ใบเลื่อยวงเดือนประสิทธิภาพสูงแบบสั่งทำและแบบ OEM | ALEKVS

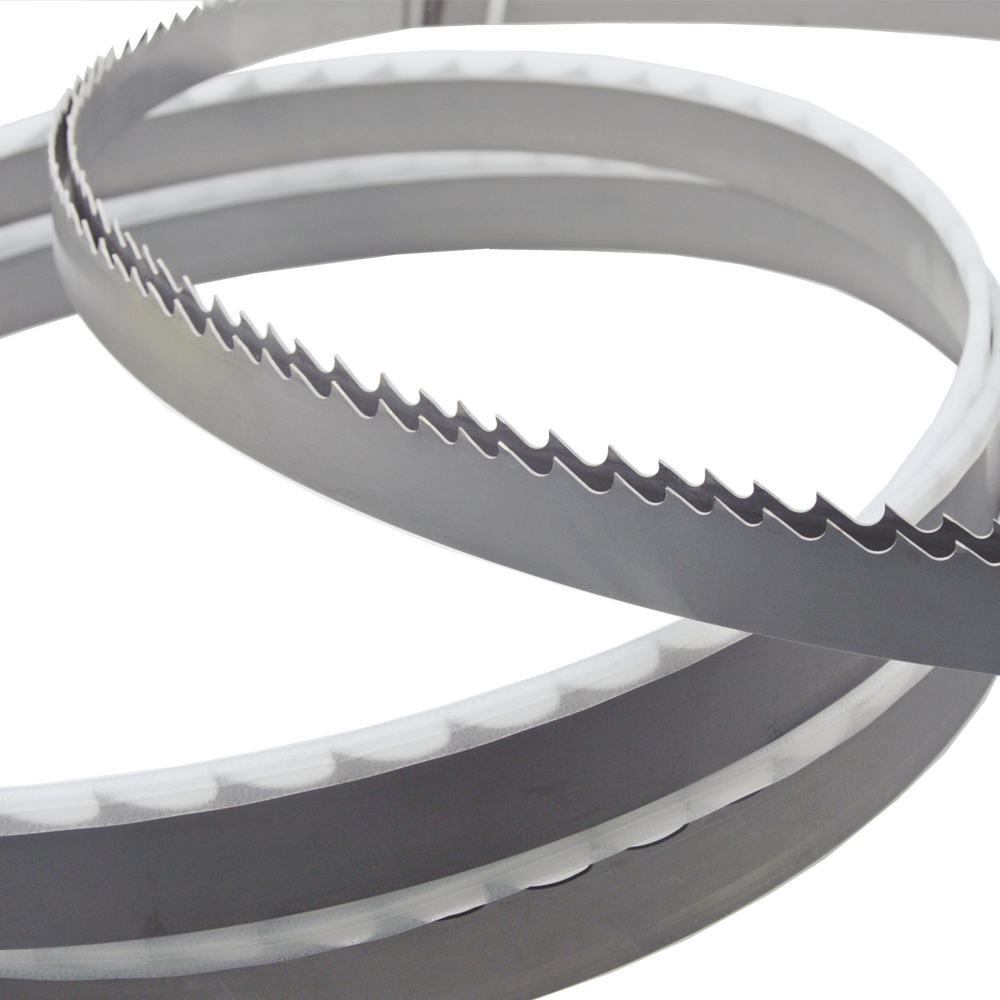

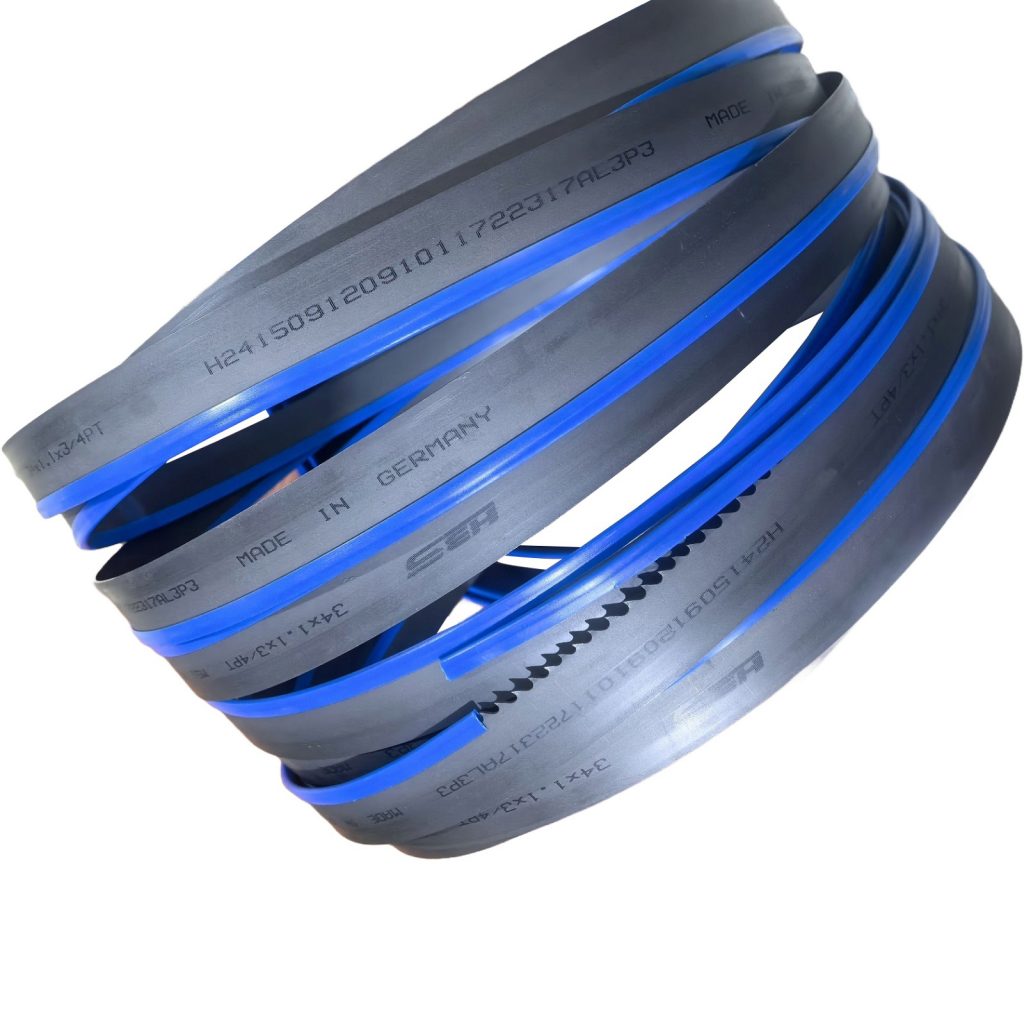

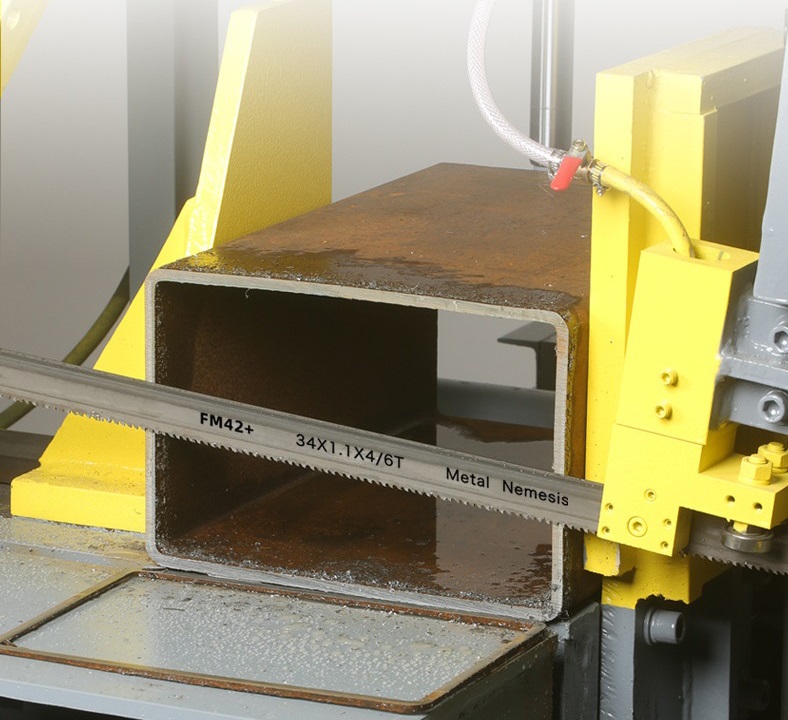

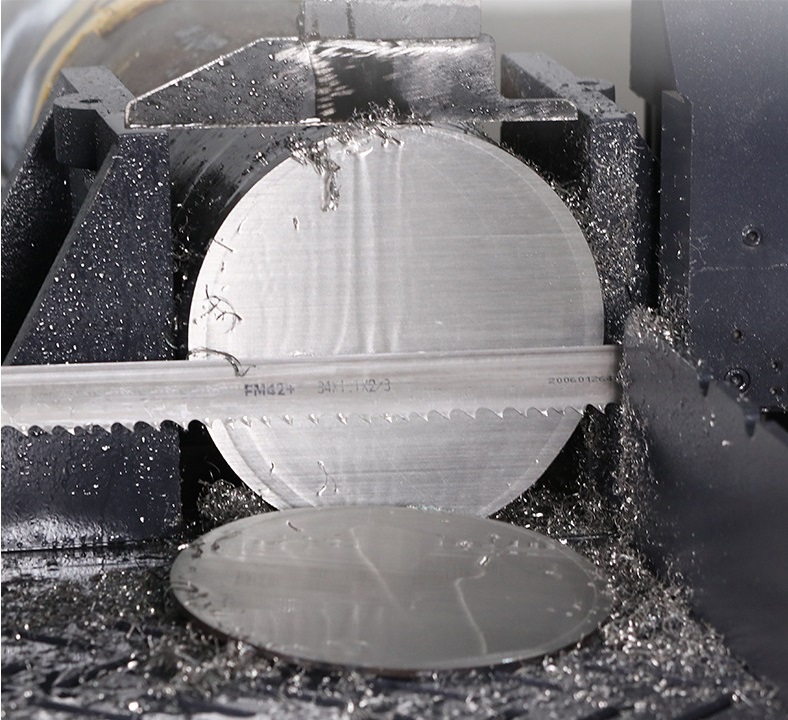

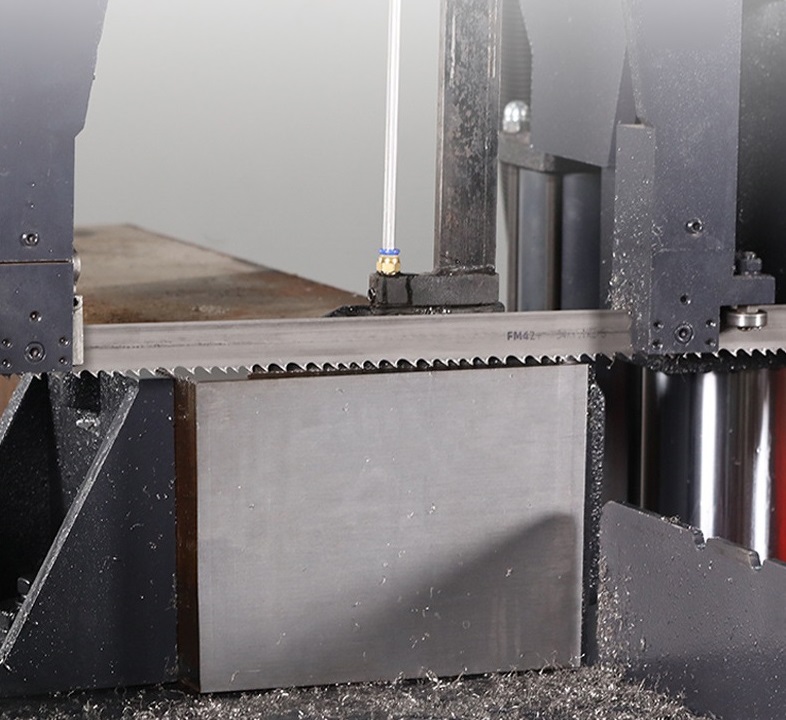

ALEKVS นำเสนอใบเลื่อยวงเดือนโลหะประสิทธิภาพสูงหลากหลายรุ่นสำหรับการตัดโลหะ โลหะผสม และวัสดุโลหะโครงสร้างต่างๆ ใบเลื่อยของเราได้รับการออกแบบมาอย่างแม่นยำ ทนทาน และใช้งานได้หลากหลาย มีขนาดและวัสดุให้เลือกหลากหลาย เช่น 65Mn, 75Cr1 และ SK85 เพื่อตอบสนองความต้องการเฉพาะทางของอุตสาหกรรม

ประเภทใบมีด:

- ใบเลื่อยวงเดือนเหล็กกล้าคาร์บอน – คุ้มค่าและทนทานสำหรับการใช้งานทั่วไป

- ใบเลื่อยวงเดือน HSS (เหล็กความเร็วสูง) – เหมาะอย่างยิ่งสำหรับการตัดโลหะแข็งด้วยความเร็วสูง

- ใบเลื่อยวงเดือนไบเมทัล – ผสมผสานความยืดหยุ่นและความทนทานต่อการสึกหรอเพื่อประสิทธิภาพที่ยาวนาน

- ใบเลื่อยวงเดือนปลายคาร์ไบด์ / TCT – ปรับให้เหมาะสมสำหรับวัสดุที่มีความแข็งเป็นพิเศษและการตัดที่แม่นยำ

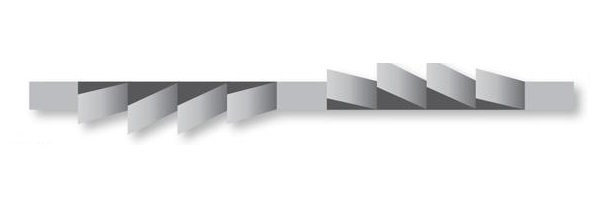

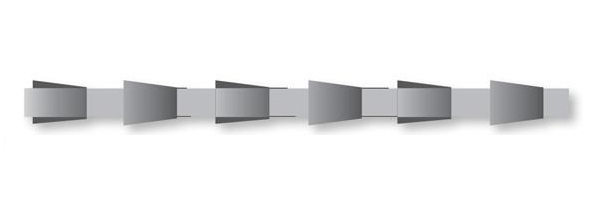

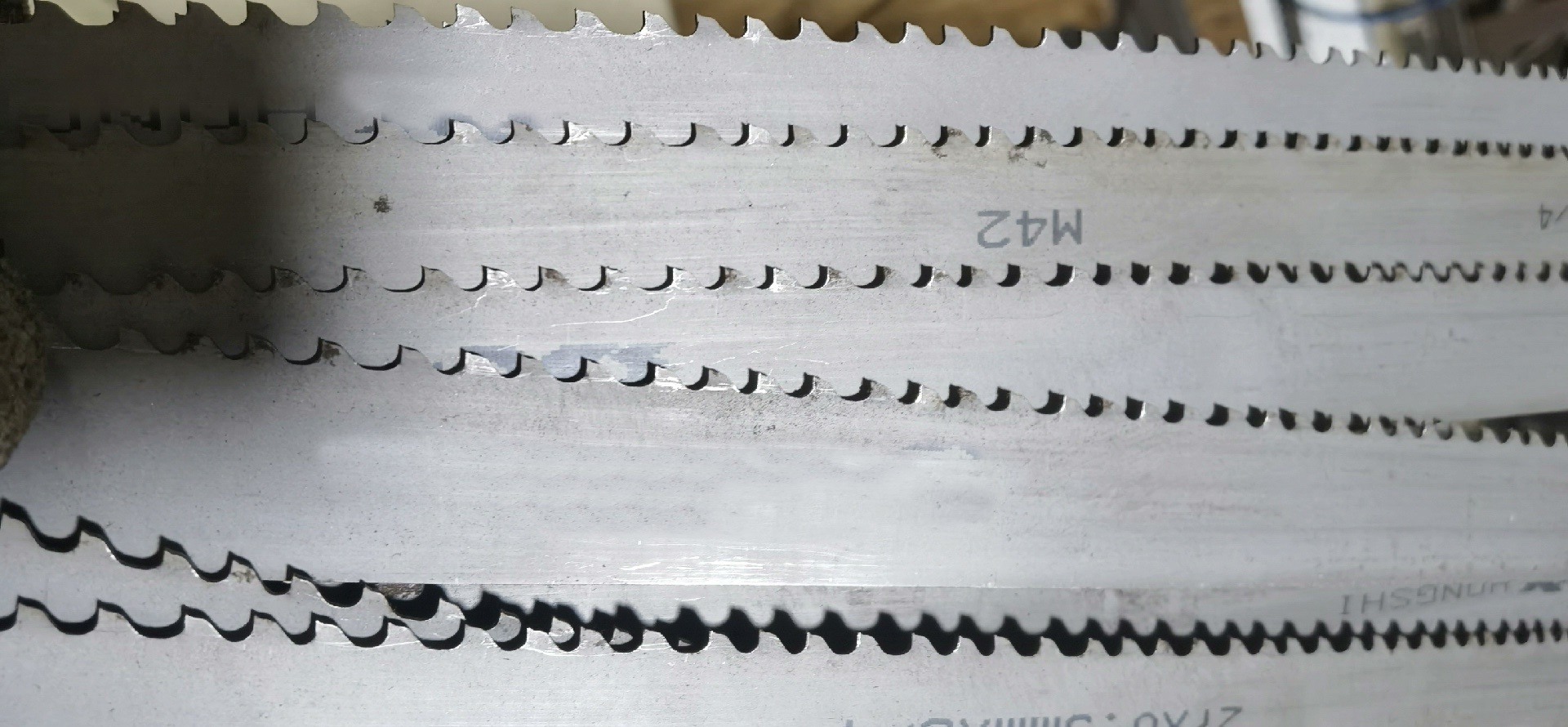

การออกแบบฟัน:

- ฟันธรรมดา – ฟันมาตรฐานสำหรับการตัดทั่วไปและการขัดผิวให้เรียบเนียน

- ฟันขอ – การตัดแบบก้าวร้าวเพื่ออัตราการป้อนที่เร็วขึ้นบนวัสดุที่อ่อนนุ่ม

- ข้ามฟัน – ฟันที่มีระยะห่างกันเพื่อลดการอุดตันและตัดวัสดุที่อ่อนหรือเหนียวได้เรียบเนียนยิ่งขึ้น

- ฟันแปรผัน – ระยะห่างของฟันเลื่อยสลับกันเพื่อลดการสั่นสะเทือนและเพิ่มประสิทธิภาพในการตัดวัสดุผสม

- ชุดคลื่น – ฟันสลับสำหรับตัดมัดหรือวัสดุที่มีผนังบางโดยมีการเสียรูปน้อยที่สุด