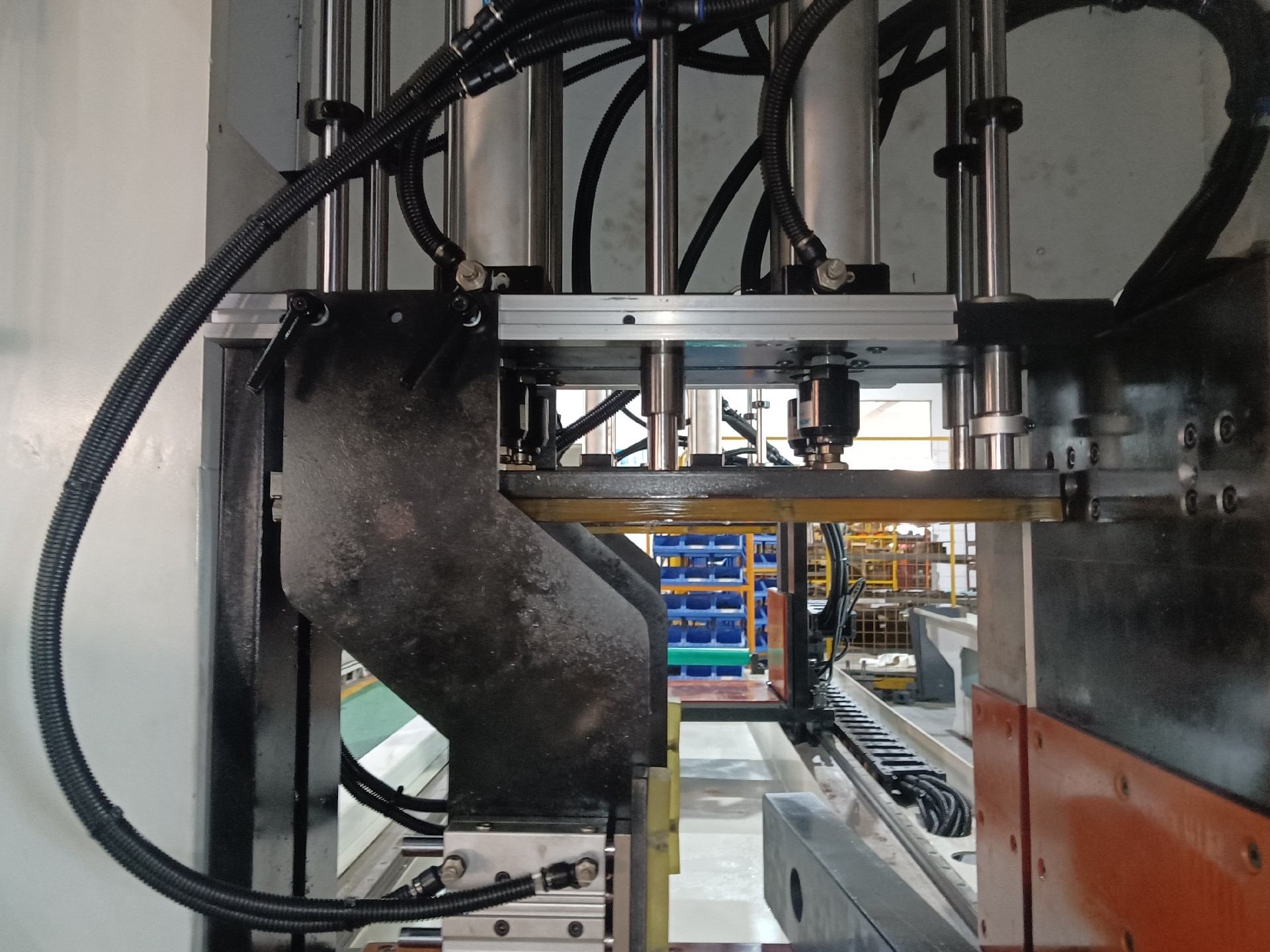

The AEK 950 Three-Axis Fully Automatic CNC Aluminum Profile Cutting Machine adopts a concealed upward-cutting structure with a fully enclosed safety guard, integrated automatic mist lubrication, a high-precision servo feeding system, and a heavy-duty clamping mechanism. With its rigid machine frame, intelligent protection functions, and efficient chip-collection system

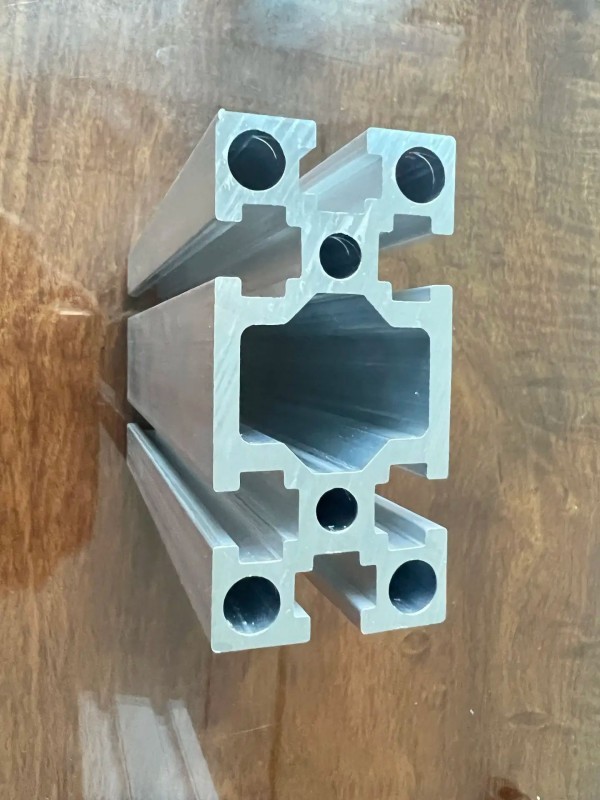

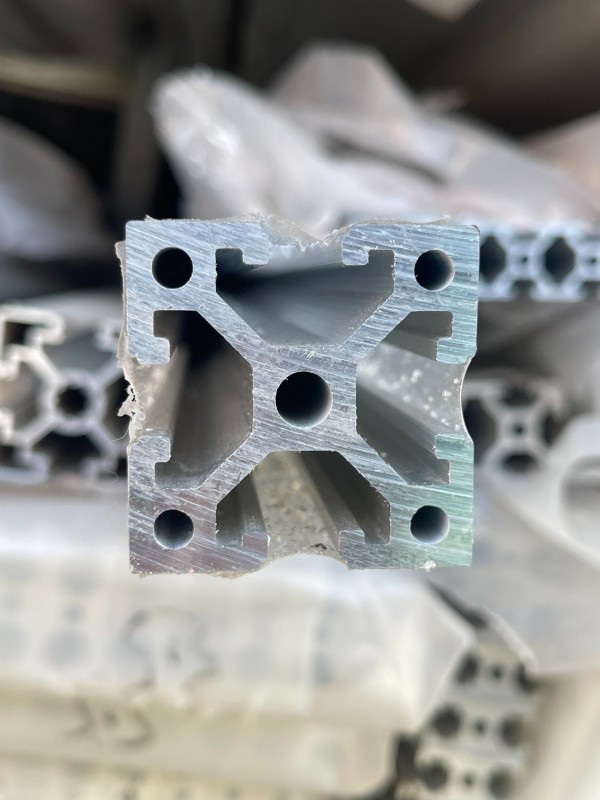

It is suitable for aluminum bars, aluminum tubes, aluminum strips, window & door profiles, and copper–aluminum composite materials. The system ensures low vibration, reduced noise, and consistently clean, burr-free cutting surfaces during high-speed operation.

The AEK 950 is designed for high-precision cutting of:

- Aluminum bars

- Aluminum tubes

- Aluminum strips

- Industrial aluminum profiles

- Window & door profiles

- Copper–aluminum composite materials

AEK 950 CNC Aluminum Pipe Cutting Machine Key Features

High-Precision Cutting

- Smooth, burr-free surfaces with no secondary processing required.

- Standard accuracy up to ±0.1 mm; can reach ±0.05 mm under specific conditions (e.g., 80×80 mm).

- Surface roughness as low as Ra3.0 for precision manufacturing.

Automatic Mist Lubrication

- Ensures clean, bright cutting surfaces and reduces saw blade wear.

- Extends blade life and supports continuous high-load production.

Fully Automatic Servo Feeding

- High-precision, fast-response, and excellent repeatability.

- Supports single or multiple-piece cutting to increase productivity.

- Customizable automation solutions based on factory layout.

Heavy-Duty Clamping System

- Top and dual-side clamps provide rigid, stable positioning.

- Easily holds irregular profiles without additional fixtures.

- Improves cutting stability and overall efficiency.

High Rigidity & Low Vibration Design

- The reinforced machine frame ensures stability at high cutting speeds.

- High-power sawing system suitable for large industrial profiles.

- Lead screw + servo pushing supports ultra-thin blades (e.g., Ø405 × 2.5 × 100T).

Safety & Environmental Protection

- Fully enclosed safety structure for operator protection.

- High-efficiency chip collector maintains a clean workspace.

- Automatic blade-dull protection prevents material damage.

- Low noise and dust-free operation for a safer, cleaner environment.

Functional Modules

- Automatic mist lubrication: Clean, burr-free cutting surfaces.

- Servo feeding system: High dimensional accuracy and smooth operation.

- User-friendly touchscreen control: Easy to learn and operate.

- Wide material compatibility: Suitable for bars, tubes, profiles, and composites.

- High-precision cutting: Excellent surface finish without rework.

- Customizable automation: Supports custom loading/unloading or integrated production lines.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.