- 1.0Chamfer

- 2.0Bevel

- 3.0Fillet / Round

- 4.0Rounding

- 5.0What does chamfer mean?

- 6.0Material Considerations and Edge Treatment Preference

- 7.0Similarities Between Fillets and Rounding

- 8.0Key Differences Between Fillet and Chamfer

- 9.0Difference Between Chamfer and Bevel

- 10.0Chamfer vs Deburring

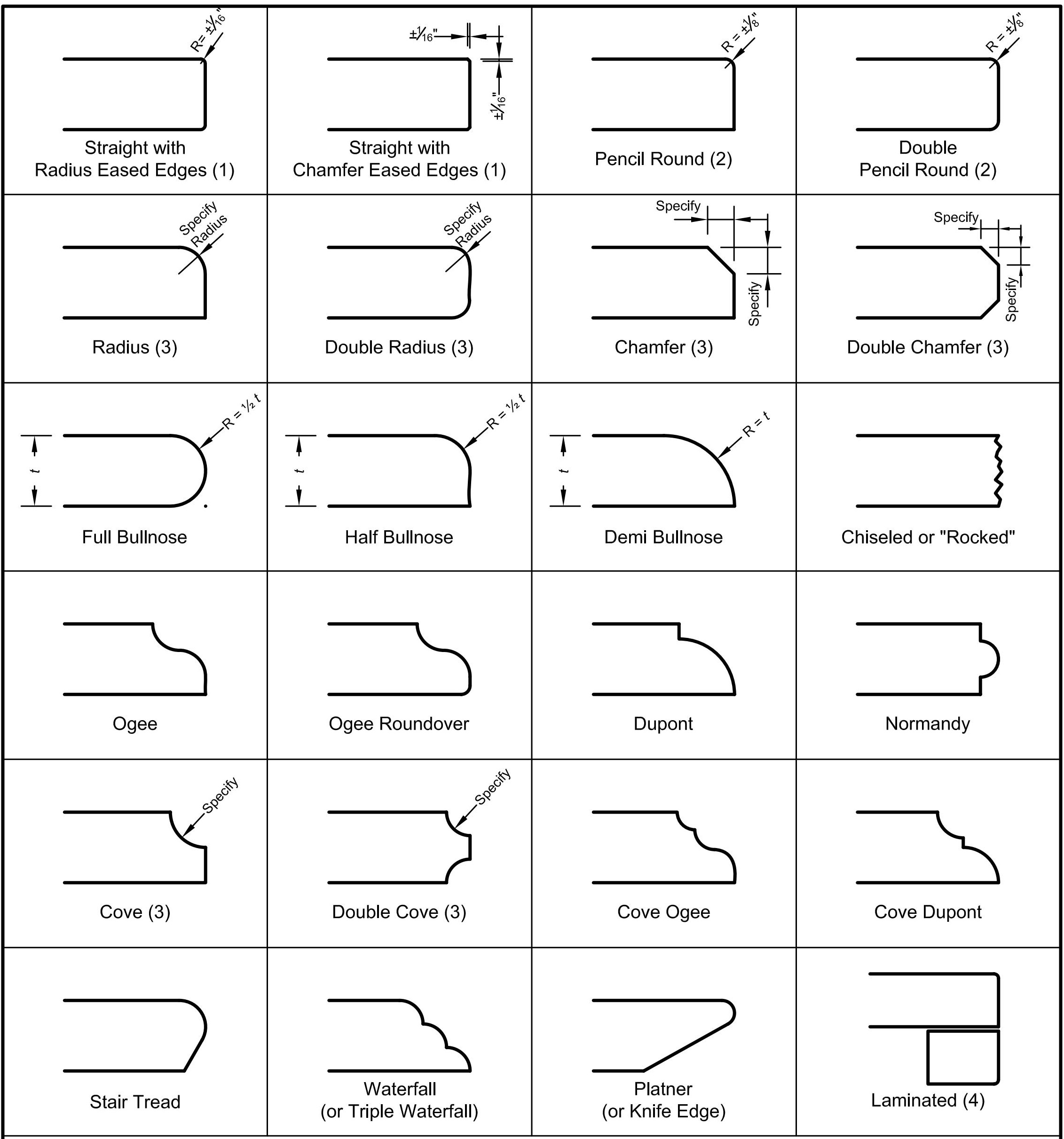

- 11.0Chamfer edge profile type

Introduction

In engineering, manufacturing, and product design, edge treatments play a crucial role in both functionality and aesthetics. Techniques such as chamfering, beveling, filleting, and rounding may appear similar at first glance, but each serves distinct purposes depending on the application. From improving safety and assembly to reducing stress concentrations and enhancing visual appeal, choosing the right edge treatment is essential for optimal performance and user experience.

This article provides a comprehensive overview of these common edge modifications—defining their geometry, functions, machining methods, drawing notations, and key differences—empowering designers and engineers to make informed decisions throughout the product development process.

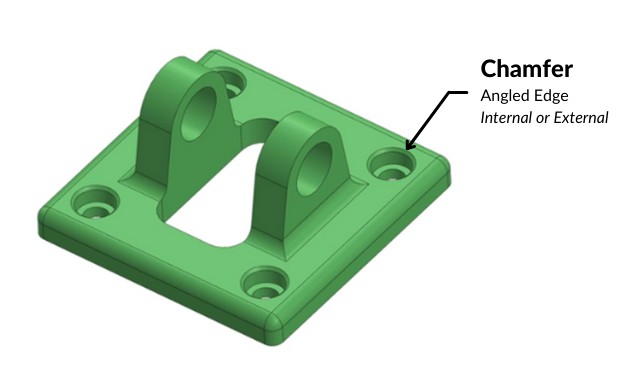

1.0Chamfer

Definition:

A chamfer is a beveled edge that connects two surfaces, typically cut at a 45° angle, though other non-standard angles such as 30° or 60° may also be used. Chamfers can be applied to both internal and external edges and are often dimensionally defined.

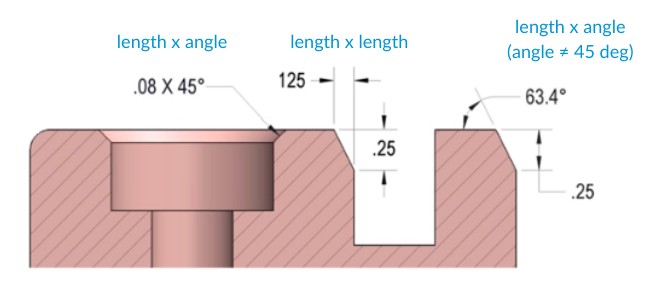

Machining and Dimensioning:

Chamfers are typically specified using angle + leg length or two-leg dimensions. For non-45° chamfers, reference to a datum is generally required. A drawing annotation such as “2×45°” indicates two chamfers, each with a 45° angle and 2 mm leg length.

Functions:

- Removes sharp edges to prevent injury or damage;

- Simplifies assembly and improves part alignment;

- Prepares surfaces for welding or countersinks;

- Enhances a sharp, geometric appearance;

- Reduces stress concentration and improves structural integrity.

Applications:

Chamfers are widely used in machining, metal fabrication, woodworking, furniture making, picture framing, and concrete formwork. In mechanical engineering, chamfers are frequently applied for assembly fits, lead-ins, and edge protection. For example, chamfers are commonly used at the openings of screw holes to guide fasteners.

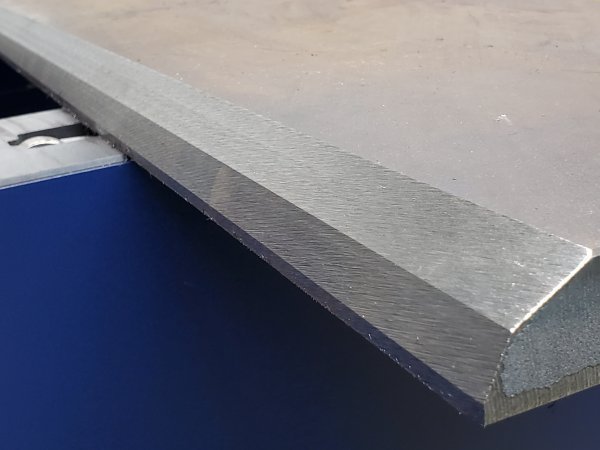

2.0Bevel

Definition:

A bevel is an angled surface that transitions between two faces, usually ranging from 25° to 45°, though other angles may be used based on functional or visual requirements. Bevels are broader in concept than chamfers and often emphasize a smoother, more gradual angular change.

Functions:

- Provides a smooth visual or functional transition between surfaces;

- Refines product outlines and contours;

- Commonly used for welding preparation, pipe beveling, and mold edge design.

Applications:

Bevels are often found in architectural detailing, furniture design, glass and sheet metal finishing, and welded pipelines.

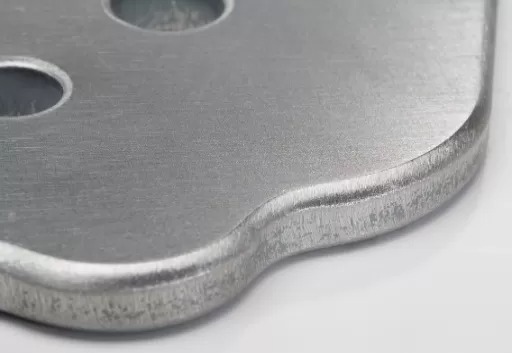

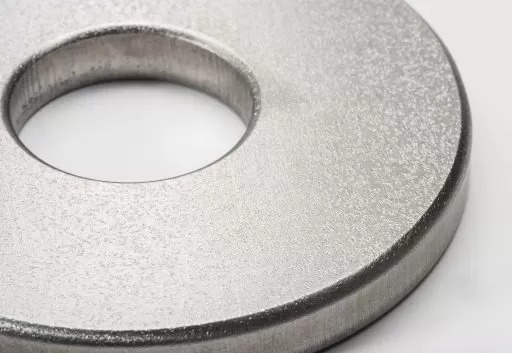

3.0Fillet / Round

Definition:

A fillet (or round) is a rounded transition between two surfaces, typically defined by a radius. Fillets may be concave (internal corners) or convex (external corners) and are used to smooth out sharp intersections. They fall under the broader category of radius-based treatments.

Functions:

- Reduces stress concentration and fatigue failure risk;

- Enhances ergonomics and handling comfort;

- Softens visual transitions for aesthetic purposes;

- Improves structural integrity, especially in load-bearing or dynamic parts.

Machining:

Fillets are usually machined via CNC milling, turning, or wire EDM. Technical drawings denote fillet radii as R + value (e.g., R5, R10).

Applications:

Commonly used in product enclosures, children’s furniture, electronic housings, and mechanical components like gear teeth or shaft shoulders. For instance, fillets are critical in automotive suspension parts to reduce fatigue failure.

4.0Rounding

Definition:

Rounding refers to the general practice of softening sharp edges across a part, often without a strict radius specification. It is typically applied for ergonomic, safety, and visual reasons.

Characteristics:

- A non-specific edge-softening treatment;

- Used to improve user comfort and safety;

- Frequently applied in consumer products, furniture, and handheld devices.

5.0What does chamfer mean?

Chamfer refers to a beveled or angled edge that connects two surfaces, typically cut at a 45-degree angle, although other angles like 30° or 60° may also be used. It is a flat, sloped surface created at the corner or edge of a part, used to remove sharp edges and facilitate assembly.

Key Points about Chamfers:

Definition: A chamfer is a cut-away corner or edge, forming an angled transition between two adjoining surfaces.

Typical Angle: Commonly 45°, but can vary based on design needs.

Notation Example: “2×45°” means two chamfers, each with a 45° angle and a specified leg length (e.g., 2 mm).

Location: Can be applied to both internal and external edges.

Function:

- Improves safety by eliminating sharp corners

- Ease the assembly and alignment of parts

- Prepares edges for welding or countersinking

- Enhances visual appearance

- Reduces stress concentration

Chamfers are especially important in mechanical components like screw holes, part interfaces, and machined edges where precision and fit are critical.

6.0Material Considerations and Edge Treatment Preference

| Material Type | Preferred Edge Treatment | Reason |

| Metal | Chamfer, Fillet | Precision, strength |

| Plastic | Rounding, Fillet | Safety, ergonomics |

| Wood | Bevel, Rounding | Aesthetics, tool compatibility |

7.0Similarities Between Fillets and Rounding

| Feature | Rounding | Fillet |

| Category | Both belong to “Radius” treatments | |

| Purpose | Soften edges, improve appearance and safety | Structural strength, stress relief, aesthetics |

| Geometry | General edge smoothing, wide curvature | Defined arc transitions with specific radius |

| Application Focus | Ergonomic surfaces, enclosures, furniture | Mechanical components, engineering structures |

| Notation | Rarely specified; often noted as “rounded edges” | Explicitly defined as R + value (e.g., R5) |

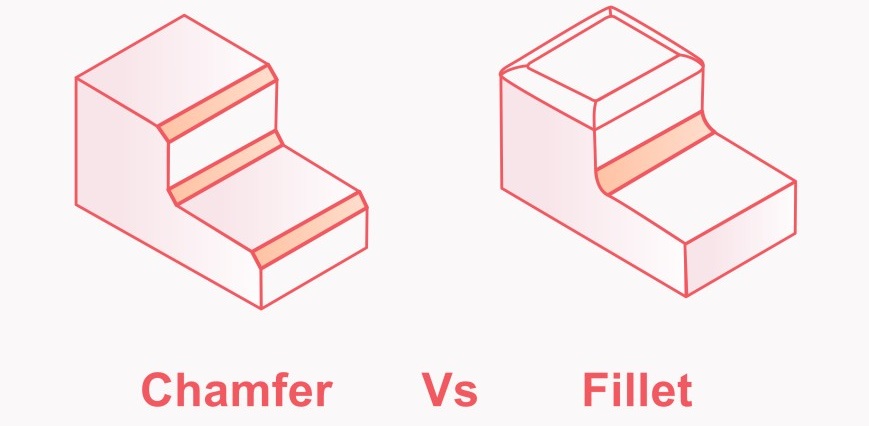

8.0Key Differences Between Fillet and Chamfer

| Comparison Criteria | Fillet (Round) | Chamfer |

| Shape | Curved (arc) | Angled (flat surface) |

| Visual Effect | Smooth and rounded | Sharp and defined |

| Functional Purpose | Stress relief and structural optimization | Remove sharp corners, aid assembly |

| Notation | Radius (R) | Angle + leg length (e.g., 2×45°) |

| Application Focus | Aesthetics, safety, fatigue resistance | Alignment, installation, edge protection |

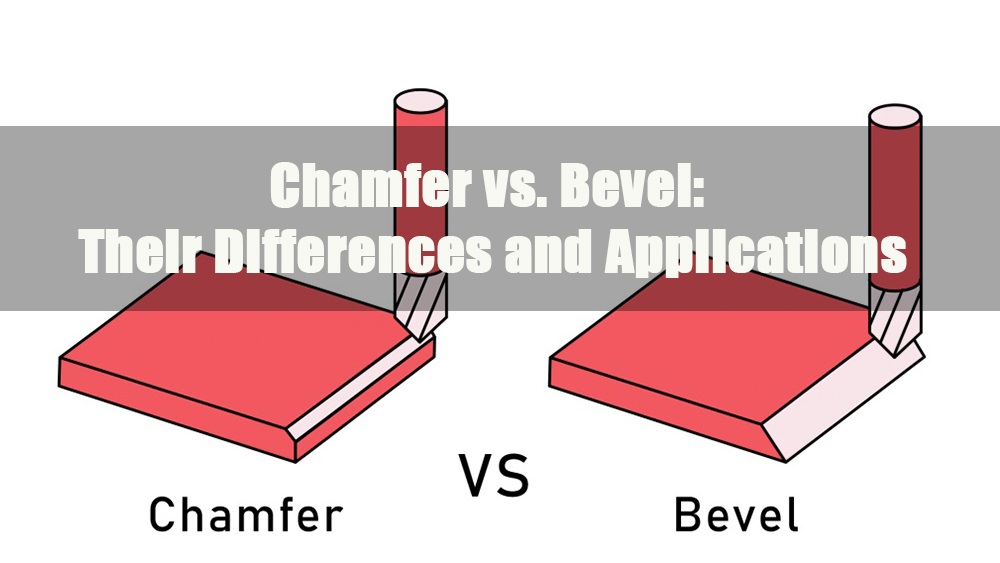

9.0Difference Between Chamfer and Bevel

- A bevel generally refers to any sloped surface cut across an edge, often used for aesthetic or general transition purposes.

- A chamfer is a more specific feature, applied for functional goals such as alignment or safety, and includes exact dimensional requirements.

- All chamfers can be considered bevels, but not all bevels qualify as chamfers.

10.0Chamfer vs Deburring

Chamfering:

- A controlled process to cut edges or corners at a specified angle;

- Improves appearance, fitment, and reduces stress points;

- Precisely dimensioned in technical drawings, often noted per ISO 13715 (e.g., C0.5).

Deburring:

- Focuses on removing burrs or rough edges caused by machining or cutting;

- Aims to enhance safety and product quality.

- Less rigid in dimensional requirements and often subjective.

Achieving Optimal Edge Finishing

- Design Phase: Select edge treatment based on application. Use fillets for stress-prone areas and chamfers for mating surfaces.

- Machining Phase: Utilize appropriate tooling such as chamfer mills, radius cutters, or CNC toolpaths.

- Inspection Phase: Verify surface finish, tolerance accuracy, and whether all edges are properly deburred or treated.

11.0Chamfer edge profile type

Conclusion

Chamfers, fillets, bevels, and rounding are essential edge treatments in engineering, manufacturing, and design. Understanding their unique properties and appropriate applications ensures that each part not only performs optimally under mechanical stress but also meets ergonomic, aesthetic, and safety requirements. The right choice of edge treatment can elevate the overall quality and functionality of any product.