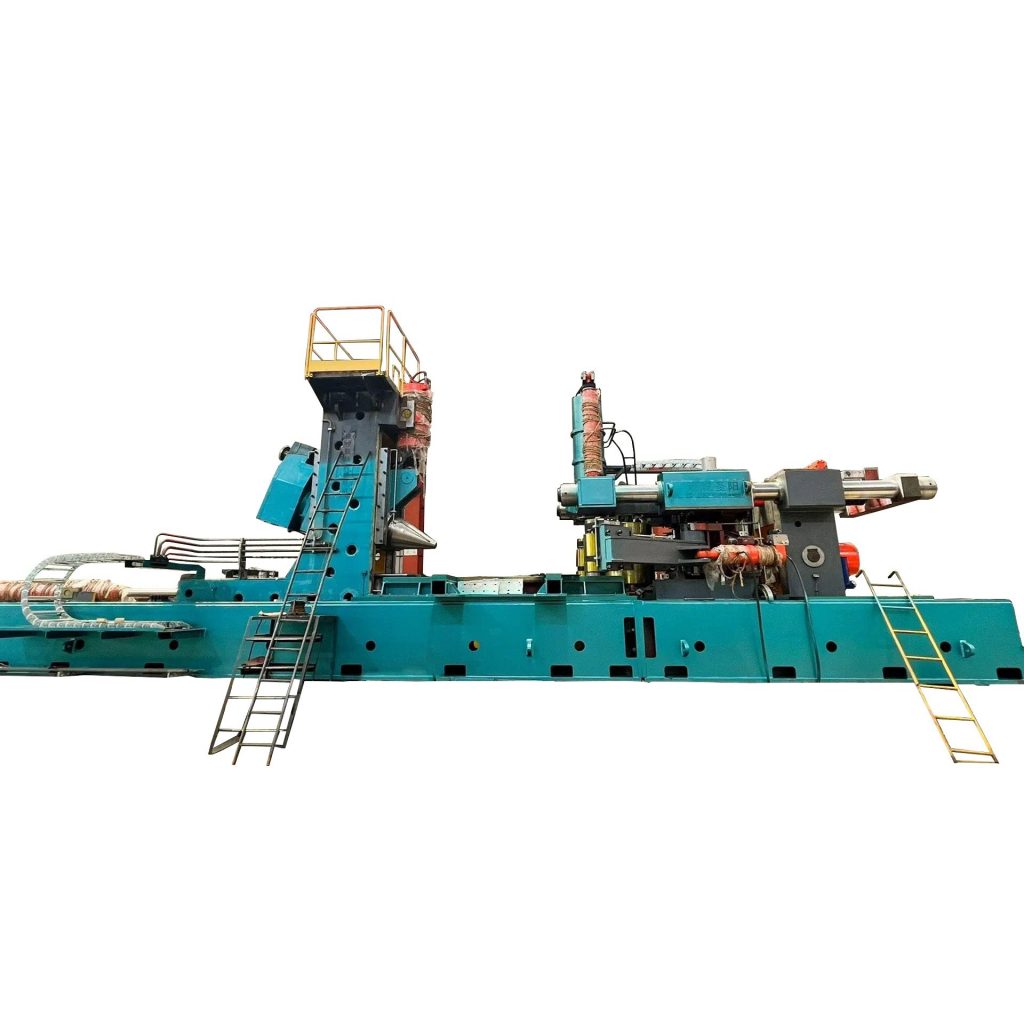

ALEKVS CNC Vertical Radial Ring Rolling Machine is a precision forging equipment based on numerical control technology. It is used for rolling heated ring blanks into seamless rings of different sizes and shapes. The servo motor with reducer and ball screw ensures stable feed, reduces the effect of temperature changes, and keeps machining accuracy stable.

ALEKVS CNC Vertical Radial Ring Rolling Machine Working Principle

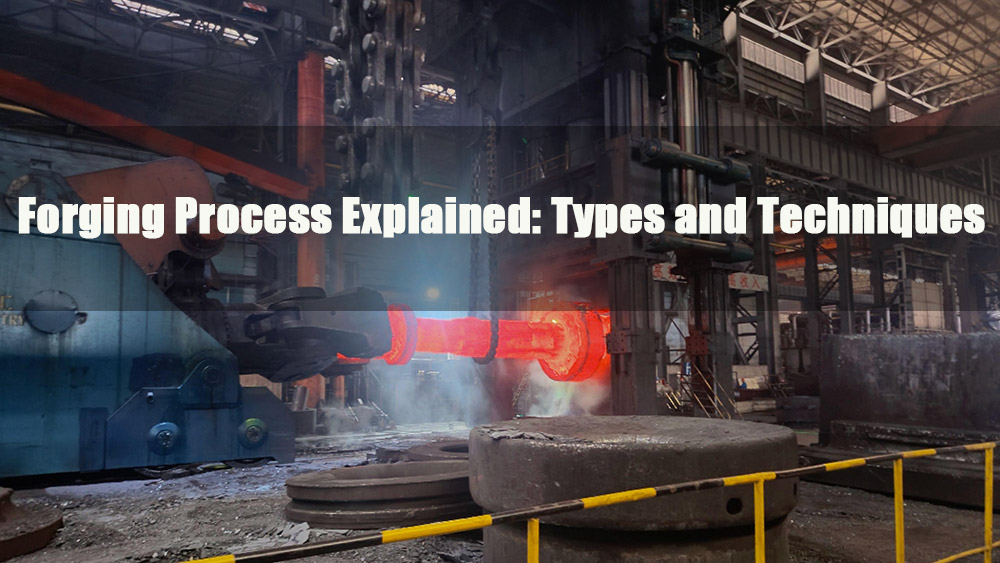

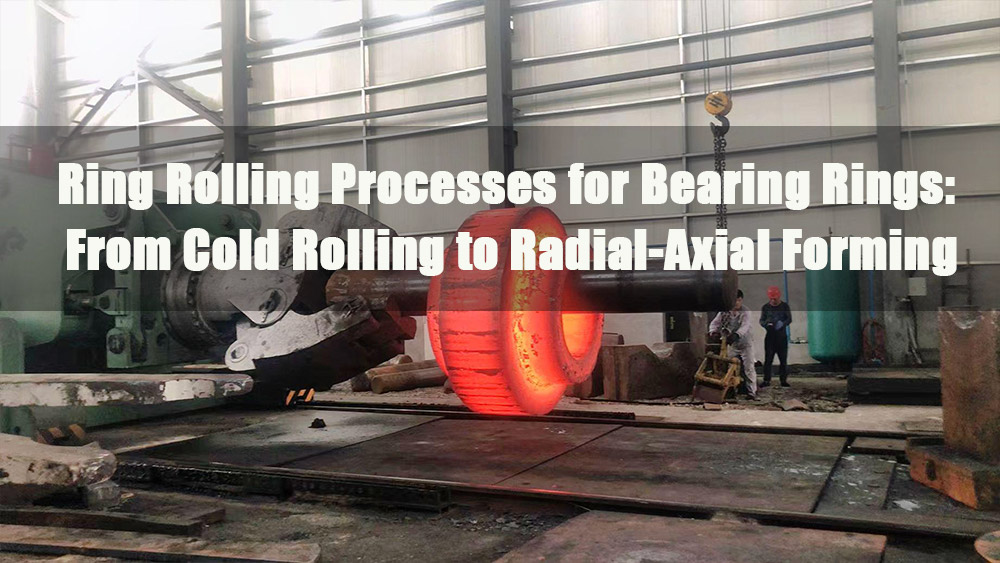

The essence of ring rolling is plastic deformation of heated metal:

- The heated ring blank is mounted on the mandrel (core roller).

- The driving roll rotates actively, applying circumferential friction and radial pressure.

- The mandrel feeds radially to reduce wall thickness while expanding the ring diameter.

- Guide rolls keep the ring stable, while the measuring roll detects real-time dimensions.

- The CNC system precisely controls parameters such as rolling force, feed rate, and spindle speed, ensuring the ring meets exact dimensional tolerances.

Main Components

- Main Frame– provides rigid support and houses all core parts.

- Driving Roll– actively powered, delivers torque and rolling force.

- Mandrel (Core Roll)– feeds radially to control wall thickness.

- Guide Rolls– stabilize the ring during rolling.

- Measuring Roll (Signal Roll)– monitors outer diameter and feeds back to CNC system.

- CNC Control System– integrates PLC, servo drives, and HMI for automated operation and precision monitoring.

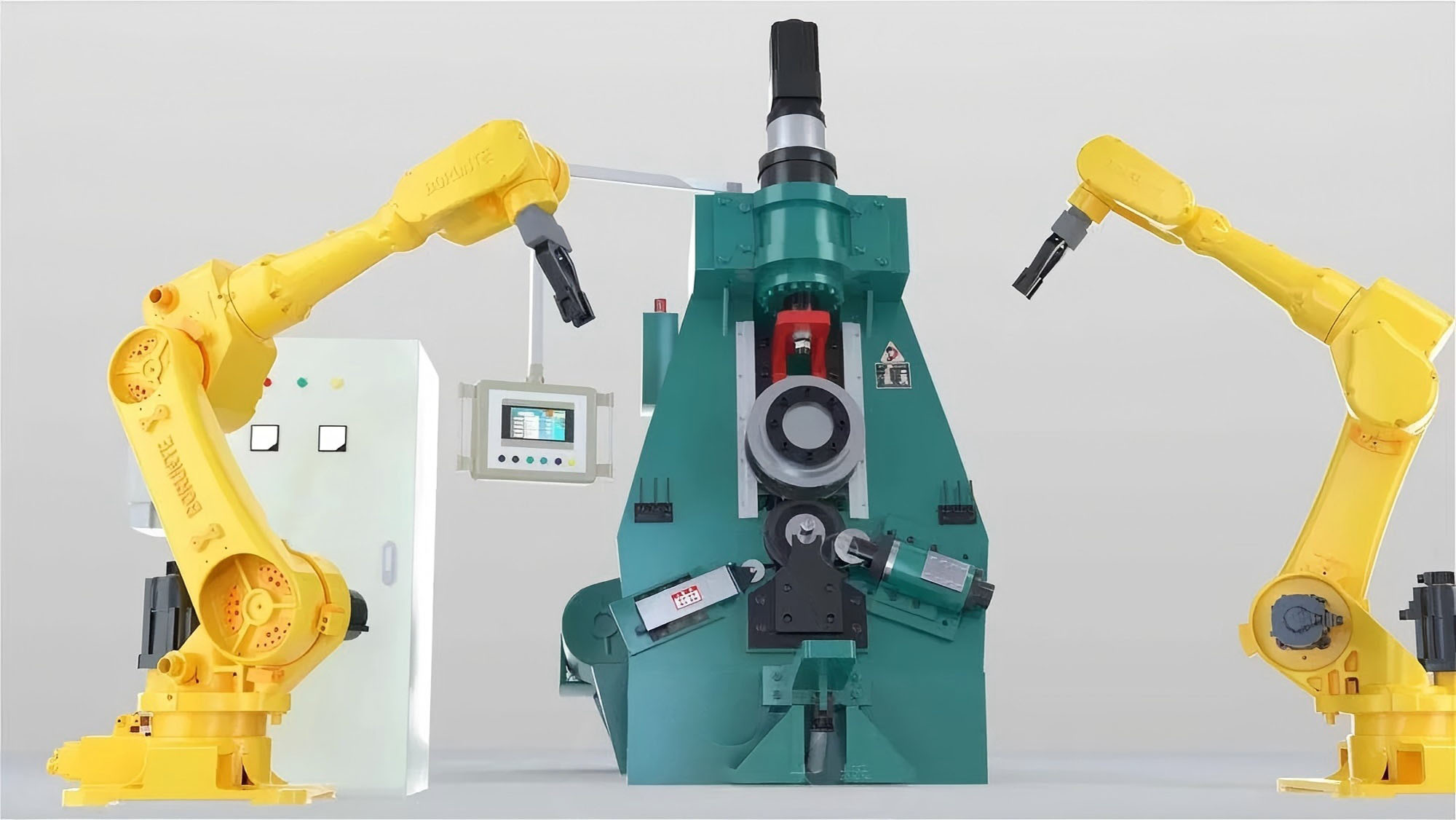

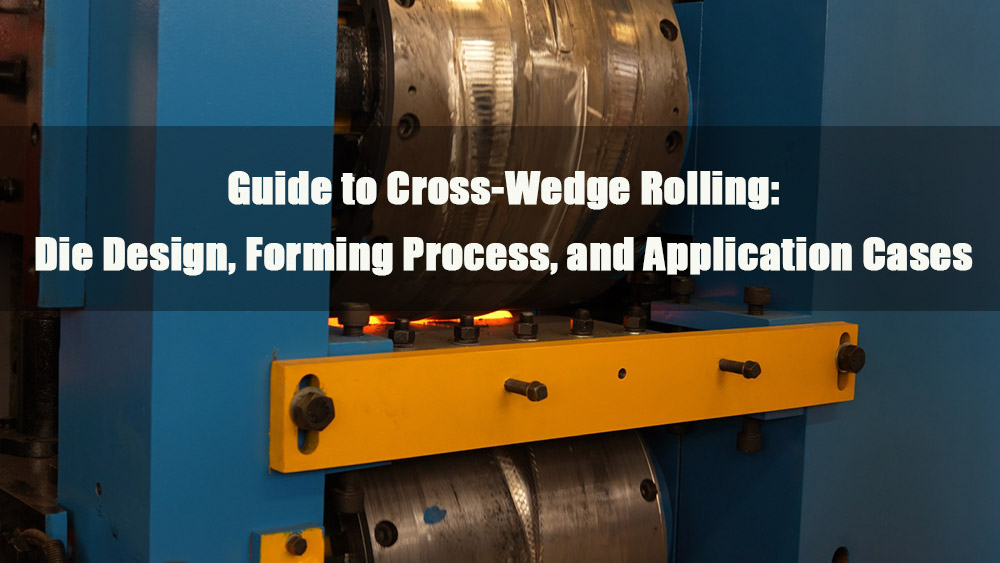

Fully Automatic Robotic Arm Loading and Unloading – CNC Radial Ring Rolling Machine

The CNC Ring Rolling Machine with fully automatic robotic arm loading and unloading offers a highly efficient and intelligent forging solution. Designed for the continuous production of precision rings and flanges, this system integrates advanced CNC control with automated material handling. The robotic arm ensures safe, accurate, and rapid transfer of workpieces, minimizing manual labor while improving productivity.

Key Features & Advantages

- High Precision– Dimensional tolerance up to ±0.1 mm, excellent roundness and surface quality.

- High Efficiency & Energy Saving– Continuous rolling replaces multi-step forging, improving productivity by 30–50% and material utilization by 20–30%.

- Superior Mechanical Properties– Continuous metal flow lines, uniform grain structure, and excellent strength and toughness.

- Automation– Optional robotic loading and unloading system for full automatic production, reducing manual labor.

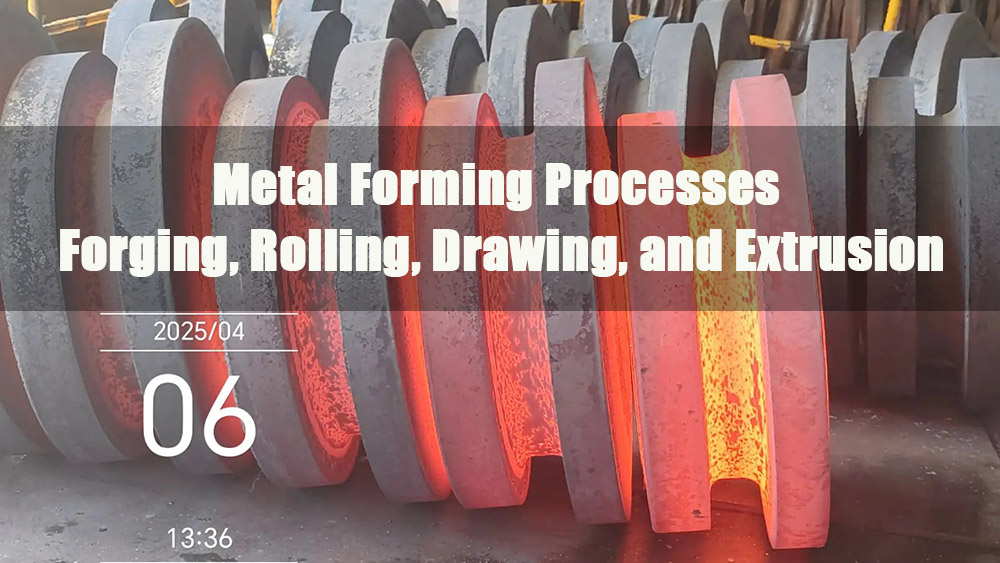

- Flexibility– Capable of producing flat rings and profile rings (with steps inside/outside) in various materials such as carbon steel, stainless steel, alloy steel, bronze, aluminum, and titanium alloy.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.