ALEKVS Round to Square Tube Roll Forming Machine

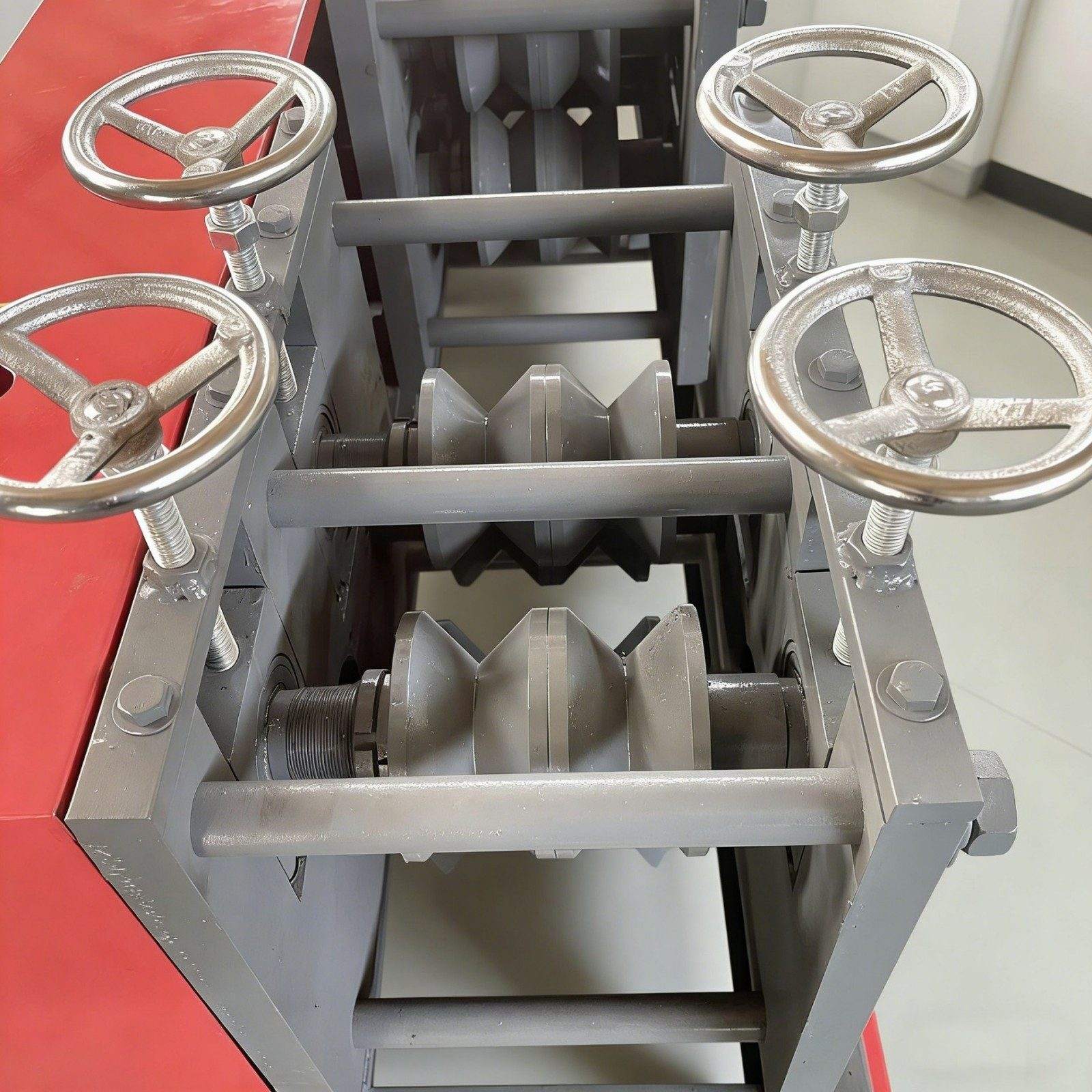

Square Tube Roll Forming Machine Component

- Entry Guide System– Ensures smooth tube feeding and precise alignment for stable forming.

- Heavy-Duty Machine Frame– Rigid welded structure guarantees long-term accuracy and vibration-free operation.

- Roll Forming Dies– Hardened alloy steel rolls deliver precise corners and consistent square profiles.

- Drive System– High-torque motor and gearbox provide stable, synchronized roll rotation.

- Sizing Unit– Fine calibration ensures accurate side length, diagonals, and straightness.

- Cutting System– Automatic length cutting for clean, efficient, and repeatable output.

- PLC Control System– User-friendly touchscreen enables fast setup and fully automated production.

Working Principle

- Feeding Stage

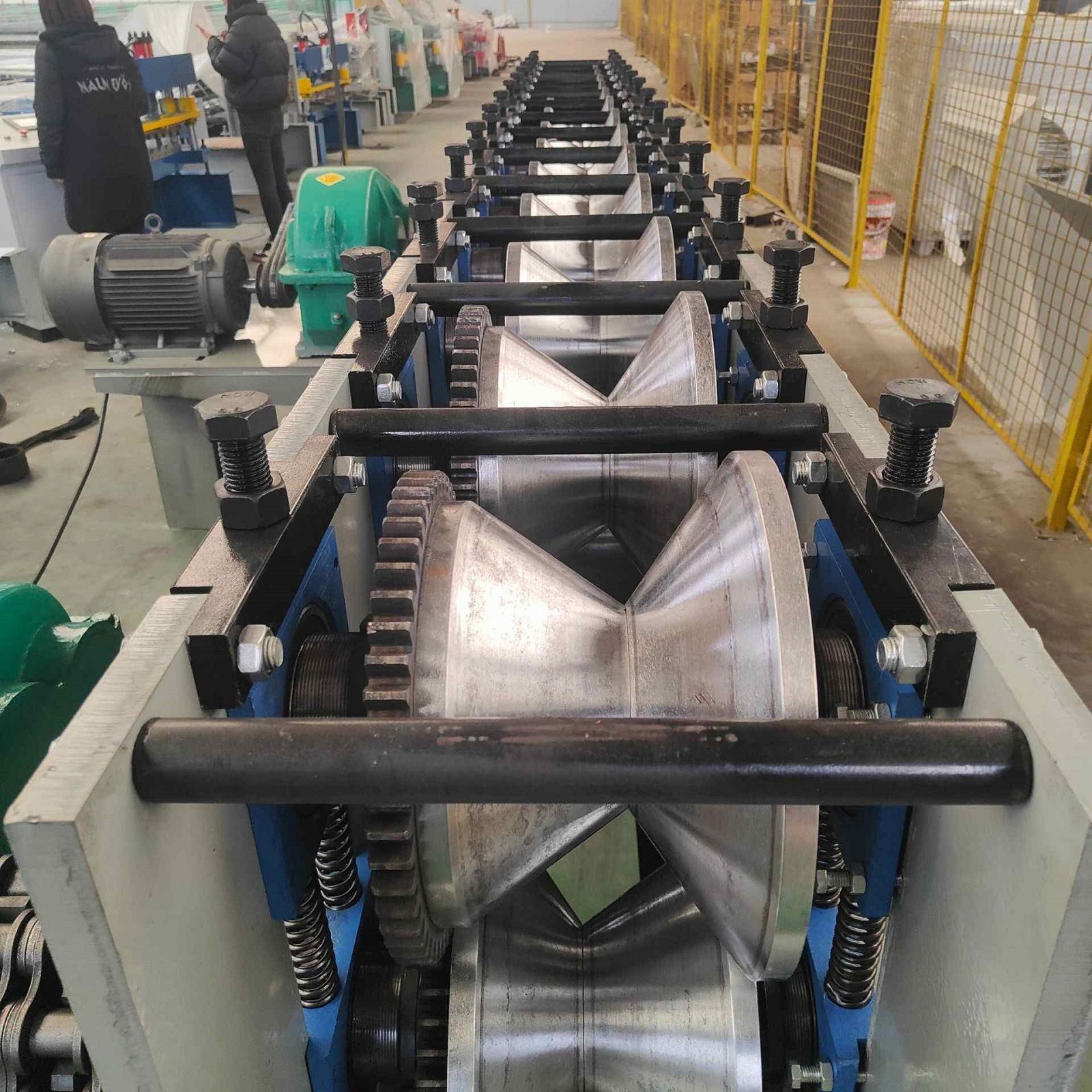

Finished round tubes (typically ERW welded tubes or seamless tubes) are fed into the machine through a guiding system, ensuring stable alignment and precise entry into the roll forming stations. - Roll Forming Stage

The round tube passes through multiple sets of forming rollers designed with specific angles and contours. Each roller set applies controlled pressure to the tube wall, gradually transforming the circular cross-section into a square or rectangular profile. - The front roller stations perform initial flattening and corner pre-forming.

- The final roller stations carry out precision shaping to ensure accurate side length, diagonal tolerance, and squareness.

- Sizing and Cutting Stage

After forming, the square tube enters the sizing unit for dimensional calibration. A cutting system—such as a flying saw or hydraulic cutting unit—cuts the tube to preset lengths. - Discharge Stage

Finished square tubes are transferred to the run-out table or stacking area, completing the forming process.

Key Features and Advantages

- Cold Forming Process, Material Properties Preserved

No heating is required, avoiding oxidation or grain structure damage. Mechanical properties of the finished tube remain consistent with the original material. - Flexible Production, One Machine for Multiple Sizes

By changing roll forming dies, the machine can produce various square and rectangular tube sizes, meeting diverse application requirements. - High Efficiency and Low Production Cost

Continuous roll forming allows production speeds of 10–30 m/min. Compared with traditional welded square tube processes, it eliminates plate uncoiling, welding, and grinding, significantly reducing labor and material waste. - High Precision and Stable Quality

Multi-stage forming combined with sizing calibration ensures tight tolerances on side length, diagonals, straightness, and surface quality. - High Automation Level, Easy Operation

The PLC-controlled system enables automatic feeding, forming, sizing, and cutting. Only 1–2 operators are required for normal production monitoring.

Application Range

- Raw Material Compatibility

Suitable for carbon steel, galvanized steel, and stainless steel round tubes. Typical wall thickness range: 0–6.0 mm(depending on machine model). - Finished Tube Applications

- Steel structure construction: columns, beams, support frames

- Storage and logistics: rack uprights and beams

- Traffic facilities: guardrails, fences, light pole bases

- Furniture manufacturing: table frames, chair frames, bed frames

- Machinery manufacturing: equipment frames and protective tube structures

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.