- 1.0Why Is 6063 Aluminum Alloy So Popular in Manufacturing?

- 2.0Mechanical Properties of 6063 Aluminum Alloy

- 3.0Chemical Composition of 6063 Aluminum Alloy

- 4.0Common Applications of 6063 Aluminum Alloy

- 5.0How Does 6063 Compare to Other Common Aluminum Alloys?

- 6.0Key Preparations Before Machining: Residual Stress Control

- 7.0How to Machine (Cut) 6063 Aluminum Alloy Efficiently

- 8.0How to Weld 6063 Aluminum Alloy Properly

- 9.0How to Heat-Treat 6063 Aluminum Alloy

- 10.0How to Ensure High Surface Quality for 6063 Aluminum Alloy

- 11.0Frequently Asked Questions (FAQ)

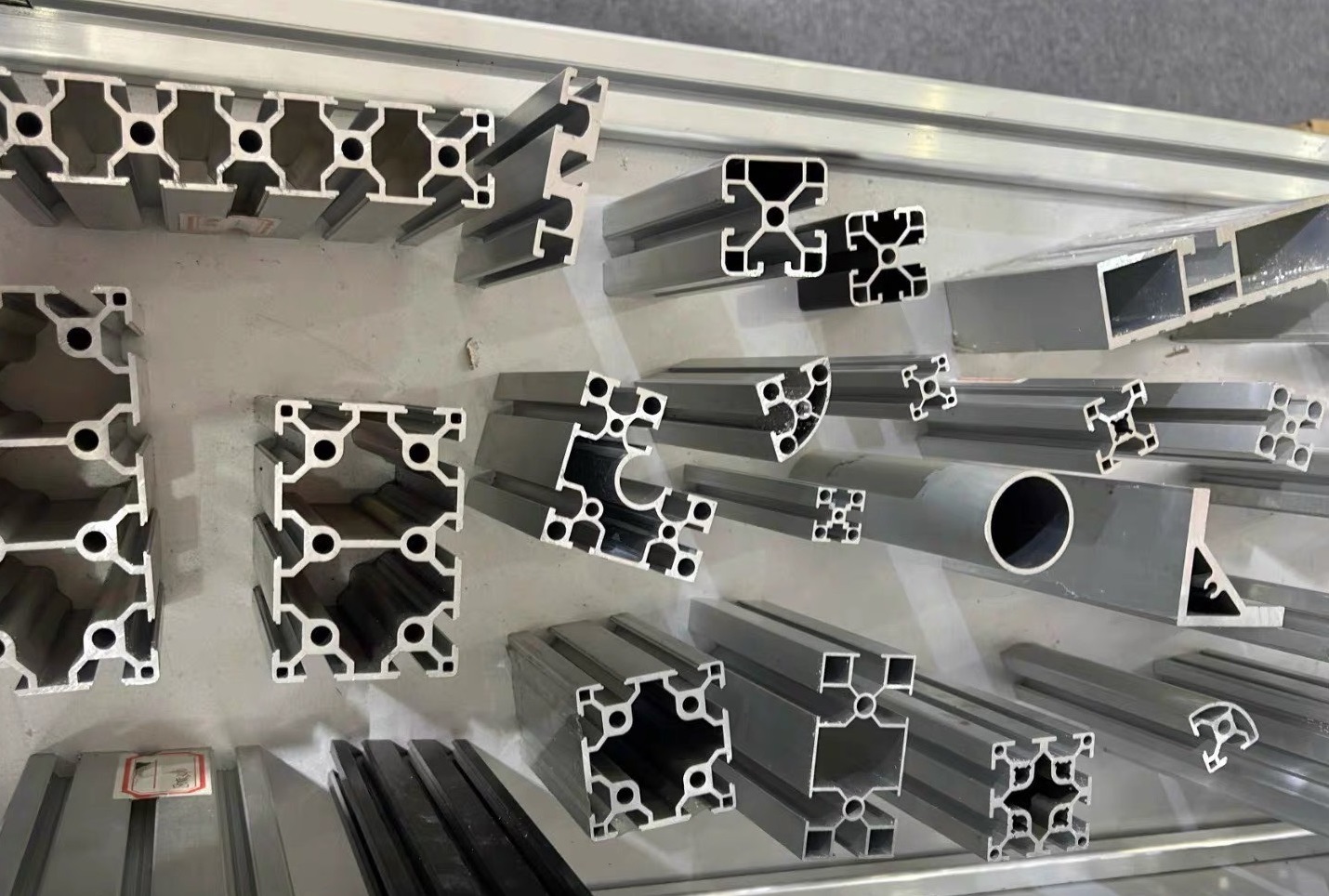

6063 aluminum alloy is also part of the aluminum-magnesium-silicon (Al-Mg-Si) family and is a heat-treatable alloy specifically engineered for extrusion. Its key advantages include excellent extrudability, superior surface finish, and strong corrosion resistance. After processing, it delivers a uniform and attractive appearance, making it a preferred material for architectural profiles and decorative components. It is also widely used in industrial framing systems and electronic equipment housings.

Through tempers such as T5 and T6, 6063 achieves a balance of medium strength and good formability, making it especially suitable for high-volume production of complex cross-section profiles.

1.0Why Is 6063 Aluminum Alloy So Popular in Manufacturing?

6063 has become one of the most widely used aluminum profile alloys due to its performance optimization for forming and decorative applications:

- Extrudability: Outstanding extrudability enables the production of complex profile shapes with high efficiency

- Surface finish: Excellent surface quality with uniform, high-quality color after anodizing

- Corrosion resistance: Strong corrosion and oxidation resistance, ideal for outdoor decorative and structural components

- Weldability: Good welding performance with minimal deformation, supporting easy assembly

- Cost efficiency: Moderate cost, stable large-scale supply, and strong overall value

- Machinability: Low cutting difficulty and convenient post-processing

Its low impurity content and uniform metallurgical structure allow it to strike an ideal balance between aesthetics and structural stability, making it particularly suitable for applications such as building façades and window-and-door systems where appearance and weather resistance are critical.

2.0Mechanical Properties of 6063 Aluminum Alloy

(Note: Specific values vary depending on temper.)

- Tensile strength (T6): 210–260 MPa

- Yield strength (T6): ~170 MPa

- Elongation: 12–18%

- Hardness: 70–85 HB

- Density: 2.70 g/cm³

- Melting range: 607–650°C

Property Differences by Temper

- 6063-O: Lowest strength (tensile strength ≈ 110 MPa) with excellent ductility; suitable for deep bending, stretching, and other heavy-forming operations

- 6063-T5: Medium strength with higher production efficiency due to on-line aging; suitable for mass-produced profiles

- 6063-T6: Highest strength achieved through artificial aging; used in applications requiring enhanced structural performance

3.0Chemical Composition of 6063 Aluminum Alloy

| Composition | Al 2024 | Al 7075 | Al 6061 | Al 6063 |

|---|---|---|---|---|

| Cu (%) | 3.847 | 1.276 | 0.192 | ≤0.10 |

| Mg (%) | 1.545 | 2.596 | 1.074 | 0.45–0.9 |

| Si (%) | 0.041 | 0.000 | 0.439 | 0.20–0.6 |

| Fe (%) | 0.223 | 0.329 | 0.307 | ≤0.35 |

| Mn (%) | 0.331 | 0.028 | 0.103 | ≤0.10 |

| Zn (%) | 0.017 | 5.135 | 0.105 | ≤0.10 |

| Sb (%) | 0.046 | 0.061 | 0.063 | — |

| V (%) | 0.015 | 0.011 | 0.014 | — |

| Pb (% or ppmᵃ) | 0.024, % | 0.000, ppm | 54.451, ppm | — |

| Sn (% or ppm) | 0.021, % | 0.013, % | 81.046, ppm | — |

| Ti (% or ppm) | 90.791, ppm | 0.010, % | 83.090, ppm | ≤0.10 |

| Cr (% or ppm) | 99.931, ppm | 0.279, % | 0.025, % | ≤0.10 |

| Zr (ppm) | 8.746 | 0.000 | 3.584 | — |

| Ni (ppm) | 60.653 | 48.240 | 76.797 | — |

| Al (%) | The rest | The rest | The rest | Balance |

The composition of 6063 supports Mg₂Si precipitation strengthening, though the Mg:Si ratio may vary slightly by batch. Low iron and low copper levels are critical factors contributing to its superior surface quality.

4.0Common Applications of 6063 Aluminum Alloy

- Architectural doors and windows, curtain wall profiles, sunroom framing

- Interior decorative profiles (ceilings, partitions, baseboards)

- Industrial conveyor line structures and equipment safety guards

- Furniture components (table and chair frames, cabinet edging)

- Electronic housings and heat-sink profiles

- Automotive trim and roof racks

- Exhibition structures and lightbox frames

5.0How Does 6063 Compare to Other Common Aluminum Alloys?

| Alloy | Strength | Workability (Extrusion) | Weldability | Corrosion Resistance | Surface Quality | Key Characteristics |

| 6063 | Medium | Excellent | Excellent | Excellent | Excellent | Preferred extrusion alloy with strong decorative appeal |

| 6061 | Medium–High | Good | Very Good | Excellent | Good | Balanced properties for structural applications |

| 7075 | Very High | Poor | Poor | Good | Fair | Aerospace-grade high-strength alloy |

| 5052 | Medium | Average | Good | Excellent | Good | Primarily used for sheet and plate processing |

6063’s core advantage lies in its extrudability and surface finish, which significantly surpass other alloys, making it irreplaceable in architectural and decorative applications.

6.0Key Preparations Before Machining: Residual Stress Control

Residual stress in 6063 extruded profiles mainly originates from cooling after extrusion. Complex or thin-wall sections are prone to deformation when stress is released during machining. Recommended practices:

- Allow natural or artificial aging after extrusion to reduce internal stress

- Leave profiles to rest for 24 hours after rough machining before finishing

- Use multi-point, evenly distributed clamping to avoid localized stress

- Follow a “symmetrical machining” approach to minimize one-sided cutting forces

7.0How to Machine (Cut) 6063 Aluminum Alloy Efficiently

With lower hardness and higher ductility than 6061, 6063 provides reduced cutting resistance but is more prone to built-up edge and tool adhesion. To achieve consistent performance—especially when using an Aluminium Cutting Machine —tool selection and cutting parameters must be carefully optimized

7.1Recommended Tools and Inserts:

- Carbide tools (preferred):

2-flute or 3-flute end mills with a high rake angle (15°–20°) and enlarged chip flutes. - Coatings:TiB₂ and DLC offer excellent anti-adhesion properties. TiN is more prone to sticking but can still be effective for light-load or short-cycle machining.

High cutting speeds, sharp edges, and adequate cooling are essential, especially on automated Aluminium Cutting Machines. - HSS tools:

Suitable for light-duty operations such as basic drilling - Drills:

Parabolic flute geometries improve chip evacuation and reduce clogging.

7.2Recommended Cutting Parameters (Reference Range):

| Process | Cutting Speed Vc | Feed Rate | Cutting Depth | Notes |

| Milling | 300–500 m/min | 0.05–0.2 mm/tooth | 1–5 mm | Coolant/lubricant required |

| Turning | 250–400 m/min | 0.2–0.4 mm/rev | 1–3 mm | Avoid low-speed cutting |

| Drilling | 80–150 m/min | 0.08–0.25 mm/rev | Adjust as needed | Step drilling + coolant for deep holes |

| Tapping | 10–20 m/min | Thread pitch | — | Use aluminum-specific taps + tapping oil |

These ranges work well for both manual setups and CNC-equipped Aluminium Cutting Machines, ensuring stable machining quality.

7.3Machining Notes:

- Cooling/Lubrication:

Use emulsions or aluminum-specific cutting fluids with EP additives to minimize tool adhesion and extend tool life—especially important for high-RPM aluminium-cutting equipment. - Tool Condition:

Keep cutting edges sharp and regrind when needed to prevent smearing or compressing the soft 6063 material. - Cutting Method:

Prefer climb milling to reduce burr formation and surface scratches. - Avoid Tool Dwell:

Do not let the tool pause on the workpiece surface to prevent indentation marks. - Thin-Wall Parts:

Use soft jaws, vacuum fixtures, or additional supports to prevent deformation during cutting, particularly when processed on fast-feed Aluminium Cutting Machines.

8.0How to Weld 6063 Aluminum Alloy Properly

6063 offers better weldability than 6061, with less distortion in the heat-affected zone (HAZ). However, strength loss in the weld and HAZ can reach 20–50% (typically around 30%), depending on base-material temper, welding method, and heat input. Post-weld aging or strength-compensation design may be required.

8.1Common Welding Methods

- TIG welding: Preferred for precise, clean weld appearance with minimal distortion; ideal for decorative components

- MIG welding: High efficiency; suitable for thick-wall profiles or mass production

- Common filler wires: ER4043 (good fluidity and weld appearance), ER5356 (higher strength)

8.2Welding Techniques

- Pre-weld preparation: Remove the oxide layer (Al₂O₃) using a stainless-steel brush or chemical degreaser until a metallic sheen is visible

- Shielding gas: Pure argon (≥99.99%), 8–12 L/min

- Preheating: For thickness >8 mm, preheat to 100–150°C to avoid cold cracking

- Welding parameters: Use low current and fast travel speeds to minimize HAZ width

- Post-weld treatment: Allow natural cooling; T6 re-aging may be applied if higher strength is required

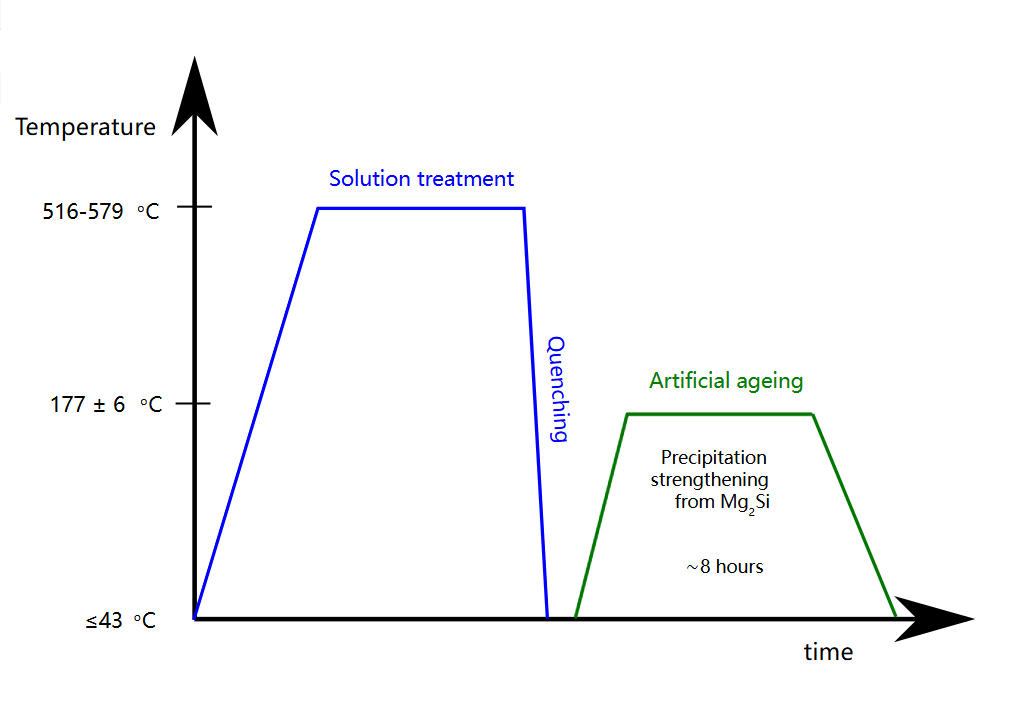

9.0How to Heat-Treat 6063 Aluminum Alloy

The core objective of heat treatment for 6063 is to optimize Mg₂Si precipitation, balancing strength with extrudability.

9.1Solution Treatment

- Heating temperature: 530–540°C (lower than 6061 to prevent grain growth)

- Holding time: 1–2 hours depending on section thickness

- Quenching: Water quench with a cooling rate ≥150°C/min to prevent premature precipitation

9.2Aging Treatment

- T6 artificial aging: 170–180°C for 8–12 hours, air cooling

- T5 on-line aging: Temperature controlled through cooling tanks after extrusion; 150–170°C for 4–6 hours, high efficiency

- Natural aging: 7–14 days at room temperature; final strength reaches ~70–80% of T6, suitable when high strength is not required

10.0How to Ensure High Surface Quality for 6063 Aluminum Alloy

6063 is considered an ideal substrate for anodizing, and surface treatment quality directly influences final product value.

10.1Common Surface Treatments

- Anodizing (clear, dyed, electrophoretic): Most common; enhances corrosion resistance and appearance

- Hard anodizing: 20–50 μm coating thickness for improved wear resistance in industrial applications

- Sandblasting and brushing: Creates matte or textured finishes and masks minor scratches

- Powder coating: Wide color range with strong weather resistance for outdoor components

- Polishing: Provides a mirror finish for premium decorative uses

10.2Surface Treatment Notes

- Pre-treatment is critical: thorough degreasing (alkaline cleaner), neutralizing, and chemical polishing to remove oxide film and contaminants

- During anodizing, avoid excessive current density to prevent rough or uneven coating

- Control extrusion die temperature to avoid surface defects such as dark lines and scratches

- Prevent contact with corrosive substances during storage to avoid discoloration

11.0Frequently Asked Questions (FAQ)

Is 6063 suitable for extruding complex profile shapes?

Yes. 6063 offers excellent flow characteristics during extrusion and supports thin-wall sections (in some processes below 1.2 mm). Final wall thickness and complexity depend on profile geometry, die design, and extrusion conditions, making it one of the best alloys for complex profiles.

Which alloy anodizes better—6063 or 6061?

6063 performs better. Its low iron and copper content results in a more uniform oxide layer, consistent coloring, and superior surface brightness, especially for light-colored decorative finishes.

What is the key difference between 6063 T5 and T6 tempers?

- T5: On-line aging, high production efficiency, lower cost, medium strength (tensile ≈210 MPa); suitable for standard door/window profiles

- T6: Artificial aging, higher strength (tensile ≈260 MPa), less deformation; ideal for structural applications or strength-critical components

How can tool sticking be prevented when machining 6063?

Focus on high cutting speed + sufficient cooling + sharp tooling: cutting speed ≥300 m/min, aluminum-specific cutting fluid, regularly sharpened tools, and avoidance of low-speed heavy-load machining.

Can 6063 be used in outdoor environments?

Yes. Its corrosion resistance, combined with anodized protection, provides long-term durability for many years. In coastal or heavily polluted environments, additional protection or periodic maintenance is recommended.

Reference

https://en.wikipedia.org/wiki/6063_aluminium_alloy

https://www.gabrian.com/6063-aluminum-properties/

https://www.metalexchange.com/press/6063-aluminum