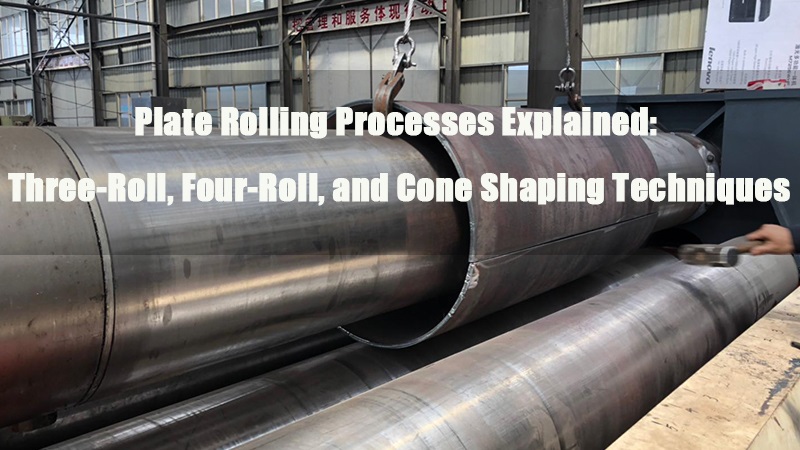

Universal 3-Roller Plate Bending Machine (W11S) – Product Showcase

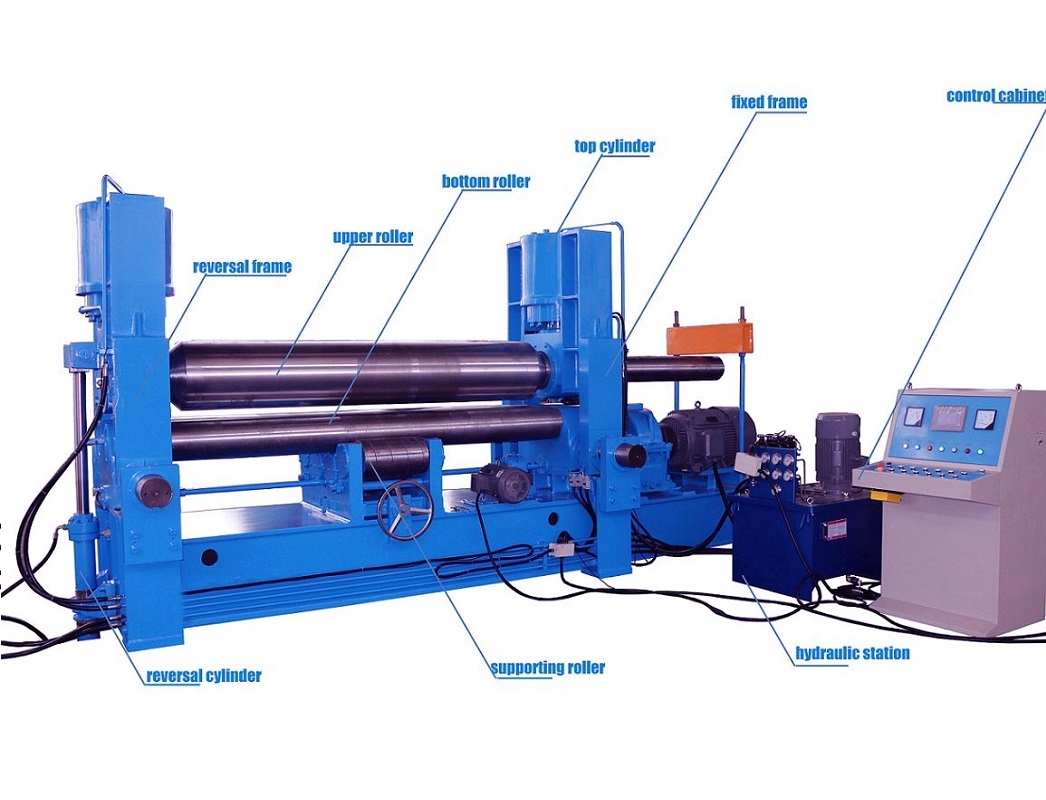

Structure & Working Principle

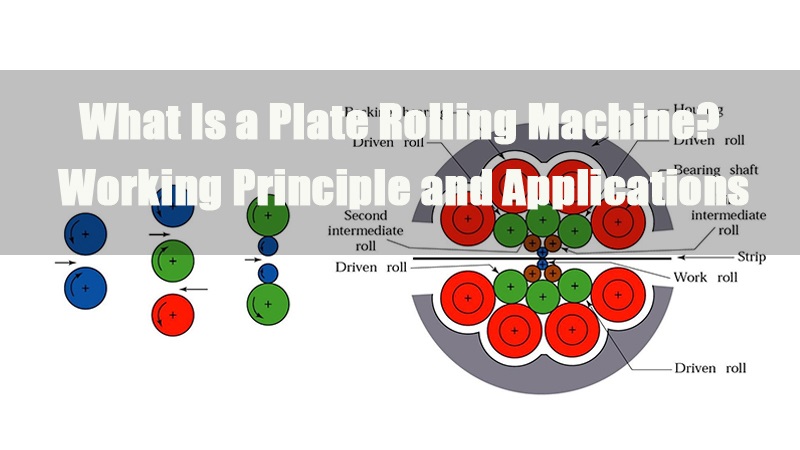

- Three-Roller Structure: One upper roller and two bottom rollers. The upper roller (universal type) is drum-shaped, with support rollers under the bottom rollers for precision across different plate thicknesses.

- Upper Roller Motion: The upper roller of the W11S Plate Rolling Machine can move vertically (hydraulic transmission) and horizontally (mechanical transmission), enabling high-precision pre-bending and multiple bending shapes.

- Drive System: The two bottom rollers are driven by a motor and a reducer, while the top roller of the W11S Upper Roller Plate Bending Machine provides hydraulic pressing and positioning.

- Tipping Device: Hydraulic tipping frame for easy workpiece removal.

- Cone Rolling Device: The W11S 3-Roller Universal Hydraulic Plate Rolling Machine can be equipped with a cone rolling device for producing cones within a certain range.

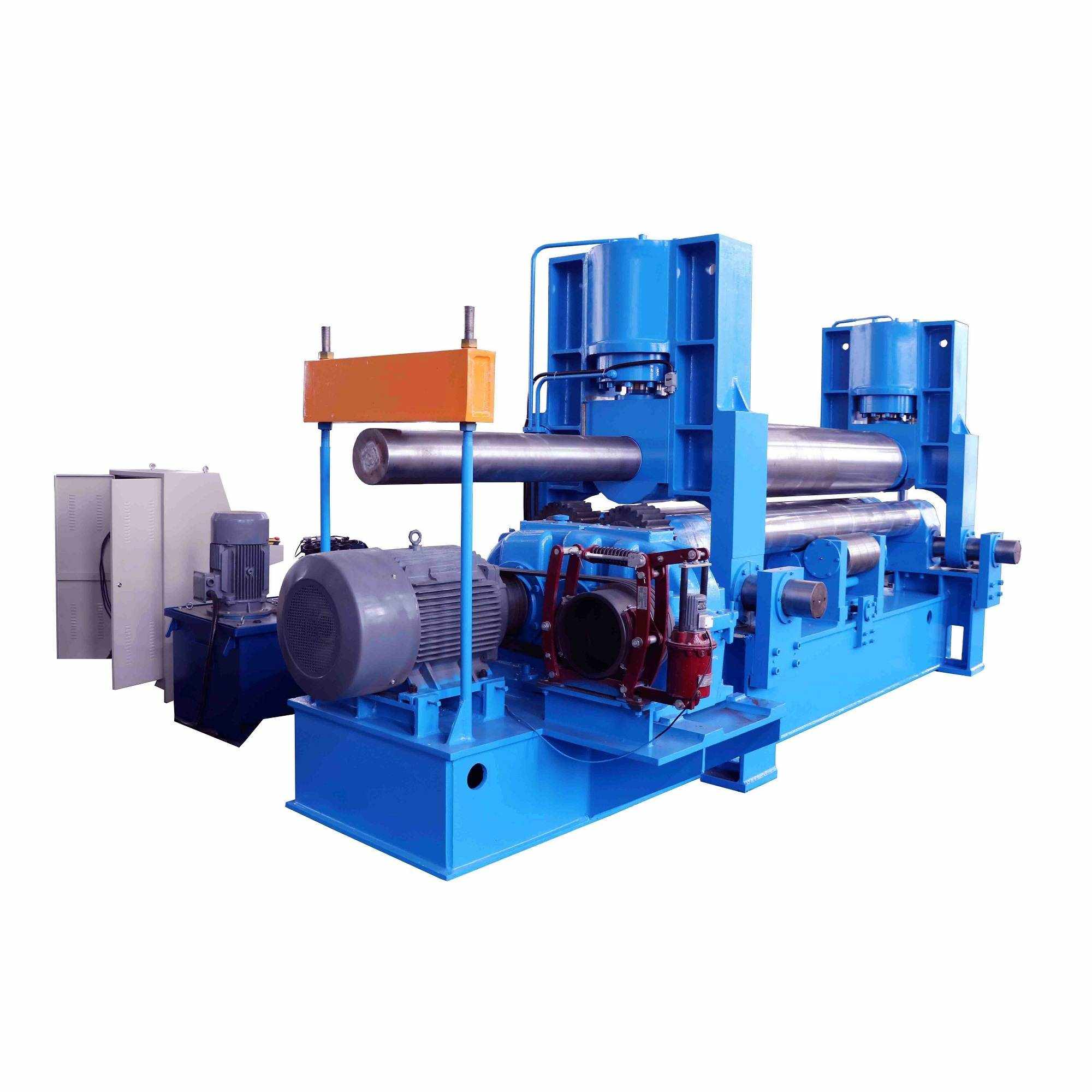

W11S 3-Roller Universal Plate Rolling Machine – Factory Installation Showcase

Performance & Features

- High-Precision End Pre-Bending

With the upper roller offset horizontally, the W11S 3-Roller Plate Rolling Machine achieves accurate end pre-bending with minimal straight edges. - NC Control, High Productivity

Equipped with a PLC programmable display and a large LCD touchscreen, the W11S Upper Roller Universal Plate Rolling Machine ensures intuitive operation, fast parameter setting, and greatly improved efficiency. - Superior Rolling Accuracy

Drum-shaped upper roller with adjustable support rollers guarantees excellent roundness and accuracy, from thin sheets to heavy plates. - Enhanced Safety

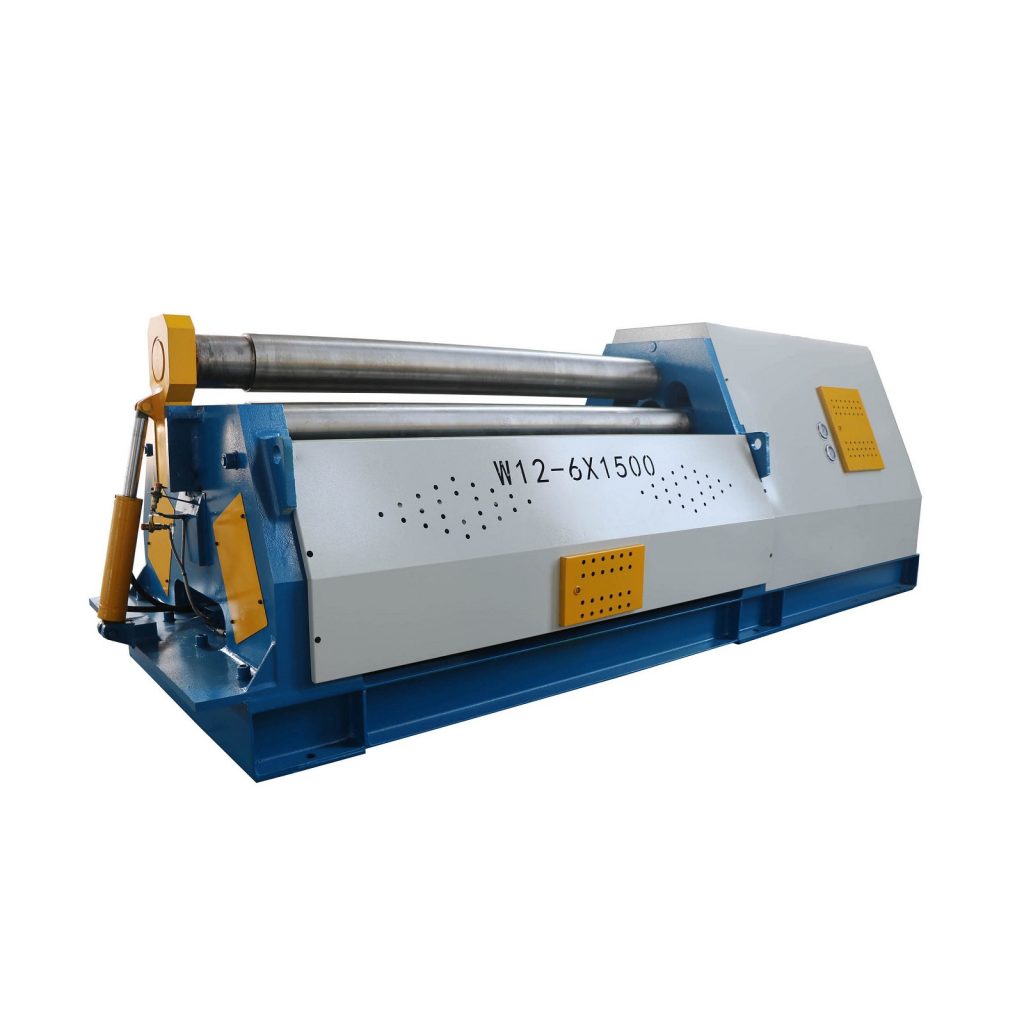

The W11S Universal 3-Roller Plate Bending Machine comes with overload protection, automatic fault alarms, cable safety switches, and emergency stop buttons to protect both operators and equipment. - Compact Integral Structure

The W11S Upper Roller 3-Roller Plate Rolling Machine adopts an integral chassis design. It requires no anchor bolts, making installation simple and relocation convenient. - Wide Bending Applications

Capable of rolling O-type, U-type, multi-radius (R-type), and cone shapes with high efficiency.- O-shape: rear bending method

- U-shape: front bending method

- Multi-radius: combined bending method

- Advanced Electronic Control System

- Electronic parallelism control

- Roller synchronization and balancing via electronic control

- EPS automatic electronic leveling keeps rollers parallel in real time

- Mobile control panel with low-voltage operation

Equipment Configuration & Quality Assurance

- Hydraulic & Electrical Systems: High-quality branded components ensure smooth and reliable performance.

- Electrical Safety: Detailed schematics with clear terminal markings, compliant with strict standards.

- Roller Material: SAE1050 (CK45) alloy steel, induction-hardened, heat-treated, precision ground, and polished.

- Lubrication & Protection: Automatic lubrication, overload safety, interlocks, and braking system.

- Durability & Support: All rollers are hardened and polished, guaranteeing long service life. Multi-year warranty with lifetime technical support.

The W11S Upper Roller 3-Roller Universal Plate Rolling Machine delivers high precision, productivity, and reliability for various industrial applications.

With advanced hydraulic and NC control systems, robust construction, and comprehensive safety features, the W11S Series Universal 3-Roller Plate Bending Machine is the ideal choice for modern manufacturers seeking accuracy, efficiency, and long-term performance.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.