- 1.0What is Shearing in Metal Forming?

- 2.0Shearing Operations and Tool Mechanics

- 3.0Punching vs. Shearing: Key Differences in Metal Cutting

- 4.0Common Types of Shearing Techniques in Sheet Metal Cutting

- 5.0Shearing Machines: Types and Cutting Principles

- 6.0How to Optimize Shearing Machine Performance

- 7.0Case Studies: Innovative Applications of Shearing Processes

- 8.0Conclusion and Recommendations

- 9.0Frequently Asked Questions (FAQ)

1.0What is Shearing in Metal Forming?

Shearing is a mechanical cutting process used to separate materials—especially sheet metal—without forming chips, burning, or melting. This technique is widely employed as a preparatory operation for downstream manufacturing due to its ability to maintain accuracy and consistency in final products.

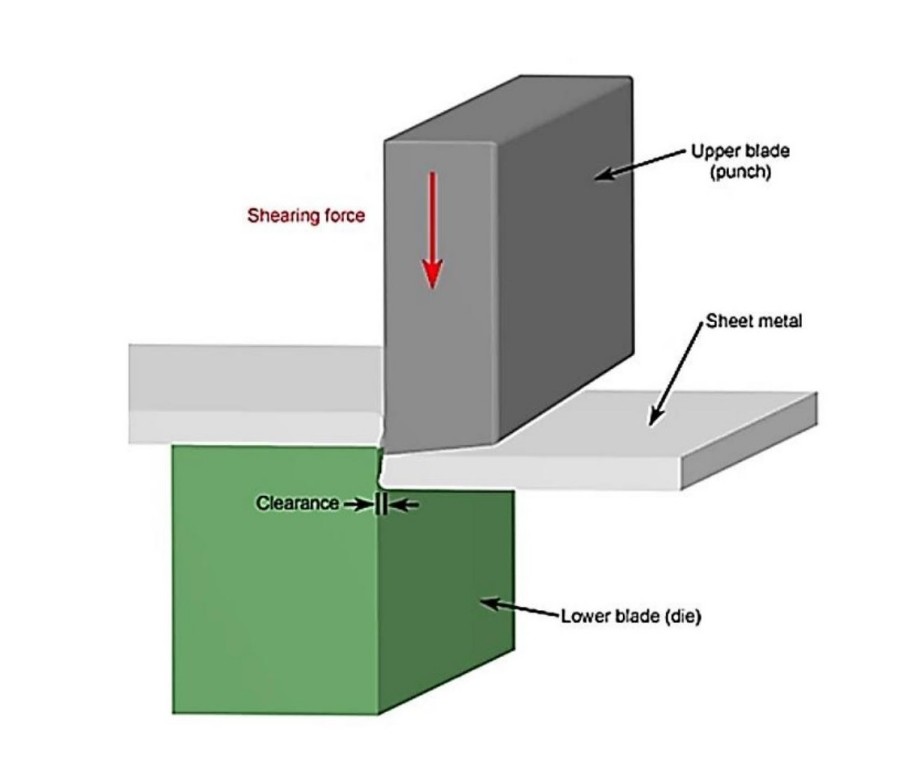

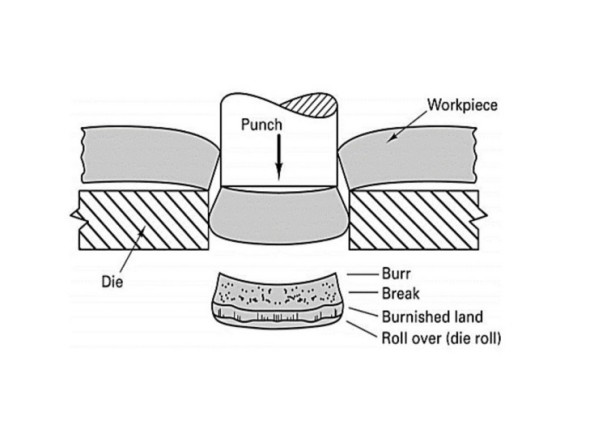

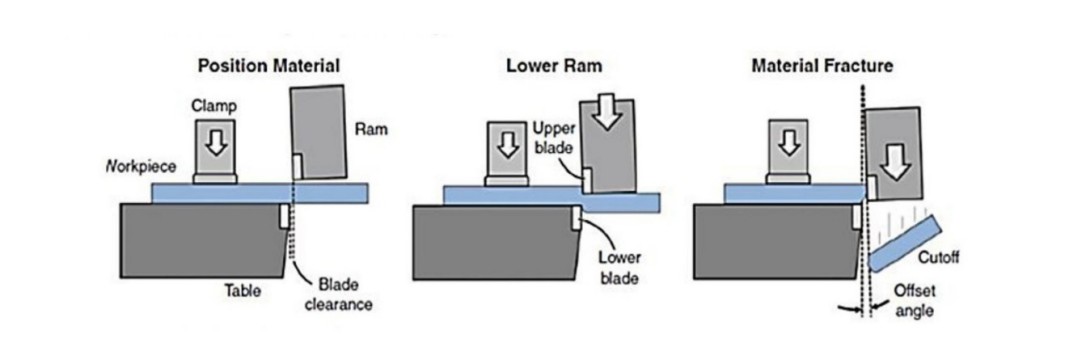

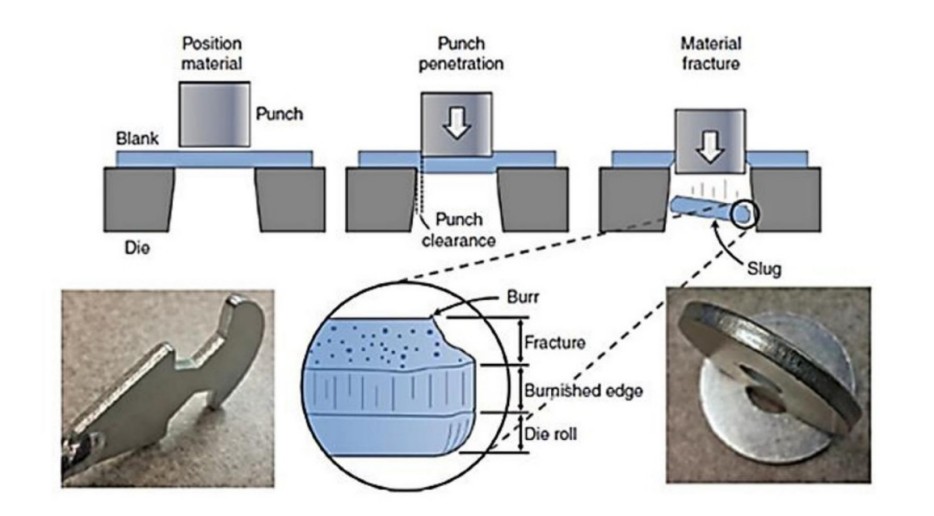

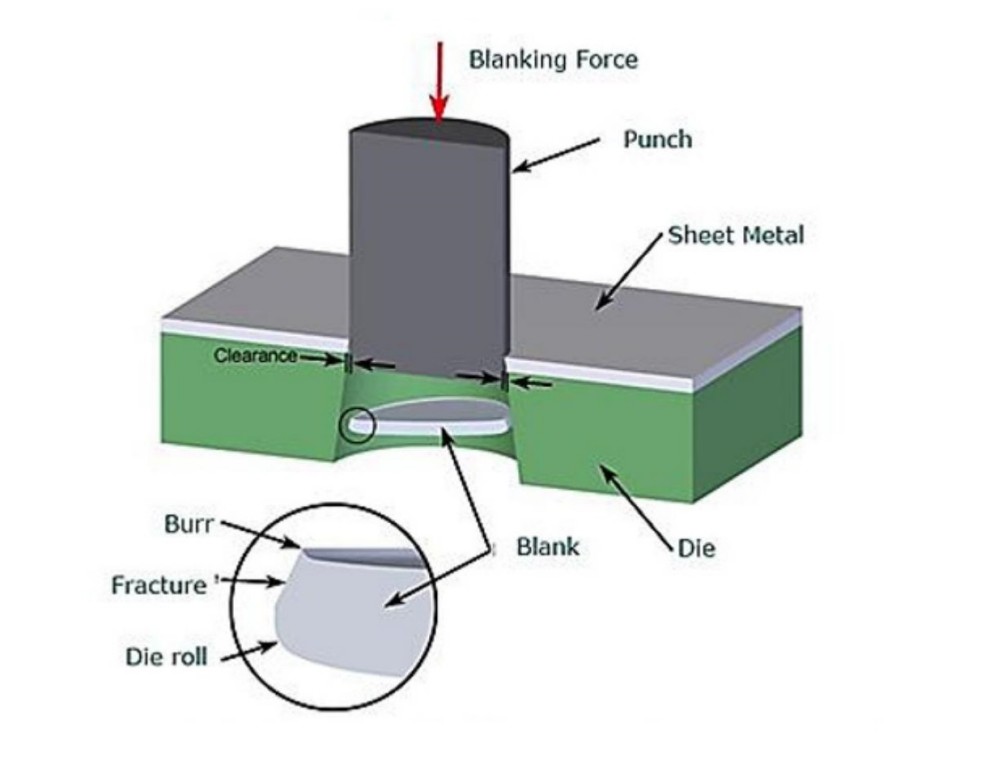

Shearing is also known as sheet metal cutting. When a shearing force exceeds the material’s ultimate shear strength, the material fractures and separates at the applied location. The shearing process utilizes two primary tools: a punch and a die (or upper and lower blades), situated above and below the sheet, respectively (Figure 1).

The clearance between the upper and lower blades typically ranges from 2% to 10% of the sheet thickness, depending on the material’s mechanical properties, such as shear strength. Proper clearance ensures efficient cutting while promoting plastic deformation without damaging the material.

2.0Shearing Operations and Tool Mechanics

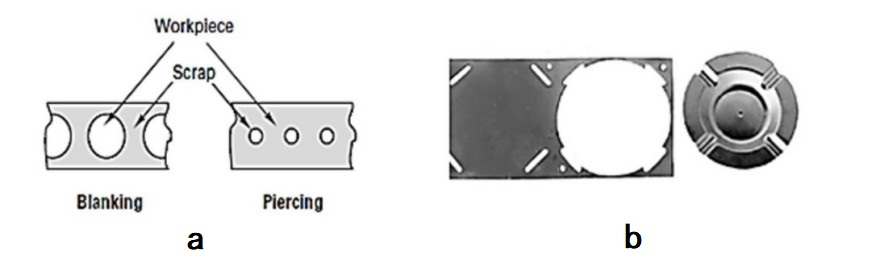

When two blades cut through a sheet, the operation is generally called shearing. However, when blades are angled or configured differently, operations such as blanking, piercing, notching, or trimming are executed. From a tool design and material behavior standpoint, all are considered shearing-related processes.

In typical shearing, the punch forces the metal through the die, producing localized deformation along a narrow shear zone. A clearance of 5%–10% of sheet thickness is maintained. When performed under compressive conditions, this reduces fractures and increases the smooth edge fraction. At sufficient pressure, the material may shear completely with minimal surface breakage.

3.0Punching vs. Shearing: Key Differences in Metal Cutting

Although often used interchangeably, punching and shearing are distinct processes. Shearing refers to applying offset forces to split material along a straight or curved path. Punching, on the other hand, involves creating closed shapes by removing material, similar to using a paper hole punch

Key differences include:

- Shearing uses opposed linear blades to separate material.

- Punching forms closed features, e.g., circular holes.

- Cutting edges directly influence the final part’s shape.

4.0Common Types of Shearing Techniques in Sheet Metal Cutting

Several variants of shearing operations exist, each suited to specific tasks:

- Simple Shearing

- Punching

- Slitting

- Blanking

- Notching

- Cut-Off

- Nibbling

- Shaving

- Trimming

- Dinking

- Lancing

- Fine Blanking

4.1Slitting: Coil-to-Strip Metal Cutting

Slitting cuts sheet metal coils into narrower strips using circular shearing blades. The process is continuous, fast, and economical, producing precise results compared to other cutting methods.

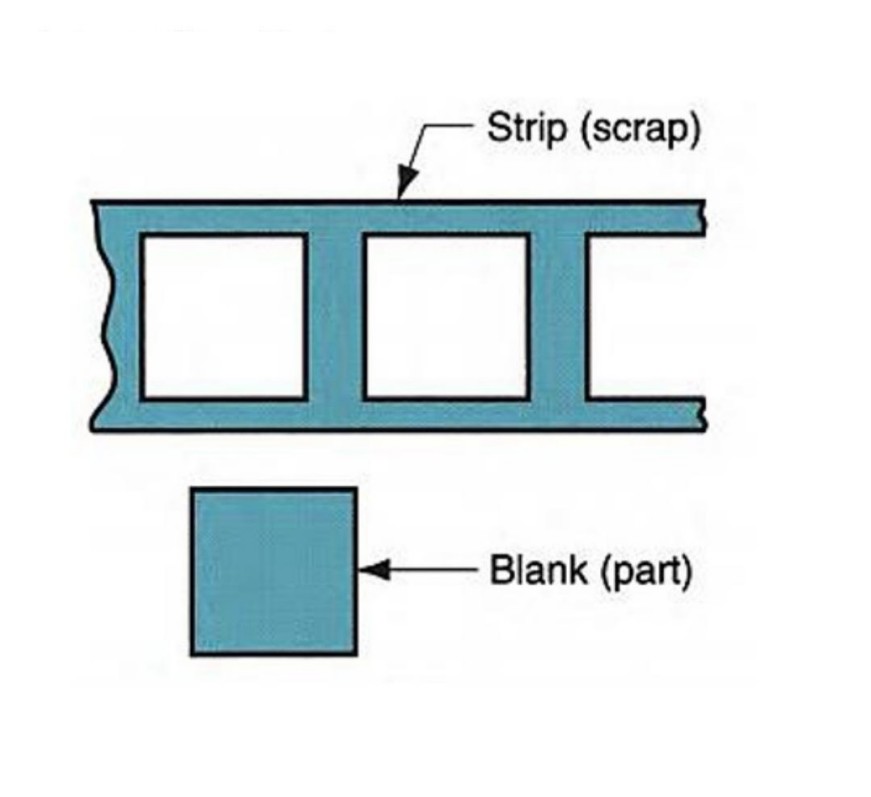

4.2Blanking: One-Step Shape Extraction

Blanking involves a punch cutting through sheet metal to remove the desired shape (the blank), separating it from the surrounding stock.

A hydraulic press drives the blanking die at high speed—up to 1000 strokes/minute—with a 10–20% clearance to enable clean shearing.

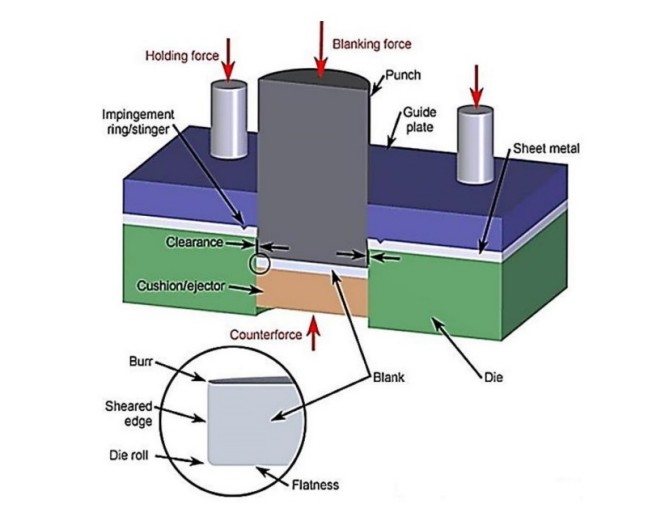

4.3Fine Blanking: High Precision Cutting

Fine blanking uses three controlled forces to achieve superior flatness, minimal burrs, and dimensional tolerance as close as ±0.0003. The setup is similar to conventional blanking but includes additional control for higher quality results.

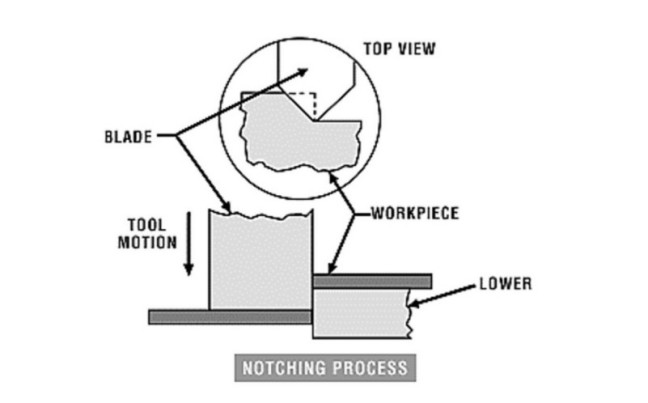

4.4Notching: Edge Scrap Removal

Notching removes scrap material from the edge of a workpiece. It’s typically a manual, low-volume process ideal for customized shapes or angles.

Advantages:

- Adjustable angle cuts

- Capable of unique geometries not feasible in standard shearing

5.0Shearing Machines: Types and Cutting Principles

Shearing machines cut metals using scissors-like motion or straight-blade action. Smaller machines may use angular movement, while larger machines rely on rake angle and clearance to optimize performance.

5.1Common Types of Shearing Machines:

- Pneumatic Shears– Powered by air cylinders

- Hydromechanical Shears– Driven by hydraulic motors

- Servo-Driven Shears– Linked directly to servo motors

- Hydraulic Shears– Provide very high cutting force

- Electric Shears – Powered directly by electric motors (usually combined with mechanical or hydraulic transmission)

- Manual Shears– Hand-powered via lever magnification

6.0How to Optimize Shearing Machine Performance

The shearing process is labor-intensive and demands precise control to maximize productivity. Key factors include:

- Ensure blades are perfectly straight

- Set clearance according to material thickness

- Confirm proper back-gauge settings

- Stabilize the sheet during cutting

- Perform regular maintenance (cleaning, component replacement)

Shearing is ideal for bronze, brass, aluminum, and low-carbon steels, producing minimal kerf and tolerances. However, it’s unsuitable for hard, brittle materials like tungsten and for parts <3.2 mm in length.

7.0Case Studies: Innovative Applications of Shearing Processes

7.1Case 1: C2S2 – Continuously Confined Strip Shearing

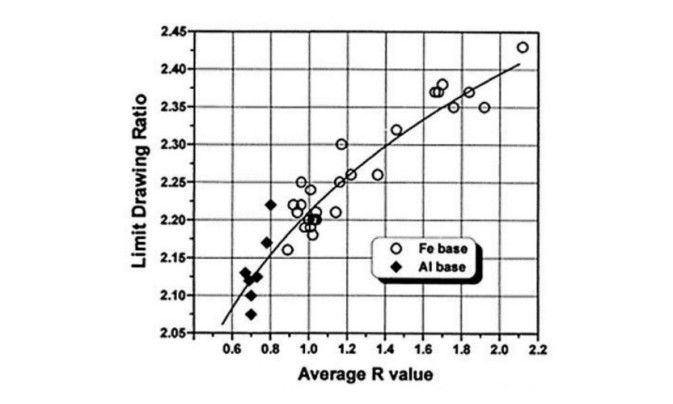

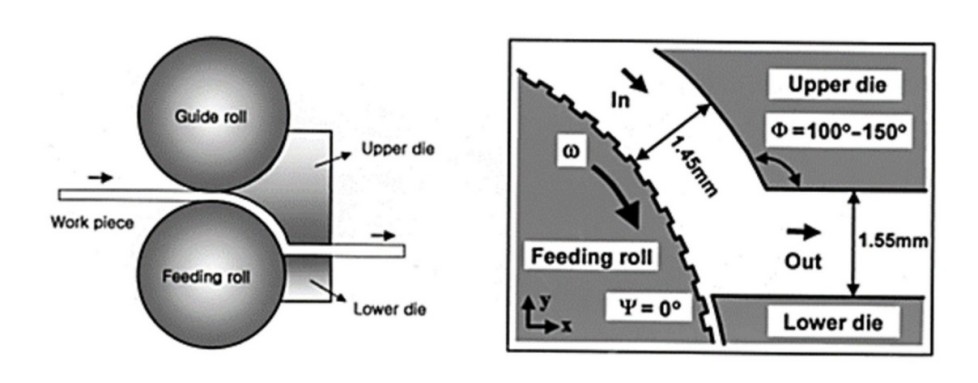

To produce lighter vehicles, aluminum (Al) sheets are replacing heavier Fe-based sheets. Using Equal Channel Angular Pressing (ECAP), engineers induce shear strain to enhance the metal’s R-value, improving formability.

The C2S2 system uses twin rolls to generate consistent shear deformation—more efficient than hydraulic presses—and can detect surface defects during operation.

7.2Case 2: Shearing for Copper-Zinc Zipper Components

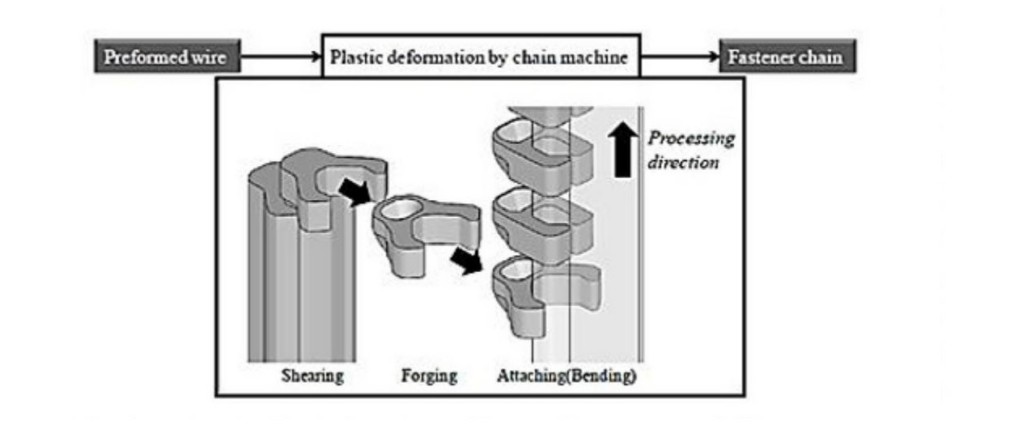

Used in garments and accessories, Y-shaped copper alloy wire is sheared into chips, forged, and bent to form zipper teeth. As designs become more complex, achieving precision in shaping requires multiple iterations .

7.3Case 3: SHAPE for Magnesium Alloy ZK60 Tubing

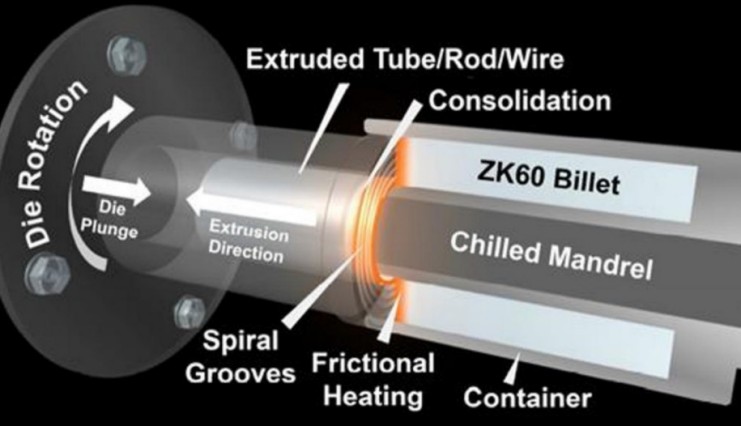

Magnesium alloys, especially non-rare-earth Mg, offer weight-saving benefits. Using Shear Assisted Processing and Extrusion (SHAPE) improves mechanical properties by refining microstructures and eliminating second-phase weaknesses.

8.0Conclusion and Recommendations

This study highlights key shearing operations, machines, and advanced applications. The shearing process is highly effective for soft-to-medium metals and is cost-efficient for mass production, but not ideal for high-hardness or precision surface finish applications.

Recommendation: Avoid shearing for lengths under 3.2 mm or high-strength, brittle metals.

Future Direction: Techniques like SHAPE and C2S2 show promise in improving material properties via shear deformation.

9.0Frequently Asked Questions (FAQ)

Q1: What is the difference between shearing and punching?

A: Shearing involves cutting material along a straight or curved path using opposing blades, similar to scissors. Punching, on the other hand, removes material entirely in a closed shape, like making holes with a punch. Both use similar tooling but differ in shape and intent of material removal.

Q2: What materials are best suited for the shearing process?

A: Shearing works best on ductile, soft-to-medium-strength metals such as aluminum, low-carbon steel, brass, and bronze. It is not recommended for hard or brittle materials like tungsten due to tool wear and the risk of abnormal deformation.

Q3:What is fine blanking, and how is it different from regular blanking?

A: Fine blanking is a high-precision version of blanking that uses three applied forces to produce smooth edges, tighter tolerances (as close as ±0.0003″), and minimal burrs. It is commonly used for precision automotive and electronic components.

Q4: How does clearance affect the shearing operation?

A: Clearance refers to the gap between the upper and lower blades (punch and die). It typically ranges from 2% to 10% of the material thickness. Proper clearance ensures clean cuts, prevents tearing or excessive burrs, and reduces tool wear.

Q5: Can shearing be used for high-volume production?

A: Yes. Shearing is well-suited for mass production, especially in sheet metal processing. Hydraulic and servo-driven shearing machines can achieve rates up to 1000 strokes per minute, making it highly efficient for continuous operations.