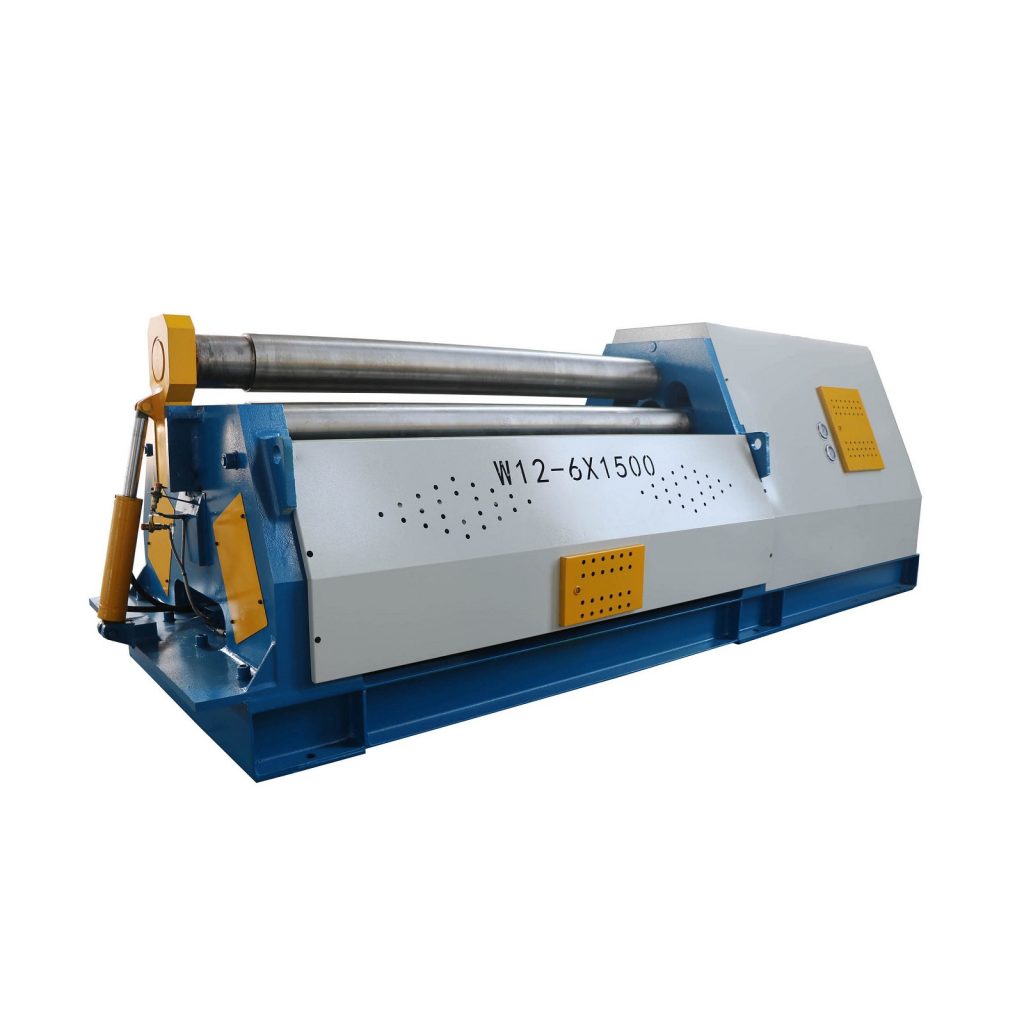

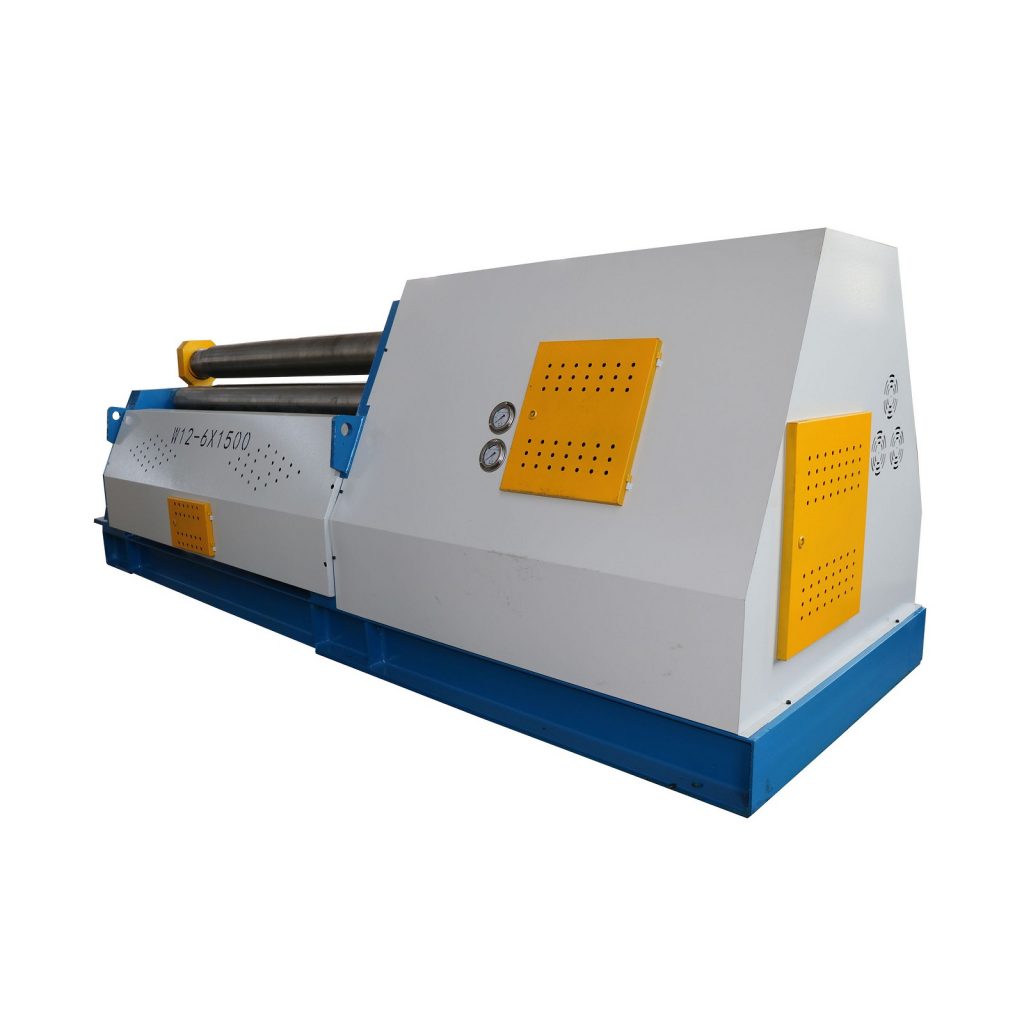

Metal Plate Rolling Machines

ALEKVS plate rolling machines undergo rigorous testing and strict quality assurance to ensure long-term reliability and outstanding performance. A two-year warranty backs each machine, and our technical team provides ongoing support for troubleshooting, training, and specification guidance throughout the life of your equipment.

Standard Models & Features

Our standard plate rolling machines are available in four sizes: 5′ × 3/8″, 6′ × 5/16″, 8′ × ¼″, and 10′ × ¼″. For unique requirements, ALEKVS also offers custom-built solutions. All standard models are equipped with:

- Powered and precision pinch roll adjustment

- Top roll swing-out design

- Emergency trip line & pedestal control

- Roll position indicators and crowned rolls

- High torque gearbox with quick adjustment

- Low-voltage push-button controls