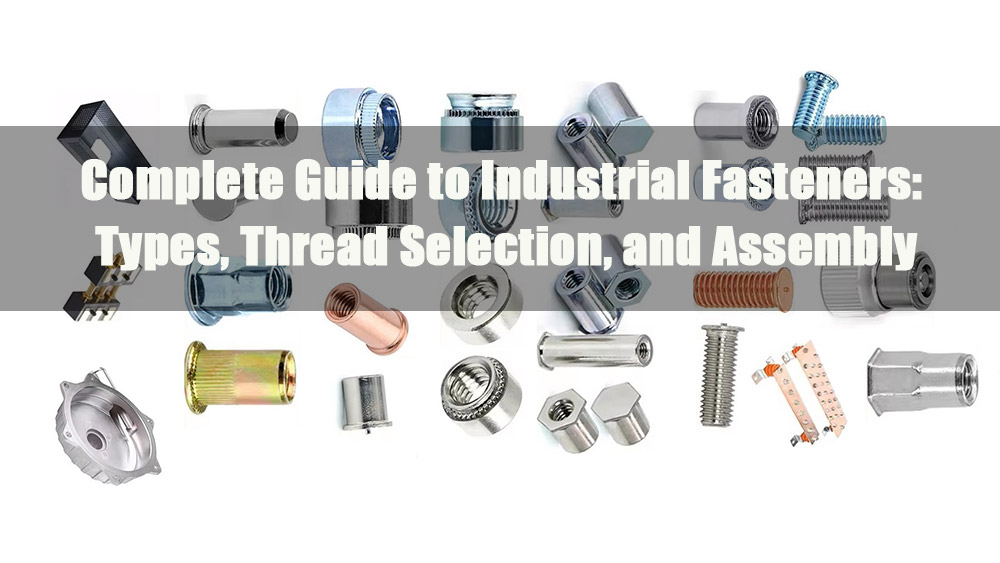

- 1.0How Are Fasteners Classified: Types and Functional Adaptations

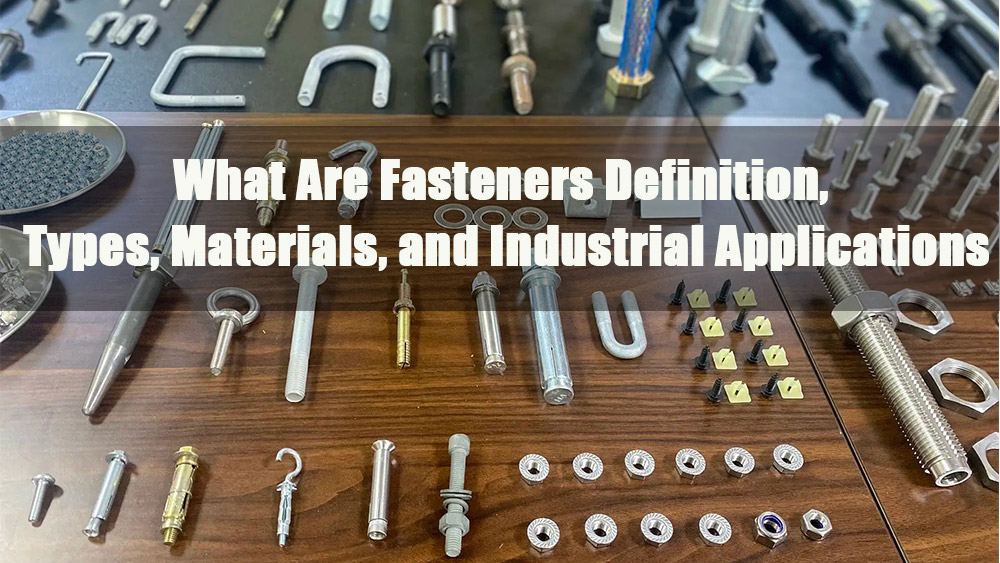

- 2.0How Fastener Materials and Surface Treatments Enhance Performance

- 3.0How Fasteners Are Manufactured: Core Production Processes

- 4.0Industrial Applications of Fasteners

- 5.0Failure Analysis and Quality Control of Fasteners

- 6.0Fastener Selection and Installation Standards

- 7.0Frequently Asked Questions (FAQ)

- 8.0Conclusion

1.0How Are Fasteners Classified: Types and Functional Adaptations

1.1Threaded Fasteners: The Standardized Connection Type

Threaded fasteners are designed based on the principle of helical motion, where precise engagement between internal and external threads produces the tightening effect. Representing more than 75% of the global fastener market, they include several major categories:

Bolts:

- Basic Structure: Consist of a head and a threaded shank, typically used with nuts. Classified by strength grades such as 4.8, 8.8, 10.9, and 12.9, where grades above 8.8 are high-strength bolts used in heavy-duty applications.

- Common Types and Applications:

- Hex Head Bolt: Features a hexagonal head and either a full or partial thread. Grade 8.8 bolts are widely used in steel structure joints, while Grade 12.9 bolts—with superior tensile strength—are suited for engine blocks and other high-load assemblies.

- Carriage Bolt: Designed with a round head and a square neck under the head, which locks into the material during installation to prevent rotation. Ideal for securing wooden structures and metal fittings.

- Flange Bolt: Integrates a circular flange with serrations under the head to distribute load evenly without a washer. Commonly used in automotive chassis and piping systems, reducing vibration loosening by up to 50%.

- Stud Bolts and U-Bolts: Stud bolts are used for connecting thick plates or anchoring machine bases, while U-bolts are designed for clamping cylindrical parts such as pipes and tubes.

Screws:

- Core Characteristics: Unlike bolts, screws do not require nuts and can be directly driven into threaded or self-tapped holes. They are among the most widely used fasteners in manufacturing.

- Common Types and Applications:

- Self-Tapping Screw: Features a sharp, triangular thread that cuts its own mating threads into materials such as plastic or thin steel sheets, ideal for lightweight assemblies.

- Machine Screw: Fully threaded and used with pre-tapped holes. For instance, M2.5 pan head machine screws are commonly used for securing printed circuit boards, with torque limited to 0.8–1.2 N·m to prevent damage.

- Socket Head Cap Screw: Incorporates a recessed hex socket for high torque application in confined spaces such as molds and precision machinery.

- Special-Purpose Screws: Include tamper-resistant and thermal-control screws used in security systems and electrical enclosures.

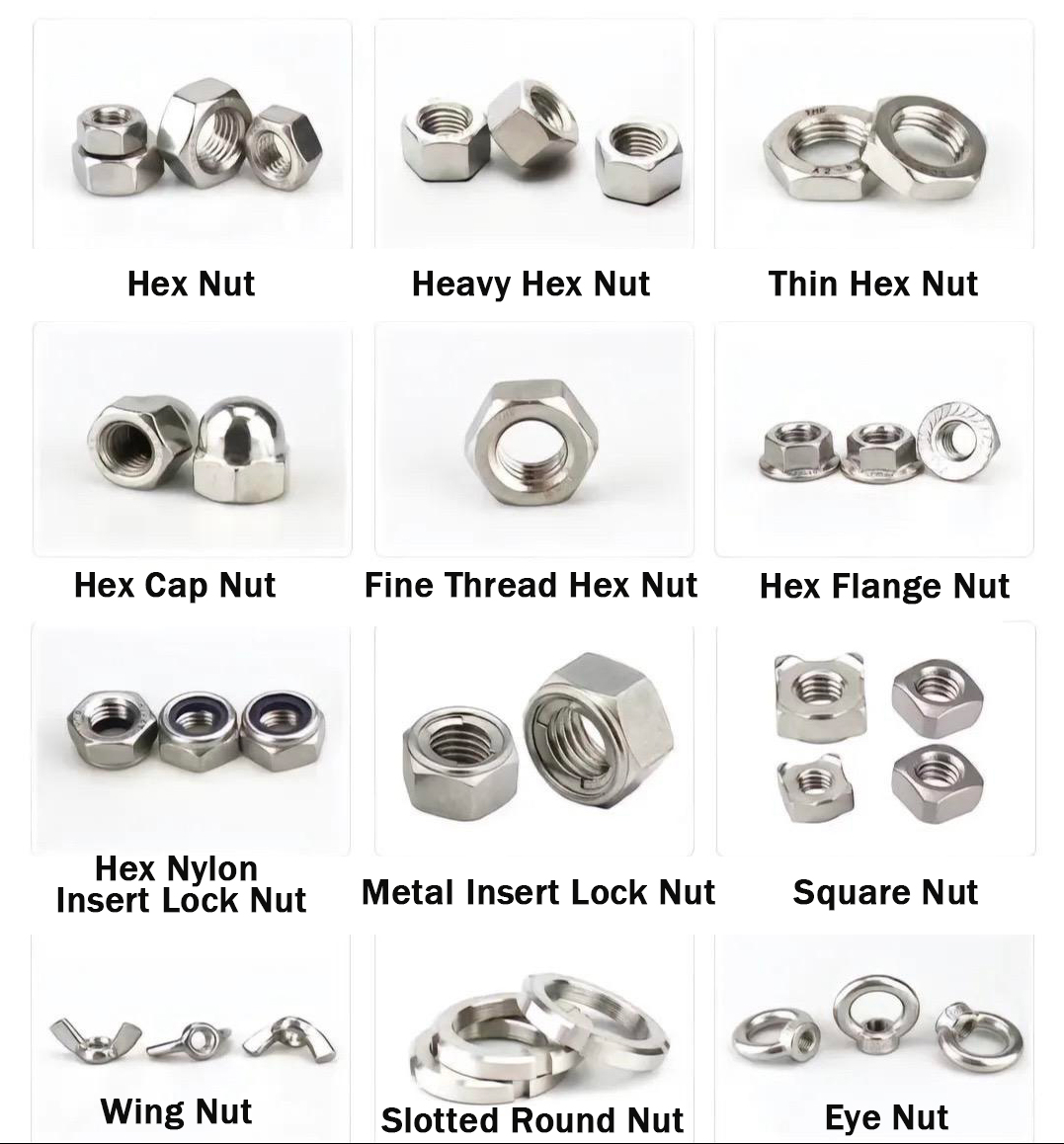

Studs, Nuts, and Washers:

- Studs: Headless components with threads on both ends. Variants include fully threaded studs for thick plate joints and equal-length double-end studs for base anchoring. For high-temperature environments, materials like GH4169 alloy are used for superior creep resistance.

- Nuts: Engage with bolts via internal threads. Based on locking performance, they include hex nuts, nylon-insert lock nuts (withstanding up to 30,000 vibration cycles without loosening), and cap nuts (offering both protection and aesthetic finish).

- Washers: Complementary components with key functions:

- Flat Washer: Distributes bolt load across a wider surface—up to five times the contact area—protecting coatings and preventing indentation.

- Spring Washer: Provides continuous preload through elastic deformation, resisting loosening under vibration.

- Sealing Washer: Made of rubber or PTFE, ensures fluid sealing in flange connections and operates across a temperature range of –200°C to 300°C.

- Lock Washer: Maintains tightness even under friction or vibration, suitable for precision and high-stability applications.

1.2Non-Threaded Fasteners: Permanent and Specialized Connection Options

Non-threaded fasteners rely on mechanical deformation or physical interlocking rather than threading, making them suitable for permanent or space-constrained assemblies. Key categories include:

Nails and Rivets:

- Nails: Basic connectors for wood and light materials. Common types include:

- Common Round Nails: Made of low-carbon steel, diameter 1–6 mm, length 10–200 mm.

- Powder-Actuated Nails: Can be driven instantly into concrete or steel, improving framing efficiency by up to four times in construction.

- Special Nails: Such as waterproof or threaded nails, designed for specific environmental requirements.

- Rivets: Create joints through deformation of the shank during setting. Types include:

- Solid Rivets: Provide strong, tamper-resistant joints, suitable for vibration- or shock-prone structures.

- Blind Rivets (POP Rivets): Allow one-side installation, used in automotive interiors and electronic housings.

- Large Flange Rivets: Equipped with oversized flanges for improved load distribution and faster assembly.

Pins and Anchors:

- Pins: Manufactured with IT6–IT8 tolerance, ensuring assembly precision within 0.01 mm. Types include:

- Dowel Pins: Maintain exact alignment between components.

- Spring Pins: Made from spring steel to compensate for hole misalignment.

- Shear Pins: Designed to break under overload, protecting primary structures.

- Anchors: Used to secure components to concrete or masonry substrates.

- Mechanical Anchors: Include expansion, undercut, and screw anchors—installation depth must be calculated based on substrate strength.

- Chemical Anchors: Combine threaded rods with resin capsules; after curing, the bond provides up to 30% higher pull-out strength than mechanical anchors, ideal for seismic reinforcement in buildings.

- Clips and Clamps: Include circlips, retaining rings, E-clips, and hose clamps, offering efficient temporary or semi-permanent fixation in automotive and electronics applications. Their advantages include fast installation, ease of removal, and reliable positioning.

2.0How Fastener Materials and Surface Treatments Enhance Performance

2.1Core Principles of Material Selection

Fastener materials must balance strength, corrosion resistance, manufacturability, and cost efficiency. Material selection varies according to the specific application environment:

Steel Materials: The most cost-effective and widely used option.

- Low-carbon steel: Used for general-purpose bolts below Grade 4.8.

- Medium-carbon steel: Quenched and tempered to produce Grade 8.8 bolts for structural applications.

- Alloy steel (e.g., 40CrNiMoA): Enables the production of Grade 12.9 high-strength bolts for heavy-duty and high-stress environments.

- Stainless steel: Grade 304/A2 offers reliable corrosion resistance in neutral environments, while Grade 316/A4, alloyed with molybdenum, provides enhanced seawater resistance, suitable for marine vessels and offshore platforms.

Nonferrous Metals:

- Aluminum alloys (e.g., 7075): Preferred in aerospace engineering for weight reduction.

- Titanium alloys (e.g., TC4): Provide outstanding corrosion resistance and biocompatibility, used in aircraft engines and medical implants.

- Copper alloys: Brass (H62) is ideal for electrical conductivity applications, while bronze (QAl9-4) performs well in wear-resistant assemblies.

- Non-metallic Materials: Engineering plastics such as nylon 66 (for electrical insulation) and PTFE (for chemical corrosion protection) are widely used. Carbon-fiber-reinforced composites offer significant lightweight advantages for advanced UAVs and new-energy vehicles.

Specially Treated Steels:

- Electro-galvanized steel: Designed for indoor applications, offering basic corrosion protection.

- Hot-dip galvanized steel: Provides a thicker zinc coating and up to three times higher corrosion resistance, suitable for outdoor environments.

- Nickel- and chrome-plated steel: Delivers a polished, decorative surface finish, ideal for visible or aesthetic components.

2.2Surface Treatment Processes: The Key to Performance Enhancement

Surface treatments significantly improve the durability, corrosion resistance, and mechanical reliability of fasteners under various service conditions.

Corrosion-Resistant Treatments:

- Electro-galvanizing: Coating thickness 5–15 μm, cost-effective option for indoor use.

- Hot-dip galvanizing: Coating thickness 50–100 μm, providing triple the corrosion resistance of electroplating; standard for outdoor steel structures.

- Dacromet coating: Zinc-chromium film 6–8 μm thick, achieving over 500 hours of salt spray resistance with no hydrogen embrittlement risk; ideal for high-strength bolts.

- Phosphating: Creates a phosphate conversion layer that enhances paint adhesion; commonly applied to automotive chassis fasteners.

- Functional Treatments:

- Nitriding: Forms a hardened nitrogen diffusion layer on the thread surface with hardness exceeding HV800, improving wear resistance and extending fastener lifespan by 2–3 times.

- Lubricant Coating: Applying molybdenum disulfide or PTFE on threads reduces tightening torque and prevents galling, particularly for stainless steel fasteners.

- Black Oxidation: Produces a thin ferrous oxide film that provides mild corrosion protection and a dark decorative appearance, often used on tool handles and hardware surfaces.

3.0How Fasteners Are Manufactured: Core Production Processes

3.1Plastic Forming Processes: The Mainstream Method for Mass Production

- Cold Forging: Conducted at room temperature, this process deforms metal blanks under high pressure through a sequence of cutting → heading → thread rolling. The continuous metal grain flow enhances tensile strength by 15–20% compared with machined parts, while material utilization exceeds 95%. Cold forging is ideal for bolts and screws below M16, enabling production capacities of up to 100,000 pieces per hour per line. Prior to forging, blanks must undergo spheroidizing annealing to reduce hardness and improve formability.

- Hot Forging: The process involves heating metal billets to 1100–1250°C—above the recrystallization temperature for steel—and then forming them under pressure. This method is suitable for large-diameter (M20 and above) or high-strength fasteners, allowing the formation of complex head geometries. Controlled cooling is critical to prevent coarse grain formation, and subsequent quenching and tempering are required to restore optimal mechanical properties.

3.2Machining and Advanced Manufacturing Technologies

- Machining Process: Performed on lathes and milling machines, involving turning → milling → threading (cutting or rolling). It offers high flexibility and precision, making it ideal for non-standard or custom fasteners (e.g., bolts with special head shapes). However, due to low material efficiency and slow processing speed, it is typically reserved for small-batch or high-precision applications, such as aerospace-grade threaded fasteners requiring dimensional tolerances within ±0.005 mm.

- Advanced Technologies:

- 3D Printing: Enables integrated manufacturing of complex fastener geometries. For example, thermoplastic polyurethane (TPU) 3D-printed bolt protectors developed for Jiangsu Oilfield reduced outdoor bolt corrosion rates from 85% to below 10%.

- Thread Rolling: Utilizes a thread rolling machine to plastically deform metal blanks at room temperature. By controlling roller speed, feed rate, and pressure, threads with IT6 tolerance and surface roughness below Ra0.8 μm can be formed. Aerospace-grade MJ thread fasteners produced by this process achieve fatigue lives exceeding 130,000 cycles—far surpassing the 50,000-cycle lifespan typical of cut-thread components.

4.0Industrial Applications of Fasteners

4.1Aerospace and New Energy Equipment

- Aerospace Sector: Fasteners in aerospace applications demand extreme precision and lightweight design—where every gram matters. The latest generation of MJ-thread fasteners use GH4169 nickel-based superalloy or TC4 titanium alloy, achieving tensile strengths of 1300–1550 MPa and 1100–1250 MPa, respectively. Combined with self-locking nuts, these bolts can withstand up to 30,000 vibration cycles without loosening. Each fastener must pass 720-hour salt spray and 30-day fungus resistance tests, ensuring reliability under extreme environmental conditions.

New Energy Equipment:

- Wind Power: Tower connection bolts are typically made of Grade 10.9 high-strength alloy steel with a Dacromet coating, designed for a service life of 20 years. Offshore wind installations require an additional fluorocarbon coating to achieve over 1000 hours of salt spray resistance.

- Photovoltaics: Mounting system fasteners are generally produced from 316 stainless steel or hot-dip galvanized carbon steel, paired with lock washers to prevent loosening caused by thermal expansion and contraction. In solar tracking systems, self-lubricating fasteners are preferred to reduce friction and maintenance frequency.

4.2Automotive Manufacturing and Construction Engineering

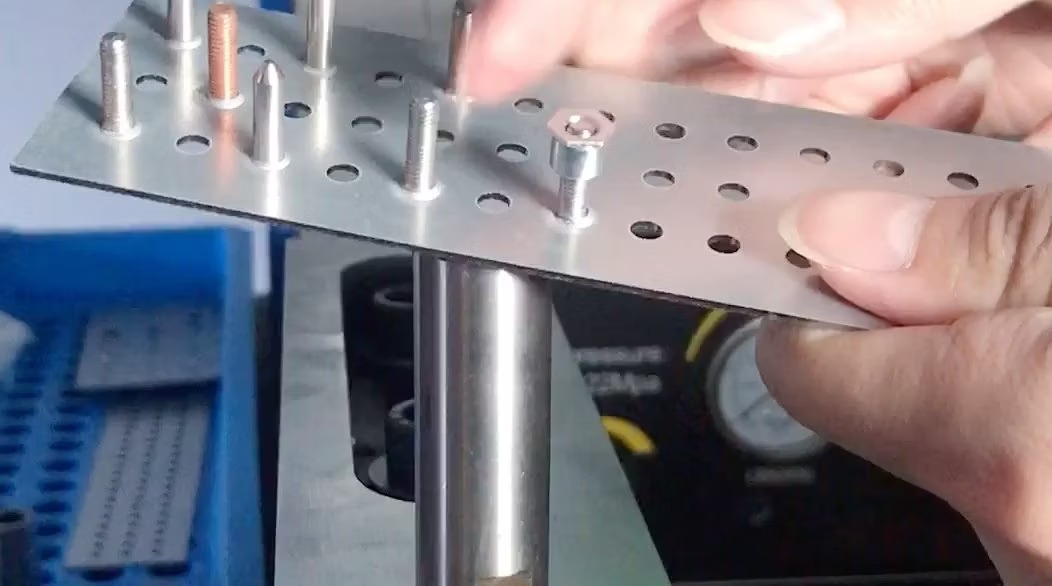

- Automotive Industry: A single passenger car typically contains 2,000–3,000 fasteners. Cylinder head bolts made from Grade 12.9 alloy steel are tightened using the torque-angle method to ensure reliable sealing. In automated assembly lines, fastener insertion machines play a key role—equipped with vision-guided positioning and servo-controlled tightening units, each unit can assemble 1,200–1,500 fasteners per hour, significantly reducing labor costs and assembly errors. Such systems are widely used for door panels and EV battery pack housings.

- Construction Engineering: High-rise steel structures rely on M24 Grade 10.9 bolts, each capable of withstanding 150 kN of tensile force. For large-scale bridges such as the Yangtze River Bridge, anchor bolts are made from corrosion-resistant alloy steel, with embedment depths exceeding 25 times the bolt diameter to ensure strong pull-out resistance.

5.0Failure Analysis and Quality Control of Fasteners

5.1Common Failure Modes and Root Causes

5.2Failure Analysis and Quality Control

5.3Intelligent Development Trends of Fasteners

6.0Fastener Selection and Installation Standards

6.1Key Factors for Scientific Fastener Selection

6.2Key Installation and Operation Standards

7.0Frequently Asked Questions (FAQ)

- What does the strength grade of a fastener mean?

- The strength grade is represented by two numbers. For example, Grade 8.8 means a nominal tensile strength ≥ 800 MPa and a yield ratio ≥ 0.8, i.e., yield strength ≥ 640 MPa.

- How can galvanic corrosion between fasteners be prevented?

- There are three main methods:

- Use fasteners made of materials with similar electrode potentials.

- Install insulating washers between dissimilar metals.

- Apply cathodic protection or anti-corrosion coatings on the fasteners.

- What is the main difference between a bolt and a screw?

- A bolt requires a nut for assembly and is suitable for detachable load-bearing joints. A screw, on the other hand, is directly threaded into a tapped hole and does not require a nut, making it ideal for light-duty or fixed connections.

- Why do high-strength bolts require dehydrogenation treatment?

- During acid cleaning and electroplating, high-strength bolts may absorb hydrogen atoms that accumulate at stress concentration areas, leading to hydrogen embrittlement. Dehydrogenation treatment removes these atoms, preventing premature failure.

- What makes smart bolts different from traditional ones?

- Smart bolts integrate sensing and communication modules, allowing real-time monitoring and data transmission of preload and stress. They transform the fastener from a passive load carrier to an active sensing element, serving as a key node in the Industrial Internet of Things (IIoT).

- How should washers be selected in flange connections?

- The selection depends on the medium’s temperature, pressure, and chemical properties:

- Low pressure/temperature → Rubber gasket

- Medium pressure/temperature → Asbestos rubber gasket

- High pressure/temperature → Metal spiral wound gasket

- What are the visual differences between fatigue fracture and brittle fracture in fasteners?

- Fatigue fracture: Displays visible fatigue striations and origins with a bluish-gray appearance.

- Brittle fracture: Shows a flat, crystalline surface with minimal plastic deformation.

- What are the advantages and limitations of 3D-printed fasteners?

- Advantages: Enable complex geometries, customized designs, and high material utilization.

- Limitations: Higher cost, lower production efficiency, and surface finish often requires post-processing.

- What are the advantages and applications of automatic fastener insertion machines?

- The core advantage is high automation. Through visual positioning and servo control, the machine ensures precise feeding, alignment, and tightening. It can assemble 1,200–1,500 fasteners per hour, significantly reducing labor errors. Common applications include automotive manufacturing, particularly in door panels and battery pack housings.

8.0Conclusion

Fasteners are the microscopic foundation of modern industry, evolving from basic connectors to intelligent sensing components in smart manufacturing systems. From the bronze rivets of ancient craftsmanship to aerospace-grade intelligent bolts, each technological leap has driven new levels of equipment performance and reliability.

In advanced manufacturing, fasteners serve as key indicators of industrial capability. For example, the MJ-thread aerospace fasteners now achieve fatigue lives exceeding 130,000 cycles, while wireless passive smart bolts ensure reliable monitoring in extreme environments. 3D printing technology further enables customized, lightweight production pathways.

From an engineering perspective, fastener design and application form a complete technical ecosystem: scientific selection lays the foundation, precision manufacturing ensures quality, standardized installation guarantees stability, and failure analysis drives continuous improvement.

Looking ahead, with the ongoing integration of intelligent sensing, green materials, and lightweight technologies, fasteners will no longer be mere connection elements — they will act as the “nervous terminals” of smart manufacturing, connecting not only structures, but also the data and intelligence of the Industry 4.0 era.

Reference

https://www.iqsdirectory.com/articles/fastener.html

https://www.scrooz.com.au/blog/what-are-fasteners

https://cf-t.com/blog/what-are-fasteners?