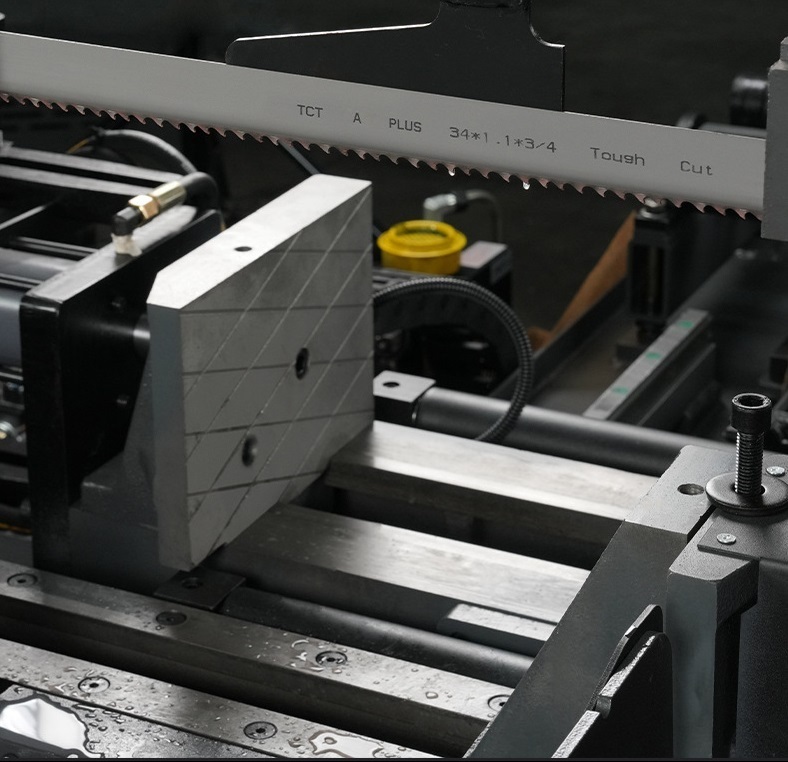

Carbide-Tipped Band Saw Blades – Multi-Hardness, Coated Options

Features & Advantages

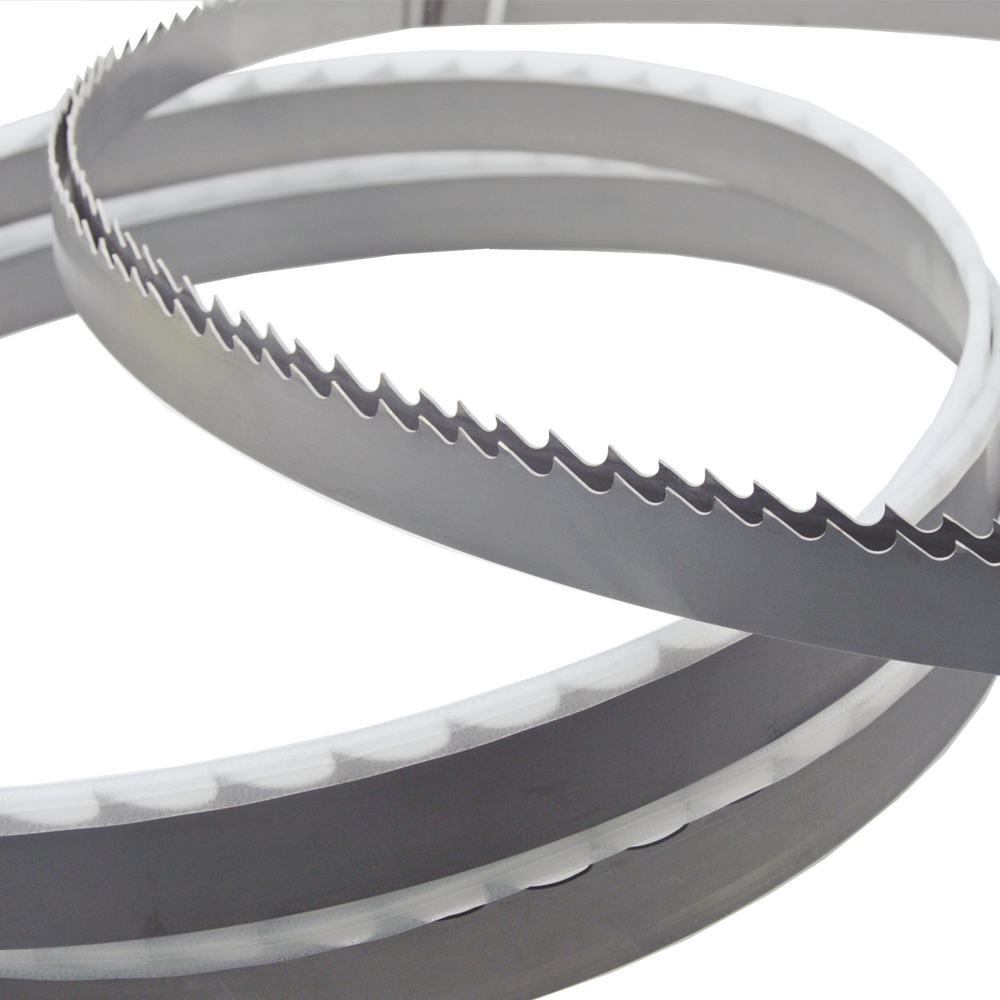

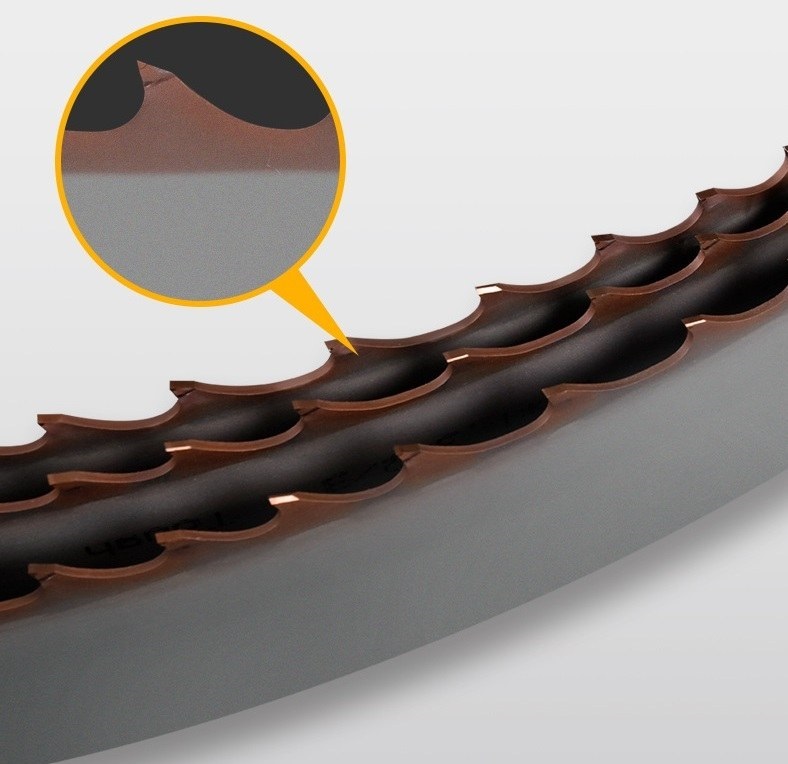

- Segmented Tooth Grinding & Geometry: Left, center, and right grinding paths reduce cutting force, lower resistance, and boost cutting efficiency.

- Optimized Tooth Count & Shape: Enlarged effective tooth count enables smoother operation and improved load distribution.

- Imported Carbide Tips: High-quality imported carbide heads guarantee durability and consistent cutting performance.

- High Hardness Teeth (90HRC): Excellent wear and deformation resistance, maintaining sharpness under heavy loads.

- WELLS Backing Material: Anti-fatigue, crack-resistant carrier material extends blade service life.

- Tooth Tip Segmentation: Specialized tooth tip division reduces load, prevents tooth pull-out, and prolongs blade life.

- Reduced Cutting Resistance: Minimizes energy consumption and heat generation, ensuring cleaner cuts and longer blade life.

Benefits

- Long running times and high performance even in capacity-constrained conditions

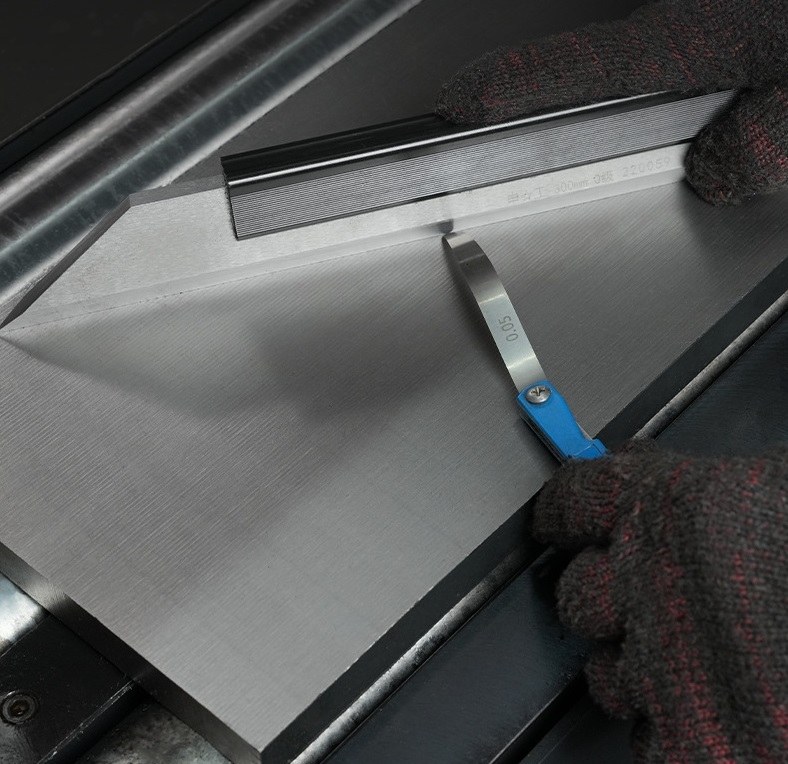

- Superior precision and cut quality for complex materials and profiles

- Reduced downtime due to fewer blade changes

- OEM customization available for specialized applications

Application

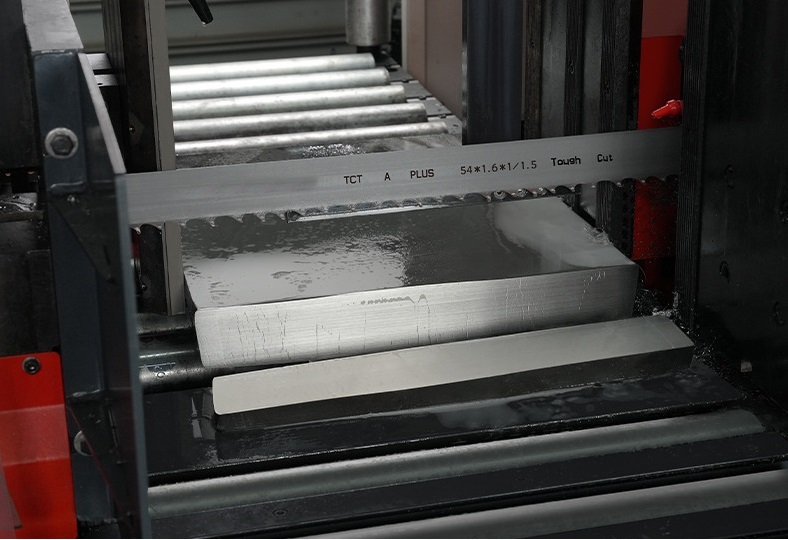

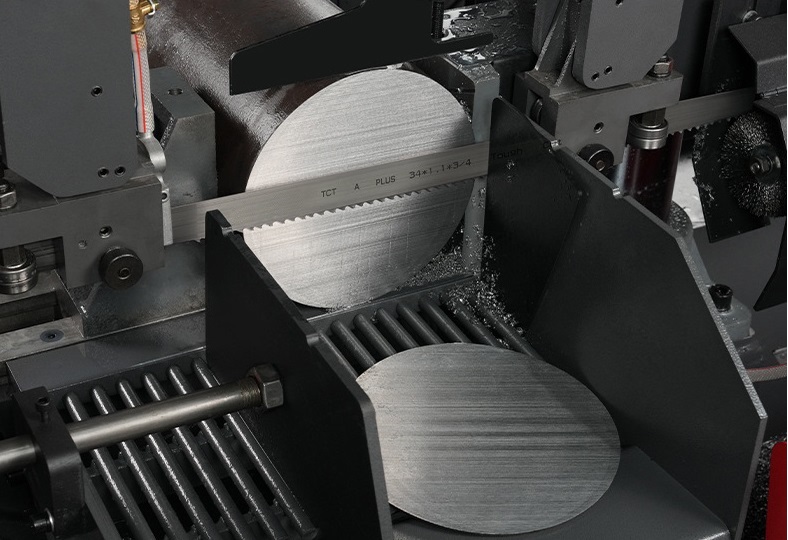

- Metalworking Workshops: Cutting pipes, rods, profiles, structural steel, and thick plates

- Woodworking: Processing timber, hardwood, and softwood

- Heavy-Duty Industrial Operations: Scenarios requiring high precision and long-lasting blades

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.