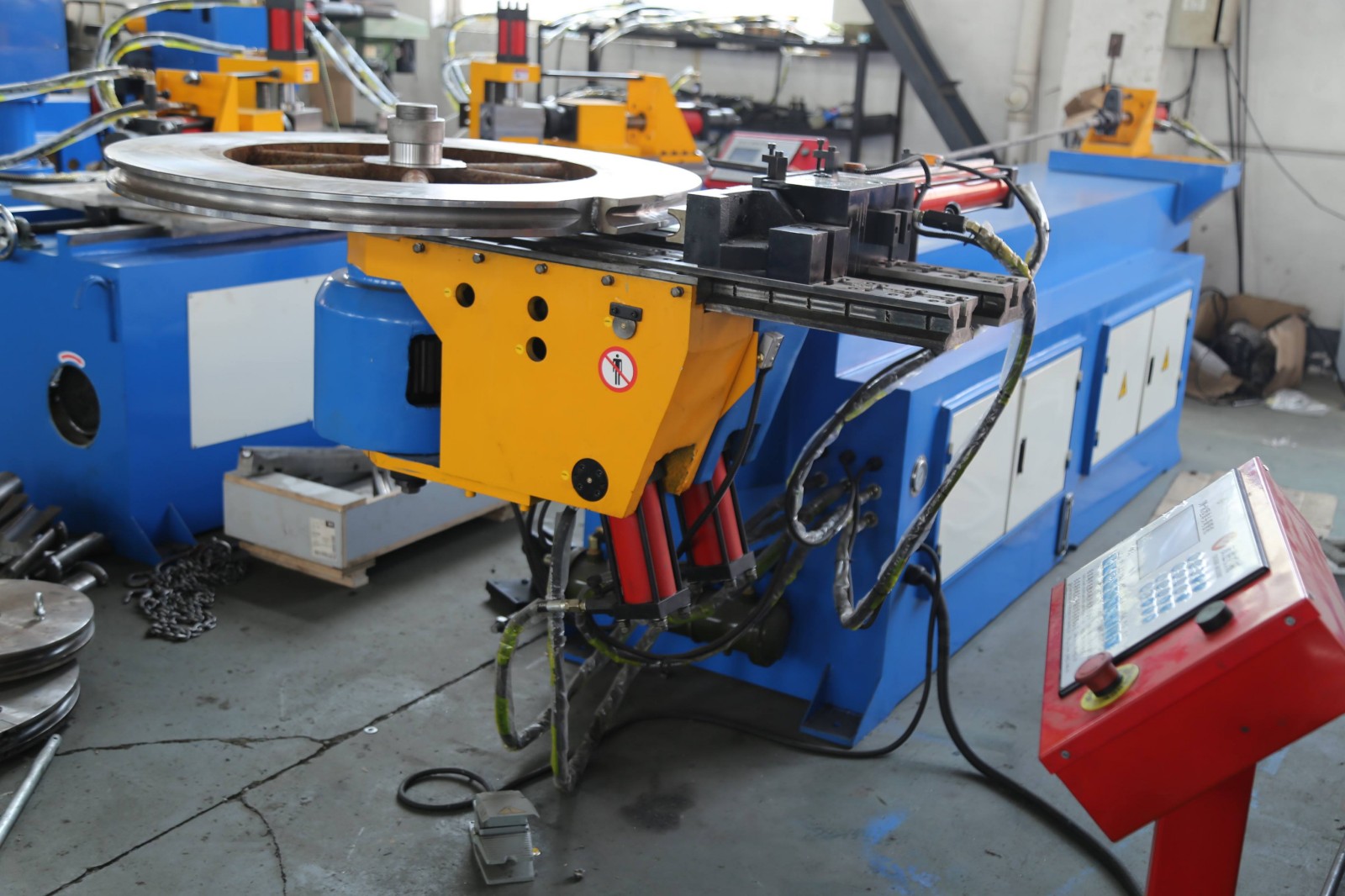

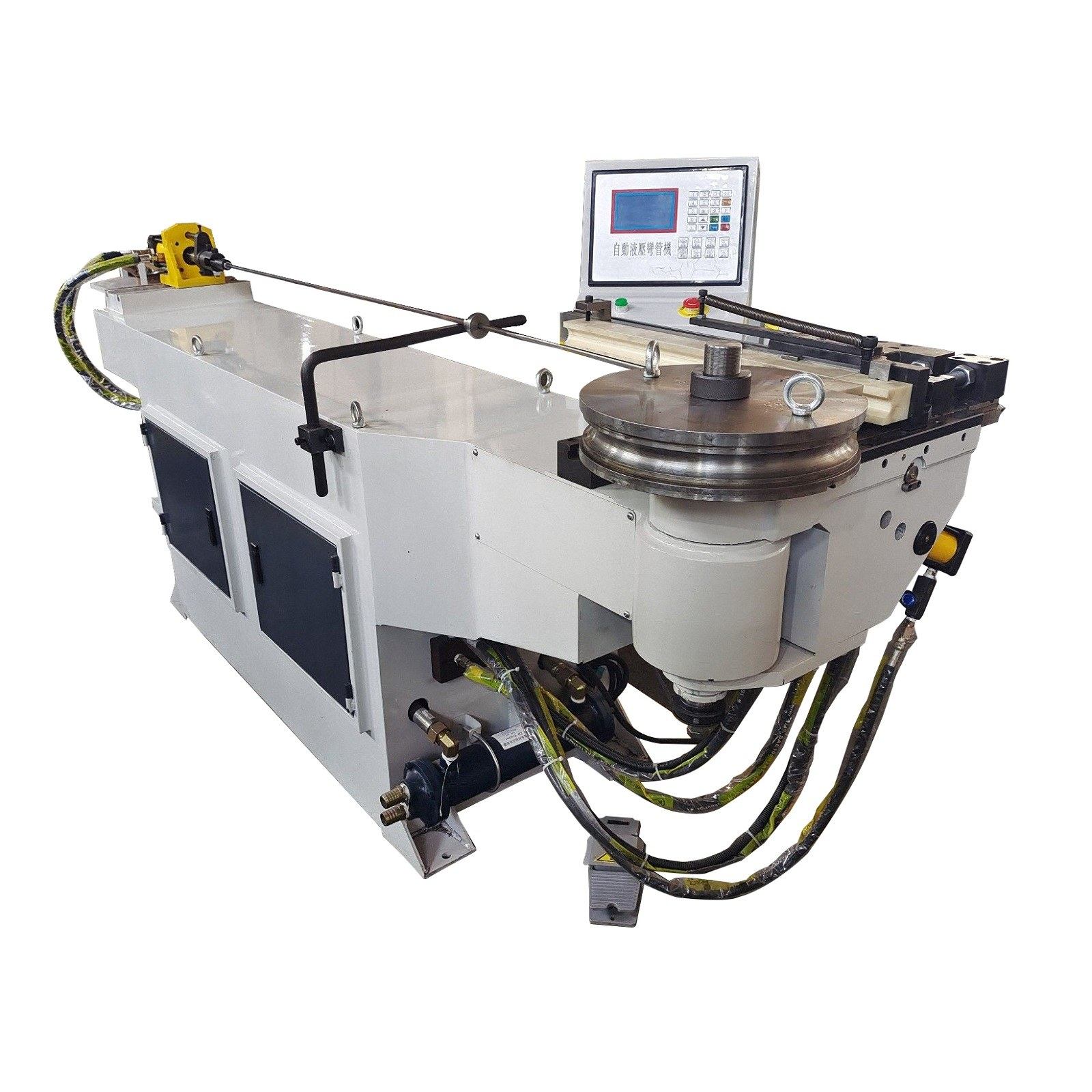

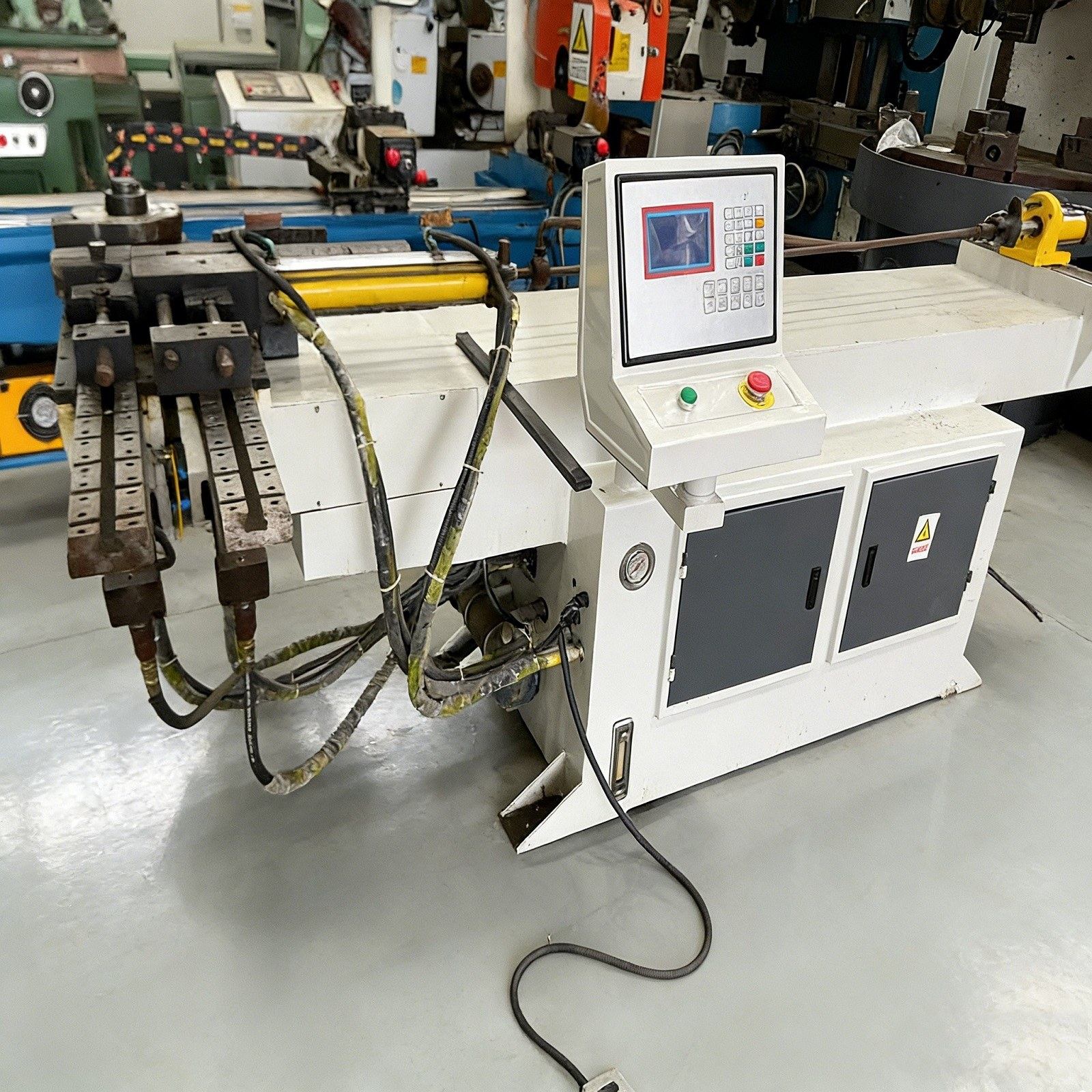

The AEK-DWNC Series is a semi-automatic hydraulic pipe-bending machine featuring an NC control system with a touch-type HMI, enabling high-precision bending control. Pipe feeding and rotation are performed manually, while the bending process is executed automatically by the hydraulic system, ensuring both operational flexibility and stable performance.

This series is particularly suitable for small to medium batch production. While ensuring bending accuracy, it effectively reduces equipment investment cost, offering an exceptional cost-performance ratio.

Typical Bending Capabilities

- Tight radius bends

- Thin-wall and heavy-wall pipe bending

- “J”-shaped bends

- 1D bending

- 180° large-angle bending

- Truck exhaust bends

- Automotive exhaust bends

- Marine exhaust system bends

- Refrigeration pipe bends

- HVAC piping bends

Core Advantages

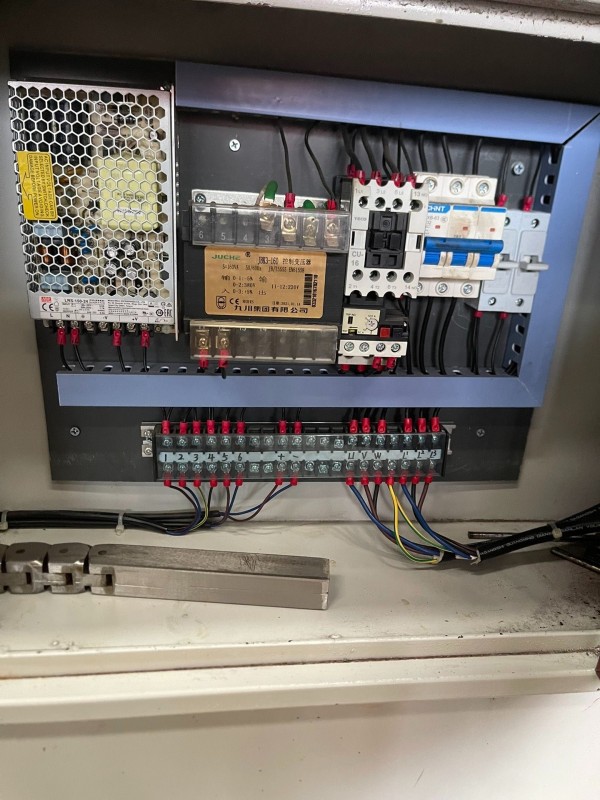

- NC microcomputer control, simple and intuitive operation:

Chinese touch-screen interface, man–machine dialogue operation, multiple modes supported, with program storage and power-off memory functions. - High-precision bending performance:

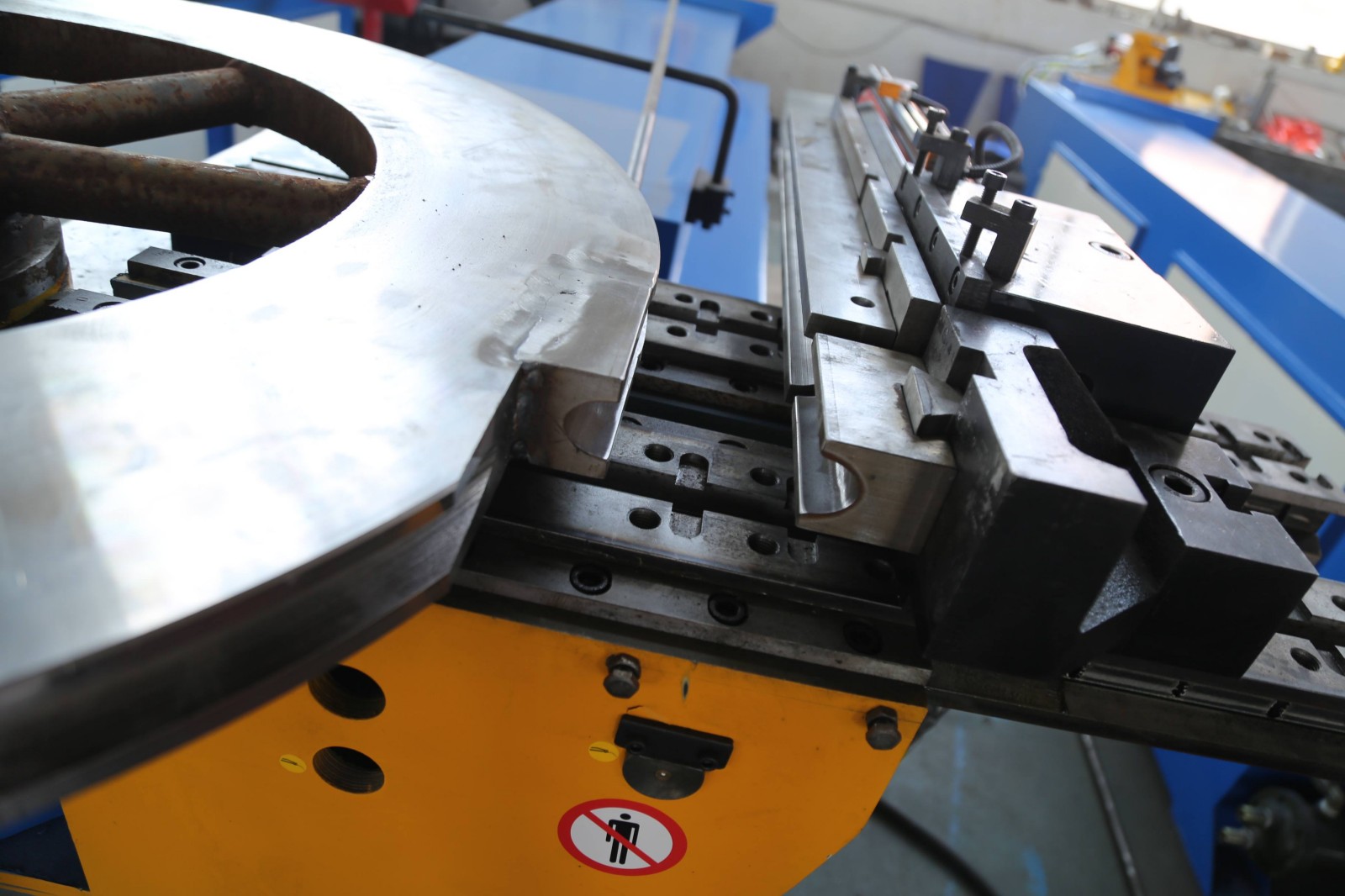

Encoder real-time tracking ensures high bending accuracy; supports multiple bend points and is suitable for thin-wall, thick-wall, and large-angle pipe bending. - Quick-change tooling design:

Fast connectors enable quick installation and removal; ideal for multi-specification, small-batch production. Anti-wrinkle and special tooling can be customized. - Triangular locking clamping structure:

The hydraulic three-point locking mechanism effectively prevents slipping and spring-back, improving bending consistency and reliability. - Multiple safety protections:

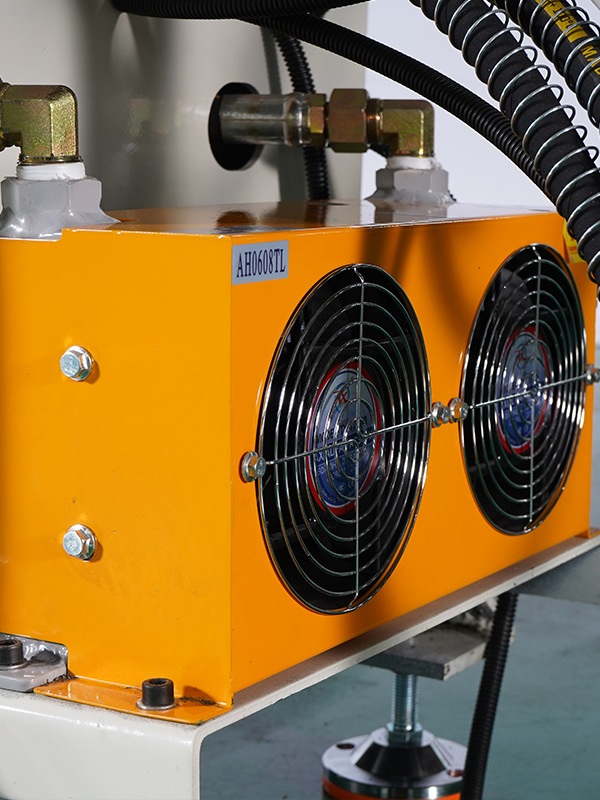

Anti-pinch emergency stop, control panel emergency stop, and thermal overload protection ensure operator and equipment safety. - Flexible cooling system:

Water cooling or air cooling options are available according to factory conditions, ensuring stable long-term operation. - High-quality components:

Key components are made from premium in-house manufactured and imported parts, providing a robust, durable, and reliable structure.

Application Industries

- Automotive components: brake pipes, exhaust pipes, bumpers, seat frames

- Motorcycle manufacturing

- Bicycle industry

- Fitness equipment

- Furniture manufacturing: steel furniture

- Air conditioning, refrigeration, and HVAC industries

- Shipbuilding, petrochemical, oil & gas pipelines, power engineering, etc.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.