1.0Steel Coil Definition

Steel is widely used in manufacturing, engineering, and construction due to its high tensile strength, flexibility, and low cost. Among its many forms, steel coil is one of the most common and widely used.

A steel coil is a cylindrical roll of steel sheet produced by hot or cold rolling to a specific thickness, then wound into coils for easier transportation, storage, and further processing. During production, steel slabs are passed through continuous rolling mills, reduced into thin sheets, and then coiled. The surface of steel coils can be smooth or ribbed, offering good ductility and strength.

1.1Common Production Processes of Steel Coils

Cold rolling is especially suitable for stainless steels such as 304 and 316 grades, which require excellent surface finish, dimensional accuracy, and corrosion resistance for use in demanding applications.

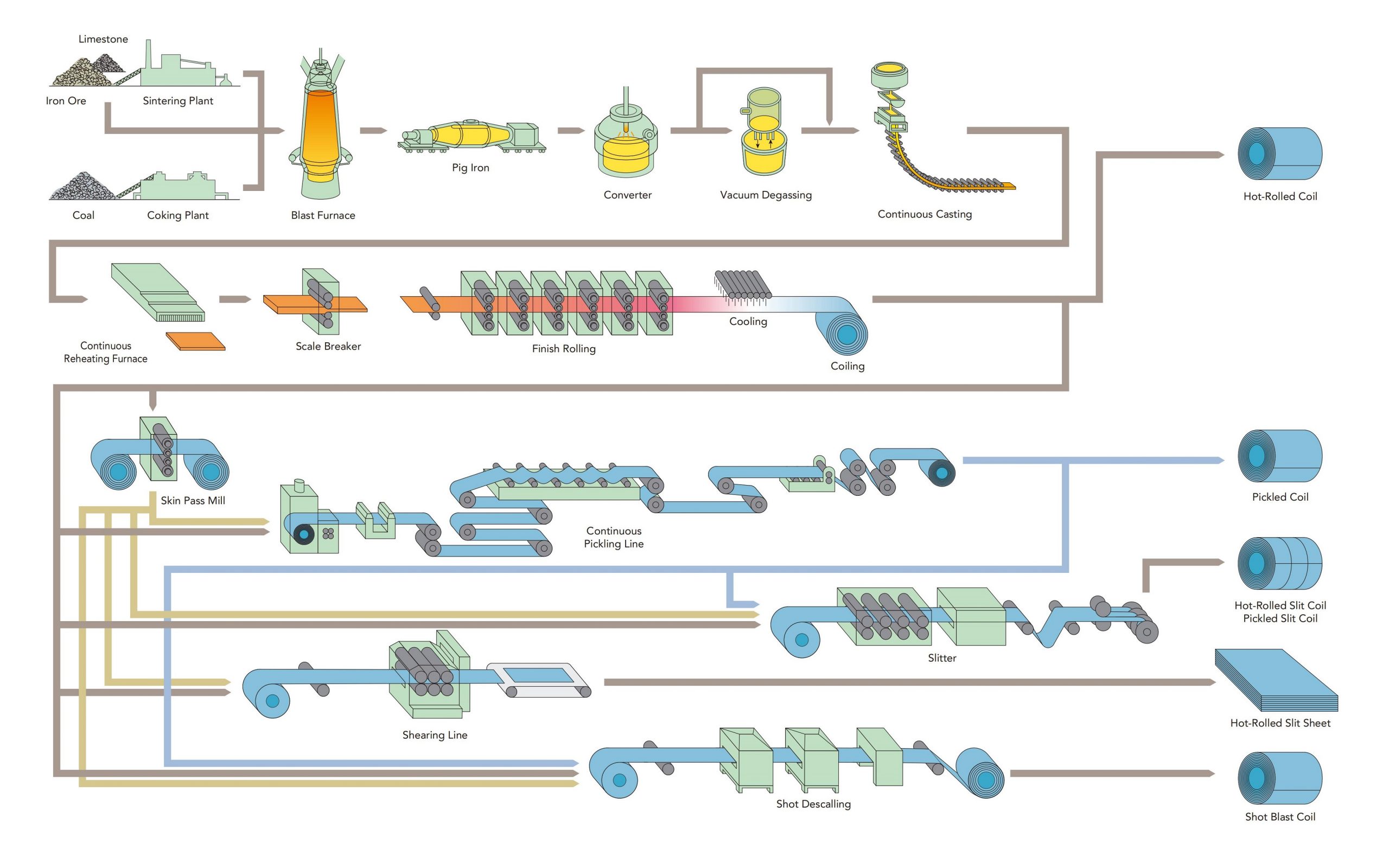

Steel coil production involves several key processes, each affecting the coil’s properties and applications:

- Hot Rolling:Steel slabs are heated above the recrystallization temperature (around 1100°C) and passed through rolling mills to reduce thickness before being coiled.

- Features: High production efficiency, lower cost, suitable for thicker coils. Surface usually has scale, with lower dimensional accuracy.

- Applications: Construction, bridges, and machinery where tight tolerances are not required.

- Cold Rolling:Hot rolled coils are further rolled at room temperature to reduce thickness and improve surface quality and precision.

- Features: Smooth surface, tighter dimensional tolerances, increased strength and hardness. Suitable for precision applications.

- Applications: Automotive, home appliances, and electronics requiring high surface quality.

- Annealing:Cold rolled coils are heated and slowly cooled to improve ductility and toughness while relieving internal stress.

- Purpose: Enhances formability and makes the material easier to process in stamping or shaping operations.

- Surface Treatment:Processes like galvanizing or electro-tinning are used to enhance corrosion resistance and expand usage.

- Features: Improved durability and corrosion resistance, ideal for industries with special environmental or performance requirements

1.2Comparison of Different Types of Steel Coils: Definitions, Features & Applications

Among cold rolled and galvanized coils, 304 and 316 stainless steels are commonly used when superior corrosion resistance and hygiene standards are required, such as in food processing, marine, and medical equipment.

The table below outlines the definitions, key characteristics, and typical applications of common steel coil types. This comparison helps identify the most suitable coil for specific needs, offering guidance for material selection and application optimization.

| Steel Coil Type | Definition | Key Characteristics | Typical Applications |

| Cold Rolled Steel Coil (CR) | Further rolled hot rolled steel at room temperature; smooth surface, high dimensional accuracy. | Smooth surface, no mill scale; tight dimensional tolerance; high strength, slightly lower ductility. | Automotive body panels, home appliance panels, precision sheet metal parts. |

| Hot Rolled Steel Coil (HR) | Steel billet heated to high temperature, rolled, then cooled and coiled. | Low cost; rough surface with mill scale; good plasticity; suitable for welding. | Building structures, bridge components, welded steel pipes. |

| Advanced High-Strength Steel (AHSS) | High strength steel with good ductility used for lightweight structures. | High strength, impact resistant; good formability. | Automotive structural parts, crash energy absorption components. |

| Galvanized Steel Coil | Steel coil coated with zinc to enhance corrosion resistance. | Strong rust resistance; good weatherability; smooth surface. | Building facades, ventilation ducts, automotive parts. |

| Electrolytic Tinplate (ETP) | Steel coil coated with tin, commonly used in food packaging. | Corrosion resistant; food-safe; easily formed into cans and containers. | Food cans, beverage can lids, metal packaging materials. |

1.3Steel Coil Grades and Performance

The performance of steel coils depends on the grade of steel used. Different grades have varying mechanical and chemical properties.

| Common Steel Coil Grades / Designations (Chinese Standard) | ASTM Equivalent Grades | Type | Description |

| AHSS, DP600, DP800, TRIP780 | A1008 CS / A1011 HSLA | Cold Rolled High-Strength Steel | High strength, good formability, energy absorption for safety |

| Q235B, Q355B, Fe 415, Fe 500 | A36, A572 Gr.50 | Hot Rolled Structural Steel | High load-bearing, good weldability, durable with corrosion treatment |

| DC01, DC03, SPCC | A1008 (CS Type B) | Cold Rolled Low Carbon Steel | Smooth surface, easy stamping, good ductility |

| Q345R, 16MnR | A516 Gr.70, A285 | Hot Rolled Medium-Thickness Plate Steel | Good pressure resistance, suitable for welding |

| A/B/D grade ship plate steel | ASTM A131 A/B/D | Hot Rolled Shipbuilding Steel | High strength, corrosion resistant, fatigue resistant |

| 45#, 40Cr, S235JR | A36, AISI 1045, AISI 5140 | Hot Rolled / Cold Rolled Carbon Steel | Moderate strength, easy to machine |

| Q195, Q215, Q235, SGCC | A653 (G90, Commercial Quality) | Hot Rolled / Galvanized Steel Coil | Weldable, good corrosion resistance (galvanized) |

| MR, SPTE (Tinplate) | ASTM A623 (ETP Steel) | Electrolytic Tinplate (ETP) | Tin-coated surface, corrosion resistant, food safe |

Advantages of Steel Coils

Steel coils offer multiple benefits, making them popular across various industries:

- High durability

- Excellent heat resistance

- Low maintenance costs

- Easy to transport and process

- Cost-effective with great value

- Can be uncoiled, cut, and slit as needed

1.4Difference Between Steel Coils and Steel Plates

Unlike steel plates, which remain flat, steel coils are continuous sheets wound into cylindrical rolls. This form simplifies transportation and allows flexible processing such as uncoiling, slitting, and cutting, greatly improving efficiency and versatility.

1.5Applications of Steel Coils

Thanks to their excellent physical and chemical properties, steel coils are widely used in electronics, automotive, construction, packaging, machinery, and energy sectors. They meet demands for strength, heat resistance, corrosion resistance, and precision processing. Their recyclability and cost efficiency make steel coils essential in modern manufacturing.

| Industry | Application Description | Key Features & Advantages |

| Electronics | Manufacturing CPU shells, phone cases, heat sinks, cores, circuit boards, and other components. | High melting point, heat resistant, easy to form, low maintenance costs |

| Automotive | Used in bodies, chassis, doors, exhausts, dashboards, rims, engine parts, suspension components. | High strength-to-weight ratio, heat resistant, non-flammable, recyclable, supports lightweight safety designs |

| Metal Stamping | For cutting, slotting, flanging, hot & cold stamping, producing precise metal parts for automotive, industrial, construction, and food & beverage sectors. | Good ductility, easy forming, high tolerance, ideal for precision parts |

| Pipe Manufacturing | Steel coils are rolled into seamless pipes for gas, heating, and plumbing applications. | High strength, corrosion resistance, continuous forming, no welding needed |

| Railway Industry | Carbon steel coils used to make train wheels and parts, leveraging high flexibility for safe operation. | High flexibility, wear resistant |

| Construction | Used for metal roofs, wall panels, decks, pipes, rebar, beams, and trusses. Coils are cut to size for structural and facade applications. | High strength, corrosion resistant, easy to process, cost-effective |

| Packaging | Used for metal cans, bottle caps, steel drums, and steel strips. Surface treated for corrosion resistance and safety. | Strong corrosion resistance, durable, safe |

| Consumer Goods | Manufacture of household appliances (fridges, washers), furniture, tools, sports equipment, and hardware. | Flexible forming, high strength, durable |

| Machinery | Producing machine frames, bearings, gears, springs, engine parts, and more due to good formability and strength. | Flexible forming, high strength, versatile |

| Energy & Electrical | Used in wind turbines, power lines, boiler tubes, pressure vessels, solar panels, transformers, and motors. |

2.0What is Hot Rolled Steel Coil?

Hot rolled steel coil is produced by rolling heated steel billets at high temperatures to the desired thickness. It is commonly used where precision is not critical and larger sizes or thicker plates are needed, such as in construction and railway tracks.

2.1Overview of the Hot Rolling Process

Hot rolling involves processing steel billets at temperatures above 1,700°F (about 927°C), which is higher than the steel’s recrystallization temperature, making it easier to shape. The process includes:

- Heating the steel billets to high temperatures;

- Passing them repeatedly through rollers to reduce thickness;

- Cooling the plates naturally, then coiling into rolls or cutting into sheets and bars.

Because the steel cools naturally, slight shrinkage and deformation can occur, resulting in lower dimensional accuracy.

2.2Typical Characteristics of Hot Rolled Steel

- Scaly surface: often covered with oxide scale, removable by pickling or sandblasting;

- Rounded edges: edges are slightly blunt due to thermal expansion and contraction;

- Slight warping: may distort during cooling;

- Good ductility: easy to form into various shapes;

- Low dimensional accuracy: not suitable for precision components;

- Stress-free: natural cooling avoids residual stresses from quenching or work hardening.

3.0What is Cold Rolled Steel?

Cold rolled steel coil is produced by further processing hot rolled steel at room temperature, resulting in higher precision and superior surface quality. The process may also include annealing and tempering, yielding thinner, more flexible steel widely used in applications requiring tight tolerances and fine surfaces.

3.1Cold Rolling Process

Cold rolled steel is made by rolling fully cooled hot rolled steel at ambient temperature. The process includes:

- Cold rolling the metal sheet between rollers;

- Additional finishing processes such as machining, grinding, and polishing to improve dimensional accuracy and surface finish.

3.2Typical Features of Cold Rolled Steel Coil

- Smooth surface with slightly oily feel;

- Sharp, clear edges with tighter dimensional tolerances;

- Square strips and tubes with good concentricity and straightness;

- Uniform structure and excellent appearance.

3.3Performance Advantages of Cold Rolled Steel

- Higher strength: approximately 20% stronger than hot rolled steel, suitable for high-stress applications;

- Greater accuracy: dimensionally stable after forming, minimal secondary processing needed;

- Superior surface: bright, rust-free, no oxide scale, ideal for applications with high surface demands;

- Good ductility: excellent plasticity, suitable for moderate stretching.

4.0What is the Weight of a Steel Coil?

The weight of a steel coil is usually measured in tons or pounds. It is calculated by multiplying the length, width, and thickness of the coil by the density of the steel. Since different steel grades have slightly different densities, the weight of steel coils can vary. Accurately knowing the weight helps with transportation planning and cost control.

Weight calculation formula:

Weight=Length×Width×Thickness×Steel Density

- Length, width, and thickness refer to the coil’s dimensions, typically measured in meters or millimeters.

- Steel density is generally about 7.85 g/cm³ (or 7850 kg/m³), but can vary slightly depending on the steel grade.

Example:

A steel coil with length 10 m, width 1 m, and thickness 0.005 m (5 mm) weighs approximately:

10×1×0.005×7850=392.5 kg

Therefore, the steel coil weight can differ significantly depending on its size and material. Understanding coil weight is essential for transportation, storage, and production planning.

5.0Steel Coil Transportation and Measurement

Transportation

Due to their heavy weight and large volume, steel coils require careful handling during transport. Within factories or warehouses, cranes and forklifts are commonly used. For long-distance transport, specialized flatbed trucks, trains, or ships designed for steel coils are employed. Because coils are cylindrical, they must be securely fastened using straps, steel cables, or other restraints to prevent rolling or shifting during transit, ensuring safety.

Dimension Measurement

Steel coil size is typically described using the following parameters:

- Width: The flat width of the unrolled steel sheet, which determines the maximum transverse size of the material.

- Thickness: The thickness of a single steel layer, usually measured in millimeters or inches.

- Length: The total length when the coil is fully unrolled, used to estimate the amount of steel available.

- Outer Diameter (OD): The diameter of the coil’s outermost layer, which affects handling and machine compatibility.

- Inner Diameter (ID): The diameter of the coil’s core, important for equipment compatibility and transport stability.

6.0Steel Coil FAQs: Safety, Temperature, Types, and Uses Explained

Why are steel coils so dangerous?

Because of their heavy weight, large size, and stored tension. Mishandling can cause serious injury or damage.

How hot are steel coils?

Hot rolled steel coils reach over 1,700°F (927°C) during production.

How are steel coils unrolled?

They’re unrolled with a decoiler machine that unwinds the coil in a controlled way for cutting or processing.

What is galvanized steel coil?

A steel coil coated with zinc to resist corrosion, often used in construction and outdoor products.

What is cold rolled steel used for?

Used in automotive, appliances, and electronics where high precision and smooth surfaces are required.

References:

https://www.reliance-foundry.com/blog/hot-vs-cold-rolled-steel?srsltid=AfmBOopy_YcPYfcWO9YFZWDGLkONTyVYDxRils2WuUCzVTzKJRc0lz1H

https://blog.tatanexarc.com/da/steel-coil-definition-and-classification/