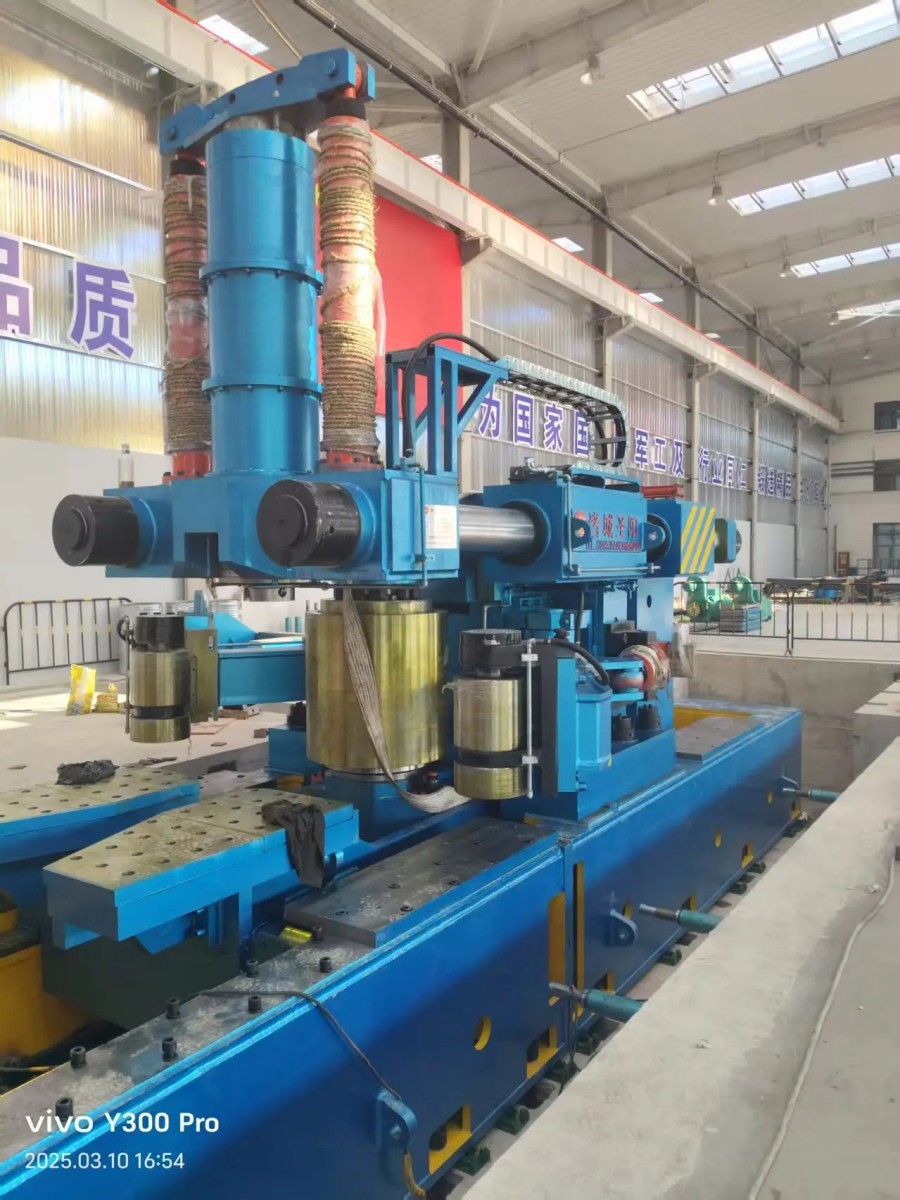

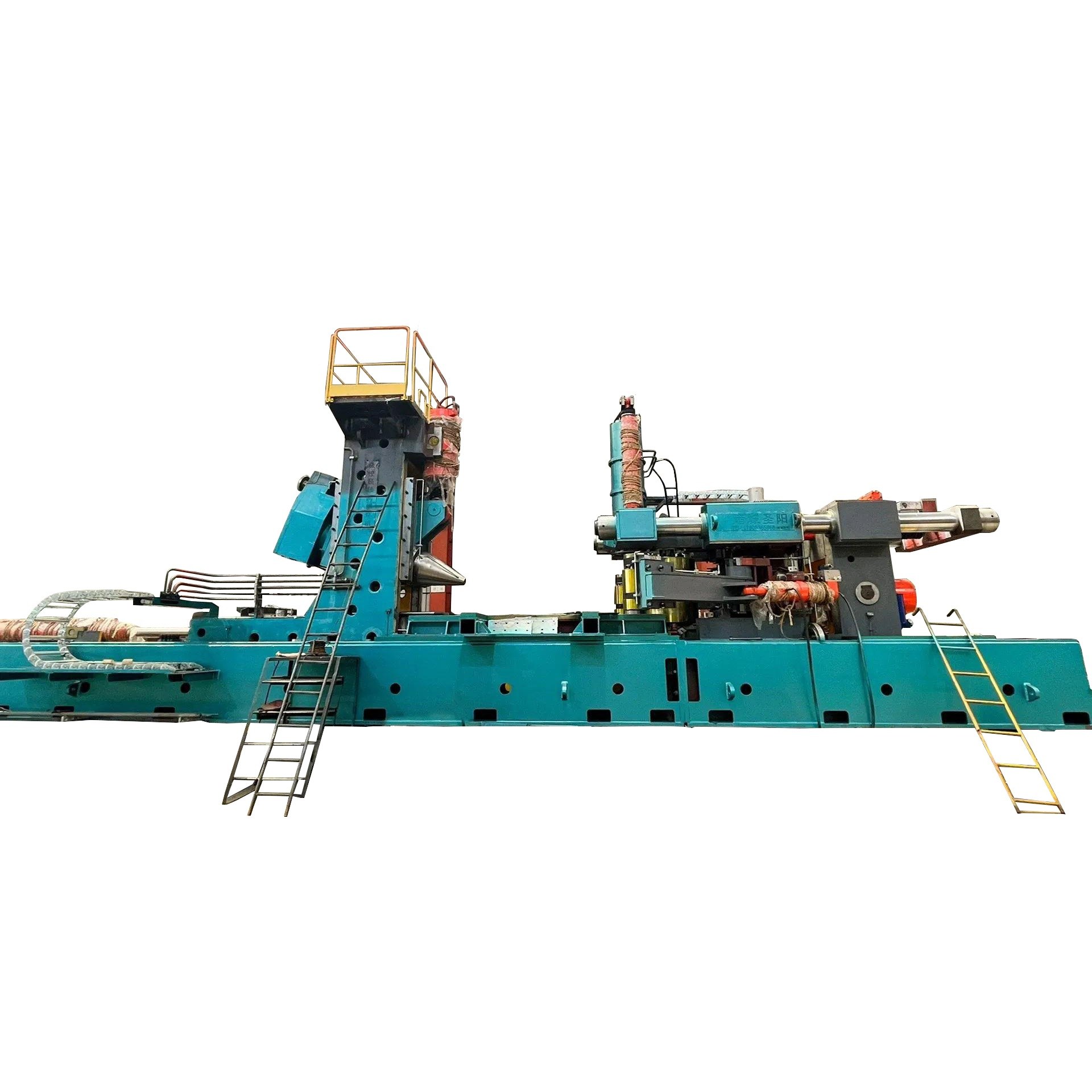

Main Technical Features of CNC Radial-Axial Ring Rolling Machine

The CNC Radial-Axial Ring Rolling Machine is engineered for high-precision hot ring rolling. It combines advanced servo technology, automation, and energy-efficient hydraulic systems, ensuring excellent dimensional accuracy, stable quality, and high productivity.

Applications

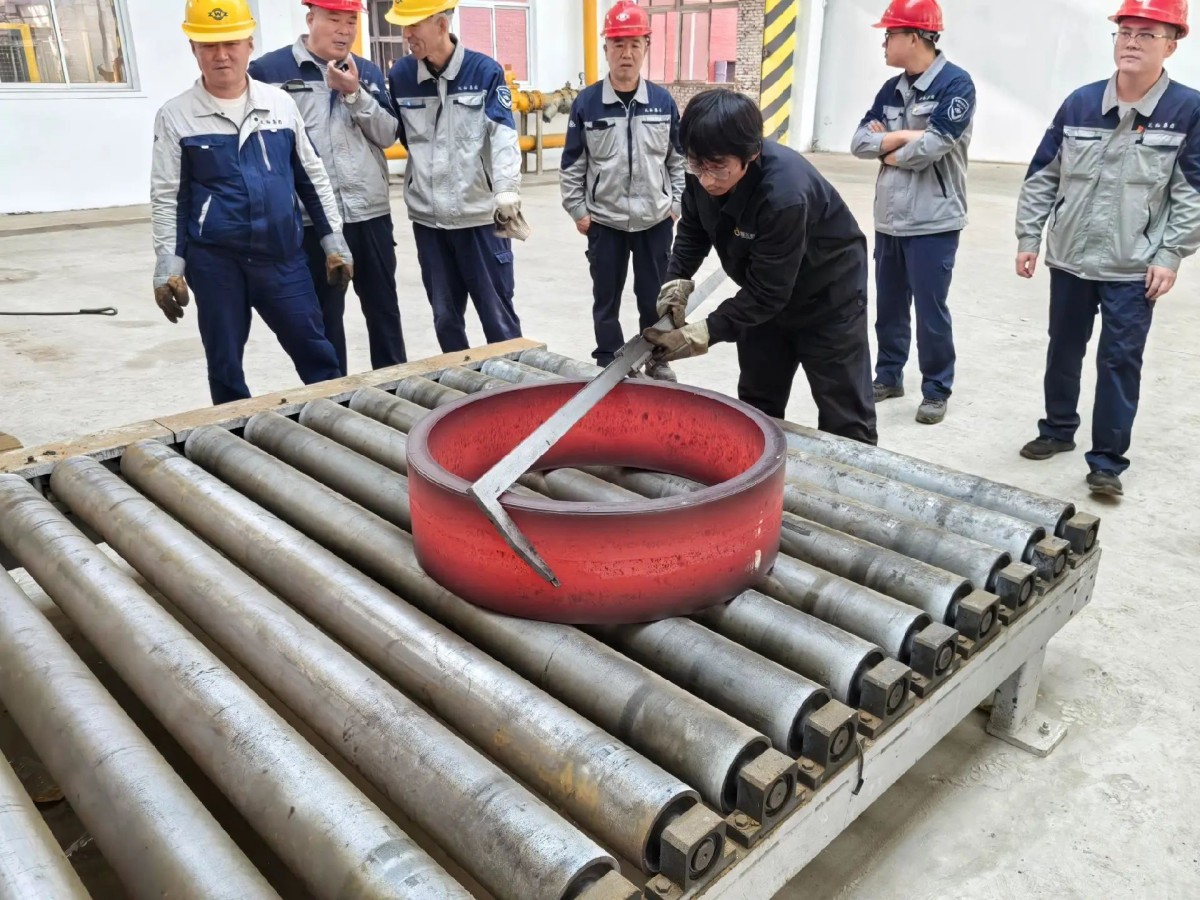

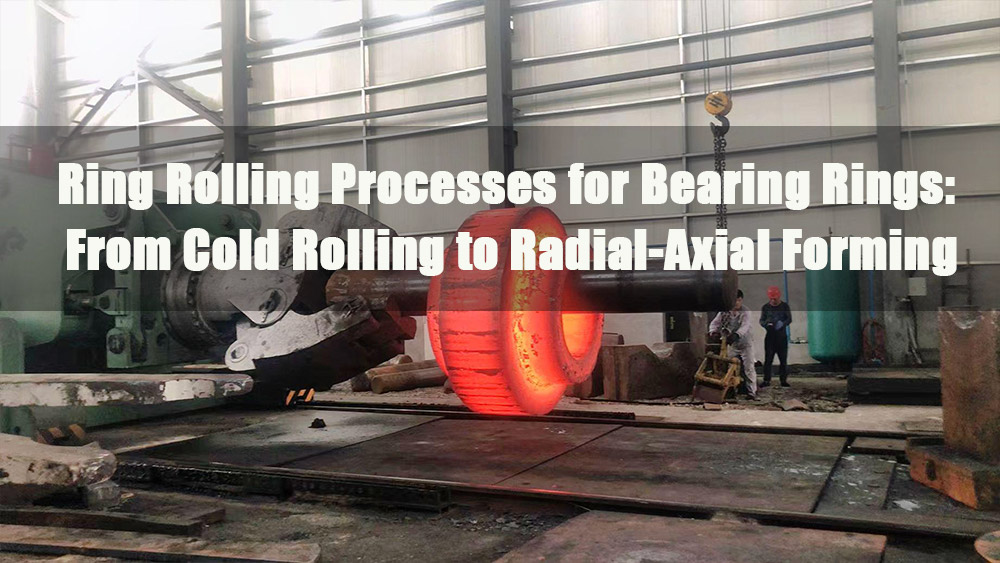

The CNC Radial-Axial Horizontal Ring Rolling Machine is suitable for processing a wide range of materials, including carbon steel, alloy steel, stainless steel, titanium alloy, copper alloy, aluminum alloy, and high-temperature alloys. It produces high-quality seamless rings such as:

- Bearing rings

- Gear rings

- Flanges(including butt-weld flanges and wind turbine flanges)

- Wheel hubs

- Thin-walled cylinders

This machine is ideal for industries requiring precise, high-strength, and seamless ring components, including aerospace, automotive, energy, and heavy machinery manufacturing.

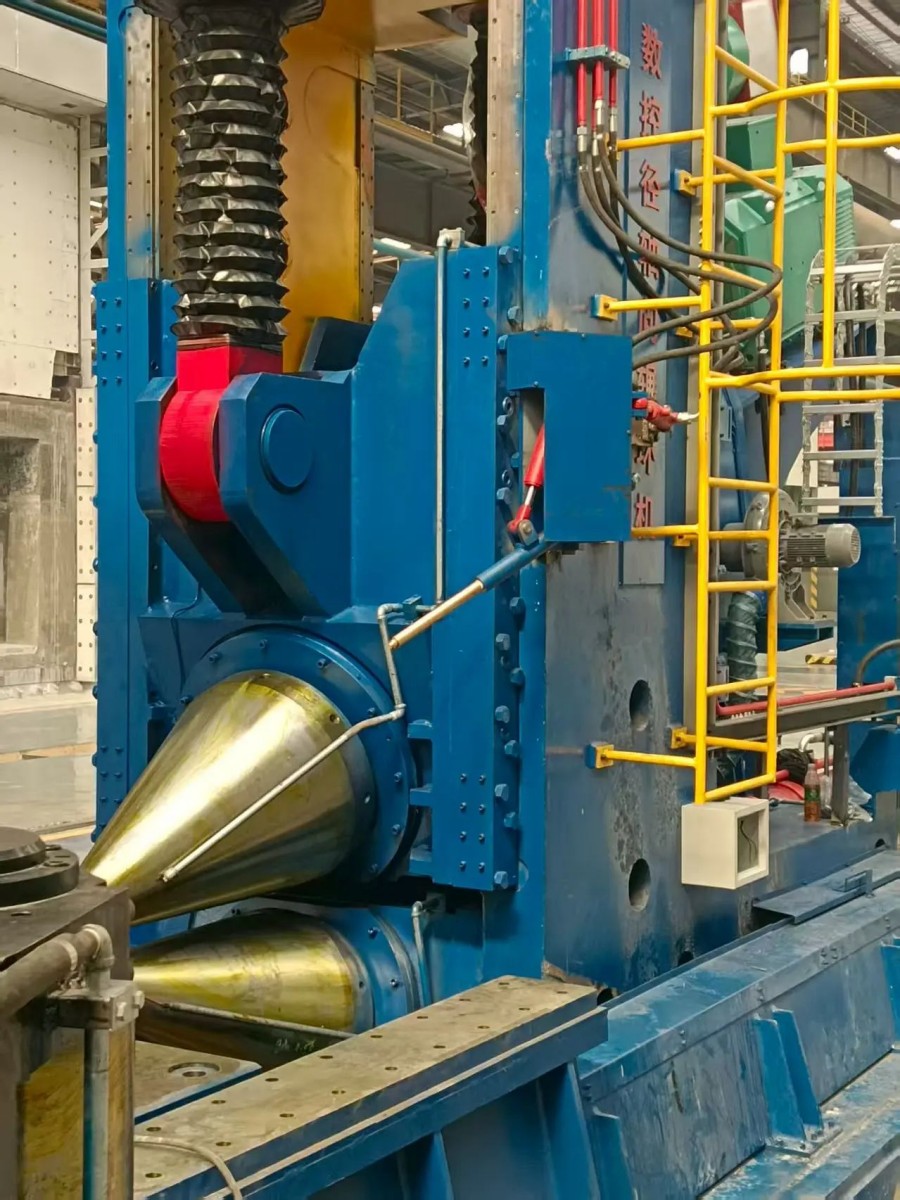

Precision Forming System

- Radial Rolling: Fast forward/backward movement, intelligent detection of the rolling start point, and servo-controlled rolling along preset radial curves.

- Axial Rolling: Rapid up/down movement with automatic starting point detection based on blank height, synchronized with radial rolling curves for accurate forming.

- End Surface Rolling: Hydraulic motor-driven with high torque, rolling speed automatically adapts to ring rotation.

- Three-Roller Technology: Provides stable rolling during forming and precise rounding at the end of the process.

Intelligent Control, Automation & Energy Efficiency

The machine integrates a smart CNC control system, automated handling, and a highly efficient hydraulic system to deliver superior performance and ease of use.

- CNC Control System: PLC + touch screen operation with dual-screen display, electronic handwheel for manual control, automatic curve generation, and remote fault monitoring.

- Real-Time Monitoring: Detection signal and thrust aligning rollers provide continuous feedback and servo follow-up control for precise positioning throughout the rolling process.

- Automation: Equipped with manipulators for automatic loading/unloading and supported by advanced algorithms for repeatable, high-quality rolling operations.

- Energy-Saving Hydraulics: Oil-electric servo with variable pump technology maintains low oil temperature, reduces energy consumption, and ensures stable operation.

- Centering Device: Hydraulic arms ensure accurate ring alignment during rolling, enhancing precision and overall product quality.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.