawing | Drawing the tube through a conical die to gradually reduce diameter | Ideal for small taper angles, thin-wall tubes, high accuracy |

| Roll Forming | Progressive diameter change through multiple roller sets | Continuous production for medium to long tubes, high efficiency |

| Hydroforming | Internal hydraulic pressure forces the tube against tapered molds | Uniform shaping, excellent dimensional control, for complex contours |

| Press Tapering | Direct axial pressing using a conical die | Simple setup, suitable for short lengths and small-batch production |

| CNC Tube End Forming | Servo-controlled push or compression with programmable precision | High automation, consistent results, ideal for mass production |

2.3Typical Forming Example: Rotary Swaging

In rotary swaging, a tube blank with a larger diameter is inserted into a swaging machine:

- The tube is clamped into a fixed fixture.

- The dies rotate at high speed around the tube.

- Around 3000 radial strikes per minute gradually reduce the tube diameter.

- Post-forming operations may include trimming, flaring, or heat treatment.

2.4Suitable Materials

Tube tapering can be applied to a wide range of metals, including:

- Stainless steel

- Carbon steel

- Aluminum alloys

- Copper / Brass

- Titanium alloys

- Others: Nickel alloys, duplex stainless steels, etc.

Different materials have varying suitability for each method. Selection should consider tensile strength, ductility, wall thickness, and other material properties.

Summary

- Tube tapering is a critical tube-end forming technique.

- Compatible with various metals and production requirements.

- Influences product performance, appearance, and assembly accuracy.

- Process selection should be based on material, dimensions, production volume, and taper geometry.

3.0Manufacturing Processes and Equipment Selection for Tapered Pipes

The manufacturing of tapered or conical pipes involves a range of forming methods and specialized equipment.

3.1Pipe/Tube End Swaging Machine

Used to radially reduce the tube end diameter, creating a tapered profile for jointing or insertion.

Key Features:

- Cold forming, chipless process with high efficiency

- Suitable for small to medium diameters in high-volume production

- Optional flaring or end-forming extensions are available

3.2Pipe/Tube End Tapering Machine

Designed specifically for forming standard or custom tapered ends on tubes. Common applications include connection tapers, flared openings, and transition sections.

Working Principle:

- Uses servo-driven or hydraulic die systems to apply simultaneous radial and axial force on the tube end

- Taper angle, taper length, and wall thickness variations can be preprogrammed

- Supports both concentric and eccentric taper geometries

Key Features:

- More suitable than swaging for longer taper angles

- Capable of processing thick-walled or hard alloy tubes

- Delivers smoother, more precise tapers, ideal for sealing interfaces or pre-welding preparation

3.3Spinning Forming

Ideal for forming tapered tubes with small to medium diameters, especially those with thick or variable wall sections. Typically performed using CNC spinning machines.

Process steps:

- Preheating the blank (if required)

- Mounting a disc or short tube onto a rotating spindle

- A forming roller applies force axially and radially, shaping the material along a taper die

- Follow-up processes may include trimming or heat treatment

Advantages:

High forming quality, seamless structure, accurate thickness control, and excellent surface finish

3.4Plate Rolling + Welding Process

Commonly used for producing large-diameter tapered pipes, particularly for diameters over DN600.

Process steps:

- Plate cutting and edge preparation

- Conical rolling using 3-roll or 4-roll plate rolling machines

- Seam welding (internal and external)

- Heat treatment and dimensional correction

Characteristics:

Flexible sizing and strong adaptability; requires high-quality welding to ensure integrity

3.5Die Forming

Suitable for the mass production of standardized tapered tubes. The process uses conical dies on hydraulic presses for either hot or cold forming.

3.6Taper Pipe Forming Machine (CNC Tapering System)

A specialized CNC machine designed for the production of tapered pipes with programmable control.

Key Features:

- Programmable taper angle and thrust path adjustment

- Compatible with carbon steel, stainless steel, aluminum alloys, and more

- High automation level, supports customized batch production

4.0Common Materials and Performance Requirements for Tapered Pipes

| Material Type | Typical Tapered Pipe Products | Application Sectors / Use Cases | Key Performance Requirements |

| Carbon Steel | – Carbon steel tapered structural pipe (e.g. Q235) – Seamless tapered delivery pipe (A106) – API 5L tapered reducer pipe |

Construction structures, oil & gas transport, hydraulic systems | High strength, cost-effective, good weldability, pressure and wear resistance |

| Stainless Steel | – 304 tapered decorative tube – 316L sanitary tapered delivery pipe – Stainless tapered medical tube |

Food, beverage, chemical, pharmaceutical, medical, interior design | Excellent corrosion resistance, hygienic, mirror-finish surface available |

| Aluminum Alloy | – Aluminum tapered light pole – Aluminum furniture leg – Tapered bicycle frame tube |

Furniture, transport equipment, outdoor structures, architecture | Lightweight, corrosion-resistant, attractive appearance, easy to form |

| Titanium Alloy | – Titanium tapered catheter – Aerospace tapered connector tube |

Medical implants, aerospace, defense | High strength, excellent corrosion resistance, biocompatibility, heat resistance |

| Nickel Alloys | – Hastelloy tapered tube – Inconel tapered corrosion-resistant tube |

Petrochemical industry, high-temperature gases, marine environments | High-temperature stability, oxidation and chloride corrosion resistance, suitable for harsh environments |

| Copper / Brass | – Copper tapered joint – Brass tapered nozzle |

Plumbing, gas transmission, decorative fittings | Excellent thermal conductivity, high formability, decorative surface quality |

| Composites | – Carbon fiber tapered tube – Fiberglass tapered tube |

High-end sports equipment, aerospace, antenna structures | Ultra-lightweight, high strength, fatigue resistance, but higher material cost |

5.0Typical Application Areas for Tapered Pipes

Furniture and Decorative Industry

- Tapered aluminum table leg tube

- Stainless steel tapered sofa leg tube (304 grade)

- Powder-coated tapered furniture tube (black finish)

- Hollow tapered chair leg tube

- Tapered pendant light decorative tube

Automotive and Motorcycle Industry

- Exhaust diffuser tapered tube

- Turbo transition cone tube

- Tapered muffler pipe transition section

- Tapered radiator transition hose fitting

Industrial and Mechanical Structures

- Tapered structural pipe reducer (carbon steel)

- Tapered stainless steel process tube

- Tapered API threaded pipe

- Hydraulic tapered pipe end connection

Municipal and Building Facilities

- Tapered street light pole tube

- Tapered flagpole tube

- Tapered billboard support tube

- Tapered railing post tube for parks

Boiler and Thermal Systems

- Boiler flue tapered transition tube

- Tapered burner nozzle

- Tapered inlet tube for heat exchangers

- Tapered hot air guide tube

Petrochemical and Fluid Systems

- 316L tapered corrosion-resistant chemical tube

- Hastelloy tapered tube for heat distribution

- Tapered flow control pipe

- Tapered distributor nozzle for liquids/gases

Aerospace and High-End Structures

- Carbon fiber tapered mast tube

- Tapered fuselage coupling tube

- Tapered jet nozzle tube for aircraft

- Tapered truss tube for satellite structures

6.0Tapered Tube Design Quick Reference

| Category | Item | Unit / Description |

| Geometric Parameters | Large End Outer Diameter (D1) | mm / inch |

| Small End Outer Diameter (D2) | mm / inch | |

| Tube Length (L) | mm / inch | |

| Taper Ratio | (D1 − D2) ÷ L | |

| Taper Angle (θ) | θ = arctan((D1 − D2) ÷ 2L) | |

| Wall Thickness (t) | mm (constant or variable) | |

| Manufacturing Methods | Swaging | Suitable for long tapers with small angles; cold forming |

| Stamping / Forming Press | Ideal for short tubes or high-volume production | |

| Taper Drawing | High precision; suitable for thin-wall, small-diameter tubes | |

| Hydroforming | Uniform forming; suitable for complex geometries | |

| CNC End Forming | Precision-controlled; suitable for consistent batch production | |

| Material Options | Stainless Steel (SUS 304/316) | Corrosion-resistant; suitable for medical, food, and structural use |

| Aluminium Alloys (6061/5052) | Lightweight; suitable for furniture and transportation | |

| Carbon Steel (Q235, 1018) | Cost-effective; ideal for structural applications | |

| Copper / Brass | Excellent ductility; for decorative or conductive components | |

| Design Considerations | Wall Thickness (t constant) | Affects strength and manufacturability |

| Surface Treatment | Polishing, plating, coating, anti-corrosion finishes | |

| Tube End Forming | Flaring, reduction, expansion as required | |

| Typical Applications | — | Automotive exhausts, furniture legs, medical tubing, bicycle frames, lighting supports |

6.1Quick Formulas for Taper Calculation

Linear Taper Ratio

1. Taper Ratio = (D1 − D2) ÷ L

Taper Angle (in degrees)

2. θ = arctan((D1 − D2) ÷ 2L)

6.2Example

| Item | Value |

| D1 (Large End) | 60 mm |

| D2 (Small End) | 30 mm |

| L (Length) | 300 mm |

| Taper Ratio | (60 − 30) ÷ 300 = 0.1 |

| Taper Angle θ | arctan(30 ÷ 600) ≈ 2.86° |

7.0Future Trends in Tapered Tube Development

As industrial equipment continues to evolve toward larger scale and multifunctionality, higher requirements are being placed on non-standard transition tubing. Key future development directions include:

Promotion of high-strength steel and composite tapered tubes

Advancements in automated tapering machines and CNC forming technologies

Modular design to facilitate integration into standardized systems

As a critical component for transition and structural optimization, the design and manufacturing of tapered tubes are becoming increasingly mature. In the future, they are expected to play a greater role in sectors such as energy, environmental protection, and equipment manufacturing.

References

https://academic.oup.com/treephys/article-abstract/22/13/891/1663763

https://www.tandfonline.com/doi/abs/10.1080/03052150310001639281

https://pdfs.semanticscholar.org/c6c4/2705d501918cbdb488e290fe79100c3ef3c9.pdf