Product Features

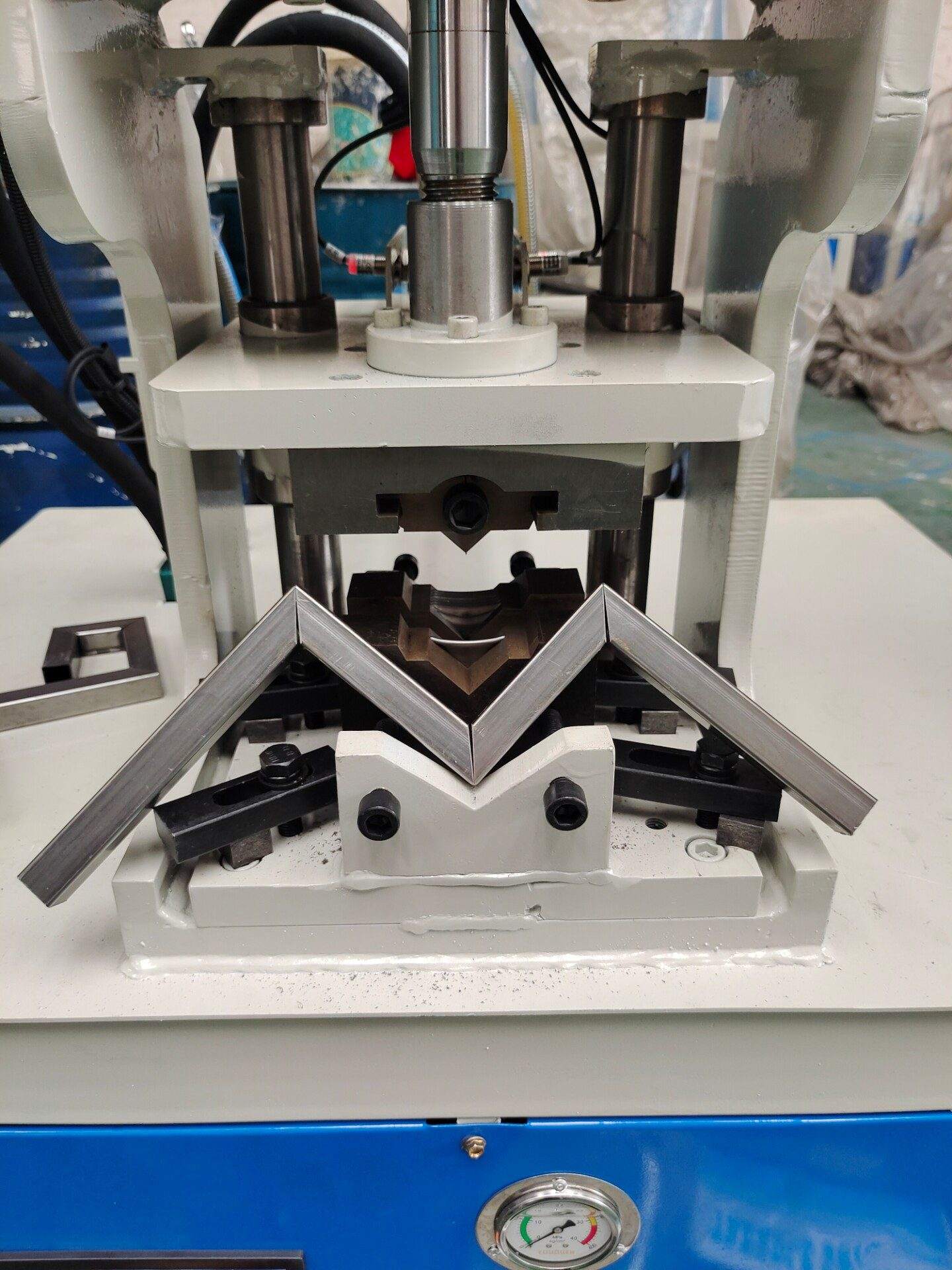

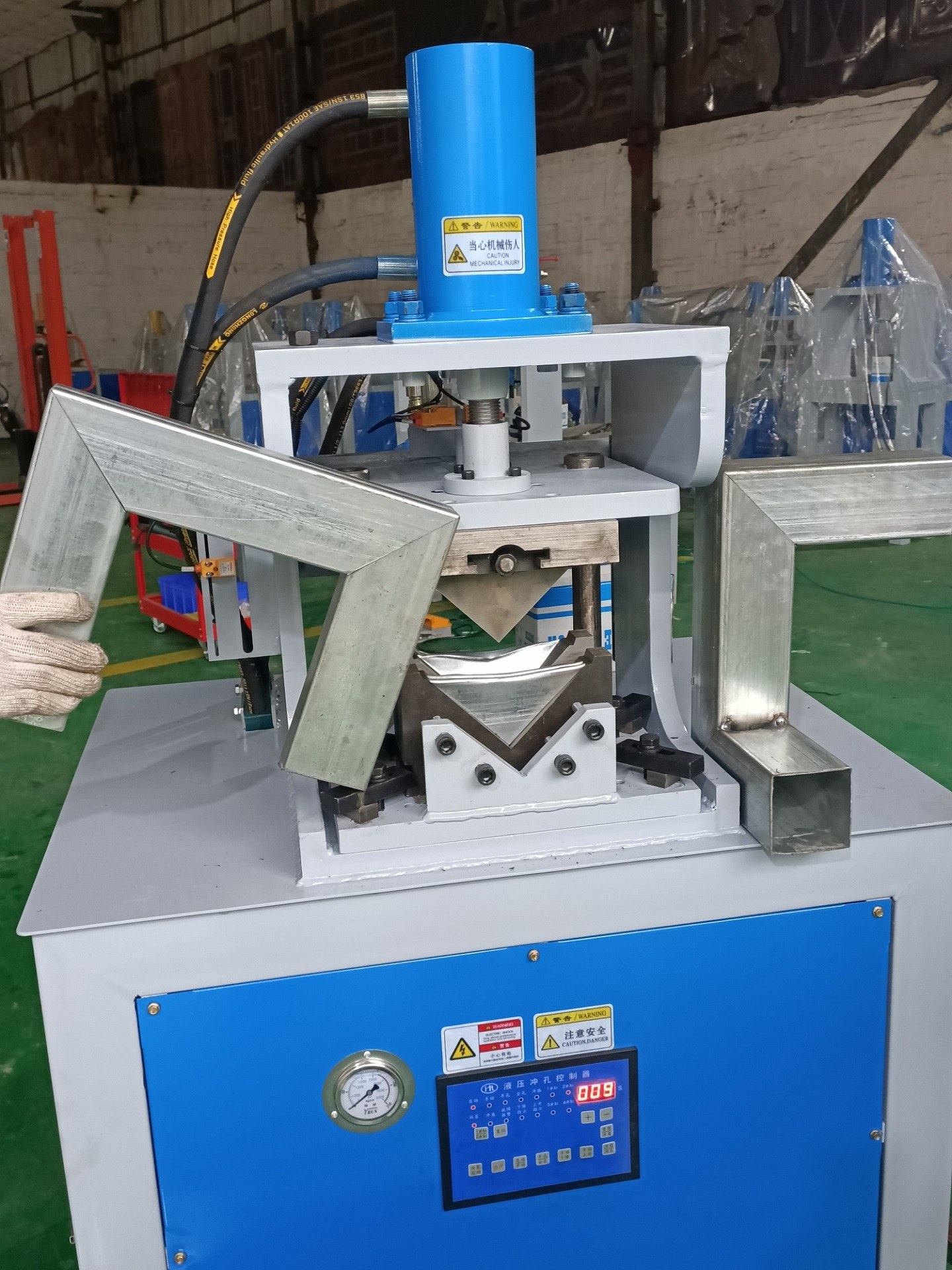

- Multi-function Integration: By replacing customized molds, it can realize multi-process processing such as punching, pipe end notching, pressing and cutting, meeting various production needs with one machine.

- High-Precision Processing: The mold base is manufactured through gantry milling process, combined with high-quality guide rails and transmission gears to ensure processing precision; the reasonably designed punch and mold set can avoid scratches on the pipe surface.

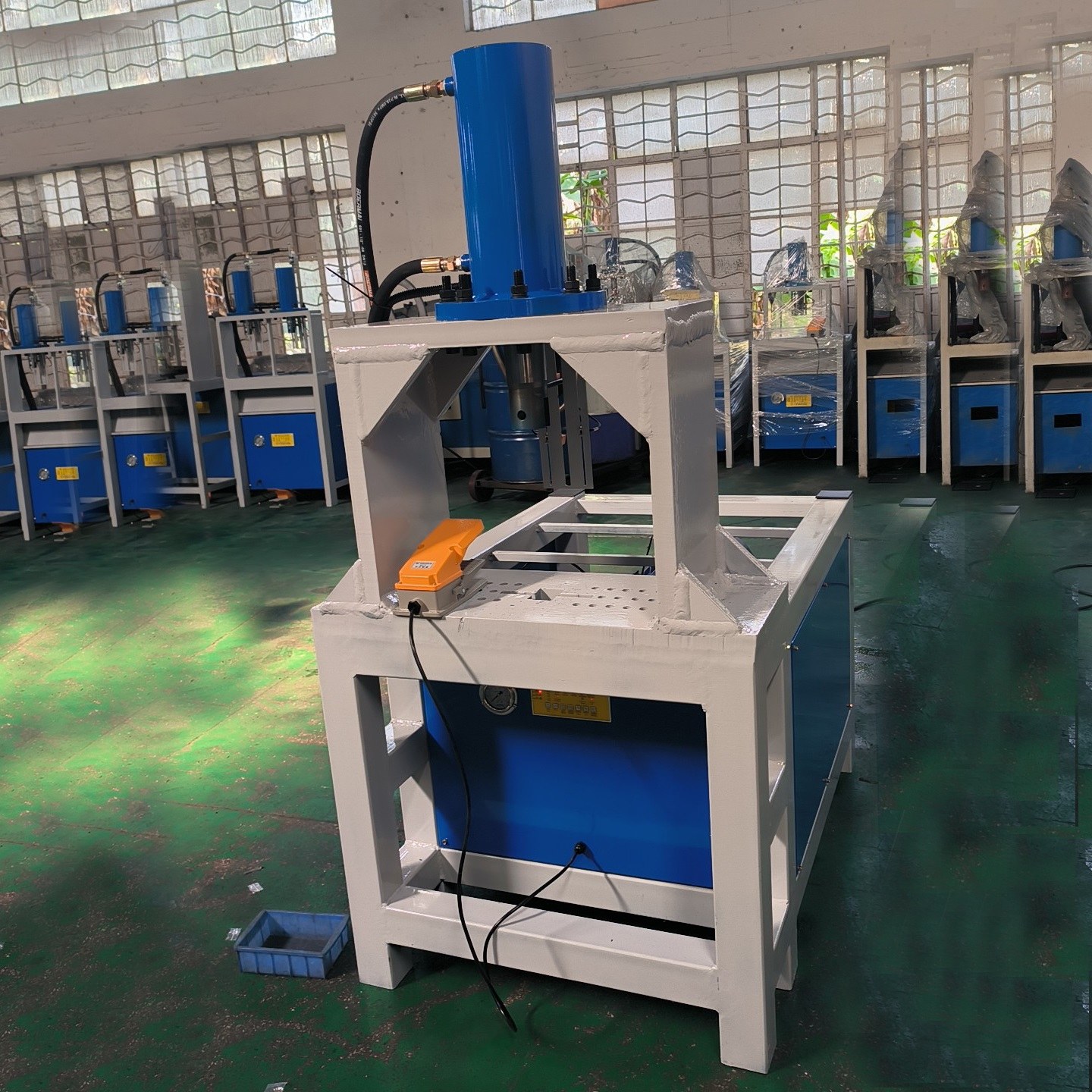

- Stable and Reliable Performance: Equipped with durable hydraulic cylinders and high-quality hydraulic hoses; the hydraulic system supports stepless pressure regulation, ensuring stable punching process; the hydraulic station is equipped with a built-in automatic cooling system to extend the service life of the equipment.

- High Customization: Exclusive molds can be customized according to customers’ requirements for pipe specifications, processed hole shapes and hole distances; meanwhile, customization and upgrading of multi-station versions are supported to adapt to different production scale needs.

- Excellent Processing Effect: The punched holes have smooth edges without burrs, and the pipes are free from deformation, effectively ensuring the processing quality of products.

Specifications

- Power Mode: Hydraulic drive combined with an electric motor

- Optional Cylinder Diameters: 63mm, 80mm, 100mm, 125mm, 140mm, 180mm, 220mm

- Equipment Category: Semi-automatic pipe processing machine (integrating punching, notching and other multi-functions)

- Mold Material: SKD11 material with tempering treatment

Application

- Processable Materials: Steel pipes, stainless steel pipes, mild steel pipes, iron pipes, aluminum alloy pipes, copper pipes, zinc-iron pipes, galvanized pipes and other various metal pipes.

- Processable Hole Shapes: Square holes, rectangular holes, D-shaped holes, triangular holes, oval holes, waist circular holes, prismatic holes, etc., supporting both half-hole and full-hole processing.

- Application Scenarios: Manufacturing and processing of aluminum ladder profiles, steel guardrails, zinc steel fences, iron protective fences, aluminum alloy shelf brackets, handrails, balustrades, railings, door and window frames, bed frames and other products.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.