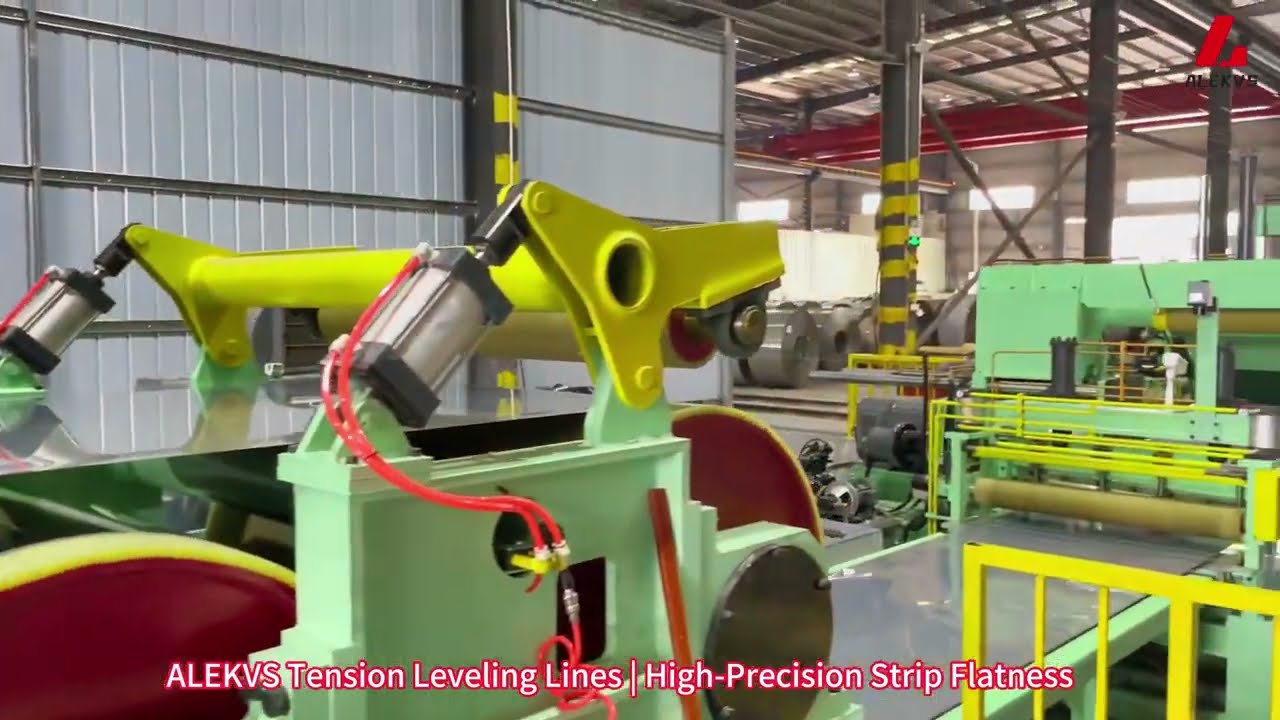

ALEKVS Tension Leveling Lines | High-Precision Strip Flatness

ALEKVS Tension Leveling Lines deliver exceptional strip flatness for the most demanding applications in steel, aluminum, and stainless steel production.

Designed for high-speed, continuous operation, our lines ensure perfect shape correction, improved malleability, and a flawless surface finish – every time.

Perfectly Flat Steel and Aluminum Strips

ALEKVS tension leveling lines correct strip shape by bending metal around small-diameter rolls under controlled tension. This elongates shorter fibers to match the longest, achieving uniform flatness and eliminating residual stresses.

Our systems process carbon steel, stainless steel, aluminum, and other metals with thicknesses from 0.08 to 6.5 mm, widths up to 2,500 mm, and speeds up to 400 m/min.

ALEKVS Advantages:

- Safe and ergonomic operation, even for thick, hard materials

- High productivity with automated coil handling and setup

- Heavy-duty levelers for demanding applications

- Advanced control algorithms for precise elongation and flatness

- Flexible designs: single/double leveling and flattening sections, customizable tension rolls