- 1.0What Is Bending in Sheet Metal?

- 2.0How Bending Differs from Other Forming Processes

- 3.0How Bar Folders and Press Brakes Are Used

- 4.0What Are Air Bending, Bottoming, and Coining?

- 5.0How Roll Bending Works

- 6.0What Are Draw, Compression, and Press Bending?

- 7.0How to Bend Tubes Effectively

- 8.0What Is Roll Forming?

- 9.0How Seaming and Flanging Work

- 10.0How to Straighten or Flatten Metal

- 11.0How to Design for Better Bending

- 12.0How to Calculate Flat Blank Size

- 13.0Summary

Sheet metal bending is a fundamental plastic deformation process used in the manufacturing of countless metal components. This guide explains the principles behind bending, the types of bending operations, tooling considerations, and best practices for design and execution.

1.0What Is Bending in Sheet Metal?

Bending is a plastic deformation process where metal is deformed around a linear axis with little or no change in surface area. Key characteristics of bending include:

- Tension on the outer surface of the bend

- Compression on the inner surface

- Thinning near the neutral axis

- Springback, or the partial return of the material after deformation

2.0How Bending Differs from Other Forming Processes

- Forming: Multiple bends are produced using a single die setup.

- Drawing and stretching: The deformation is not limited to linear axes or may involve multiple non-independent axes.

3.0How Bar Folders and Press Brakes Are Used

Bar Folders

- Suitable for light-gauge sheet metal

- Can produce bends up to 150 degrees

- Ideal for small-scale precision bending

- Used for thicker materials or more complex bends

- Capable of forming various angles and contours with the correct tooling

4.0What Are Air Bending, Bottoming, and Coining?

Air Bending

- Uses a three-point bending method

- The bend angle is controlled by the depth of punch penetration

- Less force required, more flexible for different materials

Bottoming

- The punch fully contacts the bottom die

- The bend angle is fixed by the die geometry

- Offers better control of springback

Coining

- A high-force variant of bottoming

- Material is compressed beyond its yield point

- Produces precise and repeatable bends

the bottoming position of the upper die.

5.0How Roll Bending Works

Roll bending is a continuous form of three-point bending where plates, sheets, or beams are gradually bent between rollers. It is ideal for:

- Producing large-radius bends

- Forming cylindrical or curved profiles

- Processing beams, tubes, and heavy-gauge materials

6.0What Are Draw, Compression, and Press Bending?

- Draw Bending: A rotating form block pulls the material into shape.

- Compression Bending: A movable tool compresses the material against a fixed die.

- Press Bending: A press ram drives the punch into the forming die to create the bend.

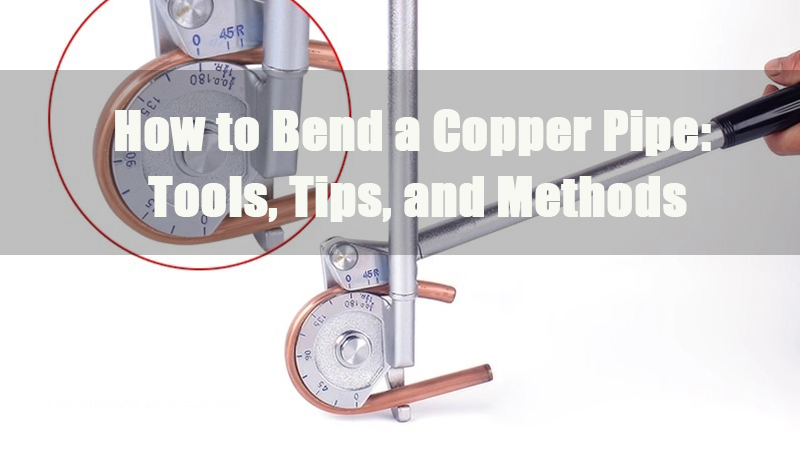

7.0How to Bend Tubes Effectively

Key parameters for successful tube bending include:

- Outer diameter (OD)of the tube

- Wall thickness

- Bend radius

Proper tooling and technique prevent deformation issues such as flattening, wrinkling, or wall thinning.

produced by roll forming

8.0What Is Roll Forming?

Roll forming is a progressive bending process where a metal strip passes through multiple rollers, each making incremental bends. Key characteristics:

- Only bending is involved, no cutting or punching

- All bends are parallel

- Ideal for producing long, complex profiles

- Setup and changeover can be time-consuming

9.0How Seaming and Flanging Work

- Seaming is used to mechanically interlock sheet edges—common in cans, containers, and drums

- Flanging involves bending the sheet edge to create a rim or stiffener

- Both operations rely on controlled bending along the edge of the sheet

10.0How to Straighten or Flatten Metal

Straightening is often required before further forming operations to ensure flatness. Common methods include:

- Roller Leveling: Material passes through alternating roller sets to gradually eliminate curvature

- Stretcher Leveling: Material is clamped and stretched to achieve the desired flatness

straightening rolls. For rods, another set of rolls is used to provide straightening in the transverse direction.

11.0How to Design for Better Bending

When designing for bending, several critical factors must be considered:

What Is the Minimum Bend Radius?

- The minimum bend radius depends on material ductility and thickness

- Bends that are too sharp may cause cracks

How Does Springback Affect the Bend?

- Large punch radii and shallow angles often result in significant springback

- Tighter bends reduce springback but increase internal stress

Why Material Direction Matters

- Bending perpendicular to the rolling direction is preferred

- For intersecting bends, align both at an angle to the rolling direction to prevent cracking

12.0How to Calculate Flat Blank Size

When planning a bent part, it’s essential to determine the correct flat blank length (L). Considerations include:

- Material thinning in the bend region

- Bend radius (R)and thickness (t)

- Use formulas or bend allowance tables to account for material behavior and dimensional changes during forming

13.0Summary

Sheet metal bending is a versatile and essential forming technique used across industries. By understanding the principles behind the process and carefully planning the design and tooling, manufacturers can ensure high-quality, accurate parts with minimal waste. Whether using press brakes, roll forming, or advanced bending dies, the key to success lies in precision and material understanding.