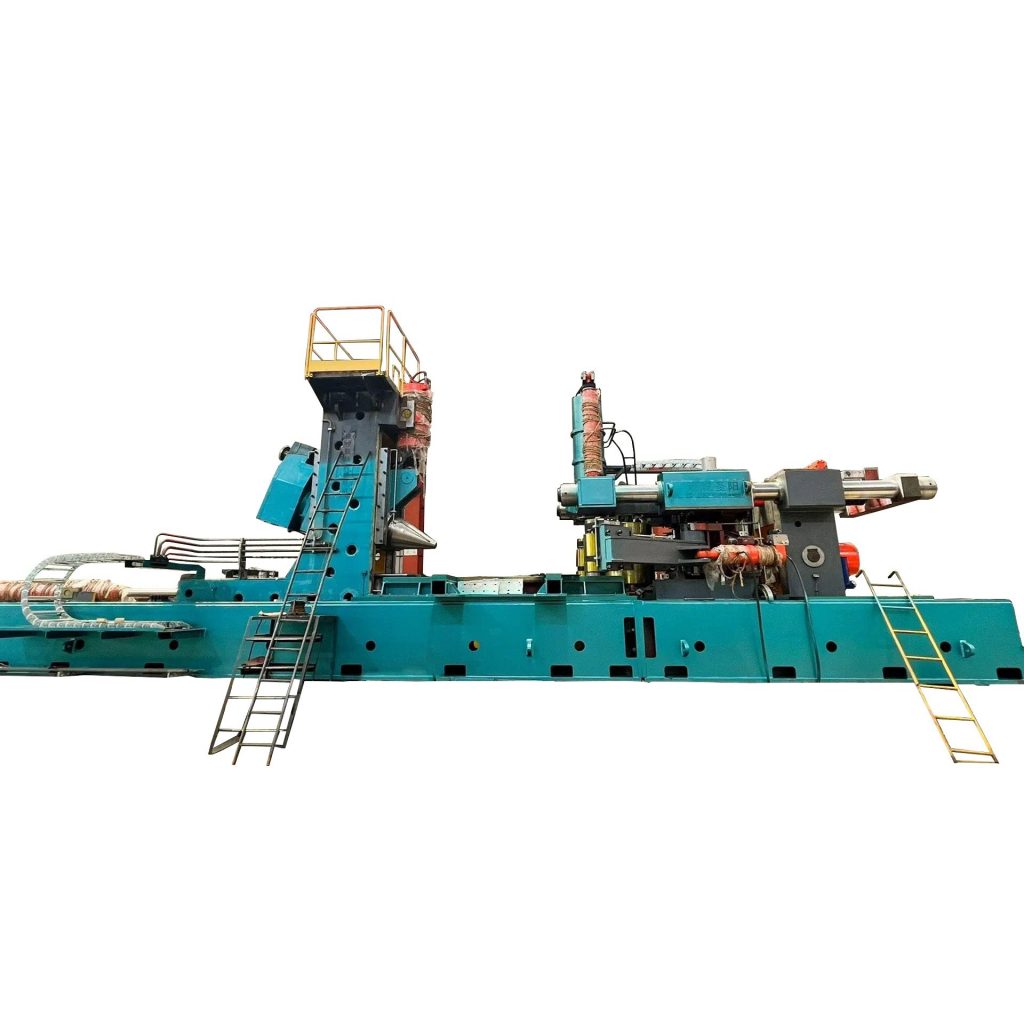

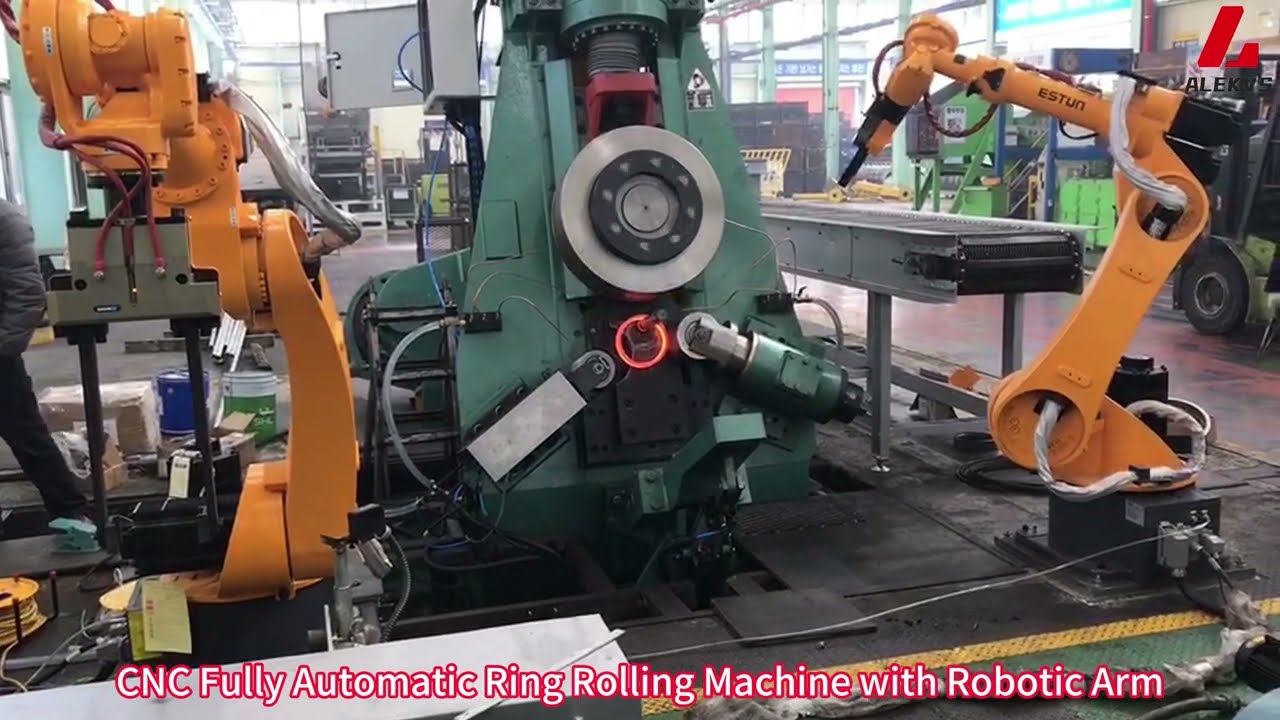

Miller, Halkalar ve Endüstriyel Parçalar için Otomatik Sıcak Dövme Makinesi

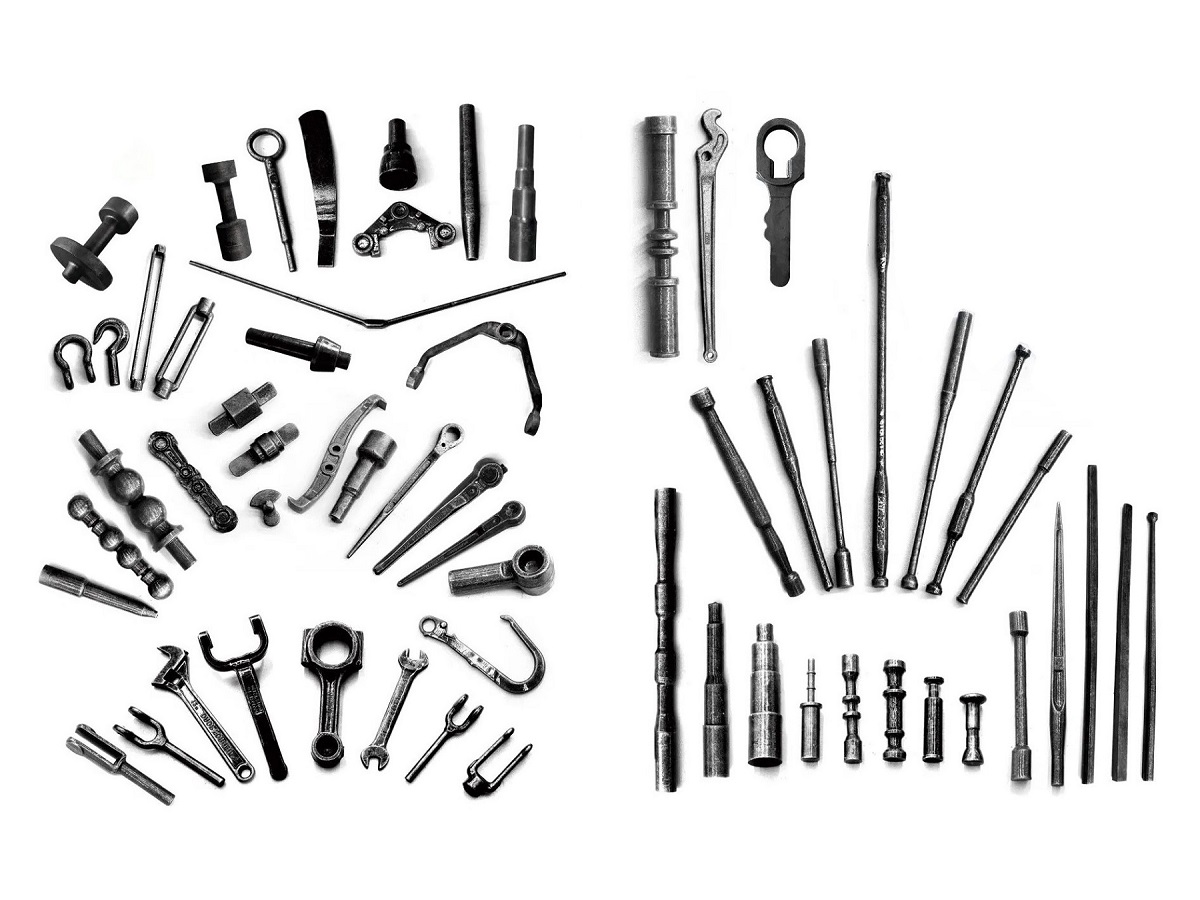

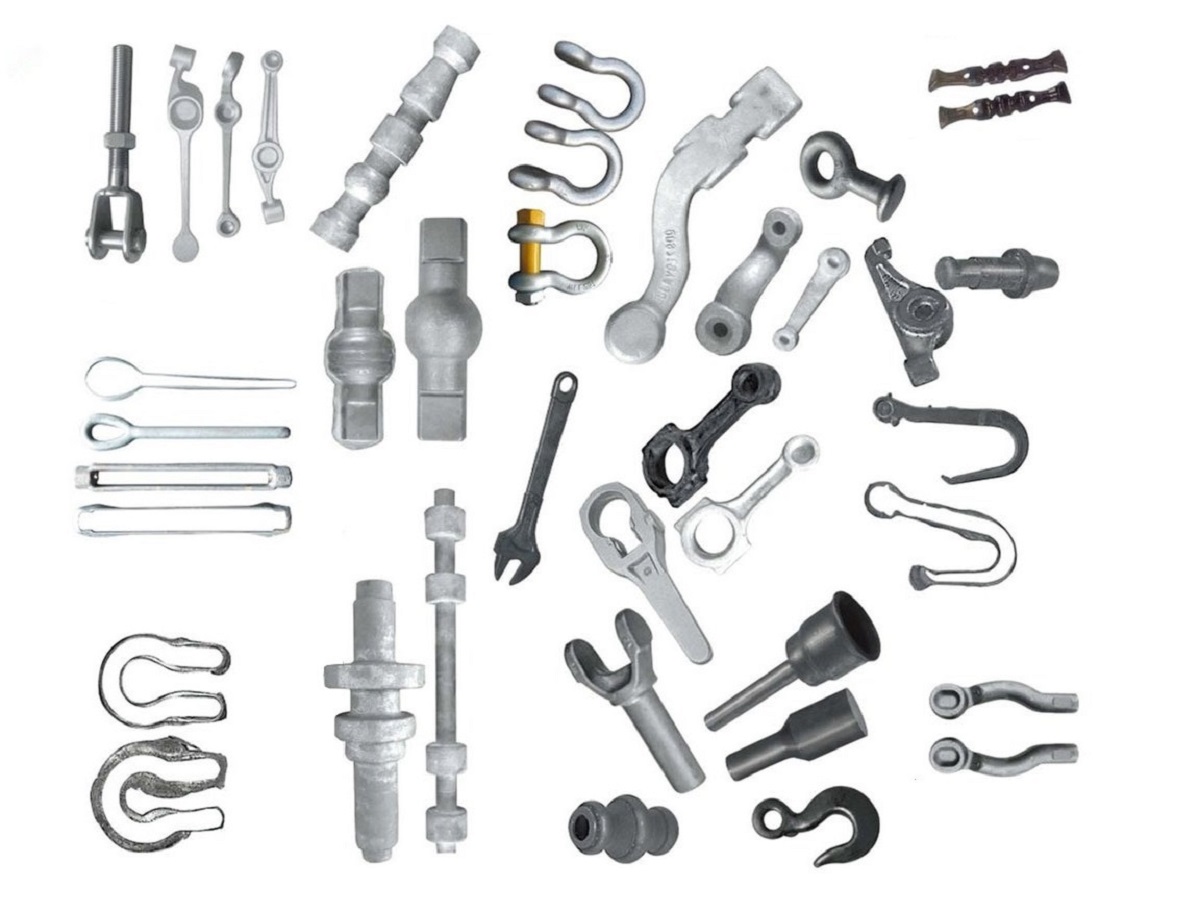

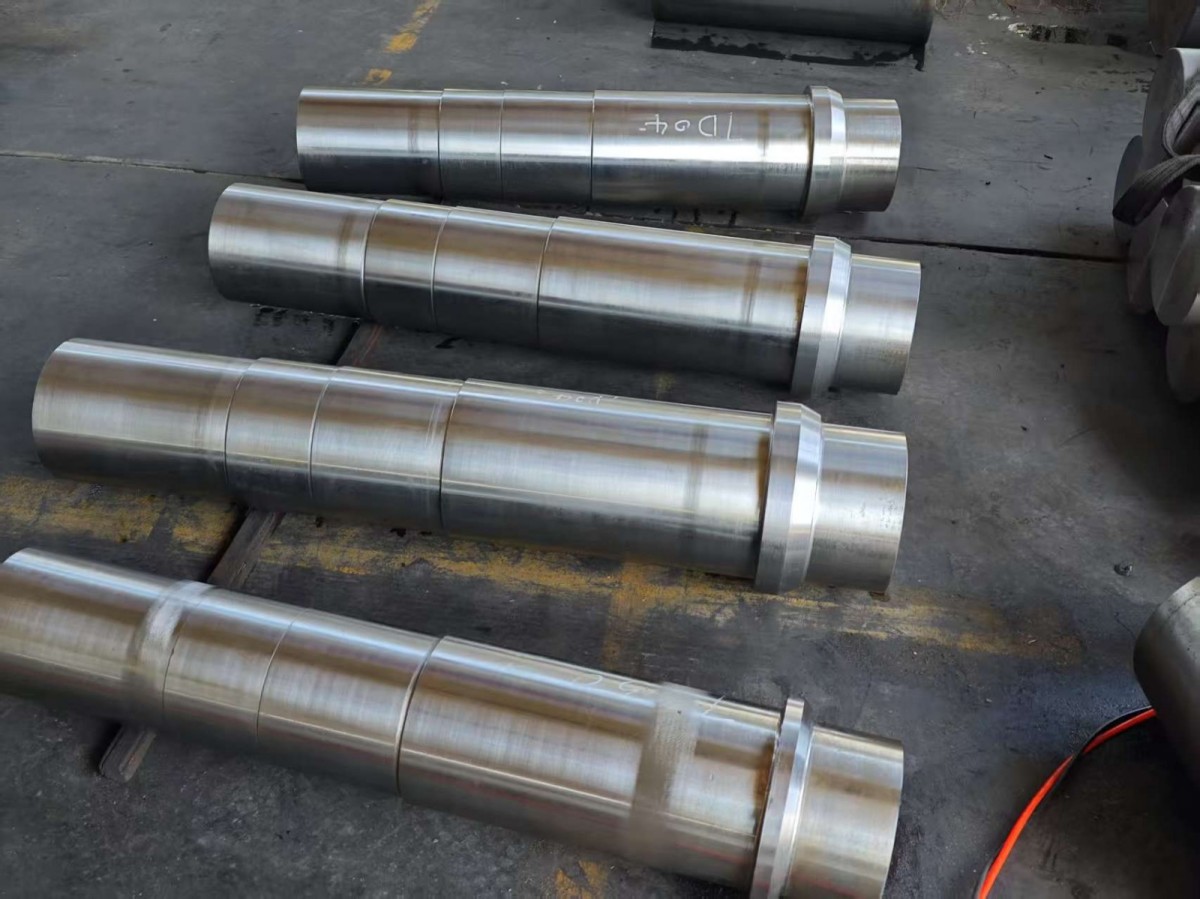

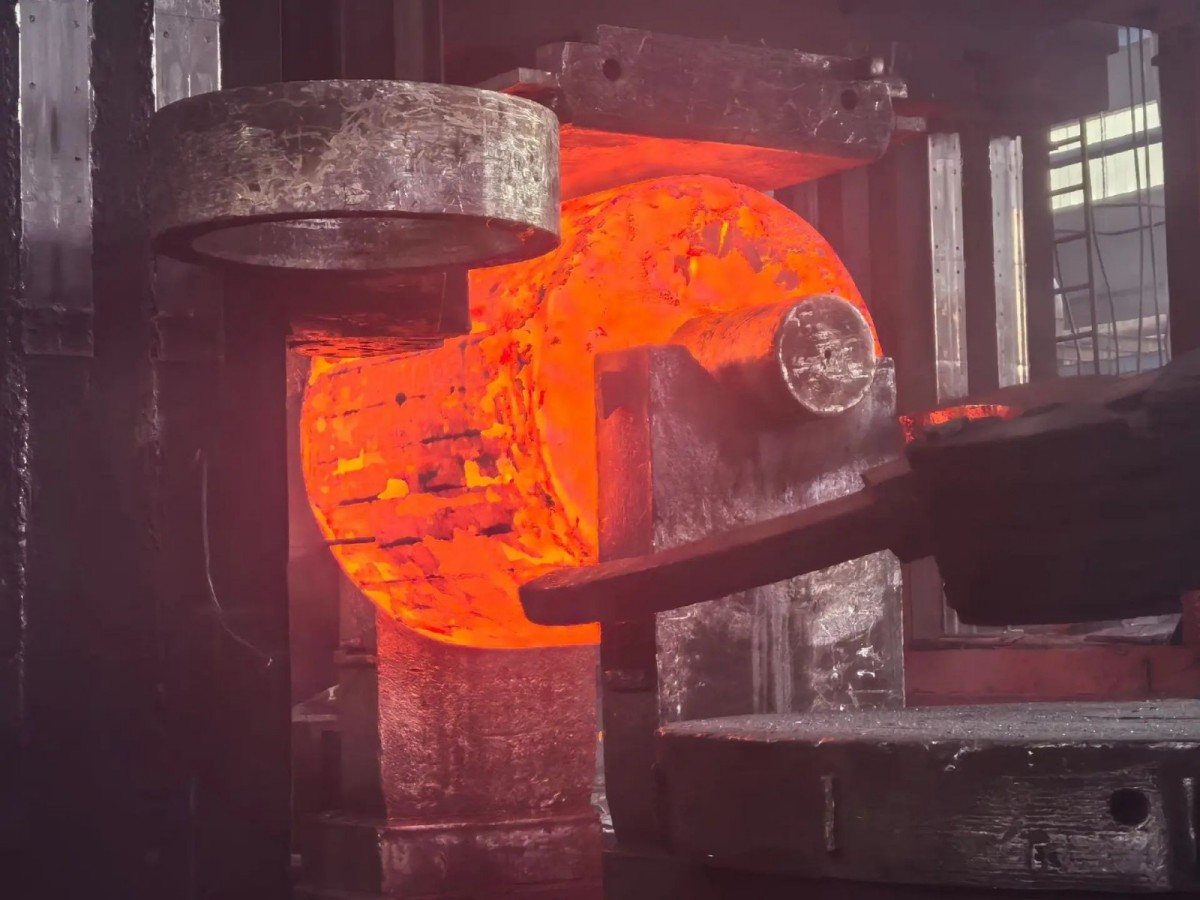

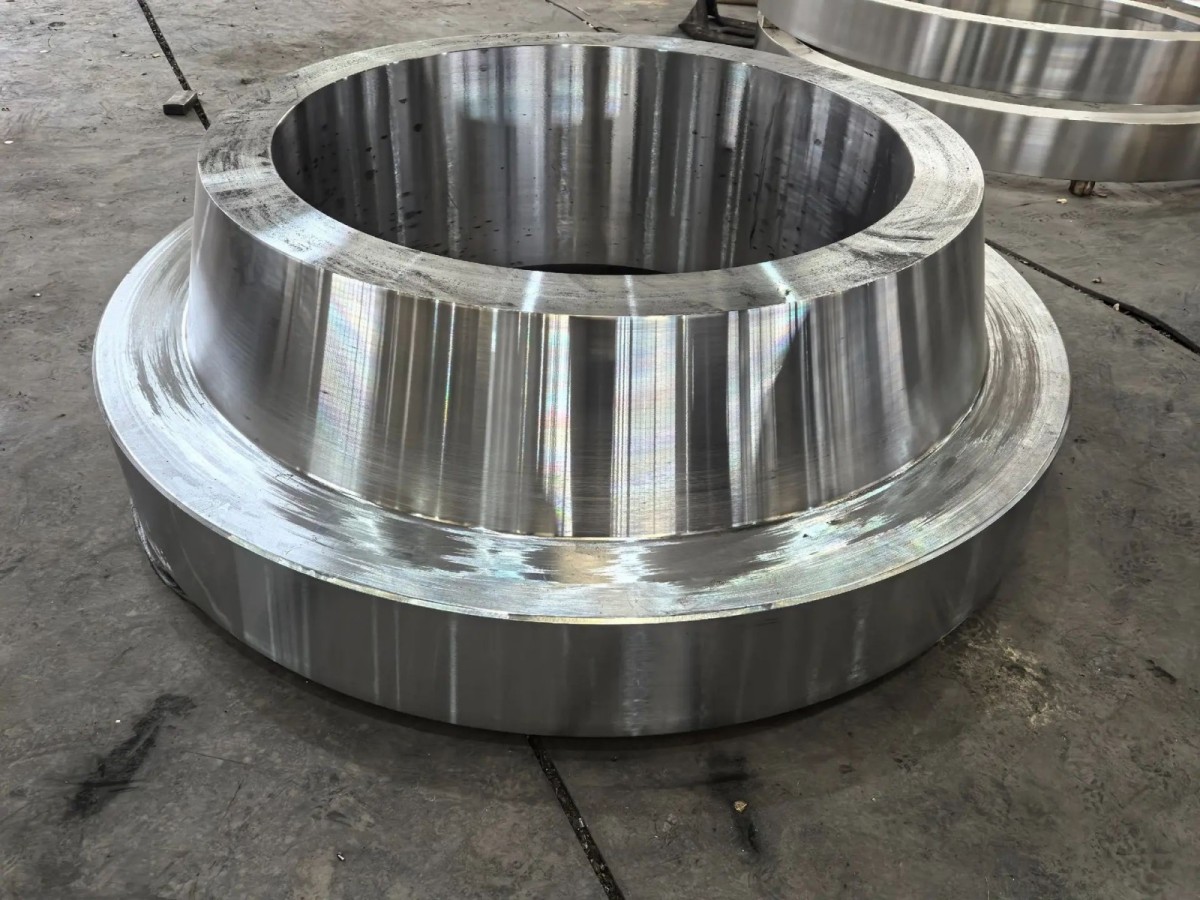

Sıcak dövme makinelerimiz, ısıtılmış kütükleri mükemmel mekanik özelliklere sahip yüksek mukavemetli bileşenlere dönüştürmek için gelişmiş metal sıcak şekillendirme teknolojisini kullanır. Darbeli dövme, sürekli haddeleme ve neredeyse net şekillendirmeyi kapsayan ekipmanlarımız, şaftlar, halkalar ve karmaşık endüstriyel parçalar için güvenilir performans sağlar.

Verimlilik, Güç ve Endüstriyel Uygulamalar

Haddeleme ve pnömatik çekiçlerden halka haddeleme ve çapraz kama haddeleme makinelerine kadar ürün yelpazemiz, verimlilik, azaltılmış malzeme israfı ve hassas şekillendirme sonuçları sunar. Otomotiv, havacılık, enerji ve ağır makine endüstrilerinde güven duyulan bu çözümler, üreticilerin maliyet tasarrufu ve tutarlı ürün kalitesi elde etmelerine yardımcı olur.