- 1.0Basic Understanding: What is a Self-Tapping Screw?

- 2.0Working Principle: How Do Self-Tapping Screws “Create Threads”?

- 3.0Key Design Features: What Determines Self-Tapping Performance

- 4.0Selection Guide: Matching Screw Type to Material

- 5.0Manufacturing Process: How Are Self-Tapping Screws Made?

- 5.1Raw Material Preparation: Choosing the right steel

- 5.2Cold Heading: Forming the head and shank

- 5.3Thread Forming: Defining self-tapping performance

- 5.4Tip Formation: Ensuring accurate penetration

- 5.5Surface Treatment: Corrosion resistance and durability

- 5.6Inspection and Packaging: Quality control before shipment

- 6.0Practical Guide: 3 Key Tips to Avoid Common Mistakes

- 7.0Frequently Asked Questions (FAQ)

Have you ever found yourself frustrated during furniture assembly, wall installation, or appliance repair because you needed to pre-drill a hole or cut threads before driving in a screw?

If so, chances are you haven’t fully taken advantage of the convenience of self-tapping screws. These fasteners, designed to “tap their own threads” as they are driven, have become essential in construction, manufacturing, and general assembly.

1.0Basic Understanding: What is a Self-Tapping Screw?

In simple terms, a self-tapping screw is a type of fastener that can create its own internal threads in the material as it is driven, eliminating the need for pre-threading with a tap.

Its key advantage lies in reducing steps: traditional screws require drilling a hole, tapping threads, and then inserting the screw. Self-tapping screws skip the tapping stage, and some types even eliminate pre-drilling, which significantly shortens installation time—especially valuable in high-volume applications such as furniture manufacturing and appliance assembly.

Applicable materials are wide-ranging: metal, wood, plastic, drywall, and more. With the right type, self-tapping screws can handle most common fastening tasks.

2.0Working Principle: How Do Self-Tapping Screws “Create Threads”?

The self-tapping process relies on the screw’s ability to either cut or displace material. There are two main mechanisms, depending on the base material:

2.1Cutting-Type Self-Tapping: Cutting threads like a tap

Suitable for harder materials (e.g., steel sheet, hard plastics).

These screws feature cutting edges or chip flutes at the tip or under the head. When driven, they act like miniature taps:

- Cutting edges remove material.

- Chip flutes carry away debris.

- Matching internal threads are formed in the substrate.

2.2Forming-Type Self-Tapping: Displacing material to form threads

Suitable for softer, ductile materials (e.g., PVC, aluminum, wood).

Instead of sharp cutting edges, they use special thread profiles with wide spacing and rounded crests:

- Threads displace the material as they enter.

- Deformed material fills the thread gaps, creating an internal thread.

- No chips are produced, reducing stress on softer materials and preventing cracking.

3.0Key Design Features: What Determines Self-Tapping Performance

The effectiveness of a self-tapping screw depends on its design. The three critical areas are the head, thread, and shank.

| Component | Common Designs | Main Functions | Typical Applications |

| Head | Shapes: pan head, countersunk, round, hex head Drive types: Phillips, slotted, hex socket, Torx |

1. Countersunk heads allow flush installation (e.g., furniture panels). 2. Drive type ensures proper torque transfer and prevents cam-out (e.g., hex socket resists stripping better than Phillips). |

Drywall installation (countersunk), appliance housing (pan head) |

| Thread | Cutting type: sharp edges + chip flutes Forming type: wide pitch + rounded crests Tip: tapered/pointed |

1. Sharp edges enable cutting, and wide pitch supports forming. 2. Tapered tips improve positioning and reduce driving resistance. |

Cutting type for metals, forming type for plastics |

| Shank | Fully threaded (entire length) Partially threaded (portion of length) |

1. Fully threaded: ideal for thin substrates or multi-layer joints. 2. Partially threaded: better for thicker materials, ensuring stronger joints without excessive pressure. |

Thin plywood (fully threaded), thick boards (partially threaded) |

4.0Selection Guide: Matching Screw Type to Material

Self-tapping screws are not universal. Choosing the correct type is essential—using the wrong one may result in thread failure or substrate damage. Common types include:

4.1Metal Self-Tapping Screws (Type ST)

- Applications: Steel sheets, aluminum panels ≤ 6 mm thick (e.g., appliance housings, metal brackets).

- Features: Sharp threads with cutting flutes, often zinc- or chrome-plated for corrosion resistance. Require a pilot hole (hole diameter smaller than screw diameter, e.g., ST4.2 screw requires 2.9–3.3 mm hole).

- Caution: Not suitable for thick metal—risk of screw breakage.

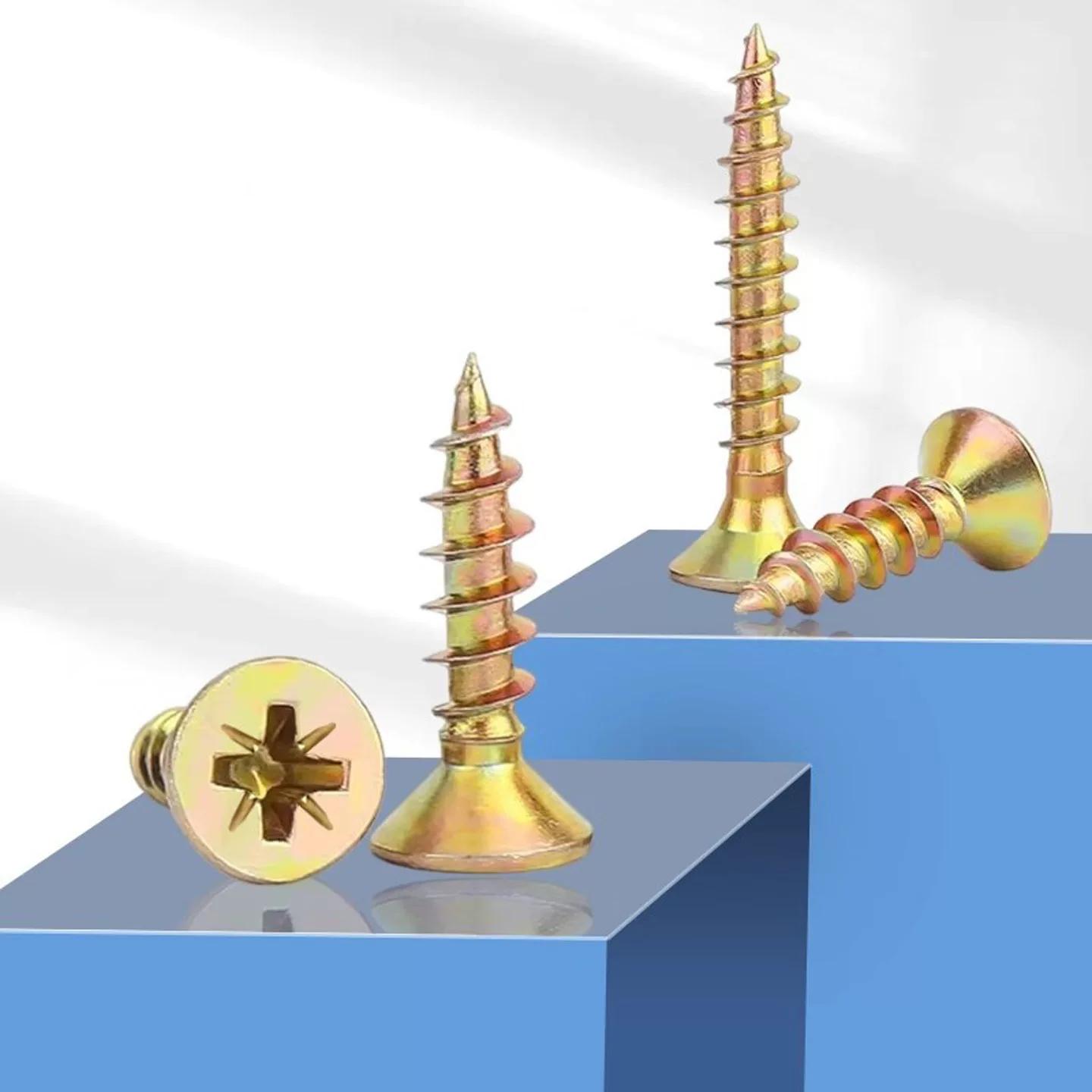

4.2Wood Self-Tapping Screws (WOOD Type)

- Applications: Solid wood, particleboard, plywood (e.g., wardrobes, desks).

- Features: Wide, deep threads for a strong grip in wood. Commonly countersunk heads to avoid surface protrusion. Some include sharp points for direct insertion in softwoods without pre-drilling.

- Caution: Pre-drill in hardwoods to prevent splitting.

4.3Plastic Self-Tapping Screws (PLASTIC Type)

- Applications: ABS, PVC, nylon components (e.g., toys, plastic casings).

- Features: Rounded threads to reduce stress, moderate pitch, sometimes dual threads for faster installation. Controlled torque is critical—tighten just enough for a secure fit.

- Caution: Do not use sharp metal-type screws, which may crack the plastic.

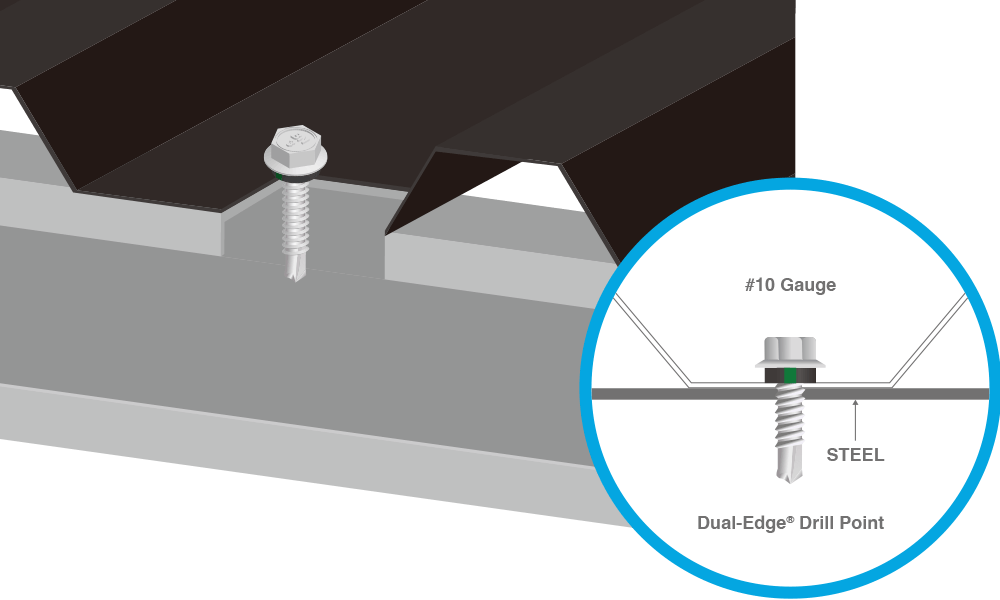

4.4Special Type: Self-Drilling Screws (Tek Screws)

- Why special: Equipped with a drill-like tip that drills a hole and taps threads in one step, eliminating the need for separate drilling.

- Applications: Thicker sheet metal (e.g., steel roofing, structural frames).

- Features: Drill points numbered 1–5, with higher numbers suitable for thicker steel (e.g., #5 drills through 1/2-inch steel).

- Advantage: Extremely efficient, widely used in outdoor construction and mass installation.

5.0Manufacturing Process: How Are Self-Tapping Screws Made?

Though small in size, self-tapping screws are produced through precise, high-efficiency processes. The principle is cold forming with controlled shaping, carried out in six main stages:

5.1Raw Material Preparation: Choosing the right steel

Material selection:

- Low-carbon steel (e.g., 1018, 1022) for general use—low cost.

- Stainless steel (304, 316) for outdoor or humid environments—corrosion resistance.

- Alloy steel (e.g., 410 stainless) for high-strength connections—magnetic properties.

Pre-treatment: Wire inspection for diameter and strength → pickling or sandblasting for rust removal → wire drawing and straightening to the required diameter for uniform forming.

5.2Cold Heading: Forming the head and shank

- Process: Carried out at room temperature by pressing the wire into shape using dies—no cutting, with material utilization over 95%.

- Steps: Cutting wire into blanks → first heading (shank preform) → final heading (head shape and drive recess).

- Accuracy: Die tolerance within ±0.02 mm ensures consistent screw head dimensions.

5.3Thread Forming: Defining self-tapping performance

-

Rolling (used in over 80% of screws): On a thread rolling machine, two dies with thread profiles press against the shank, plastically deforming the material to create threads. This process produces no chips, increases thread strength by 20–30%, and is highly efficient—making it ideal for forming-type screws in mass production.

-

Cutting (used in high-precision applications): Threads are cut using taps, generating chips. While this method achieves high accuracy, it has lower material efficiency. It is often used for cutting-type screws, followed by additional machining of chip flutes.

5.4Tip Formation: Ensuring accurate penetration

- Standard screws (wood/plastic): Ground into a 60°–90° taper.

- Self-drilling screws: Sharpened into drill-point geometry with spiral flutes.

- Accuracy: Tip concentricity with threads ≤ 0.05 mm prevents misalignment during driving.

5.5Surface Treatment: Corrosion resistance and durability

| Treatment | Application | Key Benefits |

| Electro-galvanizing | Indoor use (appliances, furniture) | Low cost, bright finish |

| Hot-dip galvanizing | Outdoor use (construction, fencing) | Strong rust resistance, ≥500 hrs salt spray |

| Dacromet coating | Automotive chassis, high-strength joints | No hydrogen embrittlement, ≥1000 hrs salt spray |

| Stainless steel passivation | Food-grade, medical equipment | Enhances the corrosion resistance of 304 SS |

5.6Inspection and Packaging: Quality control before shipment

- Testing: Thread gauge (go/no-go standards), tensile strength (carbon steel ≥400 MPa), tapping test (must drive into target substrate without stripping or breaking), and visual checks for burrs/cracks.

- Packaging: Sorted by size, packed in anti-rust paper and bubble wrap to prevent corrosion or deformation during transport.

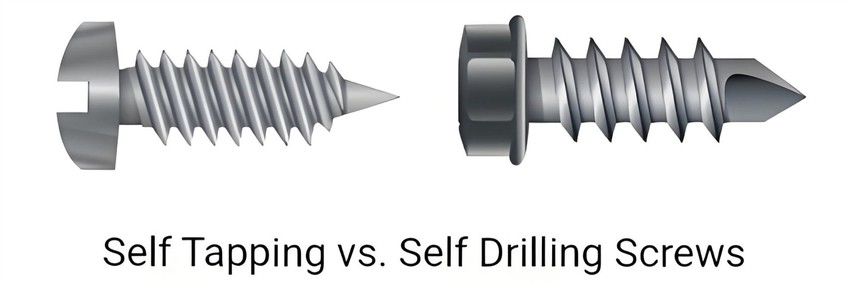

Key Difference: Self-Tapping vs. Self-Drilling Screws

Many confuse self-tapping with self-drilling screws. In fact, self-drilling screws are a subset of self-tapping screws. The main distinction is whether the screw can drill its own pilot hole.

| Comparison | Self-Tapping Screw | Self-Drilling Screw (Tek Type) |

| Core Function | Taps threads only, cannot drill | Drills hole and taps threads in one step |

| Tip Design | Tapered or pointed | Drill-point with spiral flutes |

| Pilot Hole | Required in metals/hardwood | Not required |

| Suitable Materials | Thin sheet metal, wood, plastics | Thicker metal sheets (steel roofing, structural steel) |

| Summary | “Needs a pilot hole, then creates threads.” | “Drills and taps by itself—one-step fastening.” |

Remember: All self-drilling screws are self-tapping screws, but not all self-tapping screws are self-drilling. The tip design is the giveaway—drill-point tips indicate self-drilling; pencil-like points indicate standard self-tapping.

6.0Practical Guide: 3 Key Tips to Avoid Common Mistakes

- Match the screw to the material: Wood screws should not be used in metal (risk of thread stripping), and metal screws should not be used in soft plastics (risk of cracking).

- Control tightening torque: Especially in wood and plastics, avoid overtightening. Excess torque can cause substrate cracking or screw breakage.

- Use the correct tools: Torx drive requires a matching Torx bit; do not use a flat-head screwdriver on Phillips screws (causes cam-out). When using power tools, adjust the speed appropriately—too high may generate heat and damage threads.

- Consider corrosion resistance: For bathrooms, balconies, or outdoor use, choose galvanized or stainless steel screws. Avoid plain carbon steel, which rusts easily and may seize.

7.0Frequently Asked Questions (FAQ)

Can self-tapping screws be reused?

Frequent reuse is not recommended. Self-tapping screws form threads in the substrate by cutting or displacing material. Once installed, the substrate threads match the screw precisely. Reinstallation risks wear, thread stripping, or deformation, reducing fastening strength. Temporary removal (e.g., for repair) may be possible 1–2 times, but long-term use requires replacement with new screws.

How do I choose the right pilot hole size for self-tapping screws?

The hole size depends on screw type and substrate. The principle is: slightly smaller than the nominal screw diameter to allow proper thread engagement.

- Metal (ST type): Follow industry standards (e.g., ST4.2 → 2.9–3.3 mm pilot hole; ST5.5 → 4.2–4.5 mm).

- Wood screws: For softwoods (e.g., pine), pilot holes may be unnecessary. For hardwoods (e.g., oak), drill 60–70% of screw diameter (e.g., 4 mm screw → 2.5–3 mm hole).

- Plastic screws: Drill 80–90% of screw diameter (e.g., 3 mm screw → 2.4–2.7 mm) to prevent cracking or stripping.

What should I do if a self-tapping screw breaks?

- If the broken end protrudes: Use pliers to grip and turn it out. If not possible, grind a slot on the exposed end and remove it with a flat-head screwdriver.

- If the broken end is embedded: For metal substrates, drill a small hole into the center of the screw with a fine drill bit, then use a screw extractor (reverse tap). For wood or plastic, drill through the broken screw and replace it with a slightly larger screw (take care to avoid substrate cracking).

Why are stainless steel self-tapping screws difficult to drive?

Possible causes include:

- Material mismatch: Stainless screws are harder; if used in thick or hard steel without a proper pilot hole, they may not drive in.

- Lack of lubrication: Stainless steel has a high friction coefficient. Apply light oil (e.g., machine oil) before installation.

- Insufficient torque: Manual screwdrivers may lack torque. Use power tools at medium-low speed, or choose a hex socket drive (transfers torque better than Phillips).

Can self-tapping screws and machine screws be interchanged?

- The key difference is whether a pre-threaded hole is required.

- Self-tapping screws: Create threads during installation, suitable for untapped substrates (wood, sheet metal).

- Machine screws: Require pre-threaded holes or nuts. In untapped material, they will strip or fail.

Which surface treatment is best for outdoor self-tapping screws?

The most durable options are:

- Hot-dip galvanizing: Coating thickness 50–100 μm, salt spray resistance ≥ 500 hours. Ideal for fences and outdoor steel structures.

- Dacromet coating: Zinc-aluminum-chromate layer, no hydrogen embrittlement, salt spray resistance ≥ 1000 hours. Ideal for automotive chassis and marine environments.

Avoid electro-galvanizing (thin coating 5–20 μm), which corrodes quickly outdoors.

References

www.valuefastener.com/screws/self-tapping-screws

sendcutsend.com/blog/self-drilling-vs-self-tapping-screws-whats-the-best-fastening-solution

www.fastenermart.com/understanding-tapping-screws.html

en.wikipedia.org/wiki/Self-tapping_screw

www.fastbuildsupplies.co.uk/knowledge-hub/guide-to-self-tapping-screws