Горячештамповочный станок с ЧПУ – Обзор применения и процесса

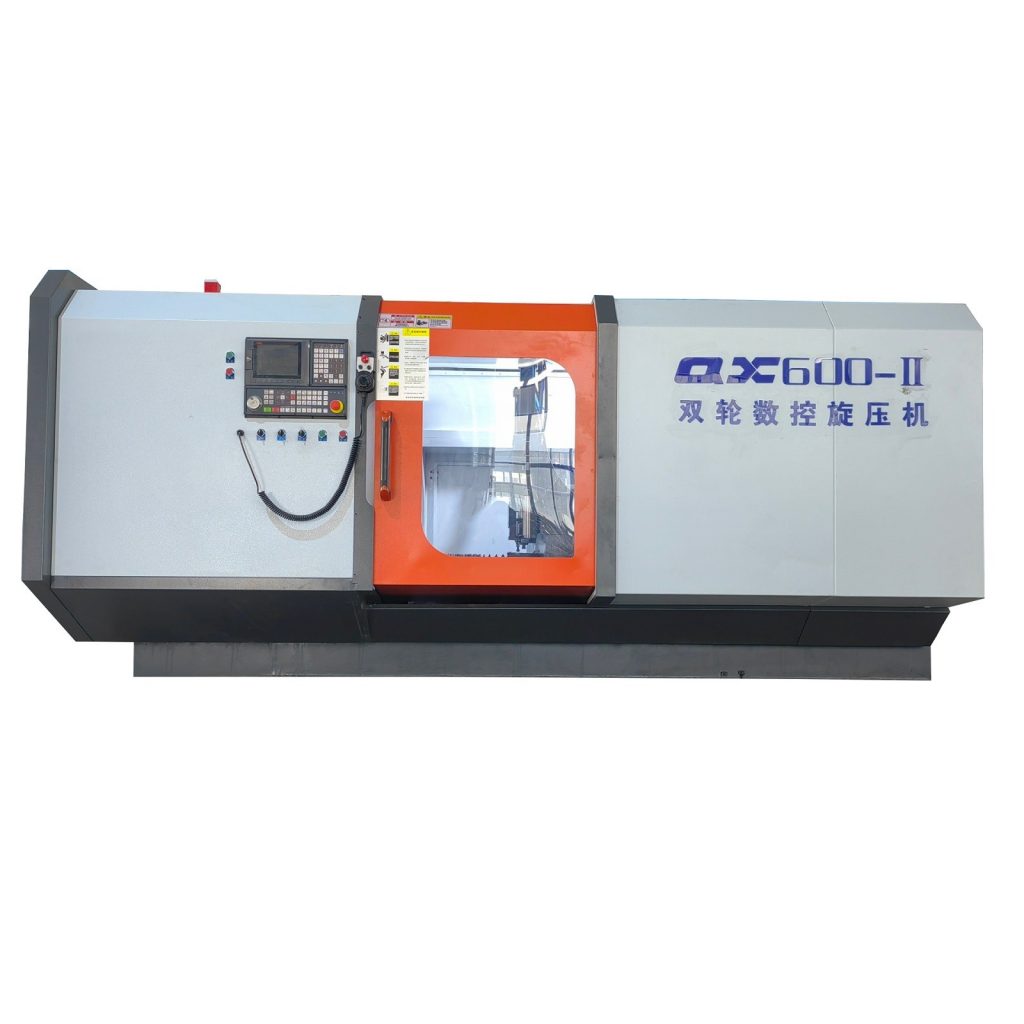

Машина горячего формования с ЧПУ — это высокоэффективное решение для формования, предназначенное для производства бесшовных цилиндрических компонентов с высоким качеством поверхности и структурной целостностью. Она широко используется при изготовлении:

- Баллоны для газа высокого давления (СПГ, СПГ)

- Корпуса гидроцилиндров

- Днища сосудов высокого давления (юбочные секции)

- Боеприпасы снаряды

- Тонкостенные бесшовные трубы с внутренней и внешней гладкой отделкой

Описание – Станок для горячей вытяжки с ЧПУ для баллонов с природным газом

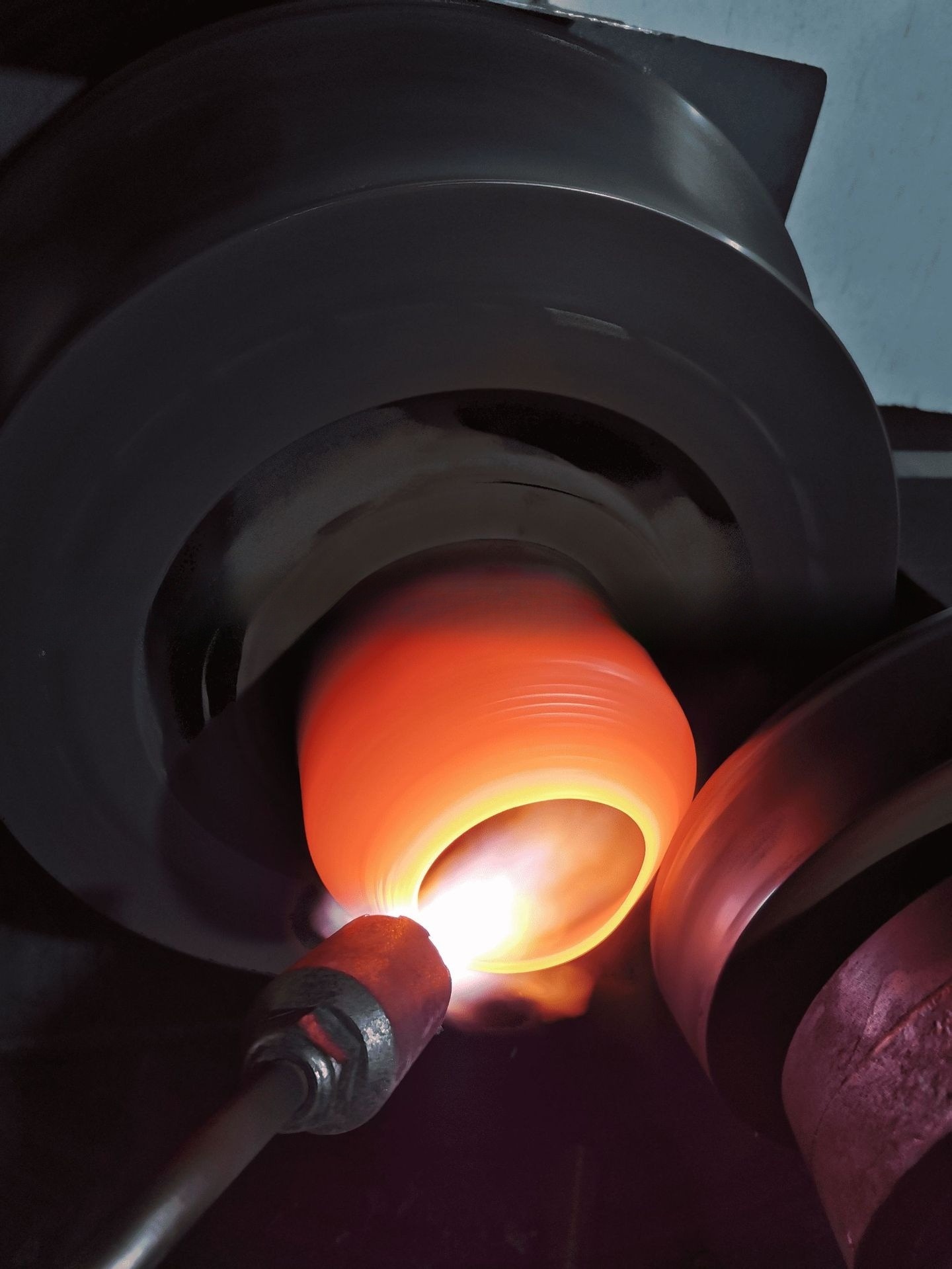

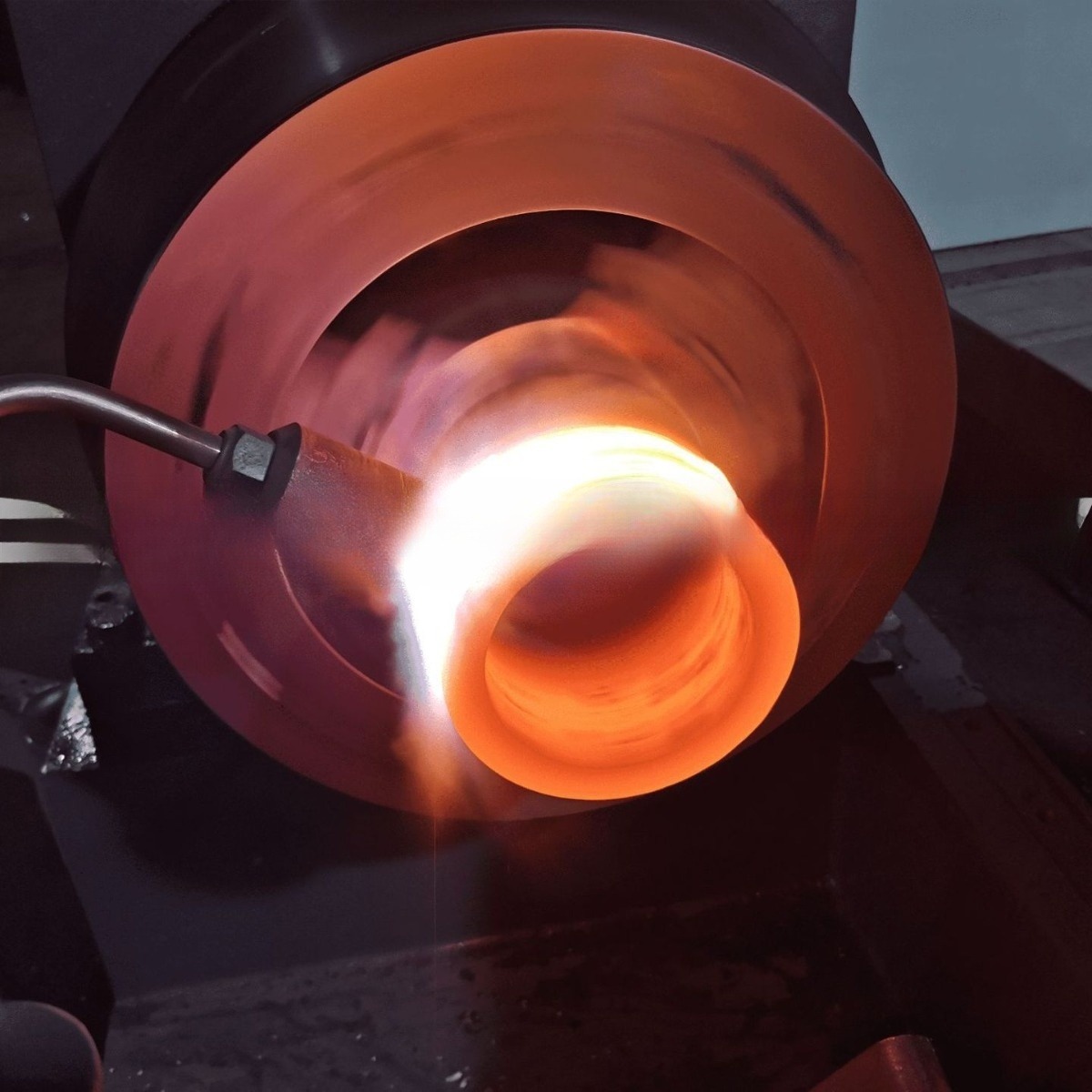

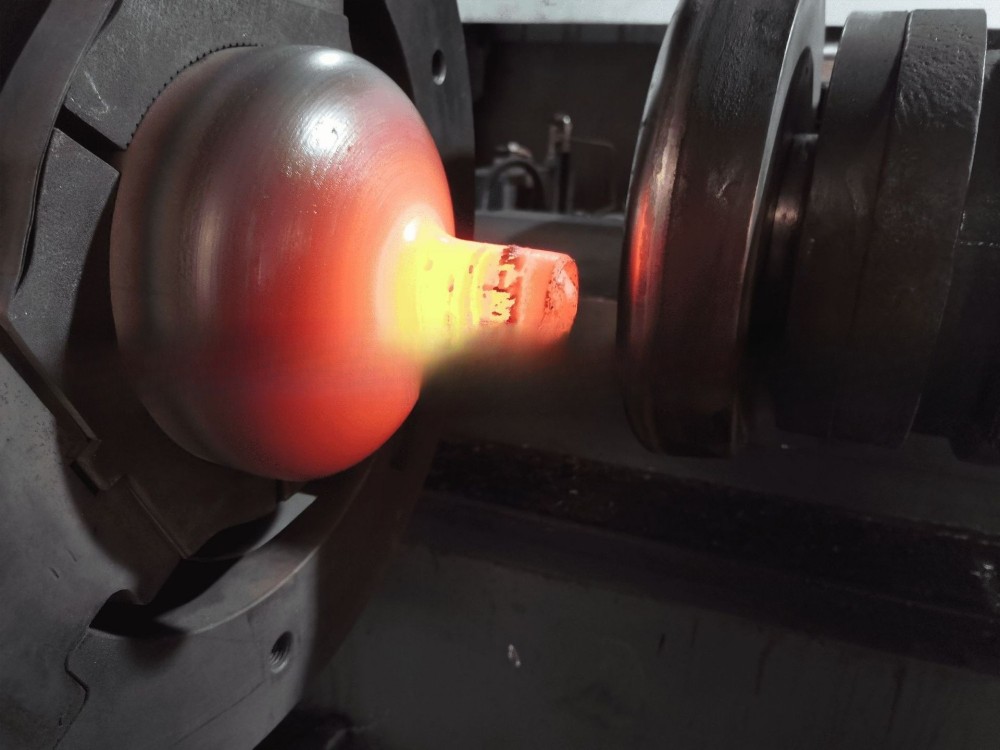

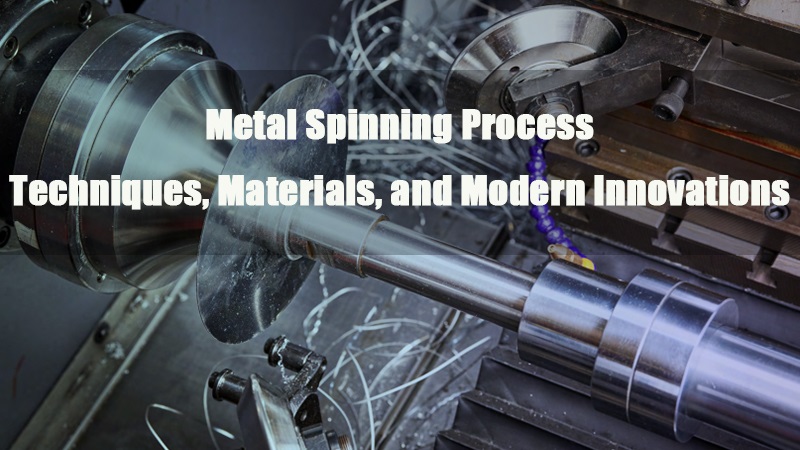

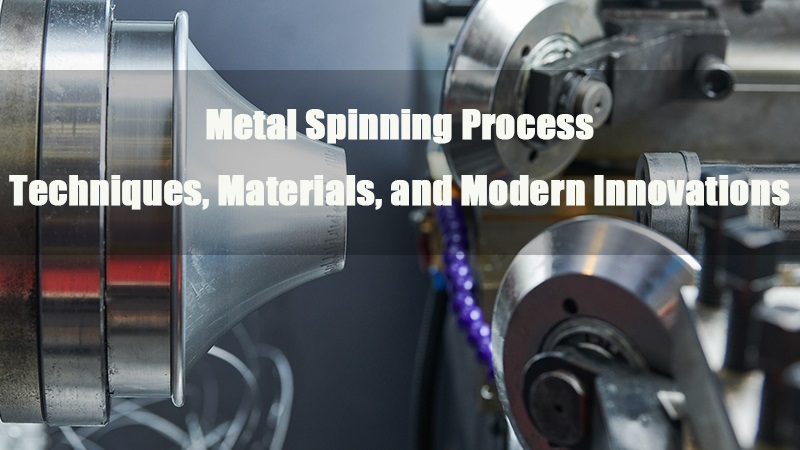

Горячее выдавливание — это передовой метод формовки без стружки, широко используемый в производстве газовых баллонов высокого давления. Этот процесс улучшает качество поверхности и обеспечивает плавную, непрерывную кривизну, что делает его идеальным для бесшовных цилиндрических компонентов.

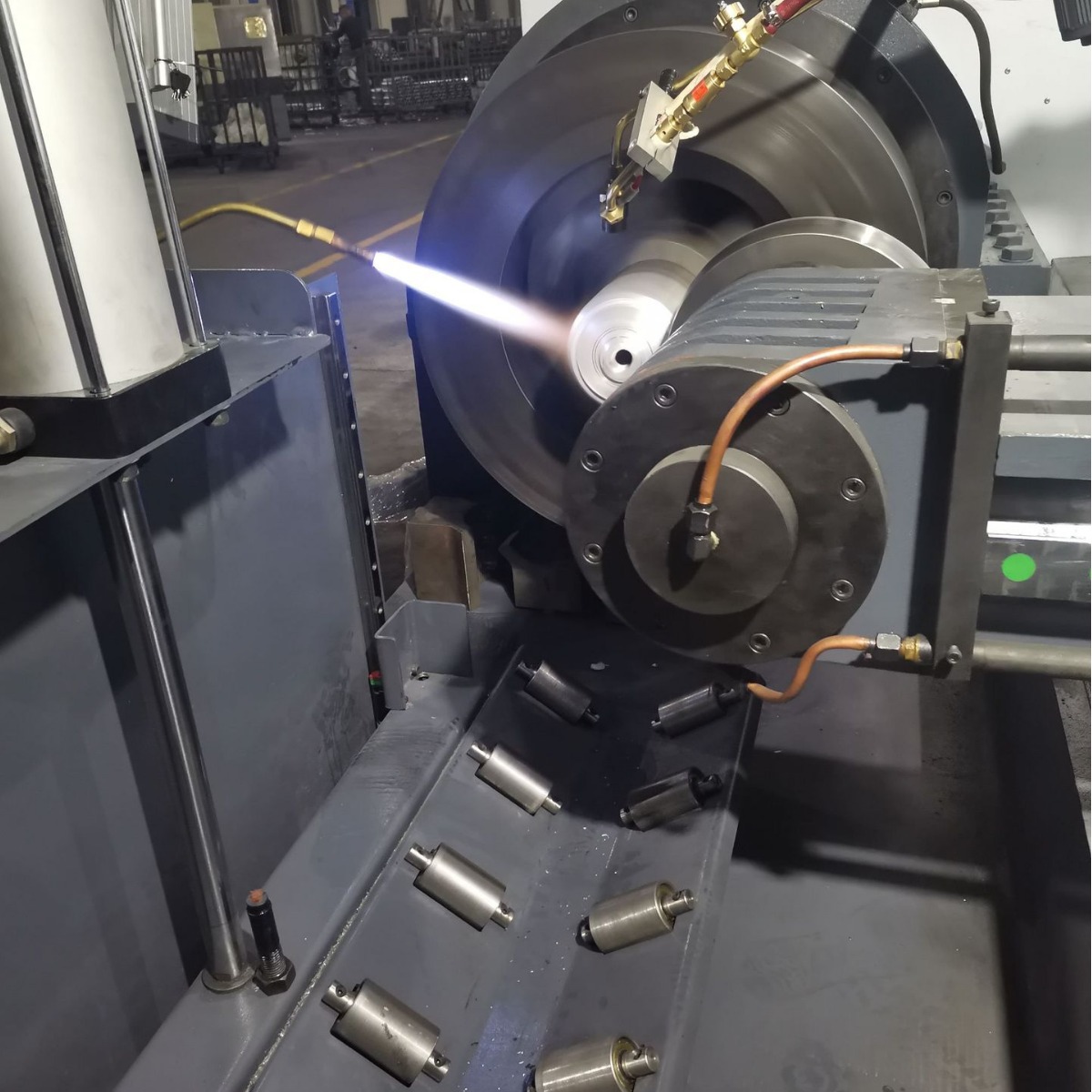

Наша машина горячего формования с ЧПУ спроектирована с учетом точности. Прядильная рука установлена на направляющей, параллельной главному шпинделю, что обеспечивает оптимальное вращательное движение и превосходную производительность формования. Каждая структурная деталь тщательно спроектирована для достижения точного формования и стабильных результатов.

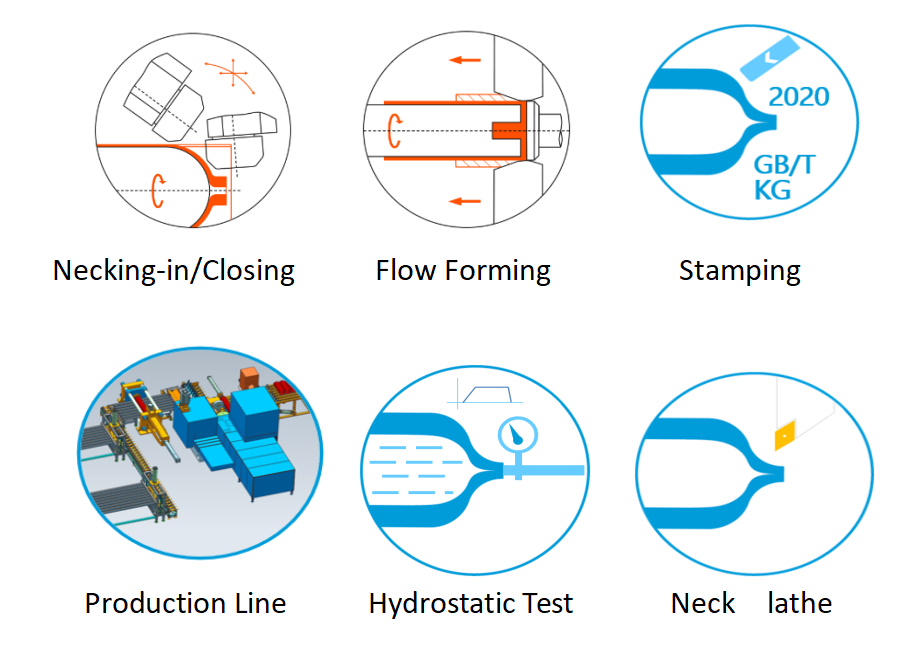

Создание линии горячей формовки баллонов для сжатого природного газа:

- Система среднечастотного нагрева

- Линия передачи

- Система загрузки и разгрузки

- Машина горячего прядения

- Система дополнительного тепла

- Гидравлическая система

- Электрическая система управления

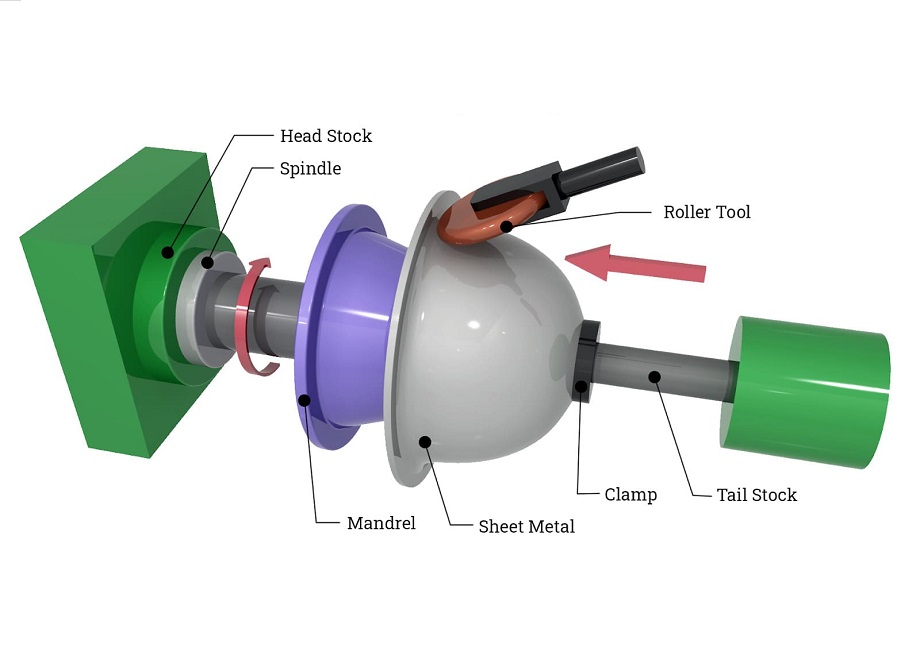

Принципы процесса прядения

Процесс выдавливания с ЧПУ — это метод формовки металла без стружки. Круглая заготовка или трубчатая заготовка вращается с высокой скоростью, прижимаясь формовочным роликом. Это заставляет материал пластично течь, принимая желаемый контур.

Пожалуйста, заполните эту форму, чтобы отправить запрос на предложение. Один из членов нашей команды рассмотрит детали и свяжется с вами в течение 12 рабочих часов.