- 1.0What Is Tube Laser Cutting?

- 2.0How Does Laser Tube Cutting Work

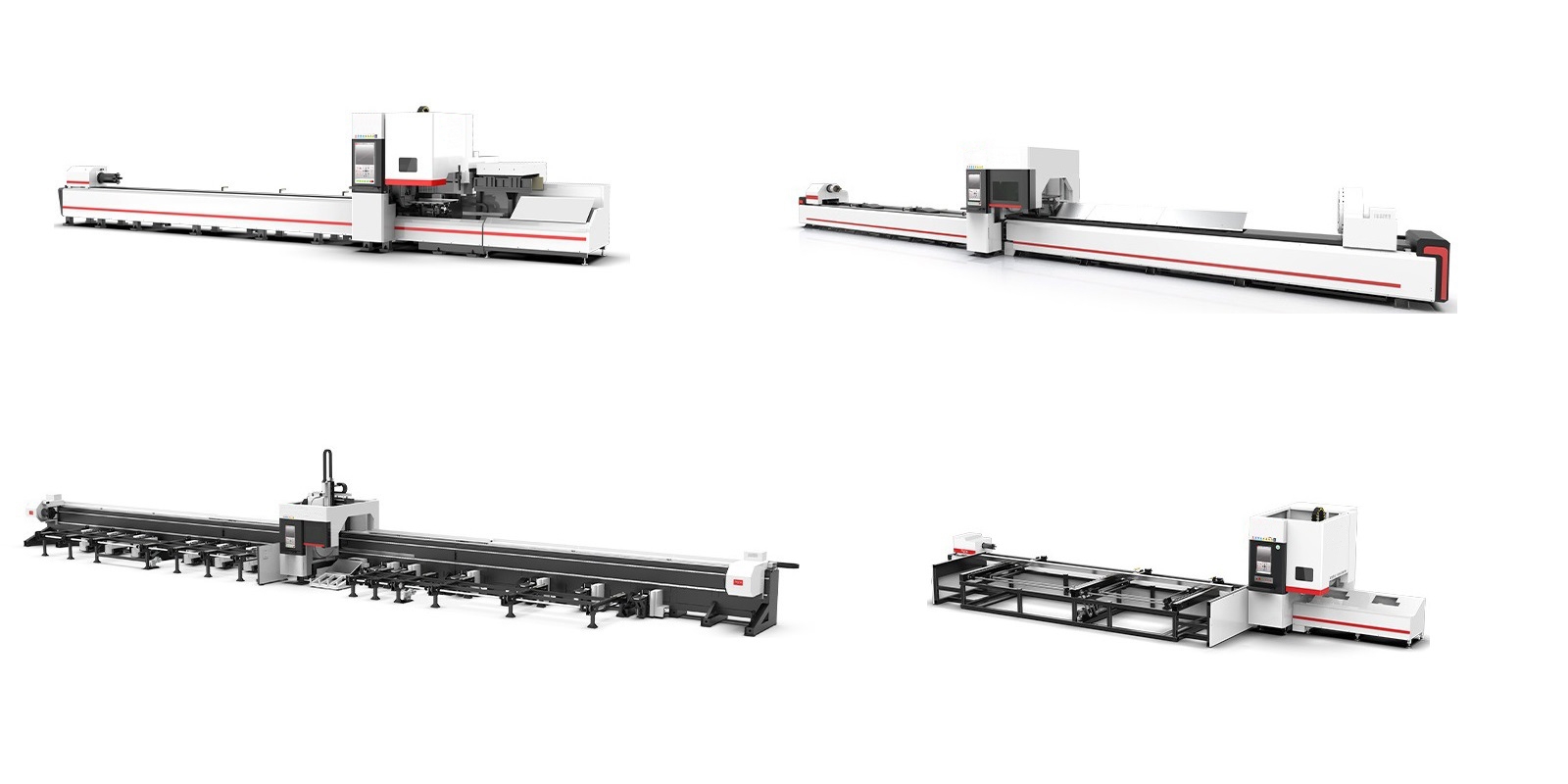

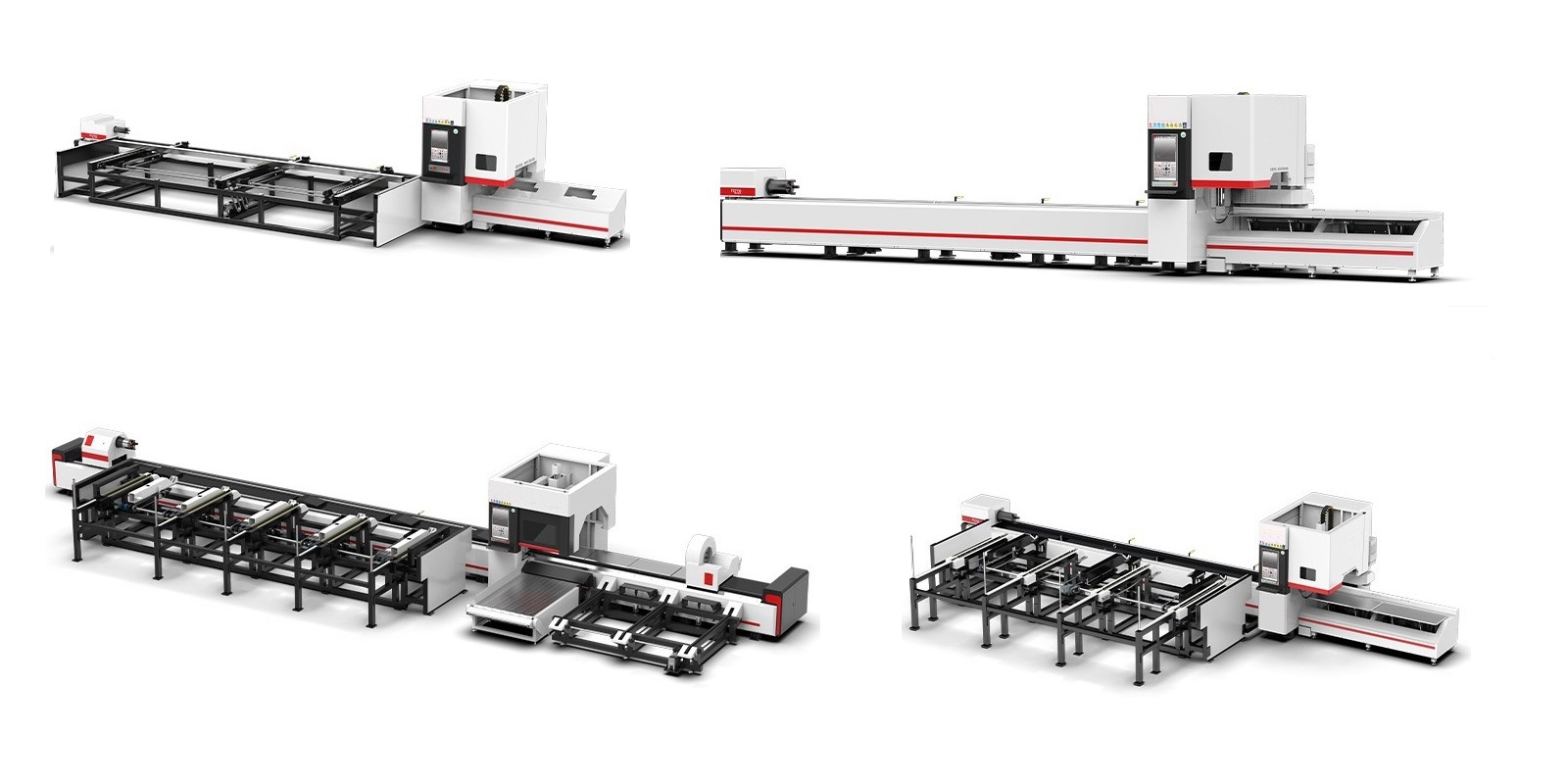

- 3.0Types of Laser Tube Cutting Machines

- 4.0What Is a Fiber Laser Cutting Machine?

- 5.0What Is a CO₂ Laser Cutting Machine?

- 6.0Comparison: Fiber Laser vs. CO₂ Laser Cutting Machines

- 7.0What Are the Tolerances for Tube Laser Cutting?

- 8.0Which Software and File Formats Are Supported by Tube Laser Cutting Machines?

- 9.0Top Brands of Laser Tube Cutting Machines

- 10.0Differences Between Tube Laser Cutters and Flatbed Laser Cutters

- 11.0Cutting Steel Tubes with Laser: Fiber or CO₂?

- 12.0How to Choose a Good Laser Tube Cutting Machine?

- 12.1Prioritize Fiber Lasers Over CO₂ Lasers:

- 12.2Look for “Zero-Tail” Cutting Capability — A Key to Cost Reduction and Efficiency:

- 12.3Evaluate Tube Compatibility Based on Processing Capabilities:

- 12.4Cutting Precision and Edge Quality: Key to Assembly and Welding:

- 12.5Automation Level Determines Efficiency and Labor Cost:

- 12.6Is the Software and Control System Smart and Easy to Use?

- 13.0Why Choose Laser Cutting for Tubes?

- 14.0Advantages of Tube Laser Cutting Compared to Other Cutting Methods

- 15.0Material Shapes Supported by Tube Laser Cutting Systems

- 16.0Advantages and Limitations of Laser Tube Cutting

- 17.0What are the key features of tube laser cutting software?

- 18.0How Does Tube Laser Cutting Drive Innovation in Manufacturing Design and Processes?

- 19.0FAQ: Common Questions About Laser Tube Cutting

1.0What Is Tube Laser Cutting?

Tube laser cutting is a fabrication process that uses laser technology to cut tubes into specified lengths or to etch detailed patterns. Compared to traditional methods such as sawing or manual drilling, this automated process is significantly faster and more precise.

Laser cutting has become a widely adopted technique across global manufacturing. It allows for high-quality, high-precision cutting of round, square, rectangular, and custom-shaped tubes, offering several key advantages:

- Fast and accurate operation: Capable of efficiently processing large-sized tubing

- High precision: Easily handles complex geometries

- Minimal preprocessing or postprocessing: No need for welding, grinding, or polishing

Tube laser cutting is a fabrication process that uses laser technology to cut tubes into specified lengths or to etch detailed patterns. Compared to traditional methods such as sawing or manual drilling, this automated process is significantly faster and more precise.

Laser cutting has become a widely adopted technique across global manufacturing. It allows for high-quality, high-precision cutting of round, square, rectangular, and custom-shaped tubes, offering several key advantages:

- Fast and accurate operation: Capable of efficiently processing large-sized tubing

- High precision: Easily handles complex geometries

- Minimal preprocessing or postprocessing: No need for welding, grinding, or polishing

Although tube laser cutting was adopted later than flat sheet laser cutting, it has seen increasing use in recent years. During the process, a high-powered laser beam is directed onto the surface of the tube, melting or vaporizing the material to create a clean cut. The movement of both the laser beam and the tube is computer-controlled, ensuring precise shaping. The system typically includes a laser generator, a resonator, and an integrated motion-controlled cutting head.

Compatible Tube Types:

The process supports a wide range of materials and shapes, including round, square, and rectangular tubing, as well as angle iron, channel sections, and custom extrusions. Tubes are typically 20 to 24 feet in length, with diameters ranging from 1 to 8 inches. Some advanced systems can handle diameters up to 14 inches. Most machines are equipped with automatic or semi-automatic loaders for efficient material handling.

The tube is clamped, rotated, and moved laterally during cutting. Multi-angle cuts can be made to achieve precise geometry. Proper programming is essential to ensure quality and efficiency throughout the operation.

Types of Tube Laser Cutting Machines:

- 2-Axis Laser Cutting Systems: Provide two-dimensional cutting, ideal for length cuts and basic connections.

- 3-Axis Laser Cutting Systems: Offer three-dimensional capabilities, enabling bevels and angled cuts for more complex applications.

2.0How Does Laser Tube Cutting Work

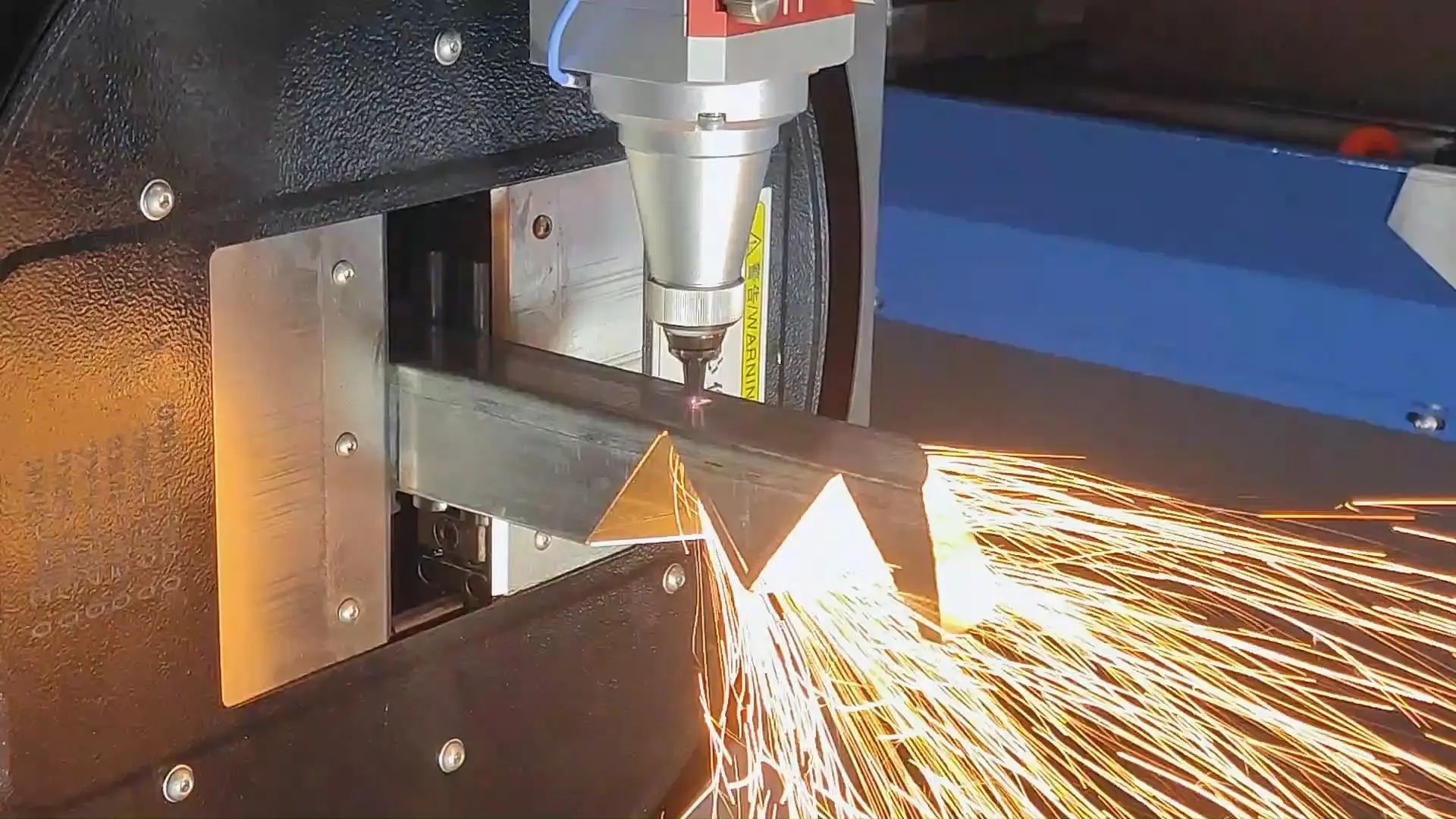

Laser tube cutting is performed using precision CNC equipment. The process involves directing a high-powered laser beam onto the surface of a tube. The beam is precisely focused on the material, allowing for accurate cutting. During cutting, the intense laser energy vaporizes the metal at the contact point, and the assisting gases blow away the vaporized material from the cut edge. This results in clean, precise cuts with minimal need for secondary processing.

Laser Tube Cutting Process:

- Material Loading: Tubes—round, square, oval, and others—are loaded into the machine manually or via an automatic feeder. The chuck then clamps and aligns the material.

- Positioning and Centering: A vision system or sensors locate the tube’s position. The rotating chuck adjusts the angle to precisely align the starting point.

- Program Input and Path Generation:Cutting paths are generated by importing CAD/CAM files or through nesting software. The system automatically calculates intersections, bevels, and complex contours.

- Laser Emission and Focusing: A laser source (commonly a fiber laser) emits a high-energy beam. A focusing lens concentrates the beam into a small spot to deliver heat precisely at the cutting point.

- Material Melting and Vaporization: The laser rapidly raises the localized temperature to thousands of degrees Celsius, melting or vaporizing the material to form a kerf.

- Assist Gas Ejection: High-pressure gases (such as nitrogen, oxygen, or air) expel molten material and help cool the cutting zone, resulting in smooth edges.

- Laser Cutting Execution: The laser head moves along the X/Y/Z axes, while the chuck rotates the tube. Multi-axis control enables 3D cutting at various angles, including intersections and bevels.

- Automatic Separation and Profiling: The system performs tasks such as hole cutting, beveling, socket formation, dovetail slots, and more. Advanced features like fly cutting and common-line cutting optimize the process.

- Automatic Unloading and Sorting: Finished parts are automatically unloaded via conveyors. Some systems also support sorting by length or shape.

- Post-Processing (Optional): Secondary operations like deburring, cleaning, or weld prep can be applied if needed.

3.0Types of Laser Tube Cutting Machines

3.1By Laser Source Type:

- Fiber Laser Cutting Machines: High energy efficiency and low maintenance; ideal for cutting stainless steel, carbon steel, and a wide range of other metals.

- CO₂ Laser Cutting Machines: Suitable for cutting thicker materials. With a longer wavelength, it works better on non-metal materials but requires more complex maintenance.

- Disk Laser Cutting Machines: Offers excellent beam quality, ideal for high-precision processing; typically comes at a higher cost.

3.2By Number of Controlled Axes:

- 3-Axis Laser Cutting Machines: Designed for 2D plane cutting and basic contours.

- 5-Axis Laser Cutting Machines: The laser head can tilt and pivot, enabling complex 3D intersection cuts, such as those required for shaped pipes.

- Multi-Axis Laser Cutting Machines: Incorporates additional degrees of freedom to handle more complex and precise cutting operations.

3.3By Cutting Configuration:

- Fixed-Tube Rotating-Laser Machines: The tube remains stationary while the laser head rotates around it for cutting.

- Fixed-Laser Rotating-Tube Machines: The laser head remains fixed; the tube is rotated by a chuck for cutting operations.

- Hybrid Cutting Machines: Combines rotary and multi-axis control for advanced 3D cutting capabilities.

3.4By Tube Type Compatibility:

- Round Tube Laser Cutting Machines: Specifically designed for processing round tubes.

- Square, Rectangular, and Shaped Tube Laser Cutting Machines: Tailored for square, rectangular, and irregularly shaped tubing.

- Multi-Function Laser Cutting Machines: Capable of handling multiple tube shapes and dimensions within a single system.

3.5By Automation Level:

- Manual Laser Cutting Machines: Suitable for small batches or prototyping.

- Semi-Automatic Laser Cutting Machines: Offers partial automation to improve throughput.

- Fully Automatic Laser Cutting Machines: Includes automated loading, programming, cutting, and unloading; ideal for large-scale production.

3.6By Laser Type:

- Fiber Lasers: The most widely used laser source, compatible with various materials.

- CO₂ Lasers: Effective for cutting specialized materials such as titanium; provides stronger gas shielding and often serves as an upgrade to plasma systems.

4.0What Is a Fiber Laser Cutting Machine?

Working Principle:

A fiber laser uses ytterbium-doped fiber as the laser gain medium. The laser beam is transmitted through fiber optics to the cutting head, where it is focused into a high-density spot using a focusing lens. This enables efficient and precise cutting.

Advantages:

- High energy efficiency (optical-to-electrical conversion rate over 30%), making it energy-saving and environmentally friendly.

- Compact structure and small footprint; low maintenance requirements.

- Short wavelength (~1070 nm) offers high absorption in metal materials, especially effective for stainless steel, carbon steel, copper, and aluminum.

- Delivers high cutting quality with smooth edges, minimal heat-affected zone, and low deformation.

- Fast start-up and short response time; well-suited for automated production.

- Long service life—fiber laser sources can operate for tens of thousands of hours.

Disadvantages:

- Limited capability for cutting non-metal materials.

- Relatively high cost, particularly for high-power models.

Applications:

Ideal for high-precision cutting of thin metal sheets and tubes made of stainless steel, carbon steel, alloy steel, aluminum, and copper alloys. Commonly used in industrial manufacturing, automotive, electronics, and medical device industries.

5.0What Is a CO₂ Laser Cutting Machine?

Working Principle:

CO₂ laser cutting machines use carbon dioxide gas as the laser medium. The laser is generated within a discharge tube and directed toward the material through a series of mirrors and a focusing lens to perform cutting.

Advantages:

- Longer wavelength (~10.6 μm) allows cutting of both metals and non-metals such as plastics, wood, and glass.

- Wide range of cutting thicknesses, especially effective for thick plates.

- Mature and stable technology with reliable performance.

- Lower initial cost compared to fiber laser systems.

Disadvantages:

- Lower energy efficiency (typically around 10–15%), resulting in higher power consumption.

- Laser transmission relies on a gas medium and mirrors, requiring more complex maintenance and greater sensitivity to environmental conditions.

- Bulky machine size with a more complex structure, requiring more floor space.

- Less effective on highly reflective materials like copper and aluminum.

- Larger heat-affected zones and greater risk of material deformation.

Applications:

Suitable for cutting carbon steel, thick stainless steel, plastics, wood, fabric, and other materials. Widely used in signage, packaging, furniture manufacturing, and mold processing industries.

6.0Comparison: Fiber Laser vs. CO₂ Laser Cutting Machines

| Feature | Fiber Laser Cutting Machine | CO₂ Laser Cutting Machine |

| Laser Wavelength | ~1070 nm | ~10.6 μm |

| Laser Efficiency | High (approx. 30% or more) | Low (approx. 10–15%) |

| Machine Size | Compact, space-saving | Large, complex structure |

| Maintenance Cost | Low | High |

| Material Compatibility | Primarily metals (especially low-reflectivity) | Metals and non-metals (e.g., plastics, wood, glass) |

| Suitable Thickness | Thin sheets and tubes | Better for thicker materials |

| Cutting Quality | High, minimal heat-affected zone | Larger heat-affected zone |

| Price | Higher | Relatively lower |

7.0What Are the Tolerances for Tube Laser Cutting?

Tube laser cutting faces greater challenges compared to flat-sheet cutting. Materials such as tubing, angle iron, and channel sections often exhibit bowing or twisting, which can complicate precise cutting.

Most tube laser systems are capable of maintaining cutting tolerances around ±0.010 inch (±0.25 mm). To achieve this level of precision, many machines use contact probe technology to detect the tube’s exact position and shape prior to cutting. While this improves accuracy, it can reduce cutting speed.

By contrast, flat-sheet laser cutting typically achieves tighter tolerances of ±0.005 inch (±0.13 mm). Nevertheless, ±0.010 inch is still considered a tight tolerance for tube processing and offers a significant precision advantage over traditional methods like sawing and drilling.

8.0Which Software and File Formats Are Supported by Tube Laser Cutting Machines?

Tube laser cutters typically come equipped with dedicated programming software and CAD/CAM interfaces that streamline the process from design to production. Commonly supported file formats include:

- .STP— Standard for 3D model data exchange

- .IGS— Used for sharing 3D geometry across platforms

- .X_T— Contains precise geometric data for complex parts

- .IFC— Open data format widely used in construction and engineering projects

9.0Top Brands of Laser Tube Cutting Machines

Several leading brands are recognized for their innovation, machine quality, and customer satisfaction in the laser tube cutting market. These include:

- TRUMPF– Known for high-precision laser cutting technologies.

- Bystronic– Offers efficient and reliable equipment.

- Amada– Renowned for strong technical support and innovative designs.

- Mazak– Advanced in automation and system integration.

- BLM Group– Specializes in laser solutions for tube processing.

- ALEKVS Machinery– Delivers cost-effective, practical tube cutting systems.

Key Factors to Consider When Choosing a Tube Laser Cutting Machine:

Material Type: Different materials may require specific laser technologies (e.g., fiber vs. CO₂).

Tube Diameter and Wall Thickness: Cutting capacity should align with the tube sizes and thickness ranges required by your applications.

10.0Differences Between Tube Laser Cutters and Flatbed Laser Cutters

While some flatbed laser cutters come with add-on modules for tube processing, they typically require extended setup times to switch between sheet and tube operations. In most cases, they support only basic 2D cutting. Many shops claim tube-cutting capabilities, but their actual performance is often limited.

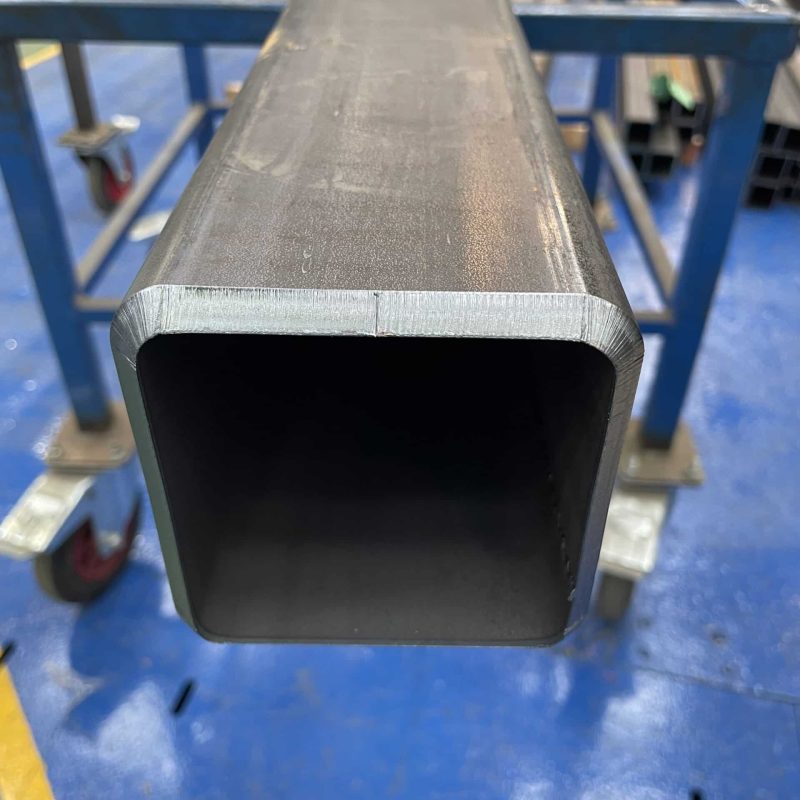

Tube laser cutters, on the other hand, are specifically engineered for processing long-length materials. These machines are capable of handling standard 20-foot or 24-foot tubes—such as 2.0×2.0×0.125 inch (approximately 50×50×3 mm) square tubing—and support automated sequential loading from bundled stock, greatly improving production efficiency. In contrast, flatbed lasers usually rely on manual loading when handling tubing, limiting their ability for continuous, high-volume operation.

In terms of cutting dimensions, flatbed lasers are restricted by the bed size, typically allowing maximum cut lengths of under 10 feet (about 3 meters). Tube lasers, however, are commonly equipped to cut tubing and profiles up to 20 feet or more in length.

From an efficiency standpoint, tube lasers can nest multiple parts along a 20-foot section, similar to part nesting on a 4×10-foot metal sheet in flatbed systems. Flatbed lasers are not well-suited for achieving this level of nesting efficiency in tubing applications.

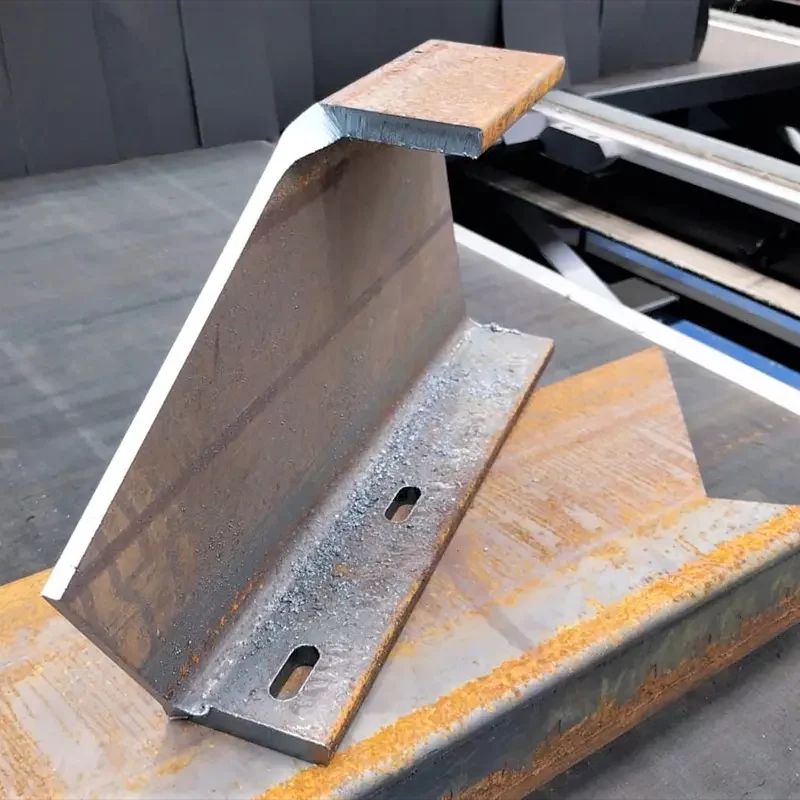

Moreover, tube laser machines often support 4-axis or 5-axis 3D cutting, making them capable of processing a wide variety of structural profiles—including angle iron, channel steel, and I-beams. These machines can also perform bevel cuts, enabling parts to be weld-ready directly after cutting, without the need for additional grinding or edge preparation.

By contrast, flatbed lasers are limited to 2D cutting along the X and Y axes, making them unsuitable for complex 3D tube and profile work.

11.0Cutting Steel Tubes with Laser: Fiber or CO₂?

Advantages of Fiber Laser Cutting:

- Low Power Consumption: Fiber laser systems consume less energy, reducing operating costs.

- Minimal Maintenance: Fiber laser sources require almost no maintenance, decreasing downtime and maintenance expenses.

- High Cutting Speeds: Fiber laser cutters deliver extremely fast cutting speeds, boosting production efficiency.

- Wide Metal Compatibility: Capable of cutting a variety of metals, including copper, brass, and metal alloys.

- Excellent Focusing Ability: Fiber lasers focus the beam into a smaller spot size, enabling more precise cuts and enhancing system stability.

Suitable Applications for CO₂ Laser Cutting:

Although CO₂ lasers are considered lower-energy sources, they remain a viable alternative, particularly for:

- Cutting Thick Tubes: CO₂ lasers are advantageous for steel tubes thicker than 4 to 5 mm.

- Low Carbon Steel Tubes: Well-suited for applications involving cutting low carbon steel tubing.

12.0How to Choose a Good Laser Tube Cutting Machine?

How do you select the right laser tube cutting machine from so many brands and models?

12.1Prioritize Fiber Lasers Over CO₂ Lasers:

Modern tube laser cutting machines predominantly use fiber lasers. Compared to traditional CO₂ lasers, fiber lasers offer several advantages:

- Higher cutting efficiency: Fiber lasers operate at shorter wavelengths and have better energy utilization.

- Lower maintenance costs: No need for costly mirrors or CO₂ gas.

- Wider material compatibility: Especially suitable for carbon steel, stainless steel, and aluminum alloys.

Recommendation: Unless you have specific non-metal cutting needs, choose fiber laser models as your first option.

12.2Look for “Zero-Tail” Cutting Capability — A Key to Cost Reduction and Efficiency:

Traditional cutting methods often leave 50–200 mm of scrap at the tube tail. Modern machines, through optimized chuck structure and motion control systems, can achieve:

- Tail waste ≤30 mm, or even true zero-tail cutting.

- Saves 5–10% of material per tube, especially beneficial in high-volume production.

Common implementations: - Dual-chuck floating/follow-up structure

- Fly cutting (on-the-fly cutting)

- Dynamic clamping length adjustment

Tip: If your business consumes large volumes of tubing annually, zero-tail functionality can significantly reduce material costs.

12.3Evaluate Tube Compatibility Based on Processing Capabilities:

Laser tube cutters support a wide variety of materials. Before purchasing, clarify your production needs.

| Capability | Description |

| Tube Types | Round, square, rectangular, oval, angle iron, channel, flat bar, special shapes |

| Supported Diameter | Common range: 20–220 mm; some machines up to 350 mm |

| Max Feeding Length | Typically 6 m, 9 m, or 12 m |

| Max Wall Thickness | 1–10 mm (depends on laser power and material) |

| Recommendation: Confirm the primary size and material types you use to avoid overspec or underspec machines. |

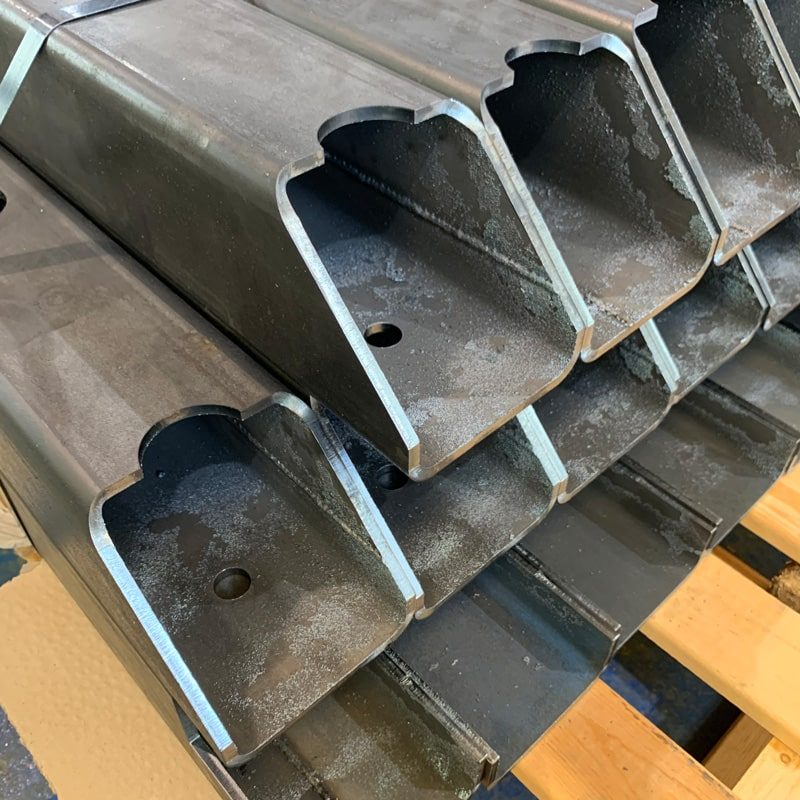

12.4Cutting Precision and Edge Quality: Key to Assembly and Welding:

A quality laser cutter should not only be fast, but also accurate and clean:

- Repositioning accuracy: ≤±0.03 mm

- Kerf width: 0.2–0.5 mm

- Edge quality: Should be burr-free and free of burn marks or oxidation, allowing direct welding or assembly

- Bevel cutting capability (e.g., 45°): Enables tighter tube-to-tube fit-up for welding

12.5Automation Level Determines Efficiency and Labor Cost:

A laser tube cutter with automated loading/unloading and intelligent machining features can greatly enhance productivity and reduce labor needs:

| Automation Feature | Advantage |

| Auto Loading | Enables batch material feeding with minimal manual input |

| Intelligent Nesting Software | Optimizes cutting paths and minimizes travel distance |

| Auto Sorting & Unloading | Sorts parts by length/type for streamlined post-processing |

| Fly Cutting | Allows continuous multi-hole cutting, reducing cycle time |

12.6Is the Software and Control System Smart and Easy to Use?

Choose a system that supports direct CAD/CAM import and 3D model parsing to simplify the workflow:

- Automatically recognizes part shapes and dimensions

- Supports popular formats (.dxf, .stp, .igs)

- Includes edge-sharing optimization and interlocking hole recognition

- Smart linkage of laser power and cutting speed

13.0Why Choose Laser Cutting for Tubes?

Metal tubing is cost-effective and structurally strong, especially when compared to similar components manufactured via CNC machining. However, traditional tube processing presents several challenges—it often requires intensive manual labor and is difficult to perform with high accuracy. Operations like drilling thick steel pipes, cutting precise angles, or machining non-circular features can be time-consuming and limited in precision.

Laser tube cutting effectively addresses these issues. Modern systems can cut highly complex geometries with tolerances within thousandths of an inch, while also supporting bevel cutting. Well-designed cut parts can be self-fixturing, improving the efficiency of subsequent assembly and welding processes.

That said, laser tube cutting machines represent a significant investment, often costing several million dollars. They are best suited for enterprise-level, high-volume production. For low-volume jobs, machine downtime can be costly, so investment decisions should carefully weigh production needs against capital expenditure.

14.0Advantages of Tube Laser Cutting Compared to Other Cutting Methods

Tube laser cutting uses a high-powered laser beam focused on the material surface to perform precise cuts. Compared to traditional and alternative cutting methods, it offers the following advantages:

- Mechanical Sawing:

Lower precision, rough edges requiring post-processing; slower cutting speed; labor-intensive with low efficiency; limited in producing complex profiles or angled cuts. - Plasma Cutting:

Effective for cutting thick metal materials at high speeds; however, it produces a wide heat-affected zone and rough cut edges that require secondary finishing. Precision is lower than laser cutting, making it unsuitable for fine or intricate parts. - Waterjet Cutting:

Capable of cutting a wide range of materials, both metals and non-metals; produces smooth edges with no heat-affected zone. However, waterjet systems are more expensive to purchase and maintain, operate at slower speeds than lasers, and are not ideal for very thin or precise tubing. - Flat Sheet Laser Cutting:

Offers high precision and clean cuts for flat materials. However, cutting tube sections often requires manual loading, and the system is limited to 2D cuts—making it unsuitable for 3D profiles or multi-angle operations. - Tube Laser Cutting:

High precision (±0.010 inch), clean edges with no need for secondary processing; supports complex 3D geometries and multi-angle bevel cuts; features automated loading for long tubes and is ideal for batch production. Though the equipment is expensive, it is highly suitable for scalable, industrial use.

15.0Material Shapes Supported by Tube Laser Cutting Systems

Tube laser cutters are not limited to standard pipes and structural profiles. They are capable of processing a wide variety of shapes, including:

- Round tubes, square tubes, rectangular tubes, and oval tubes

- Angle iron, channel steel, I-beams, and other standard profiles

- Custom extrusions with special shapes such as trapezoidal, Z-shaped, or C-shaped sections

- Structural steel tubing and complex cross-section profiles

- Polygonal tubes and other non-standard tube geometries

Advanced tube laser machines also support multi-axis 3D cutting. This allows for precise operations such as bevels, chamfers, holes, and complex contours. As a result, tube laser cutting is widely used across industries including machinery manufacturing, automotive, aerospace, and structural construction.

16.0Advantages and Limitations of Laser Tube Cutting

Advantages of Laser Tube Cutting:

- Semi-to-Fully Automated Workflow: Enables high throughput and significantly improves production efficiency.

- Minimal Material Waste: Material usage is optimized, with little to no scrap.

- High-Precision Cutting: Delivers clean, complex, and repeatable cuts with excellent edge quality.

- Broad Material Compatibility: Suitable for nearly all metal types.

- Flexible Tube Sizing: Efficiently handles most tube lengths and diameters up to 6 inches.

Limitations or Challenges of Laser Tube Cutting:

- Edge Discoloration: Some materials may show minor heat discoloration or halo effects near the cut edge, often caused by splash guards or excessive assist gas.

- Cut Entry and Exit Marks: Entry and exit points may result in small irregularities or inconsistent edge finishes.

- Wall Thickness Limitations: Best suited for thin-walled materials, typically less than 0.500″ to 1.000″ thick.

17.0What are the key features of tube laser cutting software?

- Auto Nesting: Automatically arranges cutting paths based on tube length and part dimensions to maximize material utilization and reduce waste.

- Common Line Cutting / Shared Edge Cutting: Shares cutting edges when cutting multiple parts, reducing cutting time and laser energy consumption, improving efficiency.

- Multi-Axis Path Planning: Supports 3-axis, 4-axis, and 5-axis linkage control to generate complex 3D cutting paths such as bevels, chamfers, and intersection cuts.

- Material Database Management: Stores cutting parameters for different materials (laser power, cutting speed, gas type, etc.) for quick retrieval and adjustment.

- Cutting Path Simulation: Provides 3D simulation of the cutting process to detect path conflicts and potential machining issues in advance.

- Scrap Management: Intelligently identifies scrap areas, optimizes part layout, and reduces material waste.

- Auto Dimension Calibration: Automatically adjusts cutting programs according to actual tube dimension deviations to ensure machining accuracy.

- CAD/CAM Integration: Directly imports CAD design files (e.g., .STP, .IGS formats) to automatically generate cutting programs.

- Remote Monitoring & Diagnostics: Monitors equipment status in real time, offering fault diagnosis and maintenance alerts.

18.0How Does Tube Laser Cutting Drive Innovation in Manufacturing Design and Processes?

More engineers are recognizing the potential of laser tube cutting. Previously, certain shapes and sizes were excluded due to high costs or manufacturing difficulties. Now, these geometries have become more feasible and accessible. Traditionally, tube slotting relied on mechanical machining, but today, slotting on tubes and other profiles has become straightforward.

Design Innovations Enabled by Tube Lasers:

When designing parts, considering the capabilities of tube laser cutting opens new possibilities and expands design freedom. More importantly, it allows for optimization of downstream manufacturing processes.

Limitations of Traditional Cutting Methods:

Traditional tube and profile cutting often depends on saws, which have slow cutting speeds and poor accuracy. The slow speed alone is problematic, but poor precision can cause further issues during subsequent manufacturing steps.

Example Case:

Take a 2.0 x 2.0 x 0.125-inch square tube as an example. Suppose you need to fabricate a simple 3-foot by 6-foot rectangular frame. In the past, a typical shop would miter cut the tube into four 45-degree angle pieces using a saw. Moving, measuring, and setting up the saw for accurate 45-degree cuts is time-consuming and often imprecise.

Applications of Laser Tube Cutting

The development of laser tube cutting technology spans numerous markets and industries. Metal tube processing and cutting methods are diverse, with common operations including perforation, slotting, and end cutting. These processes are often combined with joining to other tubes or sheet materials.

Applications of Laser Tube Cutting Technology:

Laser tube cutting machines are designed for precision cutting of a variety of metals and some non-metal materials, including stainless steel, steel, aluminum, copper, brass, and bronze. This technology finds widespread use across multiple sectors, primarily for manufacturing customized components. Common industries include:

- Structural engineering

- Manufacturing

- Automotive

- Aerospace

- Defense

Typical Use Cases:

- Lighting: Fabrication of custom light fixtures and supports.

- Tube Structures: Manufacturing tubular frameworks for construction and industrial applications.

- Exhaust Systems: Cutting tubes for automotive and machinery exhaust systems.

- Aircraft Components: Providing high-precision cuts for aerospace parts.

- Defense Components: Producing military equipment and related parts.

Common Tube Shapes Suitable for Laser Cutting:

- Round tubes

- Square tubes

- Angle sections

- Rectangular tubes

- Beam profiles

- Formed shapes

- Custom extruded profiles

Laser cutting technology is employed in approximately 90% of medium and large tubular structural applications. This widespread adoption is due to its flexibility and high precision, especially critical in industries with stringent requirements such as aerospace and automotive manufacturing. Laser tube cutting not only guarantees high-quality cuts but also accommodates a wide range of tube shapes and sizes.

19.0FAQ: Common Questions About Laser Tube Cutting

How to choose between fiber laser cutters and CO₂ laser cutters?

- Fiber Laser Cutters: Suitable for metals with low reflectivity, offering higher cutting efficiency and precision. Ideal for thin materials with lower maintenance costs.

- CO₂ Laser Cutters: Better for thicker materials, especially low-carbon steel and some non-metal materials. However, they have lower efficiency and more complex maintenance, making them suitable mainly for thicker metal plates.

What tube shapes can laser tube cutting handle?

Laser tube cutting machines can process a wide variety of tube shapes, including:

- Round, square, and rectangular tubes

- Oval tubes

- Custom extruded profiles such as trapezoidal, Z-shaped, and C-shaped sections

- Structural steels like angle iron, channel steel, and I-beams

What is the typical cutting tolerance of laser tube cutting?

Most tube laser cutting systems maintain a cutting tolerance of approximately ±0.010 inch (±0.25 mm). This precision suits most industrial applications and is notably better than traditional sawing and drilling methods.

What are the advantages of laser tube cutting compared to traditional methods?

Compared to mechanical sawing, plasma cutting, or waterjet cutting, laser tube cutting offers:

- Higher precision: Achieving tolerances within thousandths of an inch with smooth edges requiring no secondary finishing.

- Complex cutting capability: Able to cut intricate 3D contours and bevels for fine manufacturing requirements.

- Automation: Supports automatic loading and processing, reducing labor costs and increasing production efficiency.

Are laser tube cutters difficult to maintain?

- Fiber laser cutters require relatively low maintenance, usually limited to periodic replacement of the laser gain medium, with a long equipment lifespan.

- CO₂ laser cutters use gas and mirrors for laser transmission, necessitating more frequent maintenance, higher associated costs, and downtime.

What is the cost of laser tube cutting?

Laser tube cutting machines generally have a high upfront cost, making them suitable for enterprise-level, large-scale production. Despite the initial investment, automation and high cutting precision significantly reduce labor costs and production cycle times, justifying their use in volume manufacturing.

References

www.ametals.com/post/everything-you-need-to-know-about-the-tube-laser

www.oshcut.com/design-guide/tube-cutting-basics

www.allmetalsfab.com/common-questions-about-tube-lasers/

https://en.wikipedia.org/wiki/Laser_cutting

https://en.wikipedia.org/wiki/Fiber_laser