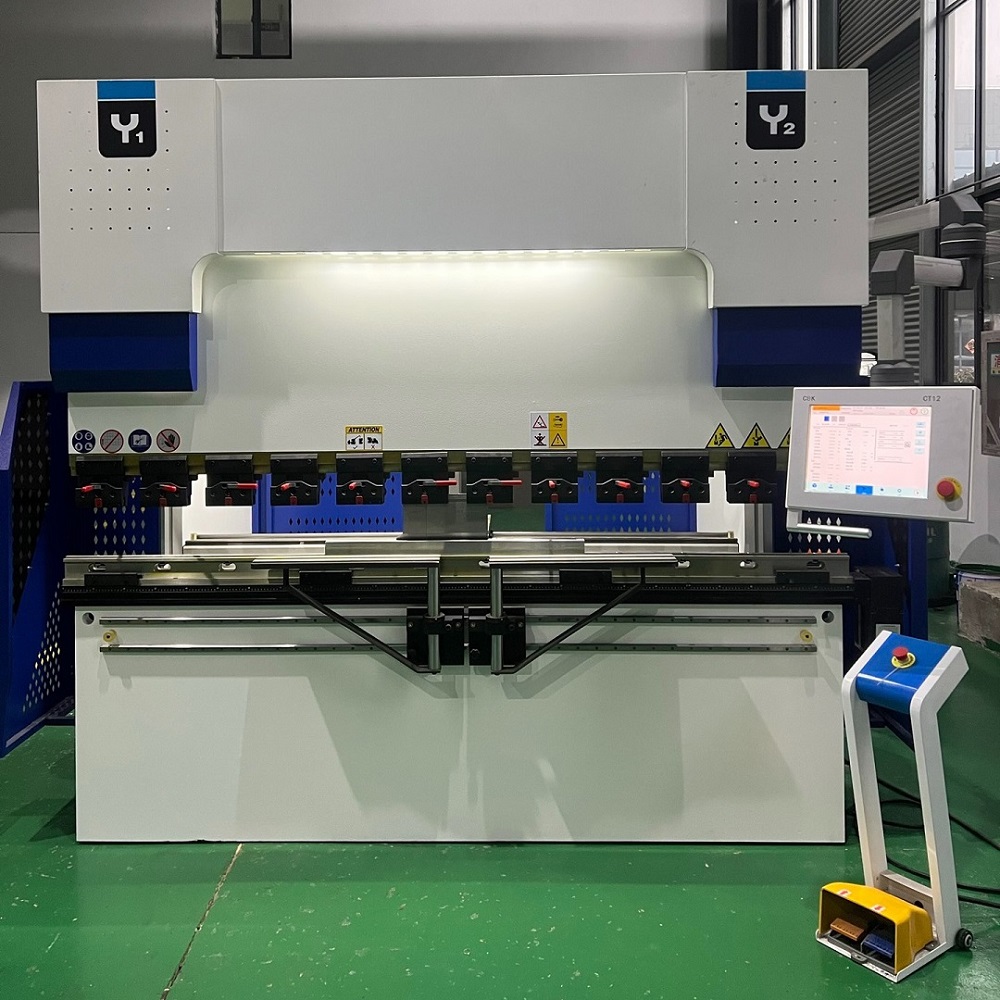

Servo CNC Press Brake Machine

Product Overview

- Welded Steel Structure:The machine frame is made of welded steel plates, with stress eliminated through large-scale tempering for long-term structural stability and processing accuracy.

- Electro-Hydraulic Servo Control: Both side cylinders are equipped with electro-hydraulic servo valves and high-precision FAGOR (Spain) grating rulers, forming a closed-loop control system for accurate feedback, precise slider movement, and consistent bending performance.

- Integrated Hydraulic System:Uses a compact, integrated control unit to reduce pipeline connections, minimize oil leakage, and enhance operational stability.

- Mechanical Crowning System (V-axis): Automatically compensates for deflection during bending. The CNC system calculates and applies the compensation in real time to ensure consistent bending quality.

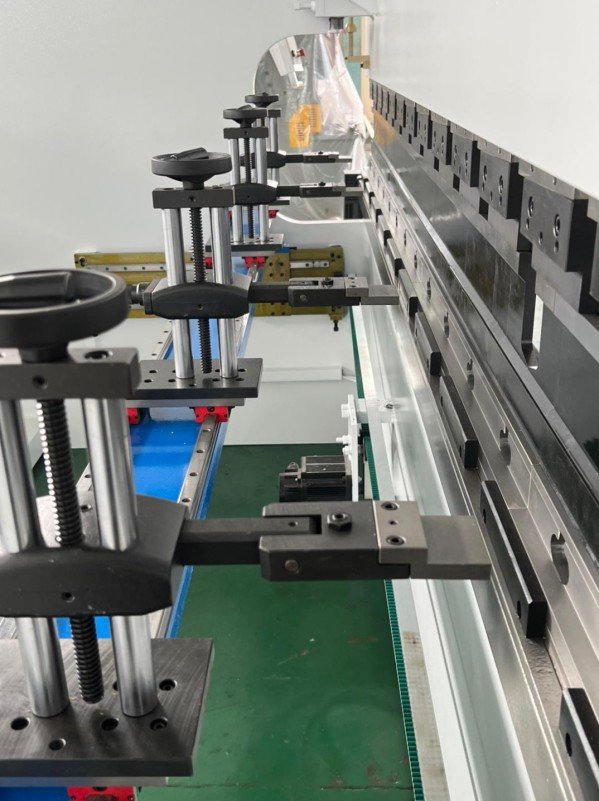

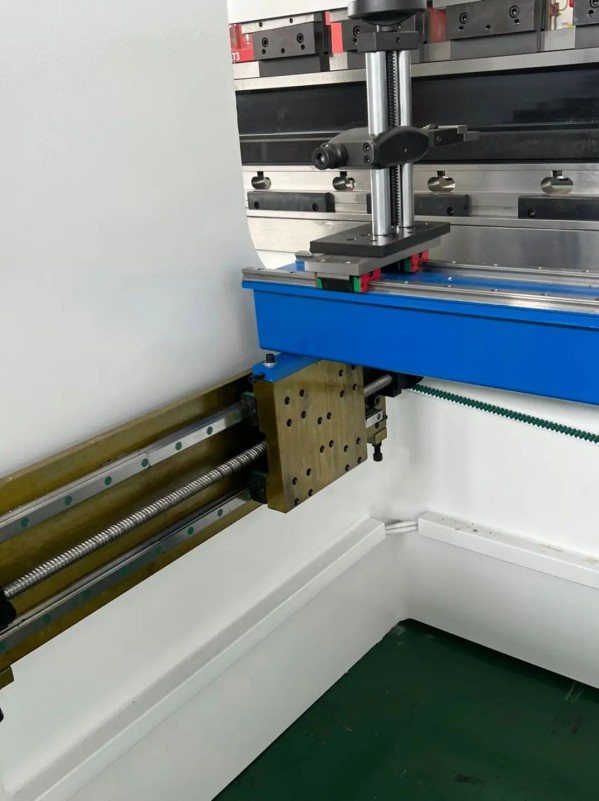

- 4+1 Axis CNC Backgauge: The X and R axes are driven by servo motors, linear guides, and ball screws, providing high-speed response and precise positioning.

CNC Control System – Delem DA-53T

- 1″ high-resolution TFT color display

- Supports up to 4 axes (Y1, Y2 + 2 auxiliary axes)

- Automatic deflection compensation

- Integrated tool, material, and product libraries

- Supports servo and frequency control

- Advanced Y-axis control algorithm

- Node interconnection (optional)

- USB interface

- Offline programming via Profile-53TL software

Key Features

- Servo Main Motor: Low noise, energy-saving

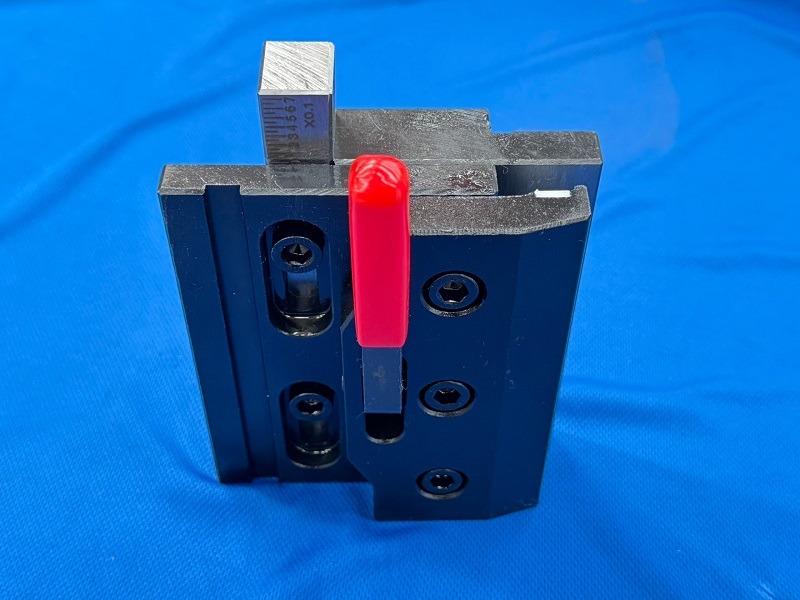

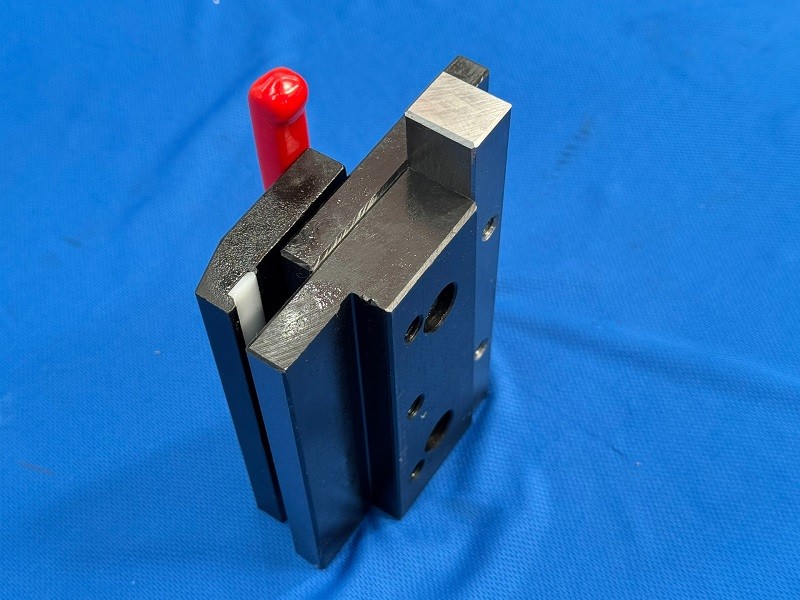

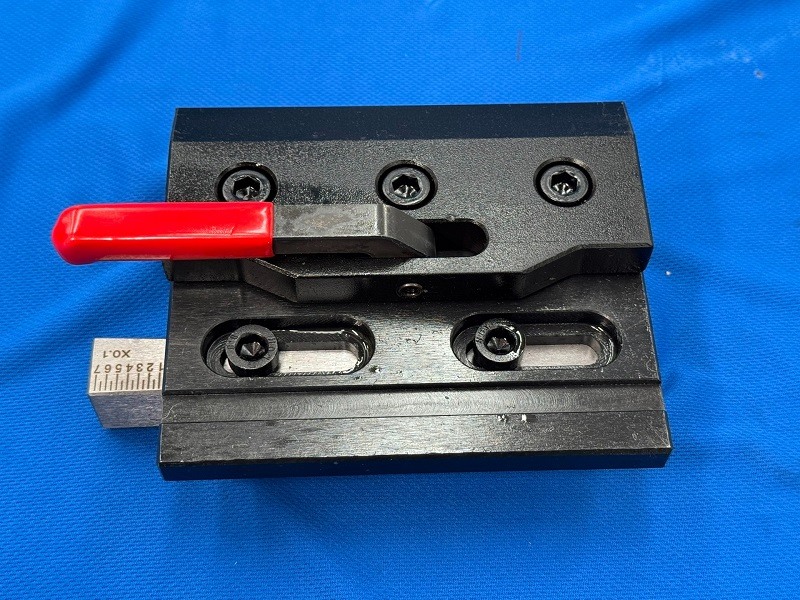

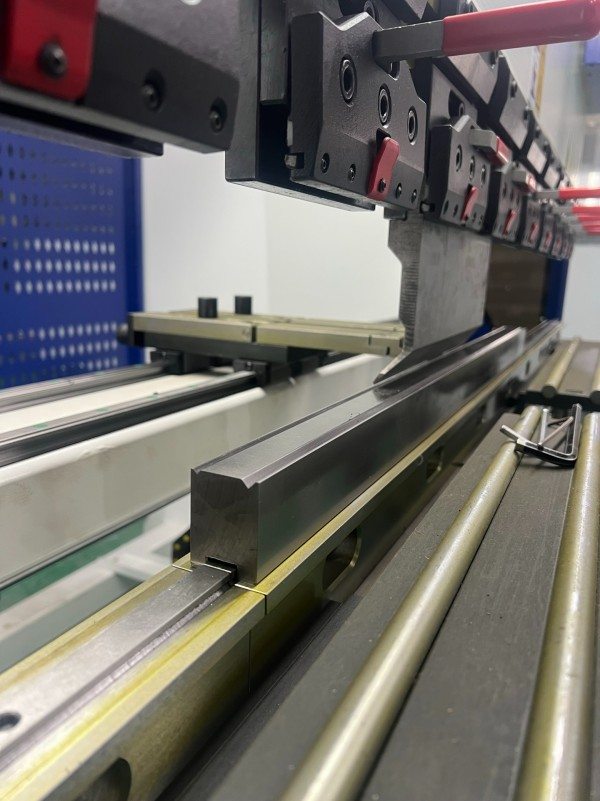

- Fast Clamp: Quick and easy punch installation for improved efficiency

- X-Axis Servo Motor: Industrial-grade brushless motor with silent timing belt for accurate movement

- High-Precision Grating Ruler: Installed on the C-frame, with 0.001mm feedback resolution to monitor cylinder movement and ensure angle precision

- Mechanical Crowning System (V-axis): Multi-point compensation for linear adjustment during bending; maintenance-free with high precision

- High-Precision Stop Fingers: Dual programmable stops ensure fast, stable, and repeatable positioning

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.