- 1.0What Is Plate Rolling?

- 2.0Overview of Plate Rolling Techniques: Methods and Applications

- 3.0Plate Rolling Process: A Step-by-Step Guide to Metal Bending

- 4.0Three Key Stages of Plate Rolling: Pre-Bending, Rolling, and Post-Bending

- 5.03-Roll Plate Rolling Machine Process: Single-Pinch Operation

- 6.04-Roll Plate Rolling Machine Process

- 7.0Key Techniques for Medium and Thick Plate Rolling

1.0What Is Plate Rolling?

Plate rolling is a metal forming process that shapes flat metal sheets into cylindrical, conical, elliptical, or other curved profiles. This is achieved by passing the plate through a series of rollers that apply continuous and controlled pressure, gradually bending the material into the desired geometry.

This process is widely used in the fabrication of pressure vessels, oil and gas pipelines, ship hulls, structural beams and columns, and industrial equipment housings. Known for its efficiency, consistency, and forming capability, plate rolling is a preferred method in many heavy-duty manufacturing applications.

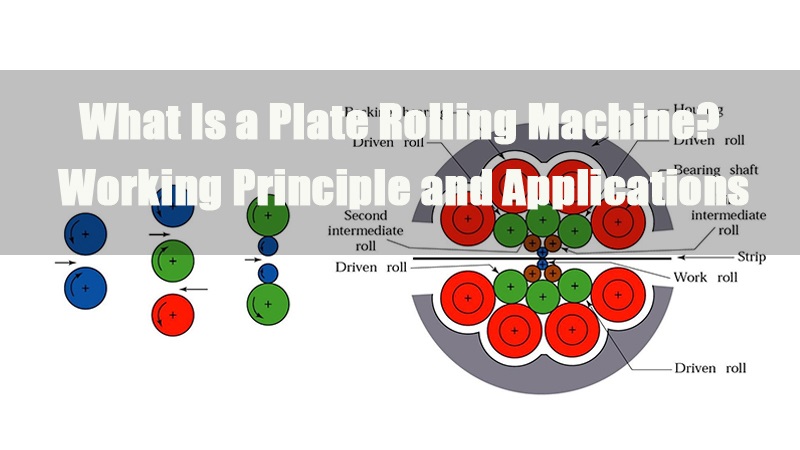

1.1Common Types of Plate Rolling Machines

| Type | Features & Applications |

| Pyramid-Type Plate Rolls | Simple design, suitable for standard rolling of medium-thickness plates |

| Three-Roll Symmetrical | Widely used for general industrial needs; offers a balance of cost and performance |

| Four-Roll Plate Rolls | Higher precision; enables automated pre-bending and rolling in one pass |

| CNC Plate Rolling Machines | Ideal for high-volume, repeatable jobs; allows programmable control |

Recommended Reading:What Is a Plate Rolling Machine? Working Principle and Applications

1.2Advantages of Plate Rolling

- Efficient Production

Automated rolling delivers faster and more consistent results than manual forming. - Material Savings

Reduces waste and preserves material integrity and continuity - Versatile Material Compatibility

Works with steel, stainless steel, aluminum, copper, titanium, and a variety of alloys. - High Precision and Consistency

Enables tight control over curvature and complex profiles across the entire length of the sheet. - Enhanced Structural Integrity

Minimizes the need for welds and joints, increasing overall strength and pressure resistance. - Shape Flexibility

Capable of forming not just simple cylinders, but also cones, double-curved surfaces, and other advanced geometries. - Heavy-Duty Capability

Suitable for rolling thick plates and large-diameter components used in ships, energy systems, and industrial machinery.

2.0Overview of Plate Rolling Techniques: Methods and Applications

Recommended Reading:Complete Guide to Metal Rolling: Hot, Cold, Flat & Shape Rolling

2.1Initial Pinch Rolling (Initial Pinch Bending)

Advantages:

- Suitable for a wide range of materials including carbon steel, stainless steel, aluminum, and titanium

- Lower equipment cost and simple operation

- High precision and repeatability, ideal for batch production

Disadvantages:

- Cannot pre-bend both ends in a single pass

- Not suitable for extremely thick or wide plates

- Requires manual flipping of the plate, increasing handling steps

2.2Four-Roll Plate Rolling

More advanced than three-roll systems, four-roll machines feature an upper and lower main roll with two adjustable side rolls arranged in a diamond shape. The central rolls handle feeding and pressure, while the side rolls assist in forming and pre-bending both ends of the plate.

Advantages:

- Single setup allows pre-bending of both ends without flipping the plate

- Capable of handling thicker and wider materials

- High forming accuracy, suitable for complex shapes

- Increases production efficiency by minimizing material handling

Disadvantages:

- Higher equipment cost

- More complex structure requiring skilled operation

2.3 Variable Geometry Rolling

This technique uses a pyramid-style three-roll configuration where roll positions can be adjusted to form cylinders, ellipses, cones, and other complex shapes. Ideal for high-thickness, high-strength materials such as stainless steel and titanium alloys.

Advantages:

- Supports a variety of geometric profiles

- Capable of rolling plate thicknesses up to 6 inches (approx. 150 mm)

- High precision, ideal for custom and high-end manufacturing

Disadvantages: - Expensive equipment

- Complex setup requiring advanced maintenance and control systems

2.4 Two-Roll Rolling (Simplified Type)

Two-roll machines use a top and bottom roll to clamp and bend thin metal sheets through applied pressure. They are typically used for small-batch forming of light materials.

Advantages:

- Simple structure and low cost

- Suitable for preliminary forming of small to medium-sized parts

Disadvantages:

- Limited precision

- Inadequate for thick plates or complex structures

3.0Plate Rolling Process: A Step-by-Step Guide to Metal Bending

Plate rolling is a critical process for shaping flat metal sheets into curved or cylindrical components. Below is a concise, structured guide for achieving precise and high-quality bending results:

Step 1: Material Preparation

Select sheet metal that meets design requirements in terms of curvature, thickness, and strength. Clean the surface to remove rust, oil, and contaminants to ensure optimal rolling quality.

Step 2: Machine Setup

Adjust the roll gap and roll positions according to the plate thickness and target bending radius. Secure the machine setup to ensure a stable and safe rolling process.

Step 3: Plate Insertion

Place the metal sheet between the upper and lower rolls. Align it accurately and center it properly.

Step 4: Pre-Bending

Lower the top roll to make initial contact with the sheet and apply moderate pressure to achieve slight bending. This reduces springback during the main forming process.

Step 5: Main Rolling

Adjust the top roll to the target radius and start the rolling machine. The rolls work together to apply continuous pressure, shaping the plate. Monitor the process in real time to ensure uniform deformation and avoid overstressing the material.

Step 6: Multi-Pass Rolling (If Required)

For thicker plates, perform multiple passes. After each pass, adjust the top roll to gradually approach the desired curvature.

Step 7: Quality Inspection

Stop the machine after forming and check for cracks, distortion, or dimensional deviations. Measure the curvature radius to verify compliance with design specifications.

Step 8: Post-Processing

If needed, perform edge trimming, surface finishing, or material adjustment. Carefully remove the workpiece to avoid secondary deformation.

3.1Key Considerations in Process Design and Quality Control

- Material Selection:Ensure plate thickness, strength, and ductility meet both process and structural requirements

- Surface and Edge Preparation:Remove oxide layers, burrs, and residual stress before forming

- Flat Zone Elimination:Use accurate pre-bending and over-bending techniques to eliminate straight ends

- Machine Calibration:Set roll pressure, feed speed, and path parameters appropriately

- Springback Compensation:Allow for material springback, especially in aluminum and other elastic alloys

- Weld Seam Management:Position welds away from stress-concentration zones or plan for post-weld heat treatment

- Inspection and Testing:Perform dimensional measurements, surface checks, and curvature error evaluations

4.0Three Key Stages of Plate Rolling: Pre-Bending, Rolling, and Post-Bending

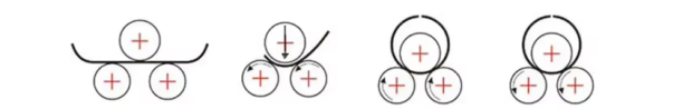

4.1 Pre-Bending

Pre-bending is the initial bending operation performed on the edges of the sheet before it enters the main rolling stage. By slightly lifting the sheet edges, the material can better conform to the roll curvature during rolling, thereby avoiding flat ends or geometric asymmetry after forming.

4.2Pre-Bending Process

Pre-bending is typically performed on the plate rolling machine through the following steps:

- The sheet is clamped between multiple rolls;

- By adjusting the gap between the upper and lower rolls, initial pressure is applied to the edges before the sheet fully enters the main forming zone;

- As the rolls rotate, the edge is gradually bent to the desired pre-bending radius.

After pre-bending, the sheet edge aligns more smoothly with the rolled arc, minimizing seam gaps and providing ideal conditions for subsequent welding or joining.

4.3Importance of Pre-Bending

- Improves forming accuracy:Controls edge curvature to ensure a smooth and continuous circular shape;

- Prevents edge deformation:Avoids flat zones or misalignment at the sheet ends;

- Enhances joint quality:Enables smooth end-to-end alignment for easier welding and assembly;

- Ensures structural consistency:Distributes bending forces evenly and prevents localized stress concentrations.

4.4Rolling

Rolling is the core stage of the forming process. During this step, the metal sheet passes through a set (or multiple sets) of rolls and is gradually bent into the desired arc or cylinder. Key control parameters include:

- Roll pressure:Adjusting the gap between upper and lower rolls;

- Feeding speed:Synchronizing material feed with deformation;

- Roll configuration:Choosing between three-roll, four-roll, or variable geometry setups depending on part size and shape.

Through continuous and incremental bending, the material undergoes plastic deformation until it reaches the target curvature.

4.5Post-Bending

After the main rolling process, minor springback or end irregularities may still exist. To correct these and further enhance geometric precision, a post-bending operation is typically performed:

- The rolled sheet is re-fed through the rolls in reverse;

- Fine adjustments are made using symmetrical pressure to ensure a fully rounded profile;

- The end edges are refined to improve flatness and uniformity.

This step is particularly critical in high-precision applications such as pressure vessels, cylindrical tanks, or large wind tower sections.

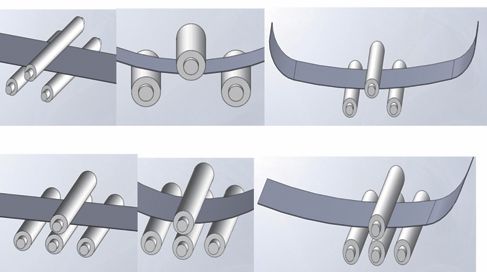

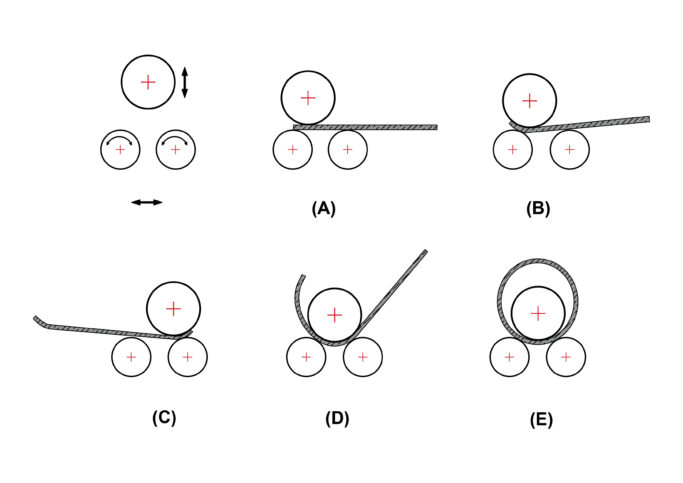

5.03-Roll Plate Rolling Machine Process: Single-Pinch Operation

This is the most common machine type. However, it requires inserting the sheet twice to perform pre-bending on both ends, which eliminates flat edges and produces a tighter seam closure.

Step 1: First End Pre-Bending

The operator inserts the sheet between the upper roll and one of the lower rolls, securing it in place. The third roll (rear bending roll) then moves diagonally upward toward the upper roll to apply pressure, forming the desired bending radius at the plate’s leading edge.

Step 2: Second End Pre-Bending & Rolling

After bending the first edge, the sheet is removed, rotated 180°, and reinserted for pre-bending the second end. The rolling process continues until the plate is fully formed into a cylindrical shell.

Note:The recommended maximum thickness or width for pre-bending is generally 75% of the machine’s rated capacity. For narrower plates, allowable thickness may be increased. Please consult the equipment manufacturer for application-specific guidelines.

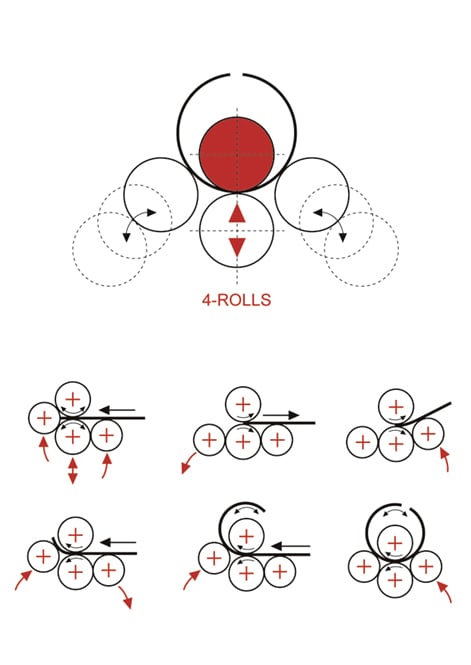

6.04-Roll Plate Rolling Machine Process

The 4-roll rolling machine provides greater precision and ease of use through full automation and one-pass rolling. The typical process includes:

- Position the metal plate parallel and square to the front roll;

- Clamp the plate between the top and bottom rolls with preset pressure;

- Feed the sheet backward between the rolls until only a minimal straight end remains;

- Raise the side roll to bend the leading edge (pre-bending);

- Continue rotating the clamping rolls to roll the plate into a circular shape;

- Lower the front roll and raise the opposite side roll;

- Rotate the shell to complete the cylindrical form;

The machine automatically corrects and finalizes the roundness by continuously feeding the plate forward until the desired geometry is achieved.

7.0Key Techniques for Medium and Thick Plate Rolling

Plate rolling is a core metal forming process that combines engineering know-how and practical experience. Success in medium and thick plate rolling depends not only on machine capability but also on deep material understanding and precise control. The following techniques are critical:

7.1Pre-Bending Treatment

Performing pre-bending on both plate ends before the main rolling eliminates flat zones at the start and end of the sheet. This helps form a continuous arc and avoids stress concentration or weak points. Special rolls are typically used to achieve consistent curvature across the entire plate.

7.2Equipment Selection: 3-Roll vs. 4-Roll

- 3-Roll Machines:Feature two lower rolls for clamping and one top roll for bending. Suitable for general-purpose forming of medium-thickness plates.

- 4-Roll Machines:Offer higher precision and automation. Ideal for high-tolerance requirements and forming complex curves or cones.

7.3Cold vs. Hot Rolling

- Cold Rolling:Performed at room temperature. Maintains material strength, surface finish, and dimensional flatness. Suitable for thin sheets or components with tight tolerances.

- Hot Rolling:Carried out at elevated temperatures. Reduces yield strength, enabling easier forming of thick plates. Preferred for large pressure vessels and structural applications.

Recommended Reading:What Are Steel Coils? Uses, Weight Calculation, and Hot vs Cold Rolled

7.4Incremental Rolling (Step-by-Step Bending)

To achieve the desired curvature, multiple rolling passes are often required. Incremental rolling involves gradually increasing roll pressure with each pass. This technique minimizes stress concentration, enhances form accuracy, and improves structural integrity.