- 1.0Introduction: Why Rebar Cutting Matters

- 2.0Safety First: Protective Systems Before Cutting

- 3.0Types of Rebar Cutting Tools: Manual, Electric, and Heavy-Duty Options

- 4.0How to Choose the Right Rebar Cutting Tool: 6 Core Judgment Dimensions

- 5.0Common Rebar Types and Cutting Compatibility Tips

- 6.0Post-Cutting Processing: Ensuring Rebar Connection and Structural Safety

- 7.0Special-Scenario Cutting Techniques: Handling Complex Construction Environments

- 8.0Tool Maintenance: Extending Lifespan and Reducing Costs

- 9.0Common Operational Mistakes: Avoiding Hazards and Improving Quality

- 10.0Summary

- 11.0Rebar Cutting FAQ

- 11.1Q1: What tools are suitable for cutting rebar at home or for small projects?

- 11.2Q2: How can rebar be cut safely on construction sites?

- 11.3Q3: Can torches or plasma cutters be used for rebar cutting?

- 11.4Q4: Which tools provide the cleanest cuts for welding or threading?

- 11.5Q5: Is post-cut treatment necessary for rebar?

1.0Introduction: Why Rebar Cutting Matters

Rebar, or reinforcing steel, is a fundamental material in modern construction. Produced from as much as 95% recycled steel, it combines cost efficiency with environmental sustainability. Delivered in standard mill lengths of up to 18 meters (60 feet), rebar must be cut to exact sizes to meet the requirements of structural elements such as beams, columns, and slabs.

Cutting rebar is therefore a crucial preparatory step. Precision and clean, burr-free edges are essential to ensure smooth tying, threading, and welding during construction. Inadequate cutting quality not only complicates assembly but can also weaken the material’s tensile strength, potentially compromising the overall integrity of the structure.

2.0Safety First: Protective Systems Before Cutting

Rebar cutting involves high-speed tools, hot sparks, and sharp edges. A three-level safety approach—personal, workspace, and operational—helps prevent hazards.

2.1Personal Protective Equipment (PPE): Protection Against Direct Injury

- Eye protection: Wear impact-rated safety goggles instead of regular glasses to block flying metal debris, especially when using Angle Grinders or Chop Saws.

- Hand protection: Use heavy-duty cut-resistant gloves, preferably Kevlar, to prevent cuts from sharp edges or slips.

- Hearing protection: Wear noise-reducing earplugs or earmuffs when using Grinders, Chop Saws, or Band Saws, as these tools often exceed 85 dB.

- Body protection: Wear long-sleeve cotton clothing, long pants, and steel-toe safety boots. Avoid synthetic fabrics that may ignite from sparks.

- Respiratory protection: For stainless steel or high-volume cutting, use a dust mask to filter metal particles.

2.2Workspace Safety: Eliminating Environmental Hazards

- Flammable materials: Keep solvents, paints, wood, and other combustibles at least 5 meters away. A dry powder fire extinguisher of at least 2 kg should be nearby.

- Ventilation and lighting: Ensure proper airflow in enclosed areas with fans and maintain adequate lighting to avoid cutting errors.

- Stable workbench: Use a metal bench with a minimum 50 kg load capacity, covered with a non-slip mat. Do not cut on scaffolds or temporary supports.

2.3Operational Protocols: Reducing Human Error

- Securing the rebar: Clamp rebar firmly with a vise, C-clamp, or rebar holder, especially when cutting bars with a diameter ≥12 mm. Never hold the cutting area with bare hands.

- Tool inspection: Check cords for damage, inspect blades or wheels for cracks, and verify hydraulic hoses for leaks before operation.

- Work assistance: For Torch Cutting, heavy sections, or elevated work, ensure a second person is present to pass tools, monitor safety, and shut off power or gas in emergencies.

3.0Types of Rebar Cutting Tools: Manual, Electric, and Heavy-Duty Options

Rebar cutting tools are categorized into four major types according to power source, application scenarios, and efficiency. A key addition is the Metal Band Saw, which is central for medium- to large-scale batch cutting. Each type of tool has its specific compatibility, operational guidelines, and advantages and disadvantages.

3.1Manual Tools: Suitable for Small DIY or Emergency Jobs

Manual tools require no electricity, are portable, and rely on human force. They are best suited for rebar with a diameter of ≤10 mm and are commonly used for temporary adjustments or in areas without power.

| Tool | Suitable Diameter | Operation Notes | Pros | Cons |

| Hacksaw | ≤10 mm | Mark cut line, clamp rebar, create guiding groove (1–2 mm), saw steadily with moderate pressure | Low cost (<$10), widely available, quiet | Labor-intensive (5–8 min for 10 mm), blades dull quickly (replace every 3–5 cuts) |

| Bolt Cutters | ≤8 mm | Place rebar in deepest notch, apply steady force with extended handles | Portable (≤3 kg), clean cuts | Cannot cut >8 mm, operator fatigue |

| Hydraulic Bolt Cutters | ≤12 mm | Align rebar, pump hydraulic lever, apply pressure until cut completes | Low effort (60% less than manual), quiet, no electricity needed | Slow (1–2 min per 12 mm), requires hydraulic oil maintenance |

3.2Electric Tools: Combining Efficiency and Portability

Electric tools are powered by household (220V) or industrial (380V) electricity. They offer fast cutting speeds and higher precision, suitable for rebar diameters of 5–30 mm. These tools are widely used for medium-scale construction projects and on-site processing.

| Tool | Suitable Diameter | Operation Notes | Pros | Cons |

| Angle Grinder | ≤20 mm | Use 4–4.5″ grinder, thin cutting disc (≤1.2 mm), maintain perpendicular angle | Fast (~30 sec for 20 mm), flexible | Sparks, moderate precision (≤1 mm deviation), fire risk |

| Circular Saw (Diamond Blade) | ≤25 mm | Use diamond/carbide blade, adjust depth = diameter +2 mm, cut at full speed | Smooth cut (≤0.5 mm deviation), efficient | Limited mobility, high blade cost |

| Cut-off Saw (Chop Saw) | ≤30 mm | Secure rebar with vise, adjust speed (1500 RPM for carbon steel, 1000 RPM for stainless steel) | High accuracy (≤0.3° deviation), burr-free | Heavy (≥15 kg), loud (≥90 dB), expensive (≥$300) |

| Reciprocating Saw | ≤30 mm | Use straight mode, select proper TPI blade (20–25 for thin rebar, 7–9 for thick rebar), maintain steady feed | Works in confined spaces, versatile | Slow (2–3 min for 30 mm), blades wear quickly |

| Portable Rebar Cutter | ≤25 mm | Electric + hydraulic drive, cuts in ≤5 sec, no sparks | Safe (no sparks/dust), portable (≤8 kg), precise | Costly (≥$400), limited battery (~50 cuts per charge) |

3.3Heavy-Duty Rebar Cutting Tools: Band Saws and Industrial Cutters

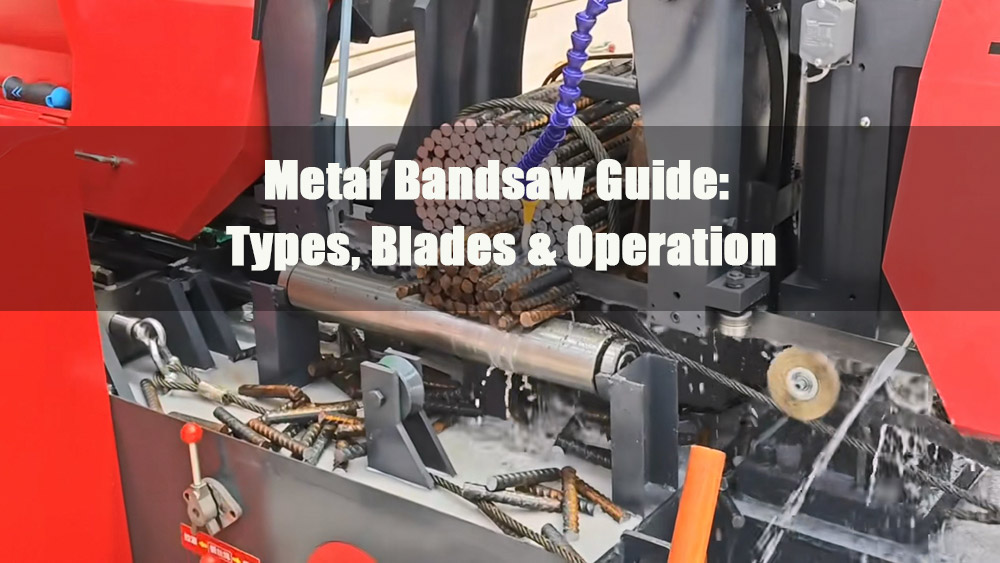

Heavy-duty tools are designed for rebar ≥30 mm and require fixed workstations such as construction processing areas or prefabrication factories. Operation is typically handled by trained professionals. The Metal Band Saw is an essential addition for medium-batch processing.

| Tool | Suitable Diameter | Operation Notes | Pros | Cons |

| Metal Band Saw | ≤60 mm | Use hydraulic feed, 5–14 TPI blades, and coolant; can cut stacked rebar up to the machine’s maximum capacity (≤300 mm) | High efficiency (50–80 cuts/hr), long blade life (500+ cuts), automated feeding (≤1 mm tolerance) | Large footprint (≥2 m), high initial investment (≥$2,000) |

| Heavy-Duty Rebar Cutter | ≥60 mm | Load rebar with a crane, adjust the clutch, and activate the automatic cutting cycle | Cuts ultra-thick rebar (≥80 mm), deformation-free | Immobile (≥450 kg), single-bar cutting only |

3.4Alternative Rebar Cutting Methods: Torch, Plasma, and Abrasive Wire

These methods are suitable for very large diameters or scenarios where precision is less critical. They require skilled operators and are generally not recommended for routine use.

| Method | Suitable Diameter | Operation Notes | Pros | Cons |

| Oxy-Acetylene Torch | Any | Heat rebar to melting point, then cut along the marked line | Cuts very thick rebar, versatile for demolition | Low precision, heat-affected zone, requires fire safety training |

| Plasma Cutting | ≤50 mm | Use a Plasma Cutter with proper gas pressure and current settings | Fast, works on stainless steel | Requires high power supply, expensive consumables |

| Abrasive Wire Saw | Large or irregular rebar | Use a tensioned abrasive wire with constant coolant supply | Can cut oversized or irregularly shaped rebar | Very slow, costly, niche application |

4.0How to Choose the Right Rebar Cutting Tool: 6 Core Judgment Dimensions

There is no “absolute best” tool for rebar cutting. Tool selection must consider project requirements, material properties, and operational context. Below are 6 key factors to guide decision-making, including batch volume and long-term cost for comprehensive planning.

4.1Project Scale

- Small DIY projects (e.g., home fences): Hacksaws, Bolt Cutters (cost ≤ $15) Ideal for low-frequency, small-scale cutting—no professional skills required, and low upfront cost.

- Medium-sized construction sites (e.g., multi-story residential buildings): Angle Grinders, Portable Rebar Cutters Balance mobility and efficiency, suitable for scattered on-site processing without fixed workstations.

- Large projects (e.g., bridges, high-speed rail): Metal Band Saws, Heavy-Duty Rebar Cutters Optimized for batch standardized processing, handles large-diameter/high-grade rebar, and reduces long-term costs.

4.2Rebar Specifications

- Diameter ≤ 10 mm: Bolt Cutters, Hacksaws Manual/small tools suffice, avoiding waste of high-power equipment.

- Diameter 10–30 mm: Angle Grinders, Circular Saws, Reciprocating Saws Electric tools offer fast cutting speeds and acceptable precision for most structural elements.

- Diameter ≥ 30 mm: Metal Band Saws, Heavy-Duty Rebar Cutters High cutting force ensures thorough cutting, preventing rapid wear of low-power tool blades.

- High-grade rebar (e.g., Grade 80): Hydraulic Bolt Cutters, Portable Rebar Cutters, Metal Band SawsHigh-hardness rebar accelerates manual tool wear; hydraulic/electric tools provide stable cutting force.

4.3Mobility Requirements

- Frequent on-site movement (e.g., between floors): Portable Rebar Cutters, Angle Grinders (weight ≤ 8 kg) Light weight and easy to carry, some support battery power (no need for fixed power sources).

- Fixed processing area (e.g., on-site rebar processing sheds): Circular Saws, Metal Band Saws, Heavy-Duty Rebar Cutters No need for mobility; stable equipment structure supports continuous batch processing.

4.4Budget Range

- Low-cost (≤ $75): Hacksaws, Bolt Cutters, standard Angle Grinders Low initial investment, suitable for temporary use or small projects with limited budgets.

- Medium-budget ($75–750): Circular Saws, Cut-off Saws, Portable Rebar Cutters Balances performance and cost, meeting regular cutting needs for medium-sized projects.

- Professional investment (≥ $1,500): Metal Band Saws, Heavy-Duty Rebar Cutters Suitable for enterprises/long-term construction; durable equipment with lower comprehensive costs for high-volume use.

4.5Cutting Quality

- Rough cuts (no post-processing required, e.g., temporary truncation): Angle Grinders, Oxy-Acetylene Torches Fast cutting speeds, no strict precision requirements, suitable for non-load-bearing elements.

- Precision cuts (for threading or welding, e.g., load-bearing columns): Circular Saws (Diamond Blade), Metal Band Saws, Portable Rebar Cutters Cut tolerance ≤ 0.5 mm, burr-free and deformation-free, directly compatible with subsequent threading/welding.

4.6Batch Volume and Long-Term Cost

- Single or small batch (≤10 pieces): Electric tools (e.g., Angle Grinders, Circular Saws) Lower upfront cost, no need to invest in high-efficiency equipment for small quantities.

- Large-scale batch (≥100 pieces): Metal Band Saws Low blade wear (one blade cuts 500+ pieces), supports automatic feeding; overall cost is ~40% lower than Cut-off Saws for high-volume production.

5.0Common Rebar Types and Cutting Compatibility Tips

The material and coating of rebar affect cutting efficiency and tool choice. Adjustments should be made accordingly to ensure cutting quality and material performance.

| Rebar Type | Key Features | Recommended Tools | Cutting Notes |

| Carbon Steel (Black Rebar) | Most common (≥80% of construction use), high tensile strength, prone to rust | Angle Grinder, Circular Saw, Metal Band Saw | Standard metal blades work; apply anti-rust coating within 2 hours of cutting to prevent oxidation. |

| Galvanized Rebar | Surface zinc coating (50–80 μm), corrosion-resistant, higher cost than carbon steel | Circular Saw (Diamond Blade), Metal Band Saw | Avoid ordinary blades (zinc accelerates wear); repair the zinc layer with zinc spray (≥95% zinc content) after cutting, then apply transparent anti-rust paint. |

| Epoxy-Coated Rebar | Carbon steel base + epoxy layer (100–180 μm), excellent corrosion resistance | Portable Rebar Cutter, Metal Band Saw | Control cutting temperature ≤120°C to prevent epoxy melting; wrap cut ends with epoxy tape to avoid rust penetration. |

| Stainless Steel Rebar | Contains ≥12% chromium, corrosion- and wear-resistant, high cost (~3× carbon steel) | Metal Band Saw (Bi-Metal Blade), Plasma Cutter | Cut 30% slower than carbon steel; use dedicated coolant to prevent stainless steel chips from clogging the blade. |

| European Manganese Steel Rebar | 1.5–2.0% manganese content, high ductility (easily bent), low corrosion resistance | Hacksaw, Angle Grinder, Metal Band Saw (low feed speed) | Use clamps with soft pads to avoid rebar bending during cutting; apply thick anti-rust oil immediately after cutting (due to poor corrosion resistance). |

6.0Post-Cutting Processing: Ensuring Rebar Connection and Structural Safety

Completing the cut does not conclude the workflow. Proper post-cutting treatment is essential to avoid safety hazards and ensure structural reliability. This includes three critical steps:

6.1Edge and Deformation Treatment

- Deburring/removing burrs: Use an Angle Grinder (with a grinding disc) or half-round file to smooth cut edges. Unprocessed burrs may cause tie wire slippage during binding or damage taps during threading.

- Straightening deformed ends: If rebar bends >1° after Torch or Angle Grinder cutting, straighten it with a Rebar Straightening Machine or hydraulic jack to ensure alignment with formwork during installation.

6.2Rust Prevention

- Carbon Steel/Epoxy-Coated Rebar: Apply epoxy anti-rust paint (≥60 μm thickness) or wrap anti-rust tape (≥50 mm width) within 2 hours of cutting.

- Galvanized Rebar: Repair the cut zinc layer with zinc spray (≥95% zinc content), then apply a layer of transparent anti-rust coating for dual protection.

- Stainless Steel Rebar: No additional rust protection is needed, but clean cut debris immediately to prevent galvanic corrosion caused by carbon steel particles adhering to the surface.

6.3Dimensional Verification

- Measurement: Use a steel tape (1 mm precision) to check the cut length. Allowable deviations:

- ≤1 m rebar: ±3 mm

- 1–3 m rebar: ±5 mm

- 3 m rebar: ±8 mm

- Batch check: For mass-cut rebar (e.g., for precast slabs), randomly inspect 5% of pieces. If the defect rate exceeds 10%, conduct a full inspection and re-cut as needed.

7.0Special-Scenario Cutting Techniques: Handling Complex Construction Environments

In actual construction, workers often encounter high-altitude, wet, or confined spaces. Tool selection and operational procedures must be adjusted to ensure safety and efficiency.

7.1High-Altitude Cutting (e.g., on scaffolding)

- Tool Selection: Prioritize Portable Rebar Cutters (no sparks, lightweight); avoid Angle Grinders (sparks may fall and cause fires).

- Safety Measures: Secure a dual-hook safety harness to a structure rated ≥500 kg; set up a safety net below to prevent rebar from falling; have assistants pass tools from the ground (do not throw tools from heights).

7.2Wet Environments (e.g., rainy conditions or underground garages)

- Tool Selection: Use electric tools rated IPX5 or higher (e.g., Angle Grinders with waterproof covers); avoid standard electric tools to prevent electric shock.

- Operational Guidelines: Wear insulating boots (≥10 kV); keep power cords elevated (avoid soaking in water); dry tools immediately after cutting to prevent moisture-induced short circuits.

7.3Confined Spaces (e.g., wall openings)

- Tool Selection: Use a Reciprocating Saw (short blade version) or a mini Angle Grinder (blade diameter ≤75 mm); avoid large tools that cannot maneuver.

- Operational Tips: Mark the cutting line on the rebar first; fix a guide plate with a magnet to prevent deviation; feed the tool slowly to avoid jamming.

7.4Irregular Cutting (e.g., angled or curved cuts)

- Angled Cuts (e.g., rebar lap joints): Use a Cut-off Saw with angle adjustment; keep angle deviation ≤0.5° to ensure tight lap fit.

- Curved Cuts (e.g., special decorative structures): Use a Curve Saw with metal-specific blades; mark the arc on the rebar and keep the saw base flush with the surface to maintain blade alignment.

8.0Tool Maintenance: Extending Lifespan and Reducing Costs

Maintenance priorities vary by tool type. Correct maintenance procedures can extend tool service life by 30–50% and reduce replacement costs.

8.1Manual Tool Maintenance

- Hacksaws: Clean blades after use (remove metal debris); apply machine oil for long-term storage (prevent rust); periodically tighten frame screws (avoid blade wobble).

- Bolt Cutters / Hydraulic Bolt Cutters: Wipe jaws clean after use (remove rebar residues); lubricate pivot points weekly (use lithium grease); replace hydraulic oil every 3 months in Hydraulic Bolt Cutters (use ISO 46 anti-wear hydraulic oil).

8.2Electric Tool Maintenance

- Angle Grinders / Circular Saws: Clean blades or cutting wheels after each use (use a steel brush to remove debris); inspect power cords (repair with insulating tape or replace if damaged); replace carbon brushes when worn below 3 mm (prevent motor burnout).

- Portable Rebar Cutters: Recharge batteries promptly after use (avoid deep discharge); check hydraulic hoses every 6 months for leaks (replace seals if necessary); replace jaws when wear exceeds 0.5 mm (maintain cutting precision).

8.3Heavy/Professional Tool Maintenance

- Metal Band Saws: Check the cooling system daily (refill emulsion if the level is low); clean blade guide blocks weekly (remove accumulated debris); adjust blade tension monthly (too loose causes tooth skipping; too tight causes blade breakage).

- Heavy-Duty Rebar Cutters: Replace gear oil every 100 hours (use ISO 150 industrial gear oil); replace the cutting clutch if wear exceeds 1 mm (prevent slipping); apply anti-rust paint to support frames regularly (protect against outdoor corrosion).

9.0Common Operational Mistakes: Avoiding Hazards and Improving Quality

9.1Mistake 1: Using Wood Blades for Rebar Cutting

- Hazard: Wood blades have low hardness (low tungsten carbide content) and easily chip or break when cutting rebar, causing flying fragments that may injure workers.

- Correct Practice: Always use metal-specific blades (e.g., carbide, diamond, or bi-metal blades) matched to the rebar material.

9.2Mistake 2: Not Securing Rebar, Holding It by Hand

- Hazard: Unsecured rebar may slip, causing cutting deviation or tool kickback—leading to hand injuries or tool damage.

- Correct Practice: Rebar of any diameter must be clamped with a fixture or vise; never touch the area near the cutting point with bare hands.

9.3Mistake 3: Omitting Cooling During Cutting

- Hazard: Overheated blades lose hardness (accelerating wear) and may anneal rebar ends (reducing tensile strength by 10–15%).

- Correct Practice: For rebar ≥20 mm, always use a cooling system (emulsion fluid for Metal Band Saws, cooling spray for Angle Grinders).

9.4Mistake 4: Leaving Burrs After Cutting

- Hazard: Burrs can scratch workers’ gloves, damage threading taps, or create gaps in welds—compromising structural integrity.

- Correct Practice: All cut rebar must be deburred, especially those used for threading or welding.

10.0Summary

The core of rebar cutting is “safety first, proper tool selection, and full-process control.”From preliminary safety measures and tool selection, through standardized operation and special-scenario adjustments, to post-cut processing and maintenance, every step directly impacts construction quality and efficiency.

For different project needs:

- Small DIY/emergency work: Choose manual tools (Hacksaws, Bolt Cutters).

- Flexible on-site cutting: Opt for electric tools (Angle Grinders, Portable Rebar Cutters).

- Batch precision cutting: Use Metal Band Saws.

- Extra-thick rebar processing: Rely on Heavy-Duty Rebar Cutters.

By avoiding common mistakes and maintaining tools properly, you can ensure safe, efficient, and precise rebar cutting—laying a solid foundation for structural safety.

11.0Rebar Cutting FAQ

11.1Q1: What tools are suitable for cutting rebar at home or for small projects?

Manual tools such as Hacksaws or Bolt Cutters are ideal for rebar with a diameter of up to 10 mm. They are low-cost, portable, and effective for small-scale or emergency tasks.

11.2Q2: How can rebar be cut safely on construction sites?

Always wear personal protective equipment (gloves, goggles, hearing protection), secure the rebar with clamps or vises, and maintain a safe workspace free from flammable materials. Use a tool appropriate for the diameter and type of rebar.

11.3Q3: Can torches or plasma cutters be used for rebar cutting?

Yes, Oxy-Acetylene Torches and Plasma Cutters can handle thick or specialized rebar. However, they reduce precision, generate heat-affected zones, and require trained operators with proper fire safety measures.

11.4Q4: Which tools provide the cleanest cuts for welding or threading?

Metal Band Saws and Cut-off Saws with Diamond Blades deliver burr-free, highly precise cuts (≤0.5 mm tolerance), making them ideal for tasks that require clean edges.

11.5Q5: Is post-cut treatment necessary for rebar?

Yes. After cutting, burrs should be removed, bent ends straightened, and anti-rust coatings applied—especially for Carbon Steel, Galvanized, or Epoxy-Coated Rebar—to ensure structural integrity and prevent corrosion.