- 1.0What Is a Plate Rolling Machine?

- 2.0Types of Plate Rolling Machines

- 3.0How Does a Plate Rolling Machine Work?

- 4.0Bending Force Setting for Plate Bending/Rolling Machines

- 5.0Pre-Bending: Four Key Reasons to Choose a Rolling Machine with This Feature

- 6.0Which Plate Rolling Machine Is Right for Your Project?

- 7.0Applications of Plate Rolling Machines

- 8.0How to Build a Manual Plate Roller Using Scrap Metal ?

1.0What Is a Plate Rolling Machine?

1.1Definition of a Plate Rolling Machine

A plate rolling machine (also known as a plate roll or sheet metal roller) is designed to form flat metal sheets into cylindrical or other curved shapes through mechanical or hydraulic power. Typical applications include the fabrication of pipes, tanks, pressure vessels, and structural components. While the primary function is rolling flat sheets into cylinders, some models can reverse the process—flattening previously rolled sheets—though such use is less common.

1.2How Does a Plate Rolling Machine Work?

1.3What Is Sheet Metal Rolling?

Sheet metal rolling (also referred to as plate bending or forming) is a fundamental process where flat metal sheets are gradually shaped into arcs or cylindrical profiles by applying controlled force. This method allows for high-precision shaping of complex geometries and is essential in modern manufacturing.

The technique relies on plastic deformation, where the material undergoes permanent shape change without cracking. As the sheet passes through the rollers, compressive forces cause the metal to yield and bend. The resulting curvature depends on several factors: roller diameter, material thickness and composition, applied pressure, and rolling speed. With advancements in technology, the plate rolling process has become more efficient, precise, and easier to automate.

1.4Industry Applications of Plate Rolling

Plate rolling plays a critical role in multiple industries due to its versatility and reliability. Below are key sectors and representative applications:

| Industry | Typical Applications |

| Construction | Steel structures, architectural façades, bridge components |

| Civil Infrastructure | Pipelines, tanks, storage vessels, framed structures |

| Defense | Armor plates, naval components, military hardware |

| Energy | Storage tanks, pressure vessels, wind tower sections, nuclear equipment |

| Industrial Equipment | Piping systems, heat exchangers, machinery parts |

| Manufacturing | Enclosures, machine shells, compressor housings, turbine casings |

| Marine | Offshore platforms, subsea pipelines, hull structures |

2.0Types of Plate Rolling Machines

Understanding the Classification of Plate Rolls by Roller Count, Drive System, Control Method, and Application

2.1By Number of Rollers

- Two-Roll Plate Rolling Machines

Designed for light-duty tasks, two-roll machines are typically used for thin sheets in small-scale operations. With a simple structure and compact size, they are ideal for laboratories and basic rolling tasks.

- Three-Roll Plate Rolling Machines

The most commonly used configuration, featuring three rollers, suitable for rolling thin to medium-thickness plates and large-diameter cylinders. Known for their balance of performance and versatility, they are widely adopted in general metal fabrication.

- Four-Roll Plate Rolling Machines

Equipped with four rollers, these machines offer greater rolling precision and control, making them suitable for thicker plates and more complex geometries. They are often used in high-precision industrial environments where consistent accuracy is required.

- Double-Pinch Plate Rolls(Also considered a type of two-roll configuration)

These machines are compact and designed for basic operations involving thin sheet metals. Common in small workshops, they meet minimal rolling needs at low precision and low load levels. - Cone Plate Rolling Machine

Specifically designed for rolling conical workpieces, this machine is often equipped with a conical rolling attachment based on a three-roller or four-roller plate rolling machine. It is suitable for manufacturing conical components used in industries such as wind towers and storage tanks.

2.2By Drive Method

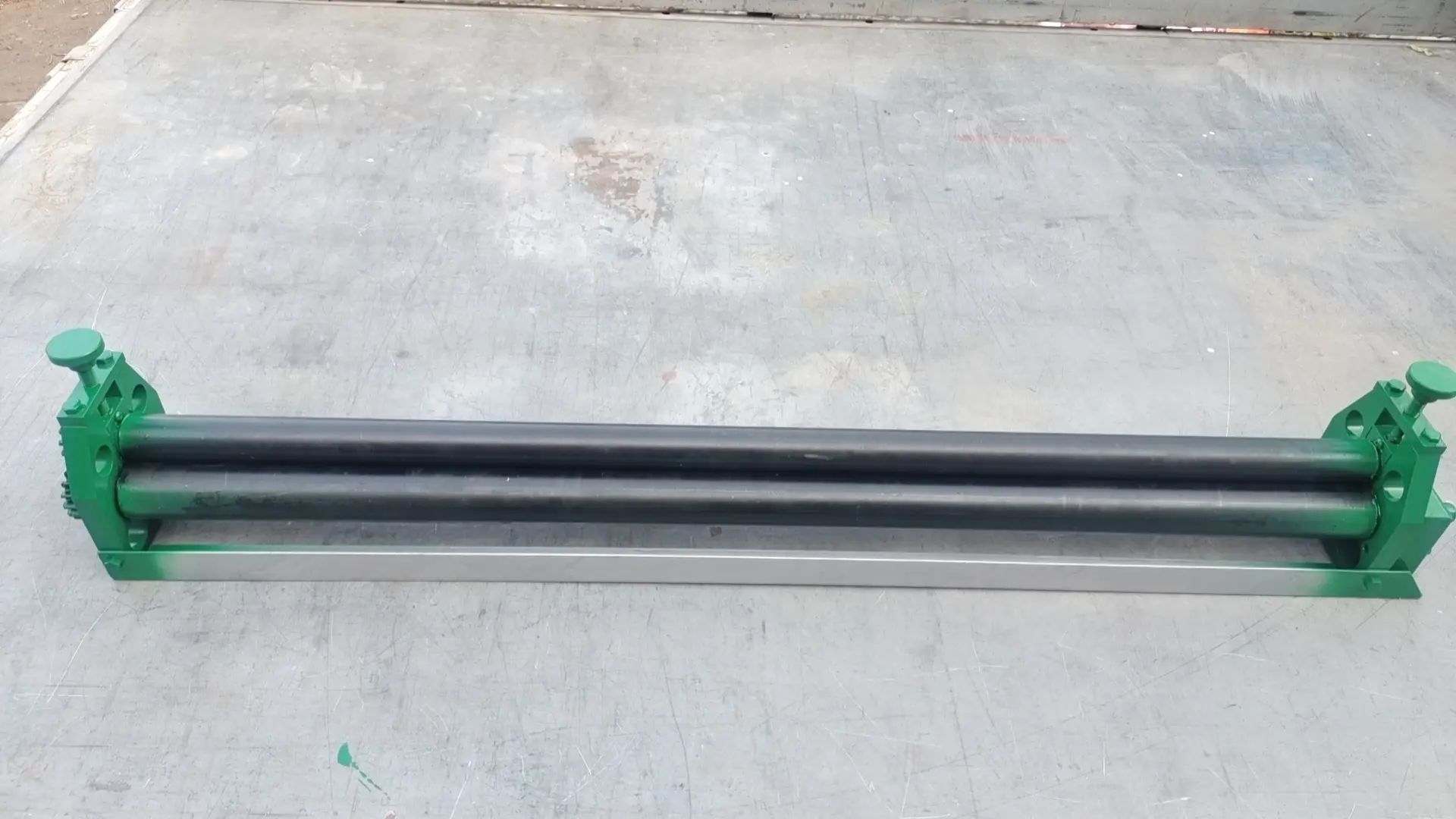

- Manual Plate Rolling Machines

Operated via hand crank or foot pedal, manual rollers are ideal for prototypes, DIY tasks, and educational use. They offer low cost and ease of use, but are limited to light-duty applications with low precision demands. - Mechanical Plate Rolling Machines

Driven by motors or gear systems, these machines are suitable for low to medium loads and small-batch production. They offer straightforward operation and are ideal for rolling thin sheets into simple shapes.

- Hydraulic Plate Rolling Machines

Using hydraulic systems to control the rollers, these machines handle higher loads and deliver greater bending force and accuracy. Common hydraulic types include:- Hydraulic 3-Roll Machines: The upper roll is hydraulically driven, suitable for medium-to-thick plates requiring high precision and forming force.

- Hydraulic 4-Roll Machines: All four rollers are hydraulically powered, offering enhanced precision and control for complex shapes and heavier-duty applications.

- Hydraulic Symmetrical Machines: Operate with symmetric upper and lower rolls, ideal for heavy plates and high-strength materials, ensuring rolling stability.

- Hydraulic CNC Plate Rolls: Combine hydraulic technology with computer numerical control (CNC) to automate the rolling process. These are designed for high-volume production, reducing manual input and increasing consistency.

2.3By Control System

- CNC Plate Rolling Machines

Equipped with computerized control systems, CNC rollers are designed for high-efficiency, high-accuracy tasks involving complex geometries. They support repeatable operations and are commonly used in mass production environments. - Hydraulic CNC Plate Rolling Machines

These machines integrate hydraulic power with CNC programming to offer both high forming flexibility and precision. They are ideal for large-scale operations requiring automation and the ability to handle a variety of materials and shapes.

2.4By Application Scenario

- Small Manual Plate Rollers

Best suited for low-load, low-precision tasks in laboratories, small-scale workshops, and prototype development. These machines are affordable and easy to operate. - Heavy-Duty Hydraulic Plate Rollers

Designed for large-scale production and thick metal sheets, these machines provide exceptional stability and load capacity. They are commonly used in heavy industries such as pressure vessel manufacturing, large pipe production, and storage tank fabrication. - Light-Duty Mechanical Plate Rollers

Ideal for thin metal sheets and applications with lower precision requirements. These are often found in small-scale manufacturing where budget, space, and simplicity are primary concerns.

3.0How Does a Plate Rolling Machine Work?

Principle and Operation of Plate Rolling Machines

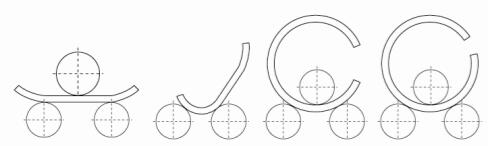

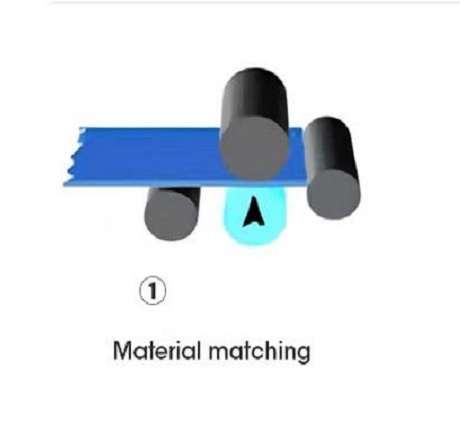

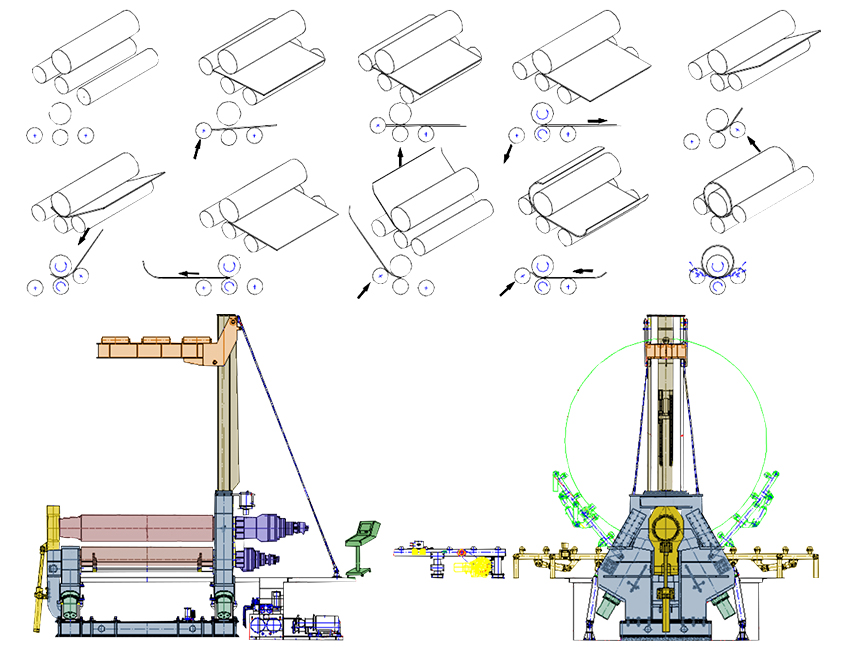

3.1Operation Process of a Plate Rolling Machine

- Raise the Bottom Roll and Position the Metal Plate

First, raise the bottom roll to the level of the punching plate so that it sits above the other two rolls. Slide the metal plate between the rolls, ensuring it aligns perpendicularly with the raised press roll. - Secure the Plate and Adjust the Rolls

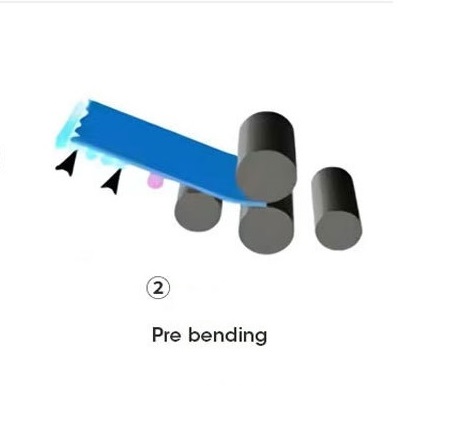

Once the metal plate is secured, lower the first (upper) roll and adjust the third or fourth roll to a proper position to allow smooth passage. At this point, the plate is centered over the punching plate. - Pre-Bending Operation

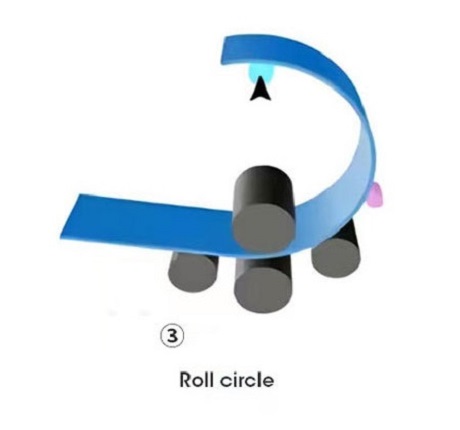

Raise the side roll that supports the metal plate to create a “pre-bend” or initial curvature. This step helps ensure accuracy and roundness in the final rolled part. - Complete the Rolling Process

Feed the metal plate through the machine until it passes beyond the top roll. Then, lower the pre-bending roll and raise the opposite bending roll into the rolling position. The machine continues to feed the plate through the rollers, clamping and bending it into the desired arc or cylindrical shape. - Welding and Finishing

Finally, the two edges of the metal plate are welded together to form a complete cylinder or the desired shape.

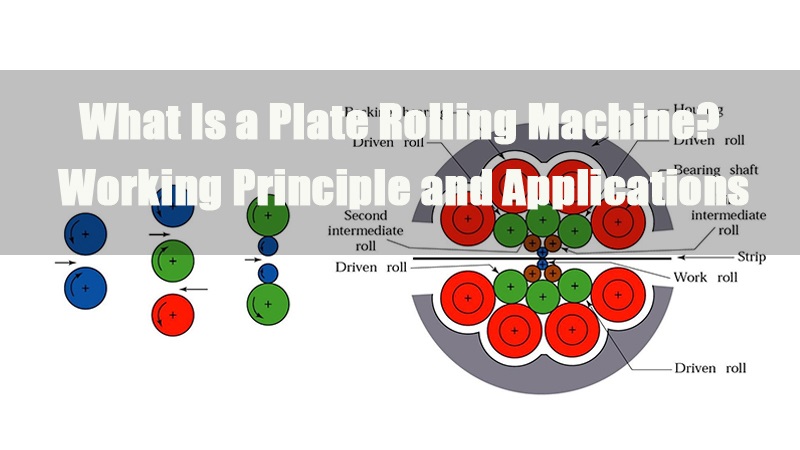

3.2Working Principle of a Plate Rolling Machine

Although plate rolling machines come in various types and produce cylinders of different shapes or sizes, they generally follow a similar operating sequence. The primary difference lies in the dimensions of the final product, but all aim to create a consistent round or cylindrical form.

Plate rolling machines are typically powered by hydraulic or mechanical systems and are equipped with three or four hardened metal rollers. Four-roll plate rolling machines are the most common, as they can efficiently process a wide range of cylindrical forms.

- Four Rolls: Two adjustable side rolls control the shape and size of the final bend.

- Roll Configuration: Three lower rollers and one larger upper roll work together to ensure accurate bending of the metal plate.

While specific designs may vary according to application needs, the standard four-roll bending machine remains the most widely used configuration due to its precision and versatility.

3.3Operating Steps for a Four-Roll Plate Bending Machine

- Raise the bottom roll to align with the punching plate.

- Position the metal plate at a right angle to the bottom roll.

- Lower the upper roll and pull the metal plate inward until it is centered over the punching plate.

- Raise the first (pre-bending) roll to initiate curvature, and begin feeding the plate through.

- Lower the pre-bending roll and raise the opposite roll to form the arc.

- Continue feeding the plate until a full cylinder is formed.

- Weld the two edges of the plate together to complete the cylinder.

4.0Bending Force Setting for Plate Bending/Rolling Machines

4.1Evaluate Working Load

The first step in metal plate bending is to assess the required working load of the plate rolling machine. This ensures the machine applies the correct pressure to achieve the desired inner or outer bending radius. During this step, operators consider variables such as plate thickness and material type to ensure forming precision. Proper load assessment lays the foundation for accurate and consistent bending.

4.2Secure the Metal Plate

Once the bending force is set, the metal plate must be firmly positioned on the bending machine’s worktable. This is critical for preventing unwanted movement during bending. Accurate alignment ensures uniform deformation and reduces the risk of irregularities or distortion. Proper securing also enhances operational safety and minimizes the likelihood of accidents.

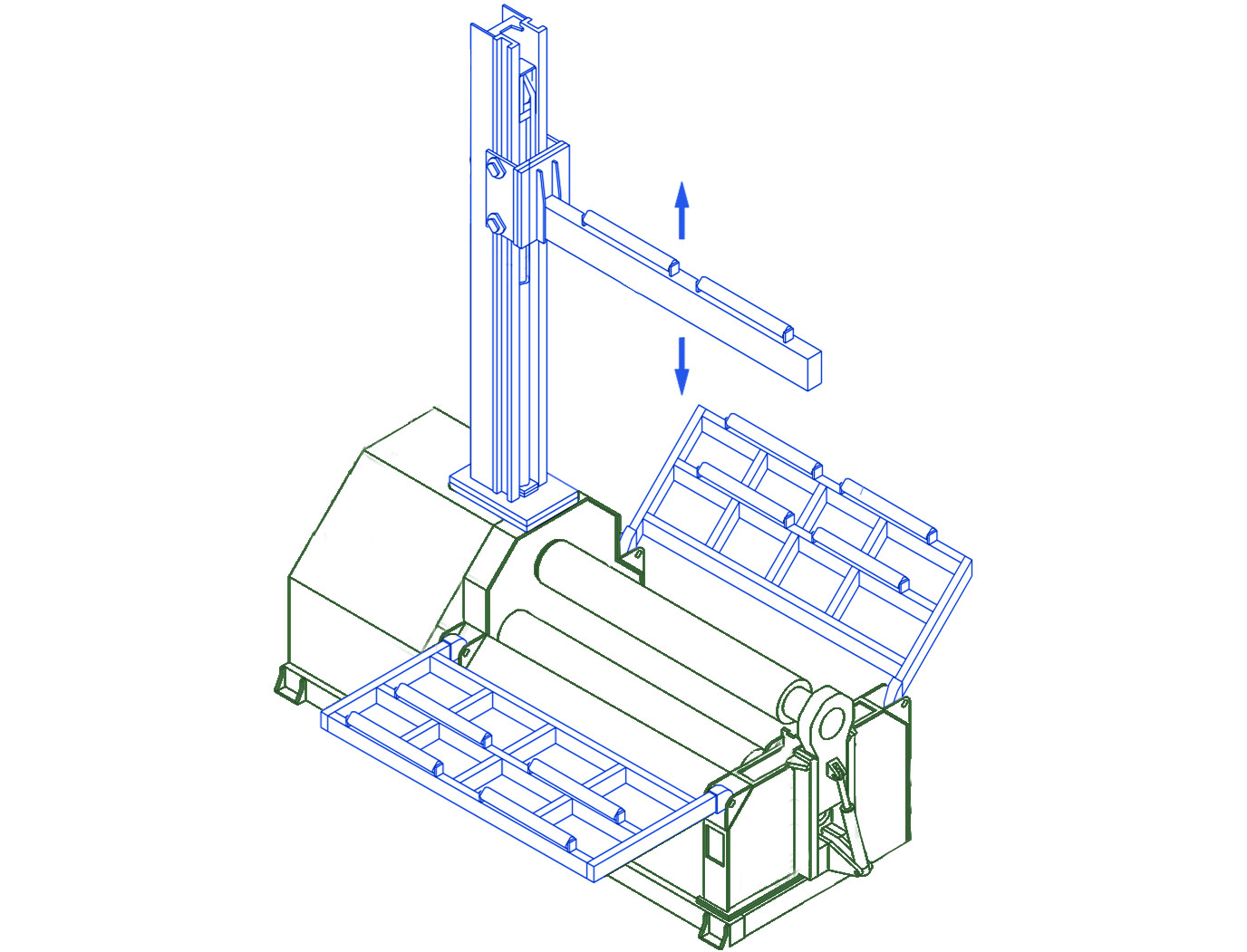

4.3Pre-Clamping / Pre-Bending

Before actual bending begins, operators often use a pre-clamping or pre-bending technique to slightly bend the edges of the plate inward. This step helps create a smoother bending process and prevents wrinkling or edge defects, ensuring a natural transition between flat and curved surfaces. It also minimizes strain on the plate, reducing deformation risk and improving the overall precision of the bend.

4.4Bending Process

Once the force is set, the plate is secured, and pre-bending is completed, the bending operation can begin. The operator activates the rolling machine, and pressure is applied uniformly as the plate passes through the rollers, gradually forming it into the desired shape. Fine-tuning may be performed during this process to meet dimensional specifications. With each pass, the plate undergoes controlled deformation, resulting in a smooth and consistent curvature. Due to the complexity of this process, experienced operators are recommended to ensure efficiency and precision.

5.0Pre-Bending: Four Key Reasons to Choose a Rolling Machine with This Feature

5.1Eliminate Waste

Pre-bending ensures precise alignment of both ends of the material, significantly minimizing scrap. By creating an optimal geometric shape for rolling, it reduces unnecessary material loss. Skilled operators play a vital role in executing pre-bending to maximize material utilization.

5.2No Additional Trimming Required

In high-efficiency production environments, every resource counts—especially materials used for trimming. Pre-bending both ends of the material ensures proper alignment, eliminating the need for post-rolling trimming. This saves both time and material.

5.3Time Savings

In large-scale manufacturing, time equals money. Every minute of delay increases production costs. Pre-bending helps operators form the desired shape more quickly, reducing operation time per sheet. This results in more parts produced within the same timeframe, boosting overall efficiency.

5.4Smooth Curves with Consistent Radius and Thickness

Pre-bending is essential for achieving high-quality rolling results. It ensures the surface remains smooth while maintaining uniform curvature and material thickness. Proper pre-bending enhances forming accuracy and minimizes downstream processing issues, ensuring the final product meets stringent quality standards.

6.0Which Plate Rolling Machine Is Right for Your Project?

Choosing the right plate rolling machine depends on your production needs, material thickness, desired curvature, and budget. Below is a breakdown of common types of plate rolling machines and their features:

6.13-Roll Initial Pinch Plate Rolling Machine

Ideal for light-duty applications, available in mechanical or hydraulic versions. The plate is clamped between two vertical rolls, while a third offset roll moves upward to bend the plate to the desired radius. Commonly used for small-scale production but requires more manual labor for larger volumes.

6.2Double Pinch Plate Rolling Machine

Suitable for a wide range of capacities from light to heavy-duty. Available in both 3-roll and 4-roll configurations, typically featuring a fixed top roll and two adjustable side rolls. This design eliminates the need to remove and reposition the plate, enhancing production efficiency—especially for medium-thickness materials.

6.34-Roll Plate Rolling Machine

Features an additional roll below the top roll for continuous clamping. This machine can perform pre-bending, rolling, and finishing in the same direction, greatly increasing efficiency. It is ideal for high-volume production, particularly with thicker plates.

6.43-Roll Plate Rolling Machine

A versatile option for general applications. Typically requires pre-bending the leading edge before rolling. The rolls change direction during the process. Though slightly slower than 4-roll machines, it features a simpler mechanical design.

6.52-Roll Plate Rolling Machine

Designed for thin sheets, these machines use large-diameter polyurethane-coated rolls to quickly form plates into small-diameter cylinders. Best suited for high-speed, specialized production with limited forming capabilities.

6.6Manual Plate Rolling Machine

Used for small-scale operations and light materials. Offers low cost and simple operation, ideal for basic rolling tasks and hobby-level production.

6.7Hydraulic Plate Rolling Machine

Powered by a hydraulic system, this type is capable of handling heavy loads and achieving high precision. Widely used in large-scale manufacturing and for rolling thicker materials.

📩 Want to learn more about selecting and configuring metal plate rolling machines? Contact ALEKVS for expert consultation!

7.0Applications of Plate Rolling Machines

Plate rolling machines are widely used across various industries. Here are some common applications:

- Automotive Industry: Used to produce body components such as doors, hoods, and trunk lids, as well as structural elements like frames and beams.

- Aerospace Industry: Applied in manufacturing aircraft components such as wing skins, fuselage panels, and engine casings.

- Home Appliance Industry: Essential for forming parts used in refrigerators, ovens, and washing machines—such as doors, casings, and structural panels.

- Construction Industry: Plays a key role in the production of metal roofing, wall cladding, and structural building components.

- Electronics Industry: Used to fabricate components for electronic devices, including circuit boards, connectors, and precision metal enclosures.

8.0How to Build a Manual Plate Roller Using Scrap Metal ?