High-performance bearings are widely utilized across critical industrial sectors such as automotive, precision machine tools, and wind power. Precision ring rolling, an advanced rotary forming technology, is employed in the production of seamless bearing rings, thereby enhancing the overall service life of bearings.

This article outlines three precision ring rolling methods designed for bearings of different size ranges:

- Cold Ring Rolling: Applied to the production of small-sized bearings.

- Hot Radial Ring Rolling: Suited for medium-sized bearings.

- Hot Radial-Axial Ring Rolling: Utilized for large-sized bearings.

0.1Introduction

Bearings are fundamental mechanical components responsible for carrying loads and transmitting power, widely applied in industries such as machine tools, automotive, railways, shipbuilding, energy, and aerospace. In advanced applications—including precision CNC machine tools, high-speed rail, wind power, and aircraft engines—bearings must not only achieve high dimensional accuracy but also ensure long service life and reliable performance under harsh operating conditions such as high speed, heavy load, elevated temperatures, and impact forces. These bearings are generally defined as high-performance bearings. The technological level of high-performance bearings not only reflects the core performance of bearing products but also indicates, to some extent, the industrial capability of a specific manufacturing region.

Structurally, bearings typically consist of bearing rings, rolling elements, and cages. Among them, the bearing ring serves as the essential foundation component, accounting for 60%–70% of the total bearing weight and cost. Consequently, the precision and performance of bearing rings directly determine the overall quality of bearings. The traditional manufacturing route of bearing rings—“forging blanks + machining”—faces common drawbacks such as high energy consumption, low material utilization, low production efficiency, coarse and non-uniform microstructure, incomplete grain flow, and inferior mechanical properties. These limitations make it difficult to meet the stringent requirements of high-performance bearings.

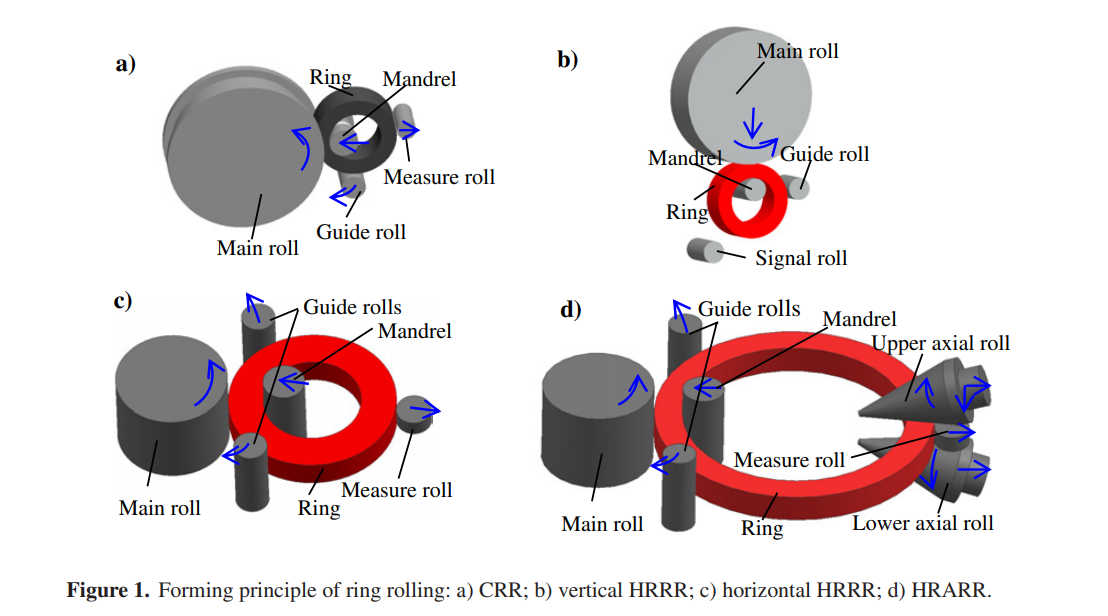

Figure 1 – Schematic Diagram of Ring Rolling Principles: a) Cold Ring Rolling (CRR);b) Vertical Hot Radial Ring Rolling (HRRR);c) Horizontal Hot Radial Ring Rolling (HRRR);d) Hot Radial-Axial Ring Rolling (HRARR).

Ring rolling technology, a precision rotary forming method for seamless rings, is based on the principle of localized plastic deformation driven by the rotation of rolls combined with linear feed. This process enables reduction of wall thickness, increase of diameter, and shaping of ring profiles, ultimately achieving the desired geometry and microstructural properties. By applying ring rolling to bearing ring production, energy consumption and material costs can be reduced while production efficiency and mechanical performance are improved, resulting in extended bearing service life. Ring-rolled bearing rings exhibit denser microstructures and grain flow aligned with the raceway direction. Today, ring rolling has been widely adopted in bearing ring manufacturing, becoming one of the indispensable advanced forming technologies for high-performance bearings.

1.0Typical Ring Rolling Technologies for Bearing Rings

1.1Cold Ring Rolling (CRR) for Small-Sized Bearing Rings

Cold Ring Rolling (CRR) is an advanced rotary forming process performed at room temperature using specialized CRR mills. Under the constraint of radial roll pass, the ring undergoes continuous localized compression, resulting in gradual reduction of radial thickness, simultaneous increase of diameter, and progressive formation of the target cross-sectional shape.

The key components of a CRR mill include: main roll system, mandrel system, guide system, measuring system, machine frame, and power & control system. During rolling, the main roll provides active rotation, while the mandrel feeds linearly along a set direction. The guide rolls adjust position as the ring diameter expands, and the measuring roll continuously monitors diameter changes. Once the preset diameter is reached, the rolling process terminates.

Application range: CRR is primarily suitable for producing small bearing rings with diameters below 250 mm.

1.2Hot Radial Ring Rolling (HRRR) for Medium-Sized Bearing Rings

Hot Radial Ring Rolling (HRRR) is a precision forming process carried out at elevated temperatures using HRRR mills. Similar to CRR, HRRR employs radial roll passes to apply localized compression, reducing radial thickness, enlarging diameter, and shaping the cross-section.

Based on the relative orientation of roll axes and the horizontal direction, HRRR mills are classified into:

- Vertical HRRR Mill: The roll axes are parallel to the horizontal plane. During rolling, the main roll performs active rotation combined with linear feed, while the mandrel rotates passively. The guide roll is positioned at the outlet side of the main roll, and the signal roll is placed opposite the guide roll. Rolling stops once the ring diameter expands to contact the signal roll.

- Horizontal HRRR Mill: The roll axes are perpendicular to the horizontal plane. The main roll rotates actively, while the mandrel performs linear feed. Two guide rolls are symmetrically arranged on either side of the main roll, adjusting position as the diameter increases. The signal roll is placed opposite the main roll to monitor the diameter in real time. Rolling ends once the preset diameter is reached.

Application range: HRRR is mainly used for manufacturing medium-sized bearing rings with diameters between 50 mm and 1000 mm.

1.3Hot Radial-Axial Ring Rolling (HRARR) for Large-Sized Bearing Rings

Hot Radial-Axial Ring Rolling (HRARR) is an advanced rotary forming process conducted at high temperatures using HRARR mills. Unlike purely radial rolling, HRARR combines both radial and axial roll passes, enabling simultaneous reduction of radial thickness and axial height along with diameter enlargement, ultimately forming the desired cross-sectional profile.

The key distinction between HRARR and horizontal HRRR mills lies in the addition of a pair of axial rolls for adjusting ring height. During rolling, the upper axial roll performs active rotation combined with downward linear feed, while the lower axial roll rotates actively without feeding. Both axial rolls are mounted on the axial frame and move outward in synchronization with the expanding ring diameter.

Application range: HRARR is primarily used for producing large bearing rings with diameters exceeding 1000 mm.

2.0Development and Application of Precision Ring Rolling Technology in Bearing Ring Manufacturing

From a global perspective, certain regions in Asia serve as key international markets and manufacturing bases for bearings. The bearing market in this area accounts for approximately 10% of the global total, with annual production approaching 20 billion units and an annual output value exceeding $30 billion. In response to globalization and sustainable development trends in manufacturing, this region is transitioning its bearing industry from a “scale-oriented” model to a “technology-oriented” model, gradually enhancing the domestic capability for high-end bearing production.

Against this backdrop, local bearing manufacturers, universities, and research institutes have conducted collaborative research focused on independently developing precision ring rolling technologies for high-performance bearing production. Significant technological breakthroughs have been achieved in key areas, including cold ring rolling, hot radial ring rolling, and hot radial-axial ring rolling, with results already implemented in practical production.

2.1Precision Cold Ring Rolling Technology for Small and Medium-Sized Bearing Rings

Precision Cold Ring Rolling Process

Building upon international semi-precision cold ring rolling technology, research teams have innovatively developed a precision cold ring rolling process tailored for bearing ring production. The core process flow is as follows:

Bar Cutting → Hot Forging of Blanks → Pre-Treatment → Rough Turning → Precision Cold Ring Rolling → Quenching → Grinding

This process emphasizes strict control of blank accuracy to improve forming quality, ultimately achieving near-net-shape bearing rings. The technical advantages of this process include:

- Improved Forming Accuracy: Ring geometry can reach grade 7–8, with surface roughness controlled at Ra 0.8–1.6 μm, representing a 1–2 grade improvement over conventional semi-precision cold ring rolling.

- Optimized Resource Efficiency: Raceways can be directly formed by ring rolling without subsequent turning, effectively reducing material waste and machining time.

- Enhanced Mechanical Performance: Raceways formed by precision cold ring rolling retain dense microstructures and continuous metal flow lines, avoiding mechanical property degradation caused by turning.

Figure 2. a) A new electromechanical servo NC precision CRR mill; b) machine tool and automobile bearing rings

Precision Cold Ring Rolling Equipment

Research teams have independently developed new CNC precision cold ring rolling mills, featuring an innovative “servo motor – reducer – high-strength ball screw” drive-feed system that replaces traditional hydraulic servo systems as the main drive-feed mechanism. This design enables precision feeding under 50-ton load conditions, achieving a feed accuracy of 0.005 mm and machining accuracy of φ100 ± 0.02 mm, surpassing many comparable international precision cold ring rolling machines (typically φ100 ± 0.1 mm).

The new cold ring rolling mill overcomes the limitations of traditional mills that rely primarily on hydraulic cylinders for drive-feed, ensuring stable forming during precision cold ring rolling and driving upgrades in mill structural design and manufacturing methods. Based on this technology and equipment, companies have achieved mass production of ball bearing rings, roller bearing rings, and joint bearing rings, with products widely applied in high-performance machine tool bearings and automotive bearings, and exported to leading international bearing manufacturers such as SKF, FAG, NSK, and TIMKEN.

Key Technologies in Precision Cold Ring Rolling

Core technologies for precision cold ring rolling of high-performance bearing rings include:

- High-plasticity pre-treatment for room-temperature cold deformation of bearing steel.

- Design and manufacturing of long-life roll pass profiles.

- Optimized process parameter design for precision cold ring rolling.

- Online precision measurement and closed-loop control during cold ring rolling.

2.2Precision Hot Radial Ring Rolling Technology for Large-Sized Specialized Bearing Rings

Precision Hot Radial Ring Rolling Process

For large tapered roller bearing rings used in high-speed railway locomotives and heavy-duty freight cars, traditional hot ring rolling processes require initially rolling the ring into a simplified cross-section, followed by machining to achieve the complete profile, resulting in poor technical and economic efficiency. To address this, research teams have developed a precision hot radial ring rolling (HRRR) process specifically for such rings. The core process flow is as follows:

Bar Cutting → Hot Extrusion of Blanks → Precision Hot Radial Ring Rolling → Machining → Heat Treatment → Grinding

By improving blank dimensional accuracy and optimizing the control of the hot radial ring rolling process, this method enables direct forming of complex cross-sections, significantly reducing subsequent machining and enhancing product performance. Compared with traditional hot radial ring rolling, this process achieves:

- Material utilization improvement:15%–20% increase.

- Production efficiency:3× higher.

- Production cost reduction: Approximately 20%.

Figure 3. a) A new electromechanical servo NC precision HRRR mill; b) high-speed rail bearing rings formed by precision HRRR

Precision Hot Radial Ring Rolling Equipment

Building upon the research of CNC precision cold ring rolling mills, the team further developed CNC precision hot radial ring rolling mills. Key innovations include:

- Replacement of traditional hydraulic servo systems with electromechanical servo systems as the main drive-feed mechanism, achieving feed accuracy of 0.01 mm and forming accuracy controlled within φ100 ± 0.25 mm.

- Improved automatic measurement and control functions, replacing manual operation used in semi-CNC mills, ensuring stable ring dimensional accuracy and enhancing automation of the hot ring rolling process.

Based on this technology and equipment, companies have realized mass production of tapered roller bearings, cylindrical roller bearings, and ball bearings, with applications in high-performance bearing manufacturing for high-speed rail, precision machine tools, and heavy-duty metallurgical rolling mills.

Key Technologies in Precision Hot Radial Ring Rolling

Core technologies for precision hot radial ring rolling of high-performance bearing rings include:

- Matched design of precision blanking process and hot radial ring rolling process.

- Precision cooling control during the hot ring rolling process.

- Online precision measurement and dynamic control of the hot radial ring rolling process.

2.3Precision Hot Radial-Axial Ring Rolling Technology for Ultra-Large Bearing Rings

Precision Hot Radial-Axial Ring Rolling Process

For ultra-large wind turbine bearings with diameters exceeding 1 meter, the traditional manufacturing process typically includes:

Bar Cutting → Bar Heating → Free Forging of Blanks → Mandrel Expansion → Machining

The mandrel expansion step requires multiple heating cycles, resulting in high energy consumption, significant material loss, and long production cycles. Moreover, it cannot fully form the bearing raceway, leading to extensive subsequent machining and difficulty ensuring product performance.

To address these issues, research teams developed a precision hot radial-axial ring rolling (HRARR) process for ultra-large bearing rings. Retaining the initial steps of bar cutting → bar heating → free forging of blanks, this process replaces traditional mandrel expansion with precision hot radial-axial ring rolling, enabling single-heating rolling and direct raceway formation. The application of this process achieves:

- Energy savings: 30%–40% reduction.

- Material savings: 25%–30% reduction.

- Production efficiency: More than 5× increase.

- Production cost reduction: Approximately 30%.

Additionally, this process overcomes the size limitations of mandrel expansion, enabling the forming of ultra-large bearing rings with diameters exceeding 5 meters.

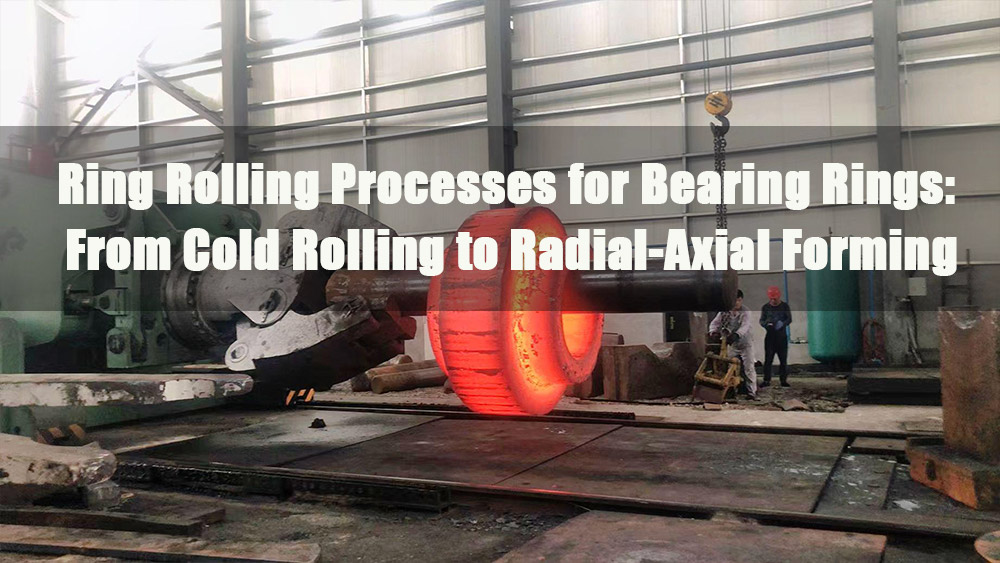

Figure 4. a) A super large scale HRARR mill RAM 9000; b) a super large scale wind power bearing ring formed by precision HRARR.

Precision Hot Radial-Axial Ring Rolling Machine

The team independently developed ultra-large CNC precision hot radial-axial ring rolling Machine(e.g., RAM 9000). Key technical specifications meet the requirements for ultra-large bearing rings:

- Maximum ring diameter: 10 meters

- Maximum ring height: 1.7 meters

- Radial rolling force: 800 tons

- Axial rolling force: 600 tons

Based on this technology and equipment, companies have achieved mass production of ball bearing rings, wheel bearing rings, and other ultra-large bearing rings with diameters of 1 meter or more, widely applied in high-performance wind turbine bearings, and exported to leading global wind power companies such as General Electric (GE, USA) and Vestas (Denmark).

Key Technologies in Precision Hot Radial-Axial Ring Rolling

Core technologies for high-performance bearing rings produced by precision hot radial-axial ring rolling include:

- Matched design of radial and axial deformation of rings.

- Optimization of the HRARR process scheme and transition stages.

- Stability control of the HRARR process.

3.0Development Trends of Precision Ring Rolling Technology in Bearing Ring Manufacturing

High-performance bearings, as core components of advanced major equipment, represent a key development direction in the global bearing industry. To meet the evolving demands of high-performance bearing products, technology, and markets, the development trends of precision ring rolling technology in bearing ring manufacturing mainly include the following three aspects:

3.1Expansion of Cold Ring Rolling Technology for Large Bearing Rings:

Due to the room-temperature properties of high-carbon chromium-bearing steel (GCr15), the diameter of bearing rings currently manufactured by cold ring rolling is generally less than φ250 mm. In the future, research should focus on developing cold ring rolling technology and specialized equipment for large bearing rings with diameters ranging from 250 mm to 500 mm, while further expanding the application scenarios of cold ring rolling for different types of bearing rings.

3.2Precision Control Technology in Hot Ring Rolling Processes:

At present, key process conditions during hot ring rolling—such as blank preparation, rolling, and cooling—are prone to fluctuations, resulting in poor stability of the geometric dimensions and microstructural properties of hot-rolled bearing rings. Future research should strengthen control technologies for hot ring rolling, achieving coordinated control of ring geometry and microstructure by precisely regulating pre-heating conditions, deformation parameters during rolling, and post-rolling cooling rates, ensuring consistent product performance.

3.3Innovation in Short-Process Manufacturing of Bearing Rings:

Currently, preparation of blanks for large bearing rings typically involves multiple steps: smelting → ingot casting → ingot cutting → upsetting → punching, resulting in a long production cycle. Upsetting and punching lead to significant material loss, and repeated heating throughout the process increases energy consumption and material burn-off, while potentially affecting internal blank quality. To address this, a “casting-rolling composite” process has been proposed, allowing direct rolling of cast blanks, significantly shortening the production process, reducing blank losses, and improving production efficiency. With its substantial technical advantages, casting-rolling composite technology is expected to become an important future direction in ring rolling manufacturing for bearing rings.

4.0Conclusion

Precision ring rolling technology has become a cornerstone in the manufacturing of high-performance bearing rings, offering significant advantages in forming accuracy, material utilization, mechanical properties, and production efficiency. From small to ultra-large bearing rings, advanced processes such as cold ring rolling, hot radial ring rolling, and hot radial-axial ring rolling enable direct shaping of complex cross-sections while reducing subsequent machining. Coupled with innovations in CNC equipment, automated control, and process optimization, precision ring rolling is not only enhancing the global competitiveness of bearing manufacturers but also driving the evolution of high-performance bearings in automotive, aerospace, wind power, rail, and other critical industrial sectors. Looking forward, the integration of precision control, short-process manufacturing, and casting-rolling composite technologies will continue to expand the applicability and efficiency of ring rolling, solidifying its role as an essential technology in next-generation bearing production.

5.0Frequently Asked Questions (FAQ)

Q1: What is precision ring rolling?

A1: Precision ring rolling is a rotary forming process that uses rotating rolls and linear feed to reduce wall thickness, increase diameter, and shape the cross-section of seamless rings, producing high-quality bearing rings with dense microstructures and optimized mechanical properties.

Q2: What types of bearing rings can be manufactured using precision ring rolling?

A2: Precision ring rolling can produce small, medium, large, and ultra-large bearing rings, including ball bearing rings, cylindrical and tapered roller bearing rings, and specialized rings for high-speed rail, wind turbines, and heavy machinery applications.

Q3: What are the key advantages of precision ring rolling?

A3: Key advantages include:

- High forming accuracy and near-net-shape production

- Improved material utilization and reduced machining

- Enhanced mechanical performance due to preserved microstructure and continuous metal flow

- Increased production efficiency and reduced energy consumption

Q4: What are the future trends in bearing ring manufacturing with precision ring rolling?

A4: Major trends include:

- Expansion of cold ring rolling to larger diameters

- Precision control technologies in hot ring rolling

- Short-process manufacturing and casting-rolling composite techniques to improve efficiency, reduce material loss, and maintain consistent product quality

References

https://www.iqsdirectory.com/articles/forging/rolled-ring-forging.html

https://en.wikipedia.org/wiki/Rolling_(metalworking)