- 1.0What Is an Aluminum Profile

- 2.0Key Characteristics of Aluminum Profiles

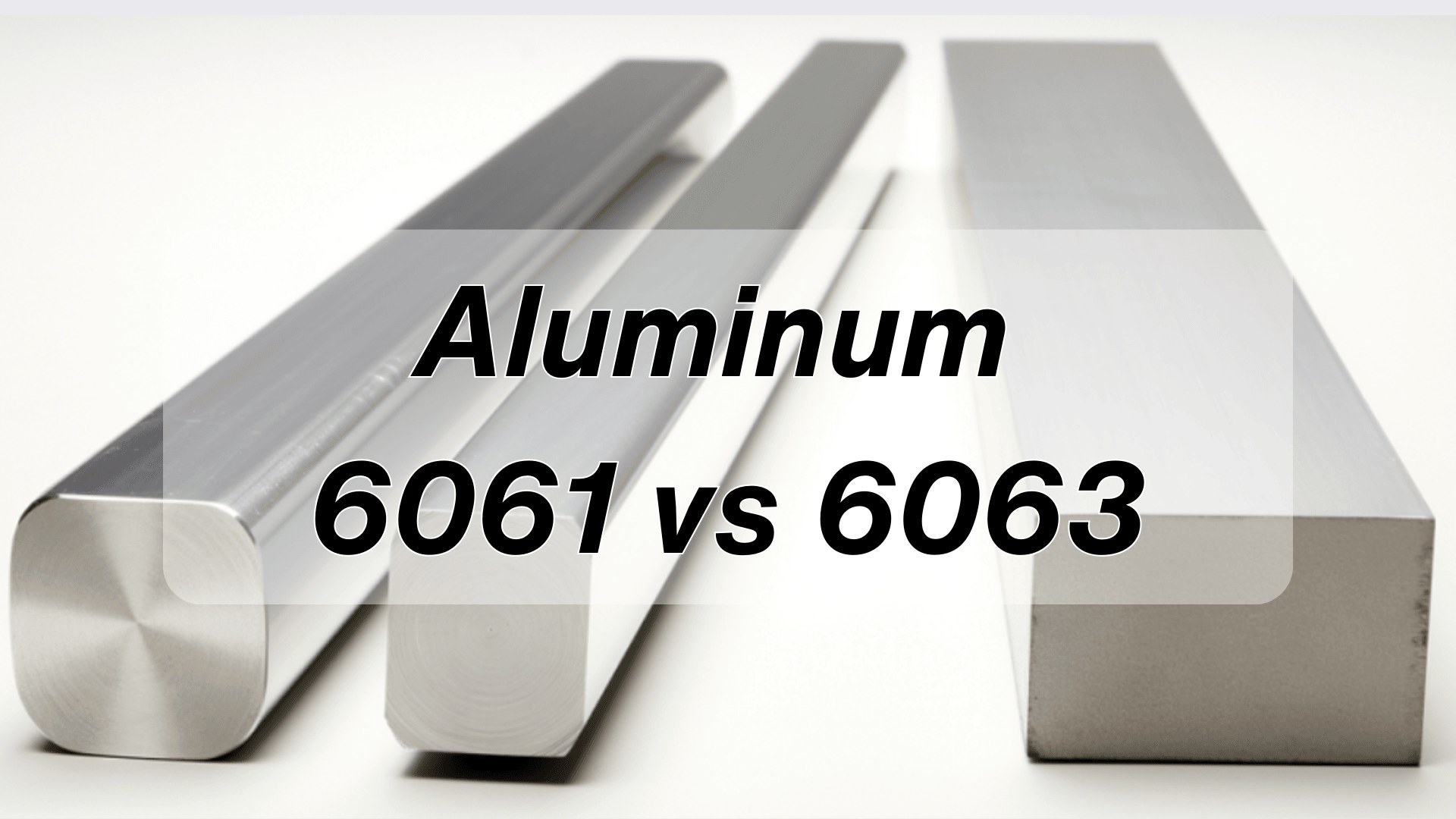

- 3.0Common Aluminum Alloys, Grades and Their Differences

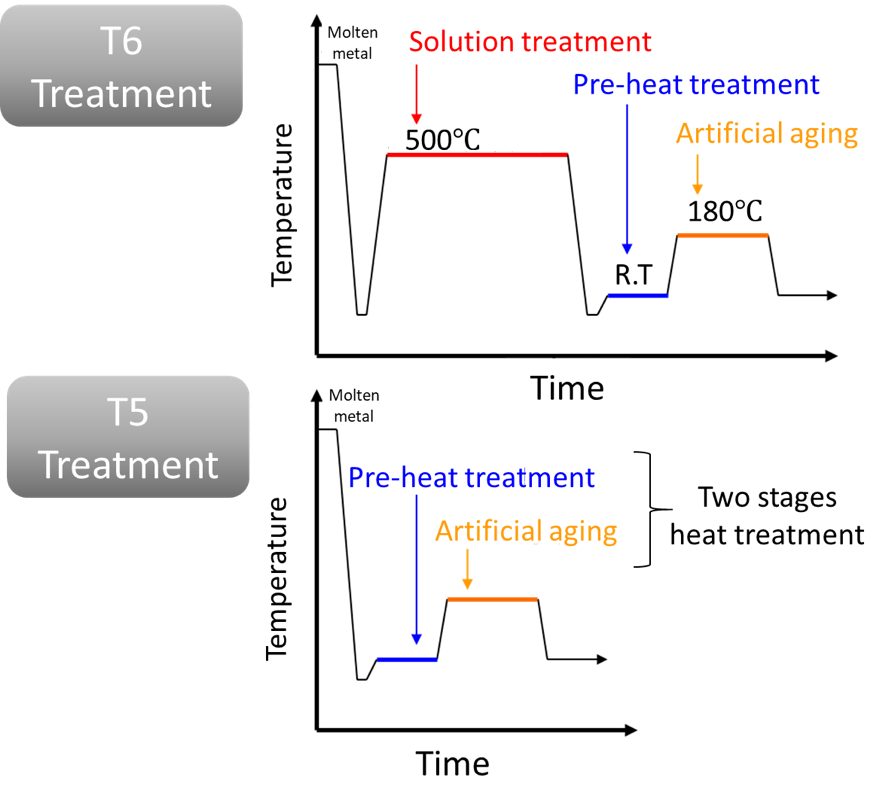

- 4.0Heat Treatment and Temper States

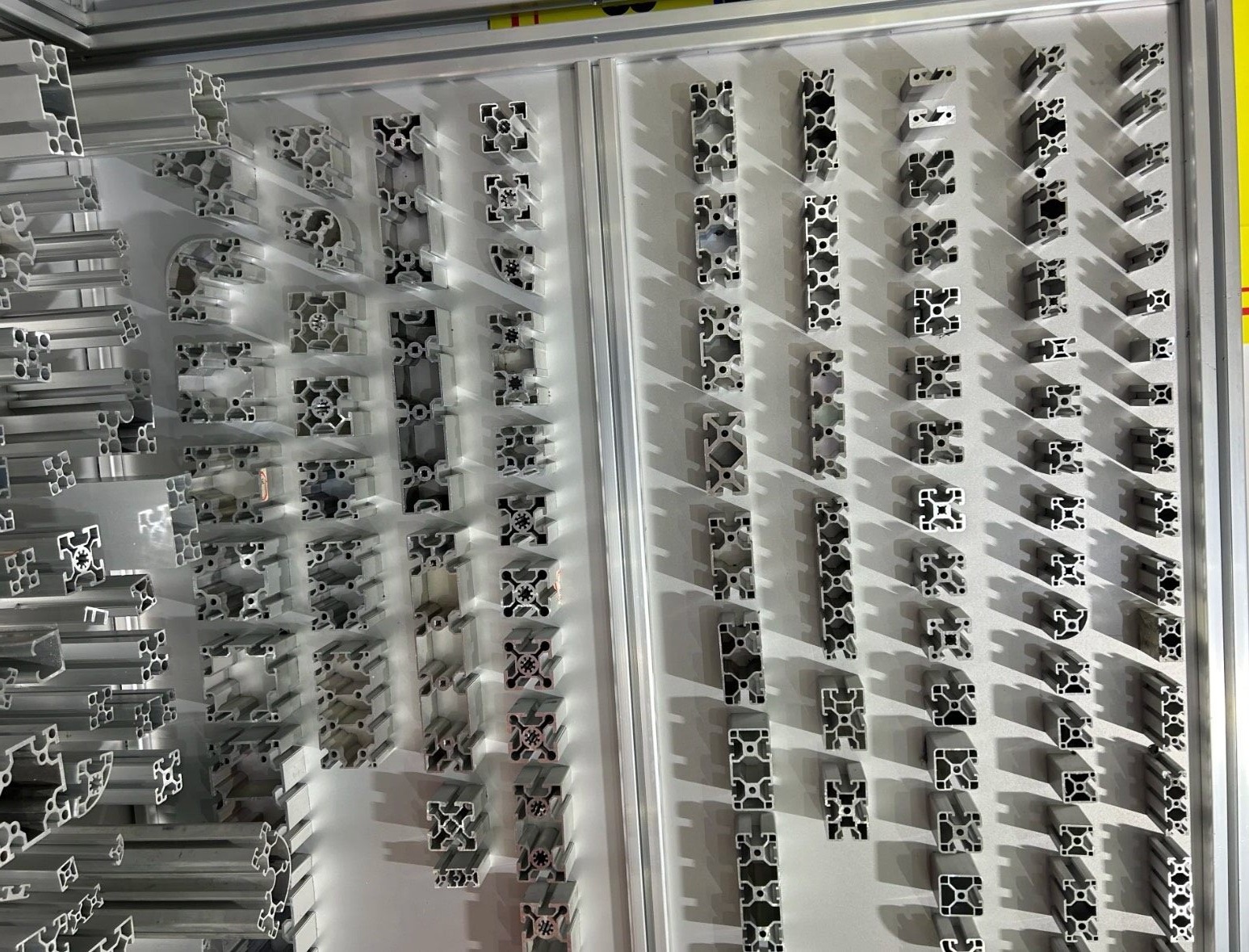

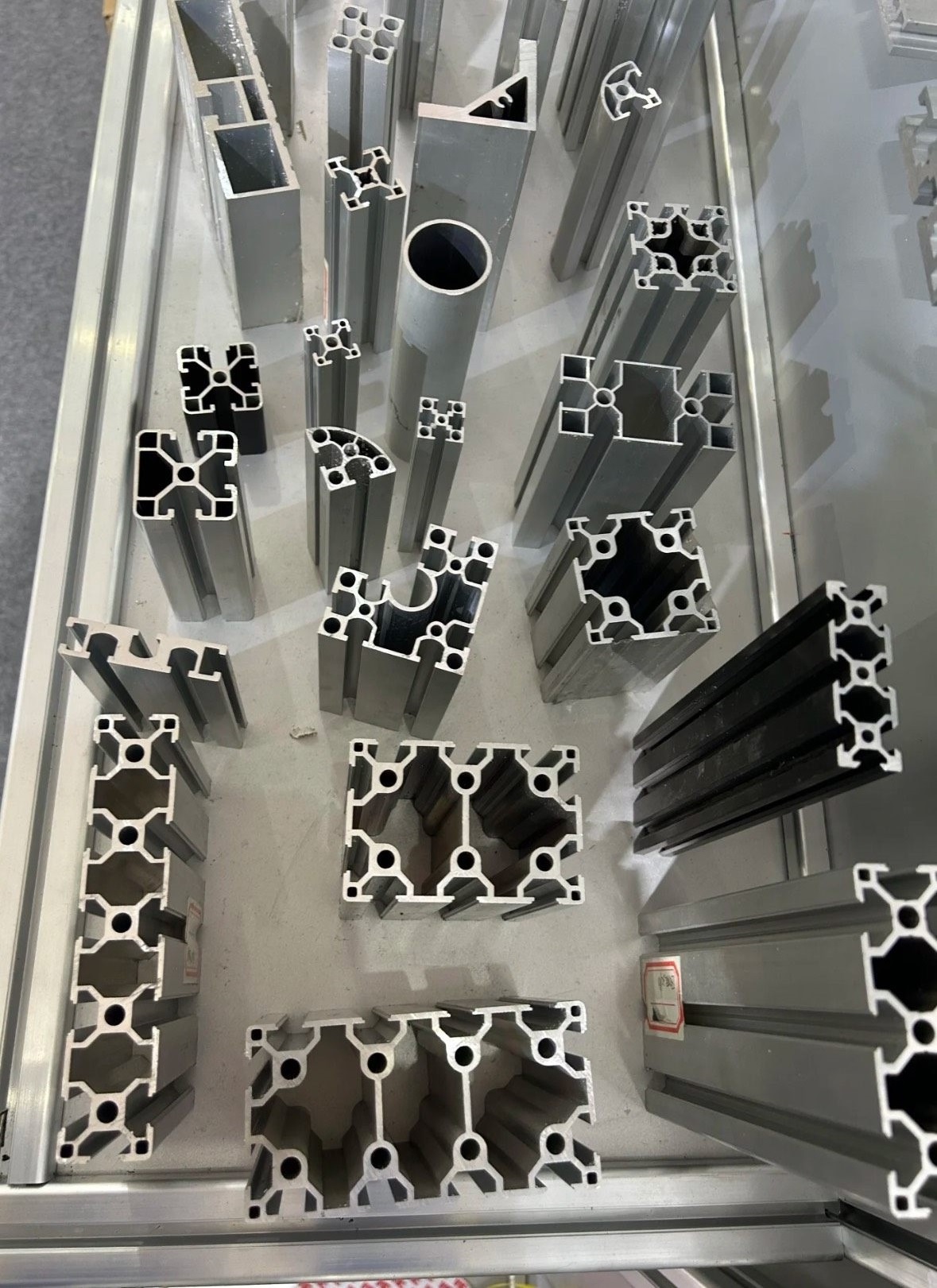

- 5.0Core Classifications of Aluminum Profiles

- 6.0Manufacturing and Surface Treatment of Aluminum Profiles

- 7.0Core Application Areas of Aluminum Profiles

- 8.0Quality Control and Maintenance of Aluminum Profiles

1.0What Is an Aluminum Profile

Aluminum Profile, also known as aluminum extrusion or aluminum framing, is a metal section made primarily from aluminum alloy through a series of processes including melting, extrusion, and surface treatment. It features a defined cross-section and standardized or customized dimensions.

The key forming process is extrusion: cylindrical aluminum alloy billets are heated to approximately 450–500°C and then forced through a custom-designed steel die under pressures ranging from 100 to 1,000 tons. This process produces profiles with uniform cross-sections and precise dimensions. After cooling and shaping, the profile retains the fixed geometry defined by the die. Through alloy optimization and process control, mechanical and functional performance can be further enhanced.

2.0Key Characteristics of Aluminum Profiles

- Lightweight and High Strength: With a density of approximately 2.7 g/cm³, aluminum profiles are significantly lighter than steel. Alloying substantially improves strength, helping reduce overall structural weight and improve energy efficiency.

- Corrosion Resistance: A naturally formed aluminum oxide layer on the surface provides effective protection against corrosion, making aluminum profiles suitable for outdoor and humid environments.

- Excellent Machinability: Aluminum profiles are easy to extrude, cut, weld, and CNC-machine, enabling flexible customization for complex structural designs.

- Environmentally Sustainable: Aluminum is 100% recyclable, and recycled aluminum requires only 5–10% of the energy needed to produce primary aluminum, supporting green manufacturing and sustainability goals.

- Low Maintenance Cost: Aluminum does not rust and resists deformation, allowing service lifetimes of 50 years or more under normal conditions.

- Functional Physical Properties: Good thermal and electrical conductivity, combined with non-magnetic behavior, make aluminum profiles ideal for electronics, heat dissipation, and precision equipment.

3.0Common Aluminum Alloys, Grades and Their Differences

| Alloy Series/Grade | Main Alloying Elements | Mechanical Performance | Surface Treatment Characteristics | Typical Applications |

| 6063 | Si (0.2–0.6%), Mg (0.45–0.9%), Cu ≤0.1% | Tensile strength ≈ 190 MPa, yield strength ≈ 145 MPa, medium strength | Excellent anodizing quality, smooth and uniform surface finish | Architectural decoration, furniture, electronic heat sinks, doors and windows, decorative structures, LED profiles |

| 6061 | Si, Mg, Cu (0.15–0.4%), Cr (0.04–0.35%) | Tensile strength ≈ 310 MPa, yield strength ≈ 276 MPa, high strength and hardness | Anodizing quality slightly inferior to 6063, excellent weldability | Heavy-duty industrial structures, machinery frames |

| 1000 Series | High-purity aluminum | Low mechanical strength | Excellent corrosion resistance and electrical conductivity | Electrical applications, heat dissipation components where material purity is essential |

4.0Heat Treatment and Temper States

| Temper State | Webster Hardness | Formation Process | Performance Characteristics |

| T5 | 8–12 | Controlled cooling and artificial aging after extrusion | Balanced strength and processability |

| T6 | Around 13.5 | Solution heat treatment followed by artificial aging | Higher strength and hardness compared to T5 |

5.0Core Classifications of Aluminum Profiles

5.1Classification by Degree of Customization

| Classification | Features | Common Shapes/Applications |

| Standard Profiles | Manufactured in industry-standard sizes and cross-sections, high cost-efficiency, easy availability | L-angle profiles, U-channels, T-profiles, square and round tubes, flat bars, Z-profiles; general frameworks, connectors, structural supports |

| Special Profiles | Designed for specific applications, with customized elements (snap-fit structures, integrated cable management channels, dedicated mounting surfaces) | Precision equipment, specialized architectural components |

| Custom Profiles | Developed with dedicated tooling based on project-specific requirements, unique cross-sections and dimensions | Personalized engineering and design scenarios |

5.2Classification by Structure and Application

| Classification | Features | Typical Applications |

| Frame Profiles | Secure edges of panels (glass, plastic sheets), combine structural stability with decorative appeal | Door and window frames, advertising displays, exhibition booths, furniture edging |

| Box Profiles | Rectangular or square closed sections, exceptional rigidity and load-bearing capacity, good thermal and electrical conductivity | Construction, automotive, machinery manufacturing, electrical applications |

| LED Profiles | Specifically designed for LED strips, utilize aluminum’s thermal conductivity for heat dissipation, support surface-mounted or recessed installation | LED lighting systems, provide uniform light distribution and mechanical protection |

| Angle Profiles | L-shaped, protect and decorate junctions of two surfaces, prevent impact damage | Indoor and outdoor decoration, equipment protection |

| Sigma Profiles | Cross-section similar to Greek letter Σ, high structural strength | Load-bearing and fastening components in industrial machinery, factory installations |

| Hollow Beam Profiles | Hollow structures without strict cross-section limitations (rectangular, square variants) | Horizontal support frameworks in buildings and bridges, heavy-load applications |

| Dedicated Functional Profiles | Include SD sliding window profiles (high weather resistance), RCW curtain wall profiles (high-rise façades, sealing and protection), door profiles (fix heavy glass doors), louver profiles (ventilation, daylighting, privacy, water resistance), T-profiles (trusses, corner supports) | Sliding window systems, high-rise building curtain walls, heavy glass door structures, ventilation systems, truss frameworks |

5.3Other Classification Methods

| Classification Basis | Types | Selection Criteria |

| Manufacturing Process | Extruded profiles, cast profiles, rolled profiles | Based on production efficiency and product performance requirements |

| Surface Finish | Mill finish profiles, anodized profiles, powder-coated profiles | According to application environment and aesthetic requirements |

6.0Manufacturing and Surface Treatment of Aluminum Profiles

6.1Key Points of the Manufacturing Process

The extrusion process gives aluminum profiles exceptional design flexibility, enabling the production of both simple solid bars and complex multi-cavity cross-sections. A complete production flow includes billet heating → container heating → die heating → extrusion → quenching → straightening → cutting to length → racking → aging → delivery. Each process parameter directly affects final product quality.

Process Control Requirements

- Extrusion temperature, pressure, and cooling rate must be continuously monitored to ensure dimensional accuracy and consistent mechanical performance.

- Extrusion dies must be polished and preheated to 440–480°C (for porthole dies, holding time ≥1.5 hours); the container is heated to 380–430°C and cleaned regularly.

- Billets are inspected to remove defects and heated according to wall thickness (≥1.4 mm: 440–540°C; <1.4 mm: 400–540°C).

- Initial extrusion pressure should not exceed 210 kg/cm²; pressure is released for degassing at 110–160 kg/cm². Exit temperature should be ≥500°C, and the butt thickness controlled within 15–30 mm.

Quenching and Aging

These are critical steps for enhancing mechanical properties. For 6063 alloy (T6 temper), forced air cooling is required, with a cooling rate ≥80°C/min down to below 170°C. 6061 alloy can be quenched using strong air, water mist, or water cooling. Aging allows alloying elements to precipitate, significantly improving strength.

6.2Main Surface Treatment Methods

| Treatment Method | Process Principle | Performance Characteristics | Limitations | Typical Applications |

| Anodizing | Form a dense aluminum oxide layer through electrochemical reaction (thickness 5–25 μm) | High hardness, excellent corrosion and wear resistance, dyeable in multiple colors, service life up to 20 years | Non-conductive, color uniformity sensitive to process control | Architectural components, electronic heat sinks |

| Powder Coating | Electrostatic application of powder followed by curing at 180–200°C | Wide range of colors and finishes (matte, gloss), excellent weather resistance, anti-fading, solvent-free, environmentally friendly | Bright shades may fade, surface defects (orange peel, powder detachment) may occur | Curtain walls, outdoor facilities |

| Mechanical Surface Treatment | Brushing, polishing, sandblasting to create distinct textures | Brushing conceals scratches, polishing produces mirror-like finish, sandblasting provides matte non-reflective surface | — | Decorative components, precision equipment |

| Electrophoretic Coating | Coating particles deposited under electric field to form smooth uniform layer | Strong adhesion, impact resistance, superior coating fullness compared to anodizing | Limited color options (silver, champagne, black), color variation may occur | Architectural doors and windows, furniture profiles |

| Conductive Anodizing | Form thin oxide layer (0.5–5 μm) | Retain electrical conductivity while providing basic protection | — | Electronic components |

| Wood Grain Transfer Printing | Simulate natural wood textures on profile surface | Enhance decorative appeal, combine aluminum’s performance with wood’s aesthetics | — | Furniture, architectural decoration |

6.3Core Tooling and Equipment

- Extrusion Dies: Core tooling for profile forming, custom-designed according to cross-section geometry; die quality directly determines dimensional accuracy and shape precision, requiring regular maintenance to prevent wear-related defects.

- Fixtures and Clamping Systems: Used for positioning and securing profiles during machining; proper design ensures accurate positioning, prevents movement and vibration, maintains tight tolerances and batch consistency, and protects tool life.

- Cutting Tools: Including saw blades, drills, milling cutters, taps, and reamers; tools must have high precision and excellent surface finish, with optimized material, coating and cutting-edge geometry for aluminum; specialized tools and dedicated lubricants are recommended due to aluminum’s tendency to adhere to tools at high speeds and temperatures.

6.4Commonly Used Processing Equipment

- High-Speed Electric Spindle Machining Centers: Capable of multi-directional machining within 180° range around extruded surface; can process up to three sides of square profiles in a single setup, suitable for complex machining requirements.

- Dedicated Aluminum Profile Machines: Simplified machines for cutting and drilling operations; easy to operate, suitable for processing structurally simple components.

- Aluminum Cutting Machines: Designed specifically for aluminum profiles; high cutting accuracy, burr-free edges, suitable for various cross-sections and thicknesses, supports fixed-length cutting for doors, windows and frame pre-processing.

- Aluminum Profile Bending Machines: Used for bending profiles with precise angle control (0°–180° adjustable); can process thin- and thick-walled profiles into arcs, right angles and other complex shapes, meeting architectural and industrial design requirements.

6.5Key Factors in Profile Machining

- Equipment Selection: Machines should be selected based on process complexity and part geometry to ensure compatibility with required tooling, stable quality and optimized production cycles.

- Tool Wear Control: Effective lubrication, chip evacuation systems and regular maintenance reduce tool wear, maintaining machining accuracy and extending tool life.

- Process Monitoring: Machining monitoring and data recording systems enable full traceability, ensuring all parts are processed under consistent parameters for stable and reliable production.

- Safety Assurance: Fully automated equipment minimizes operator contact with moving components; appropriate personal protective equipment is required at each process stage.

6.6Secondary (Deep) Processing Methods

- CNC Machining: Suitable for high-precision components, capable of producing complex holes and slots with tolerances up to ±0.01 mm; 6061 requires slightly lower cutting speeds than 6063 due to higher hardness; typical applications include precision connectors and electronic enclosures.

- Cutting and Drilling: Cutting methods include sawing and laser cutting; laser cutting offers high precision and smooth edges, ideal for thin-walled or complex profiles; drilling requires controlled feed rates, and thin-walled profiles must be securely clamped to prevent deformation and poor hole quality.

- Bending and Welding: 6061 has better weldability than 6063 and requires post-weld heat treatment to restore strength; 6063 is more prone to cracking during welding, requiring careful process selection.

7.0Core Application Areas of Aluminum Profiles

- Construction Industry: Used in curtain wall systems, doors and windows, solar mounting structures, bridges, stadiums, high-rise building frames, skirting boards, etc. Thermal-break window and door profiles, combined with insulation strips, deliver excellent thermal and acoustic performance, meeting modern energy-efficient building requirements.

- Transportation Industry: Applied in aircraft and automotive chassis, cooling systems, and interior components. The lightweight properties help improve fuel efficiency, while high-strength aluminum alloys are extensively used in aerospace applications to reduce weight and enhance performance.

- Electronics and Electrical Industry: Commonly used for heat sinks, equipment housings, and cable management systems. High thermal conductivity and electromagnetic shielding properties protect sensitive electronic components while improving heat dissipation efficiency.

- New Energy Industry: Used in solar panel mounting systems and wind turbine components. Resistance to extreme weather conditions and recyclability align well with the sustainability requirements of the renewable energy sector.

- Industrial and Machinery Industry: Applied in machine frames, workbenches, conveyor systems, and industrial safety enclosures. Modular aluminum profile systems enable fast assembly and reconfiguration, supporting the flexibility required by automated production lines.

- Decoration and Furniture Industry: Used in display cabinets, furniture frames, and LED decorative lighting. Aluminum profiles combine aesthetics with functionality and can be surface-treated to suit different design styles and interior environments.

8.0Quality Control and Maintenance of Aluminum Profiles

8.1Quality Standards and Inspection

- Standards Compliance: Production complies with internationally recognized standards, including ISO 9001 (Quality Management Systems), ISO 14001 (Environmental Management Systems), and relevant EN, ASTM, and DIN standards for aluminum profiles, ensuring strict control over mechanical strength, dimensional tolerances, and long-term durability.

- Testing Methods: Regular testing includes tensile strength testing, hardness testing, and corrosion resistance testing. Statistical process control and real-time monitoring are implemented to ensure production stability and consistency.

- Certification and Compliance: Third-party certification is used to verify product compliance, providing reliable quality assurance for various application scenarios.

8.2Daily Maintenance Guidelines

Aluminum profiles require minimal maintenance. Routine cleaning with clean water or neutral detergents is sufficient to remove dust and oil residues. Corrosive cleaning agents should be avoided. For outdoor applications, surface coatings should be inspected periodically, and any damage should be repaired promptly to extend service life.

Reference

https://www.tuofa-cncmachining.com/tuofa-blog/t6-temper-aluminum.html=

https://www.unionfab.com/blog/2025/04/aluminum-6061-vs-6063

https://news.cision.com/otto-fuchs-drilling-solutions/i/strength-to-weight,c2242389