Provide a variety of slitting solutions – ALEKVS Slitting Lines

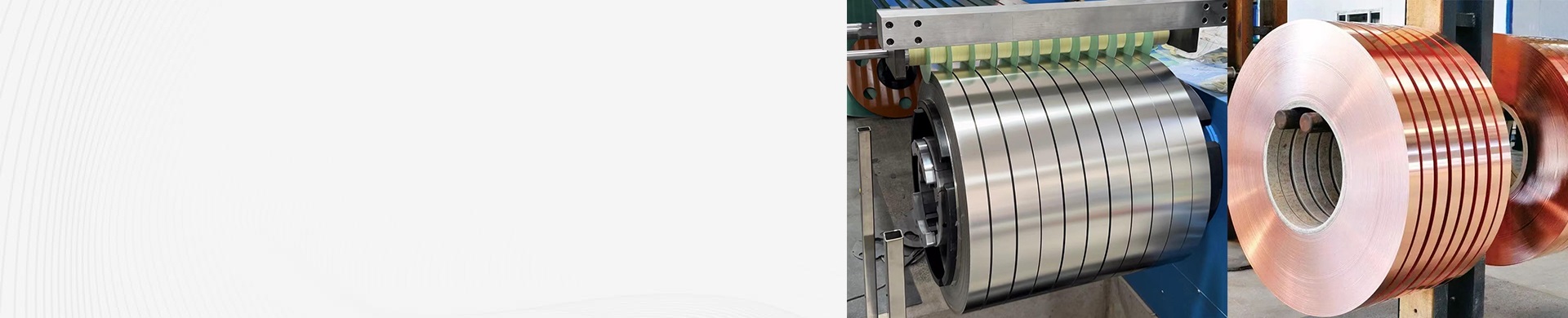

ALEKVS slitting lines are designed for processing various metal coils with thicknesses from 0.1 mm to 20 mm. Equipped with advanced technology and automated control systems, they deliver outstanding performance and high production capacity for service centers and steel processing facilities.

Product Range:

- High-Speed Slitting Line: Designed for maximum efficiency and rapid coil processing

- Light Gauge Slitting Line: Ideal for thin materials with consistent precision

- Heavy-Duty Slitting Line: Built for thick and high-strength metal coils

- Stainless Steel Slitting Line: Optimized for stainless steel with burr-free edges

- Aluminum Slitting Line: High-speed, clean cutting for aluminum coils

- Silicon Steel Slitting Line: Specialized for electrical and transformer steel

- Galvanized Steel Slitting Line: Reliable processing for coated steel materials

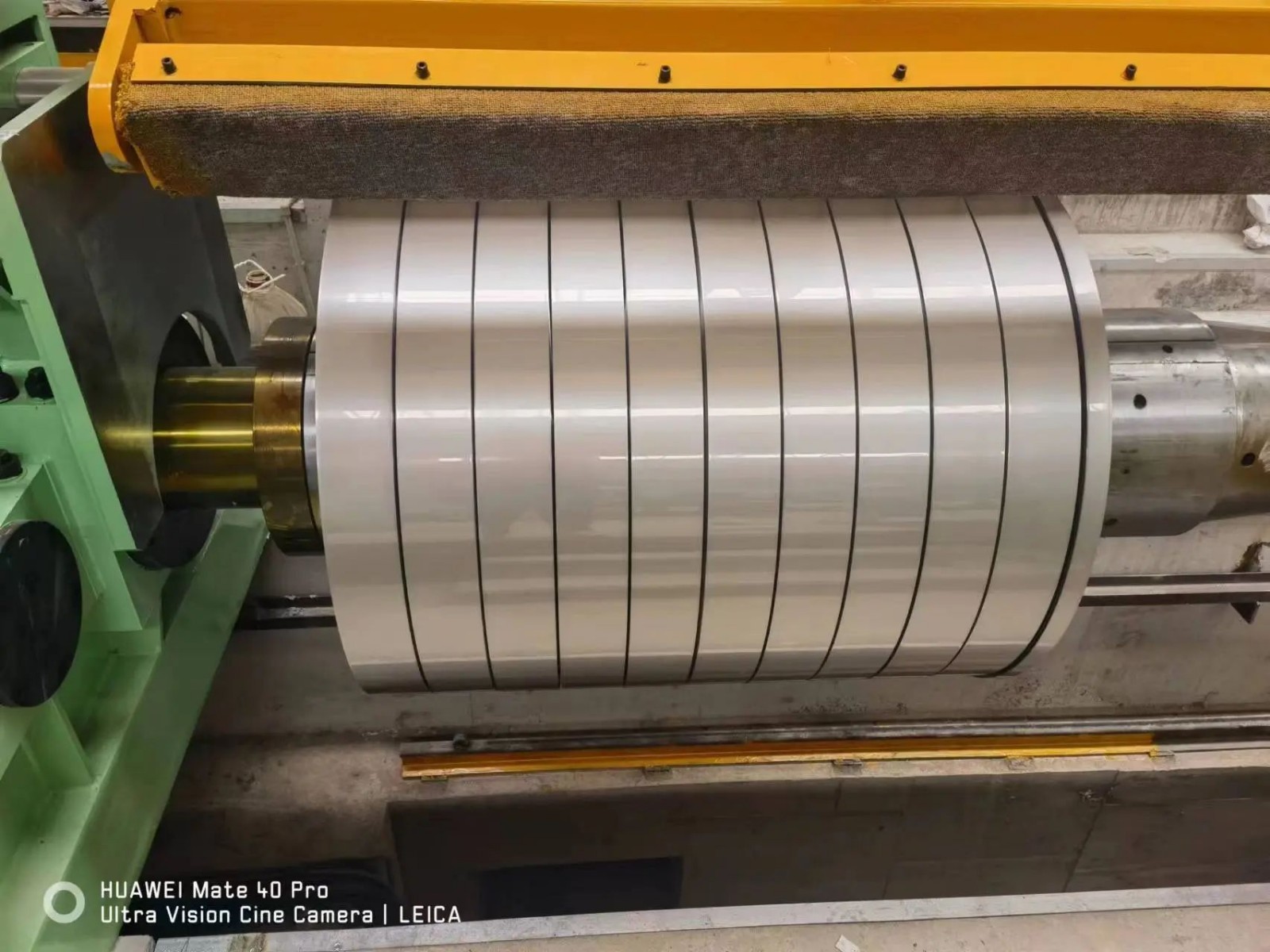

- Color Coated Coil Slitting Line: Designed for pre-painted or coated coils

- Precision Slitting Line: High-accuracy slitting for demanding applications

- Slitting and Recoiling Line: Complete solution for slitting and recoiling operations

ALEKVS Metal Plate Slitting Line Gallery