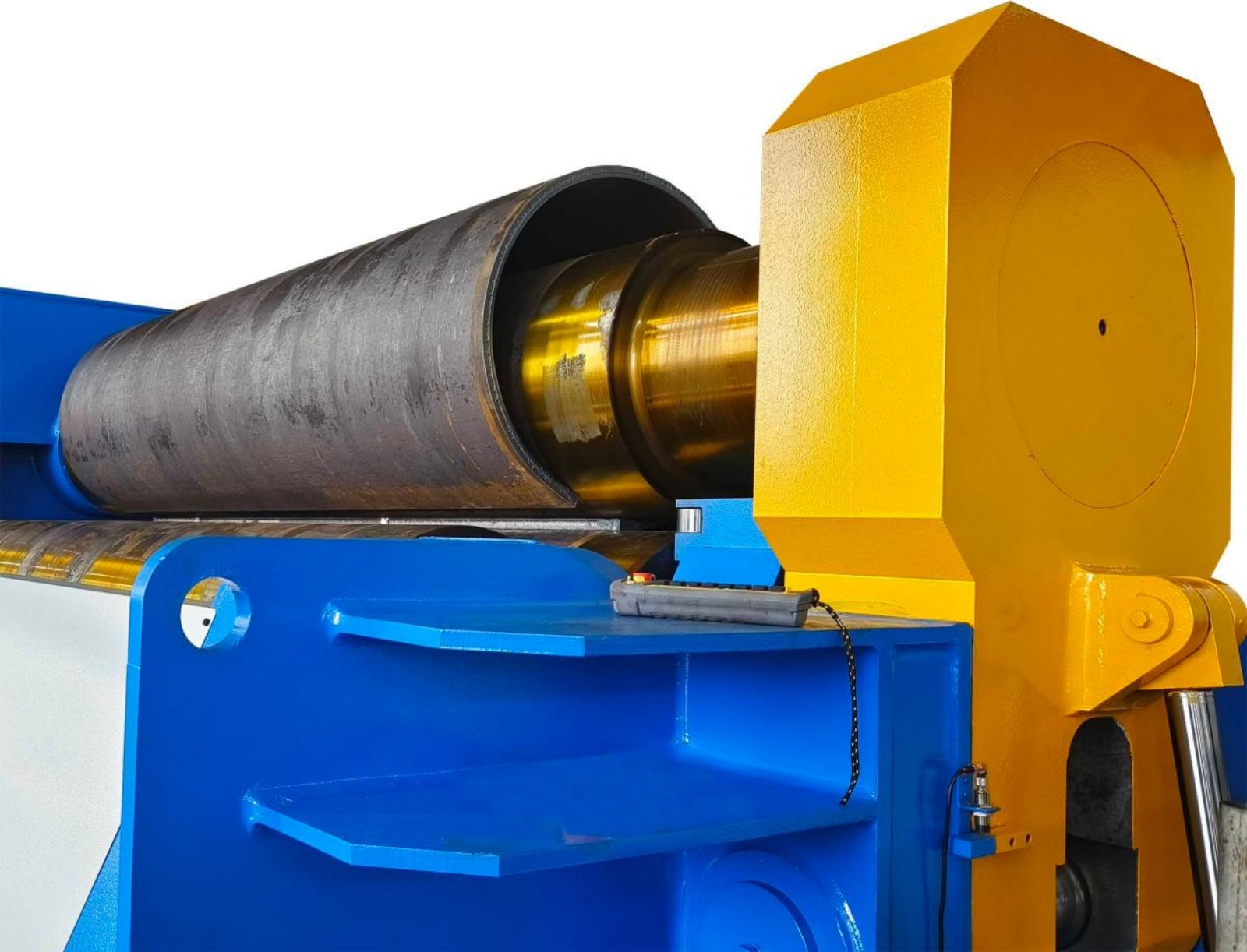

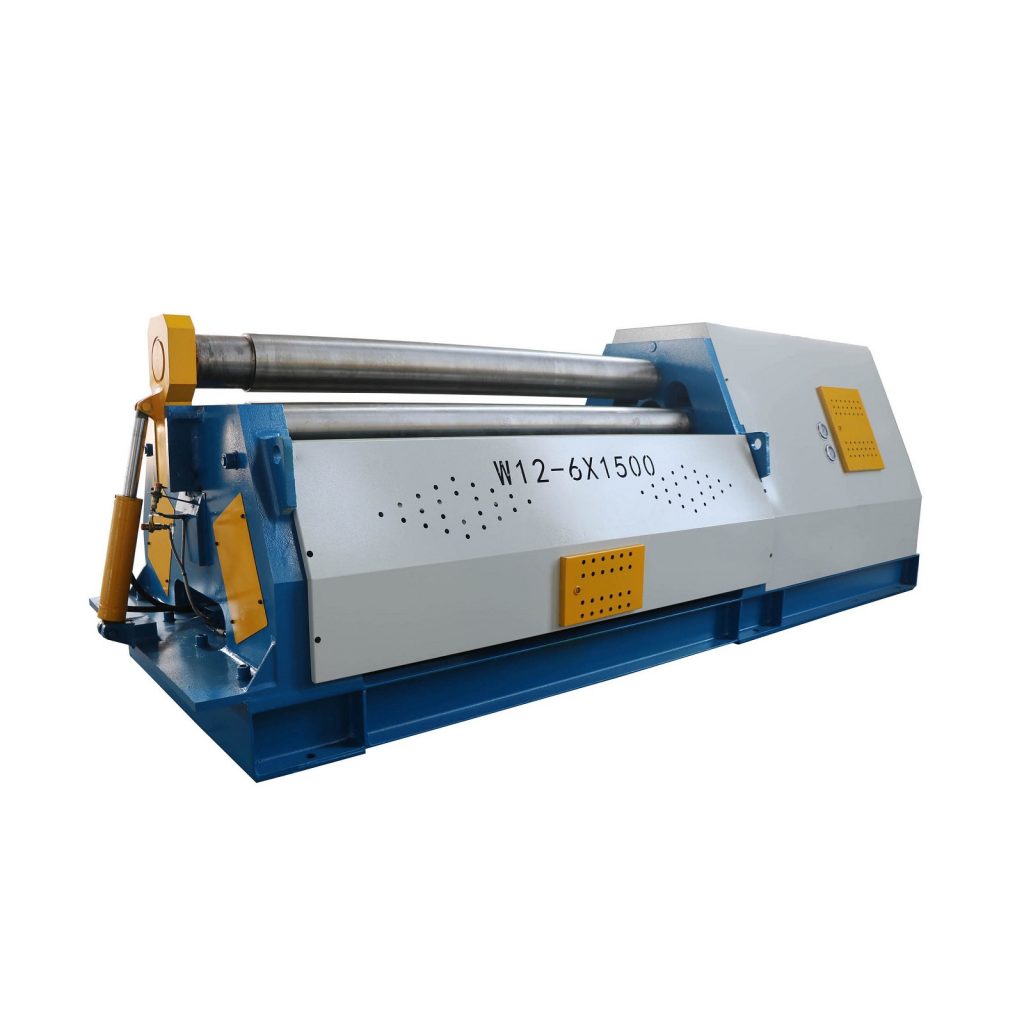

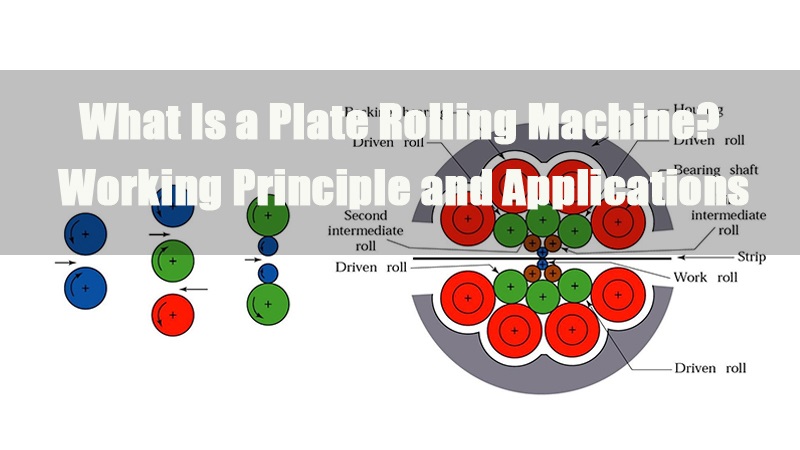

The AEK-W12NC 4-Roller Plate Bending Machine is a high-performance double-pinch plate bending solution, designed for precision, strength, and reliability. Each roller is independently driven, with rectilinear sliding ways coated in anti-friction material, ensuring smooth motion, heavy-duty load capacity, and zero maintenance.

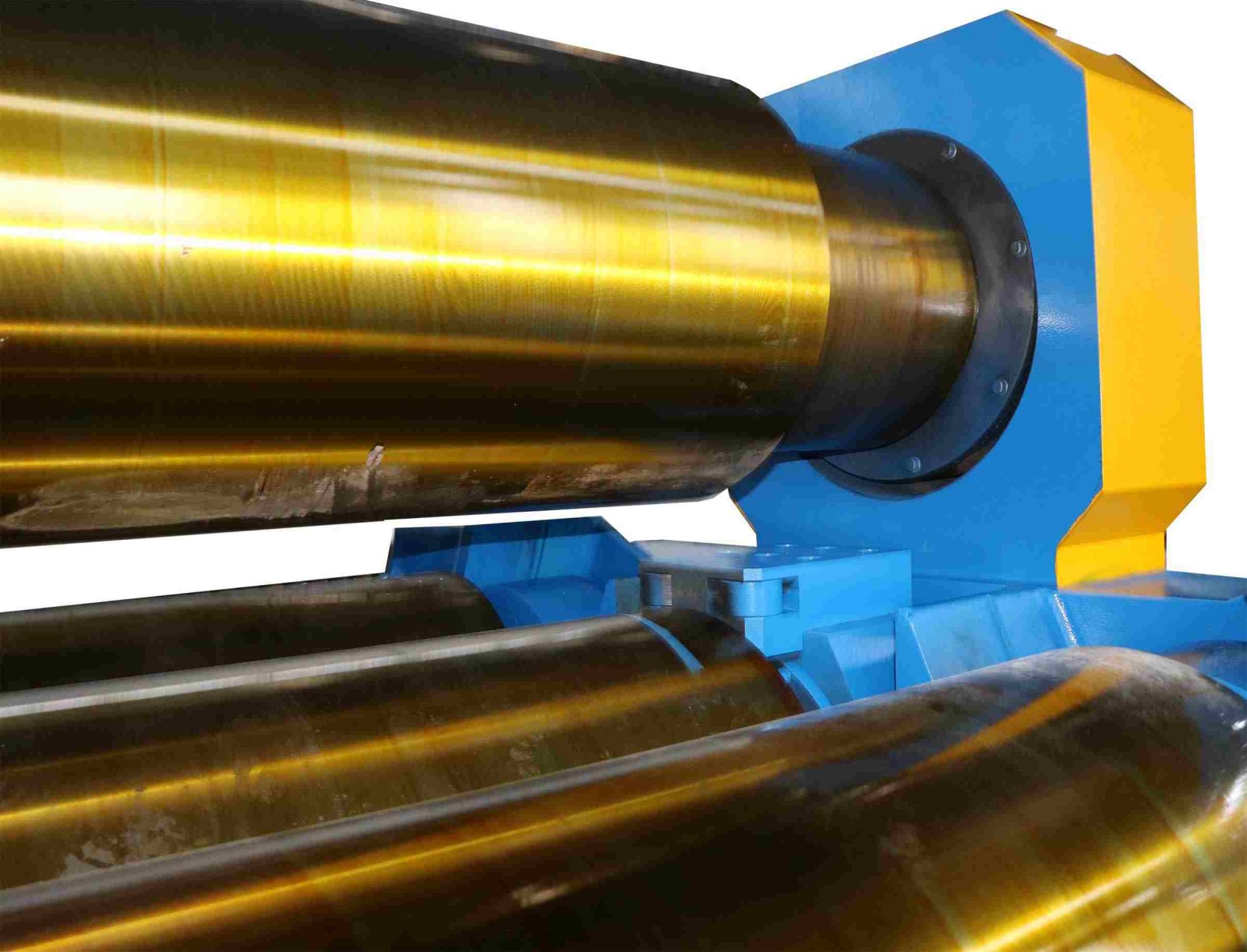

Equipped with spherical roller bearings, all rollers are manufactured from alloy steel, induction-hardened, heat-treated, and then ground and polished for maximum durability and accuracy.

Key Features:

- Heavy-duty linear sliding guides for side and lower roller movement

- Electronic parallelism control system for precise bending

- Full electronic synchronization and balancing control of rollers

- Variable tilting of side and bottom rollers (positive/negative)

- Conical bending capability

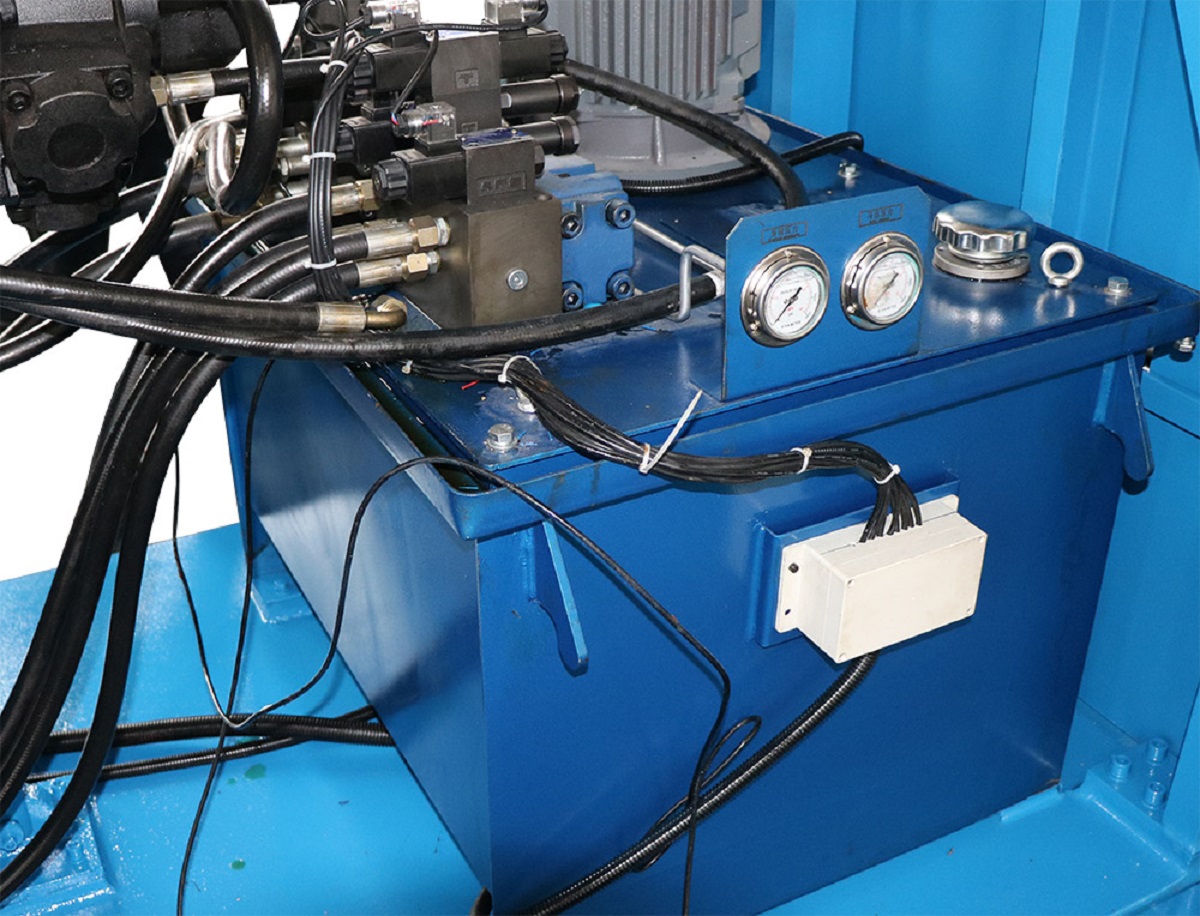

- Independent hydraulic motor drive for each roller

- Anti-friction sliding system for enhanced efficiency

- Instant braking system for safe roller rotation

- Reversible side hydraulic drive

- Mobile control panel with low-voltage operation

- Ergonomic push-button controls for operator convenience

Applications

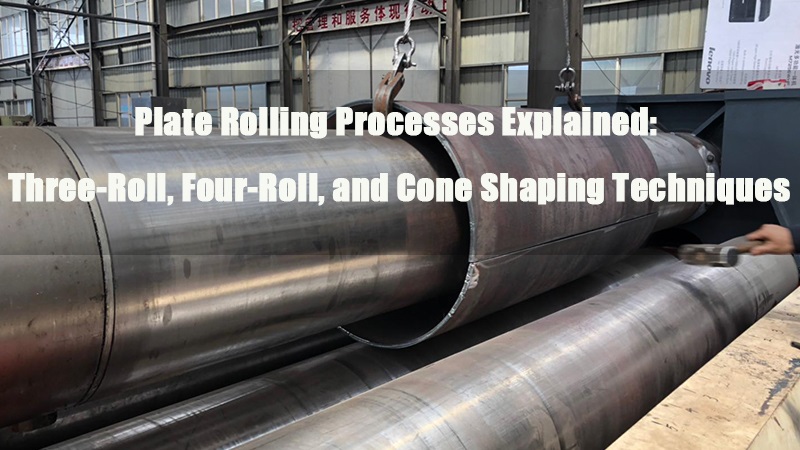

The AEK-W12NC 4-Roll Plate Rolling Machine is widely used in industries such as:

- Shipbuilding – rolling heavy steel plates for hull structures.

- Petrochemical – manufacturing pressure vessels, tanks, and pipes.

- Construction – producing structural steel components and pipelines.

- Energy & Power – wind tower sections, boilers, and heavy-duty equipment fabrication.

- Metal Fabrication – custom cylindrical, conical, and large steel components.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.