- 1.0What Is Roll Forming?

- 2.0What Is a Roll Forming Machine?

- 3.0Workflow of a Roll Forming Machine

- 3.1Pre-Processing Stage

- 3.2Forming Process

- 3.3Secondary Operations (Post-Forming Processing)

- 3.4Die Cooling and Adjustment

- 3.5Pre-Cut vs. Post-Cut Comparison

- 3.6Defect Correction and Adjustment

- 3.7Safety and Operational Protocols

- 3.8Roll Forming Die System: Rafted Tooling

- 3.9Complete Roll Forming Line Workflow

- 4.0Key Components of a Roll Forming Machine

- 5.0Setup and Operation of Roll Forming Machines

- 6.0Safety Considerations in Roll Forming Operations

- 7.0Common Types of Roll Forming Machines (By Application and Product Type)

- 8.0Why Choose Roll Forming?

- 9.0Advantages of Roll Forming

- 10.0Applications of Roll Forming Machines

1.0What Is Roll Forming?

Roll forming—also known as roll-forming or rollforming—is a continuous bending process used to shape long strips of metal (typically from coil stock) into desired cross-sectional profiles.

The metal strip passes through a series of precisely positioned rolls, each making incremental bends until the final shape is achieved. This method is ideal for producing long, consistent profiles in high volumes.

Key Advantages of Roll Formed Products:

- Lightweight: Compared to similar shapes made through extrusion, roll-formed parts are typically lighter and use thinner wall sections.

- High Strength: The cold forming process induces work hardening, significantly increasing material strength.

- High Production Efficiency: The process is continuous and automated, allowing for faster production speeds and lower energy consumption.

- Easy Surface Treatment: Materials can be pre-coated (e.g., painted or galvanized) before forming, eliminating the need for secondary surface finishing.

In Summary: Roll forming provides a high-speed, stable, and flexible manufacturing solution through a fully automated, continuous process, making it ideal for producing consistent metal profiles at scale.

2.0What Is a Roll Forming Machine?

2.1Introduction to Roll Forming Machines:

A roll forming machine is a key piece of metal forming equipment widely used in the production of industrial and everyday products. It enables the efficient fabrication of components such as garage doors, automotive panels, metal roofing sheets, tiles, ridges, wall panels, siding, metal purlins, door frames, and railings.

2.2Definition and Basic Working Principle:

A roll forming machine shapes flat metal strips or coils into continuous components with uniform cross-sections. The process involves feeding the material through a sequence of roll stands, each set progressively bending the material closer to the desired profile. Through plastic deformation, the metal takes on a permanent shape. After forming, the parts are cut to specified lengths and stacked for packaging. The design of each roll station determines the final profile, ensuring high precision and complex geometries.

2.3Overview of the Roll Forming Process and Its Applications:

Roll forming machines perform continuous cold bending of metal strips at room temperature, producing long parts with consistent cross-sectional profiles. The core principle is gradual shaping through a series of roll tooling stations, each imposing a slightly greater bend than the previous. This progressive forming ensures accurate profiles while maintaining cross-sectional integrity and minimizing deformation or stress concentration.

Roll forming machines can manufacture a wide variety of metal profiles—including C and U purlins, channels, angles, and tubes—with high precision. The technology is widely used across industries such as automotive, construction, aerospace, and home appliance manufacturing.

Known for their efficiency, accuracy, and cost-effectiveness, roll forming machines have become the preferred solution for producing high-quality, complex metal shapes. They streamline production, reduce material waste, and meet the demands of modern metalworking standards.

2.4Evolution of Roll Forming Technology:

- Historical Development:

The origins of roll forming trace back to ancient times when artisans manually shaped metal. The first industrial use of roll forming machines emerged during the 18th-century Industrial Revolution, primarily for producing metal roofing. With ongoing advancements, machine design and functionality have significantly improved, enhancing both output and accuracy. - Modern Advancements in Roll Forming and Materials:

Today’s roll forming technologies leverage computer-aided design (CAD) and manufacturing (CAM) to boost production precision and speed. Automation and robotics have further enhanced efficiency, minimized manual labor, and expanded production capabilities.

3.0Workflow of a Roll Forming Machine

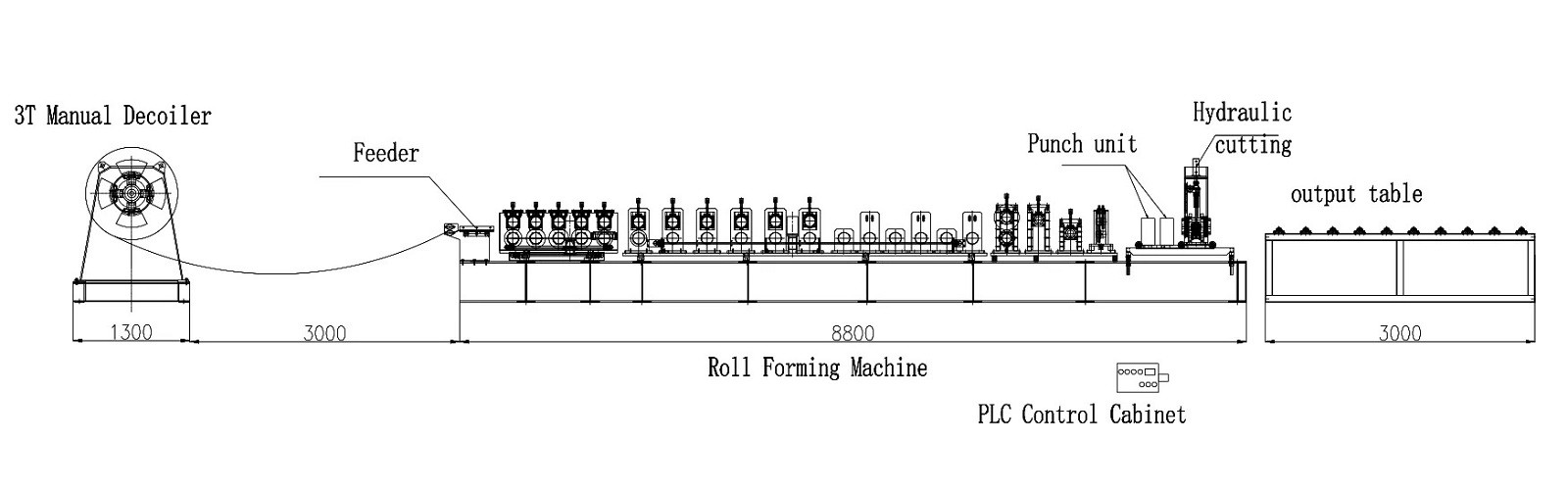

Roll forming machines shape metal sheets or coils into desired profiles through multiple stages involving rollers, dies, punching, and cutting. This continuous process spans from raw material feeding to the final product. Below is a detailed breakdown of each stage:

3.1Pre-Processing Stage

- Passive Decoiler: Raw metal coils are unwound by a passive decoiler to facilitate further processing on the production line.

- Straightener: The metal strip is straightened to remove curvature and ensure flatness before entering the roll forming system.

- Servo Feeder: A servo feeder delivers the sheet metal precisely into the forming machine, ensuring continuous workflow and dimensional accuracy.

3.2Forming Process

- Roll Forming Machine: The sheet metal enters the roll forming machine, passing through multiple roller stations. Each roller set gradually bends or compresses the material to achieve the desired profile. Tool steel rolls continuously shape the material through progressive deformation.

- Role of Forming Dies: Dies in the roll forming machine incrementally define the required contour. The configuration of each roller set is tailored to the thickness, hardness, and material type. As forming complexity increases, more roller stands or dies are introduced to meet the bending or folding requirements.

3.3Secondary Operations (Post-Forming Processing)

After primary roll forming, secondary processes are typically applied to achieve tighter tolerances or enhanced functionality. Common operations include:

- Automatic punching

- Slotting

- Laser cutting

- TIG welding

- Precision forming under tight tolerances

- Profile straightening

- Hardware insertion

- Minor assembly

These processes can be integrated inline (immediately after cutting) or performed offline at dedicated workstations. This increases the versatility of roll-formed components, enabling compliance with stringent industry standards in construction, transportation, solar energy, and industrial equipment.

Common Secondary Processes

- Punching

Punching can occur before or after forming. Pre-forming punching increases forming difficulty, while post-forming punching may raise costs. Process sequencing must be optimized based on production needs. - Hydraulic Cutting

After roll forming, materials may be cut to length. Cutting location critically impacts final shape and product quality.

3.4Die Cooling and Adjustment

High-speed rolling generates heat during the forming process, which may affect the material shape. Cooling systems—either dry cooling or overflow cooling—are used to regulate die and material temperatures. Each method has advantages and limitations; selection depends on production requirements.

3.5Pre-Cut vs. Post-Cut Comparison

| Process | Precut | Postcut |

| Advantages | – No need for expensive cutting dies | – Increased productivity; reduces material jamming |

| – Burr-free ends | – Better part control with reduced burrs | |

| – Simple operation with lower maintenance costs | – Capable of producing short parts down to 2-3 inches | |

| – Eliminates end deformation | ||

| Disadvantages | – Flared ends, especially in deeper sections | – Higher costs for cutting equipment and dies |

| – Requires more forming stations, increasing costs | – Increased maintenance requirements | |

| – Challenging to form short parts; prone to deformation | – Possible end deformation or roughness |

3.6Defect Correction and Adjustment

Roll forming may introduce bending, bowing, or twisting defects. A straightener can correct such distortions during production by compensating for stresses accumulated in the forming process.

3.7Safety and Operational Protocols

Due to the high operating speed of roll forming machines, operational safety is critical. Key measures include:

- Operator safety training

- Installation of protective devices (e.g., safety guards)

- Routine equipment maintenance and inspection

- Special care during die changes and machine adjustments

These practices ensure safe, efficient, and continuous operation.

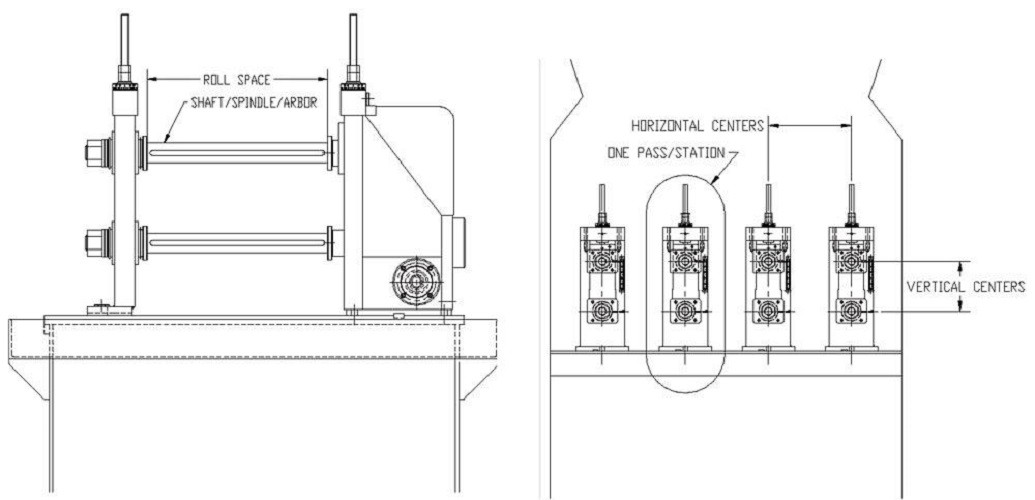

3.8Roll Forming Die System: Rafted Tooling

In rafted tooling systems, dies are mounted on shafts and pre-set for each forming stage. Switching profiles is simplified by swapping entire die rafts, significantly reducing setup time and cost.

Advantages:

- Minimizes tooling changeover errors

- Enables rapid die changes (typically within 30–45 minutes)

- Enhances production flexibility with on-demand profile switching

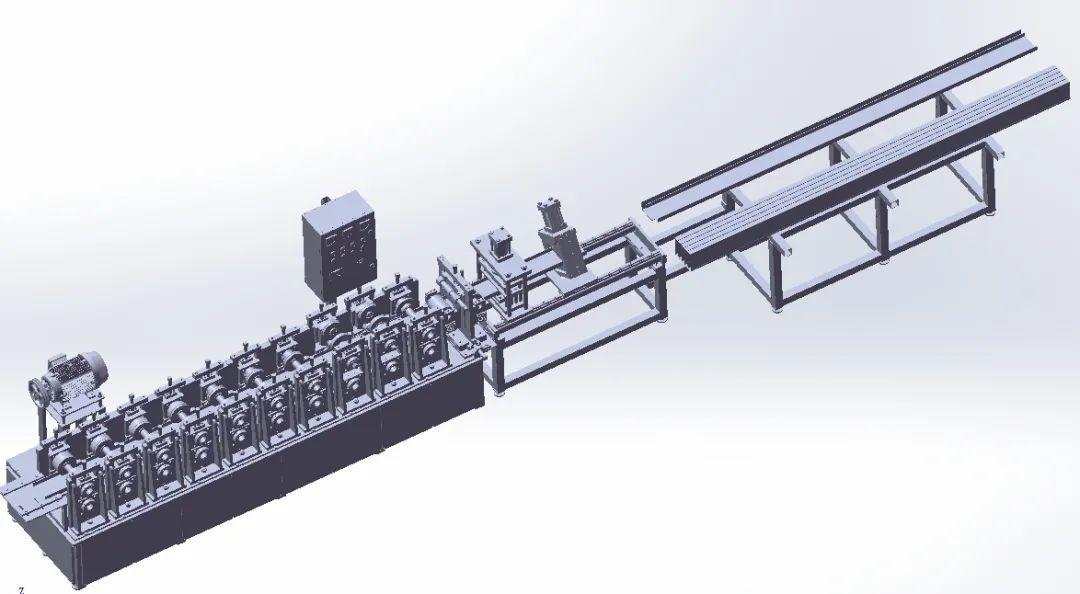

3.9Complete Roll Forming Line Workflow

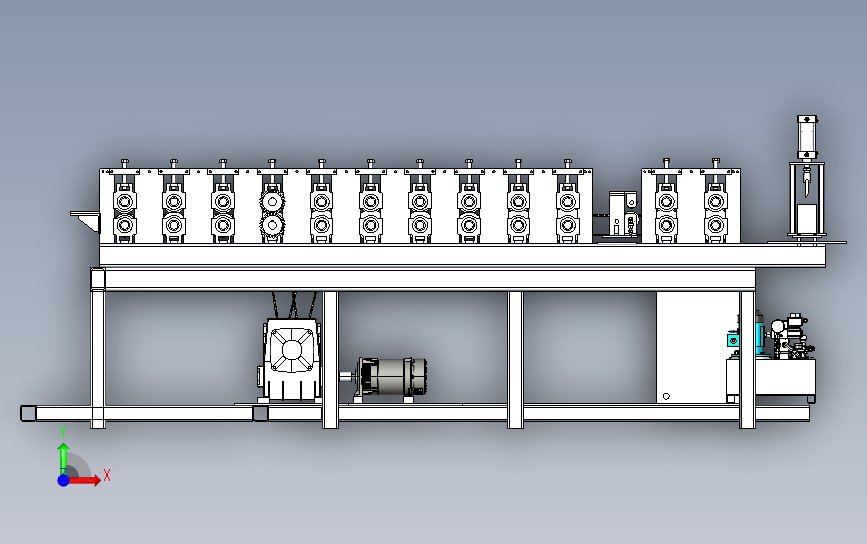

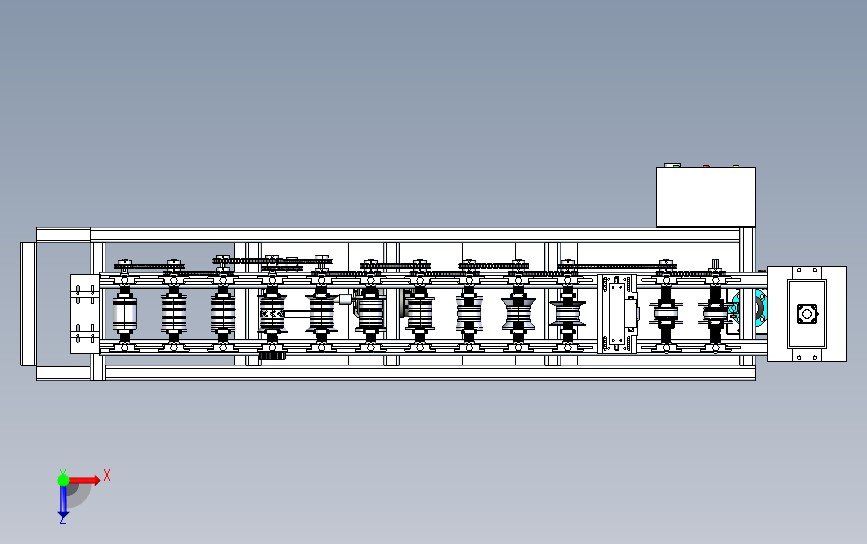

Each production line comprises a series of precisely arranged and highly integrated stations, which sequentially process the sheet material. Key components include:

- Coil Uncoiler

- Edge Guide or Side Rollers

- Pre-Punch Press (if applicable)

- Roll Forming Machine Body

- Profile Straightener

- Cut-Off Press

As the sheet advances through the line, each roller set imparts a slight, continuous bend. The cross-sectional profile evolves progressively across stations. Complex shapes require more forming steps and roller stands.

At the final stage, the strip enters the cut-off press and is trimmed to length using a single set of cutting dies. Variable product lengths can be achieved without tooling changes. Additional inline processes, such as welding or punching, can also be incorporated

Formed products are conveyed to the discharge station, where operators may conduct minor inspections. Typically, no major surface treatment is required due to the clean, continuous nature of the forming process.

4.0Key Components of a Roll Forming Machine

Understanding the primary components of a roll forming machine helps manufacturers operate and maintain the equipment more effectively, thereby improving production efficiency and product quality.

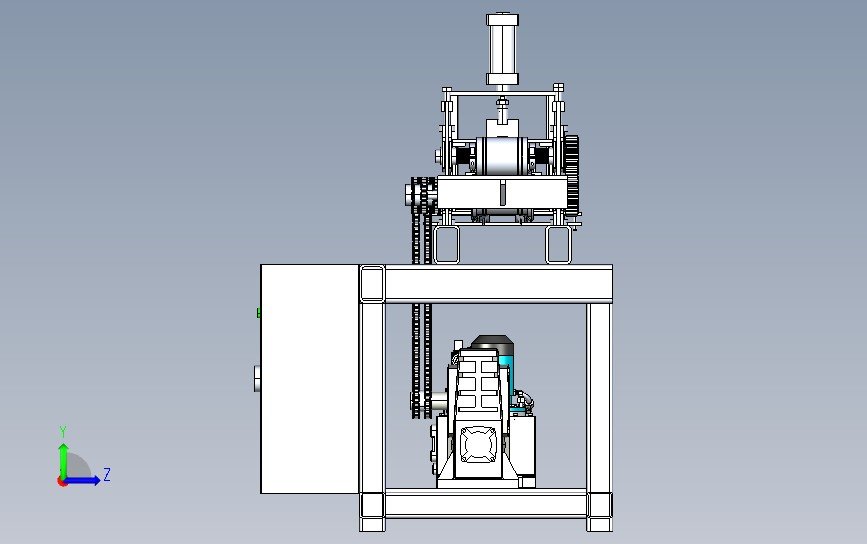

4.1Machine Base

The machine base is the fundamental and most critical structural foundation of a roll forming machine. It is typically constructed from high-quality materials such as steel or cast iron to provide sufficient stability and support. A rigid and durable base is essential for ensuring forming precision and operational stability during production. Any misalignment or vibration in the base can result in product deformation or dimensional deviation. This is why manufacturers place great emphasis on the material selection and structural design of the machine base.

4.2Roller Stands and Tooling

The roller stand is one of the most important components of a roll forming machine. It consists of multiple pairs of rollers through which the metal sheet passes sequentially. As it travels through each roller station, the sheet undergoes continuous bending until the desired cross-sectional profile is formed.

The number and arrangement of roller stands are determined based on the complexity of the product’s profile.

Tooling refers to the various forming dies, spacers, and guide rails used in conjunction with the roller stands. These tools define the final geometry, dimensions, and surface finish of the product. Manufacturers typically design and customize specific tooling sets for each product based on production requirements.

4.3Drive System

The drive system supplies the power and control required to move the sheet metal steadily through the machine. Common drive types include mechanical, hydraulic, and servo systems:

- Mechanical Drive:

Power is transmitted through gears, chains, or belts. This setup is reliable and cost-effective but may be limited in terms of production speed and precision. - Hydraulic Drive:

Uses hydraulic power for transmission, ideal for heavy-duty operations requiring strong force and stable control. - Servo Drive:

Powered by electronic motors that offer high-speed and highly precise motion control. This system is suitable for producing complex profiles and ensures high repeatability in batch production.

5.0Setup and Operation of Roll Forming Machines

Proper setup and operation of a roll forming machine are essential for ensuring high-quality production and machine stability. The following outlines the key steps for machine setup, operation, and safety precautions.

5.1Roll Forming Machine Production Setup

Setting up a roll forming machine is a critical step in ensuring the desired quality of formed profiles during production. This process generally includes tooling preparation, roller stand adjustments, and machine calibration to meet the specific requirements of the target profile.

1. Alignment and Calibration

Precise alignment and calibration are crucial during setup. Operators must carefully align roller stands, guide rails, and tooling to ensure that the metal strip passes through the machine smoothly and evenly. Even slight misalignments can negatively affect profile accuracy, surface finish, and overall quality.

2. Machine Configuration

Operators must configure machine settings such as line speed, feed rate, and cutting mechanism to match the required production parameters. Proper machine calibration is essential for optimizing both production efficiency and profile quality.

5.2Machine Operation

During actual production, operating the roll forming machine involves managing key parameters such as speed and material feed. Operators must continuously monitor the forming process and make timely adjustments to maintain stable operation.

1. Speed Control

Controlling the machine speed is a key factor in roll forming operations. Speed directly influences product quality, production throughput, and energy consumption. Operators must adjust speed precisely to maintain optimal production flow.

2. Feed Control

Consistent and uniform material feed is essential to achieving stable forming results. Improper feeding may lead to material jams or inconsistent profiles. Operators should carefully monitor the feed system and resolve issues as they arise.

3. Monitoring and Adjustment

Throughout the production process, operators must monitor the machine’s performance, watching for signs of material misfeeds, tooling wear, or other irregularities. If any abnormalities are detected, immediate adjustments or shutdowns should be performed to prevent defective products.

6.0Safety Considerations in Roll Forming Operations

Safety is paramount when operating roll forming machinery. Operators must follow strict safety protocols and take necessary precautions to minimize the risk of accidents or injury.

- Personal Protective Equipment (PPE)

Operators should wear appropriate PPE—such as safety shoes, gloves, and protective eyewear—to ensure personal safety during machine operation.

- Safe Operating Procedures

All operators must undergo comprehensive safety training for roll forming equipment. This includes identifying common hazards, performing emergency stops, and troubleshooting equipment failures to respond swiftly to unexpected situations.

- Equipment Safety Inspections

Regular maintenance and inspection of the roll forming machine are essential. All safety devices—including guards, emergency stop buttons, and interlock systems—must be in proper working order to maintain a safe operating environment.

- Workplace Safety Management

Operators must remain vigilant of the hazards surrounding the machine. Avoid standing too close to moving parts or open sections of the machine during operation.

7.0Common Types of Roll Forming Machines (By Application and Product Type)

| Category | Roll Forming Machine Types | Application Scenarios |

| Structural Building | – Floor Deck Roll Forming Machine – Light Keel Roll Forming Machine |

Steel structure buildings, floor support systems, suspended ceilings |

| Cladding & Roofing | – Wall Panel Roll Forming Machine – Sandwich Panel Roll Forming Line |

Industrial buildings, residential cladding, cold storage enclosures |

| Doors & Frames | – Roller Shutter Door Forming Machine – Door Frame Roll Forming Machine |

Commercial shutter doors, steel door frames and casing |

| Transportation | – Highway Guardrail Roll Forming Machine – Truck Body Panel Forming Machine |

Highway safety barriers, truck and trailer side panels |

| Piping Systems | – Tube Mill Line (Square/Rectangular Pipe) – Rainwater Downpipe Forming Machine |

Construction drainage, pipe systems for steel structures |

| Storage Racking | – Racking Upright Roll Forming Machine – Beam/Bracket Roll Forming Machine |

Warehouse shelving and storage systems |

| Solar Mounting | – Solar Mounting Bracket Roll Forming Machine | PV mounting structures, U/C/Z profile supports |

| Cable Management | – Cable Tray Roll Forming Machine – Cable Trunking Roll Forming Machine |

Electrical installations, wire management systems |

| Custom Profiles | – Custom Profile Roll Forming Machine | Tailor-made cross-sections as per customer drawings and specs |

8.0Why Choose Roll Forming?

Roll forming, while a complex metal manufacturing process, offers distinct advantages that make it especially valuable under specific production conditions. It provides exceptional cost-effectiveness and production benefits in the following scenarios:

8.1High-Volume Production

For large-scale orders—typically exceeding 10,000 parts—roll forming becomes the most cost-efficient manufacturing method. When designs and production runs are highly repeatable, the efficiency and automation of roll forming significantly reduce per-unit costs.

8.2Complex Metal Designs

When the design of metal channels requires intricate bends, holes, notches, knockouts, labeling, stamping, or embossing, roll forming can integrate these features directly in-line. This eliminates the need for additional secondary processes or workstations, making it ideal for complex geometries and functional requirements without compromising throughput.

Conclusion

Although roll forming involves higher initial investment and precise setup requirements, it delivers unmatched advantages for high-volume production and complex metal parts. For large-scale, repeatable orders or components with sophisticated shapes, roll forming offers an efficient and economical solution.

9.0Advantages of Roll Forming

- Low-Cost Production

Roll forming significantly reduces material and labor costs by maximizing material utilization and minimizing the need for secondary processing. The equipment can also accommodate different flange widths, further enhancing cost-effectiveness. - High Production Efficiency

Designed for continuous and high-speed operation, roll forming greatly reduces downtime and material waste, significantly boosting overall production efficiency. It is particularly well-suited for high-volume manufacturing. - Strong Customization and Complex Profile Capabilities

In addition to standard profiles, roll forming can produce complex cross-sections and custom designs. It is ideal for meeting specific dimensional and functional requirements, making it a preferred choice for non-standard profile fabrication. - High Throughput

Roll forming offers exceptionally high output rates, making it widely used for mass production of products such as drywall studs, metal ceiling panels, rolling shutters, tubing, cable trays, shelving systems, metal furniture, louvers, and solar panel frames. - Excellent Material Versatility

The process can handle a wide range of materials, from conventional DX51 steel to high-strength steels like S390, making it suitable for diverse industry applications and project requirements. - Low Energy Consumption

Unlike extrusion, roll forming is a cold-forming process that requires no metal heating. This not only reduces energy consumption but also enhances the strength and durability of the final product. - Support for Modern Technologies

Roll forming can be seamlessly integrated with modern manufacturing technologies such as coil punching, in-line perforation, and laser cutting. This improves automation and flexibility, and is widely applied in the production of filter frames, fire dampers, modular structures, and light steel framing (LSF) systems.

10.0Applications of Roll Forming Machines

With outstanding production efficiency, high precision, and excellent material utilization, roll forming machines have become a fundamental and indispensable process in modern manufacturing.

10.1Main Application Areas

- Construction Industry

Roll forming machines play a crucial role in the construction sector, primarily producing roofing panels, wall panels, purlins, columns, and other structural components. - Automotive Industry

In automotive manufacturing, roll forming machines are used to produce key components such as roof rails, door beams, bumpers, and chassis reinforcements. - Warehousing and Racking

Metal racks and shelving systems in factories, retail stores, and large warehouses require stable and durable metal structures. Roll forming machines produce rack supports and frameworks with excellent load-bearing capacity and stability. - Solar Energy Industry

With the rise of clean energy, solar panels require stable and durable mounting structures. These structures are typically made from profiles produced by roll forming machines, providing a reliable and robust foundation for solar panels. - Transportation Equipment

From trailers to buses, highway guardrails to road barriers, many transportation equipment components such as chassis rails, side panels, and structural parts are manufactured using roll forming. - Agricultural Equipment

Roll forming is widely used in agriculture to produce large volumes of uniform metal materials for grain bins, silos, fences, and foundational farm structures. This process is well-suited for large-scale agricultural infrastructure.

References

https://www.iqsdirectory.com/articles/roll-forming.html

www.thefabricator.com/thefabricator/article/rollforming/understanding-metal-roll-forming-and-its-tooling

https://en.wikipedia.org/wiki/Roll_forming