Principais características do servo alimentador NC para chapas metálicas

- Alta precisão de alimentação: Controlado por um sistema de feedback de circuito fechado computadorizado, garantindo precisão de ±0,03 mm. Com pinos de posicionamento na matriz, a precisão pode chegar a ±0,02 mm.

- Alimentação de alta velocidade e curso longo: Suporta operação de alta velocidade e alimentação de longa distância, melhorando significativamente a produtividade e a estabilidade operacional.

- Função de alimentação em vários estágios: Até 20 conjuntos de diferentes comprimentos de alimentação podem ser pré-programados, cada um suportando até 999 tempos de perfuração — ideal para processamento complexo de matrizes.

- Manual de fácil utilização Modo de: Oferece configurações de velocidade manual de 3 níveis para controle flexível e preciso durante a configuração e o ajuste do molde.

- Interface de operação inteligente: Equipado com uma interface homem-máquina (IHM) intuitiva para configuração rápida e fácil de parâmetros (faixa de comprimento de alimentação: 0,1 mm – 9999,99 mm).

- Mecanismo de Liberação Eficiente: Disponível com opções de liberação mecânica ou pneumática. O ponto de liberação é controlado com precisão e pode ser facilmente sincronizado com o sinal de prensagem.

- Modos de controle duplo: Suporta operação por botão do painel e controle por volante para operação flexível e multifuncional.

- Memória de trabalho para troca rápida: O armazenamento de memória integrado permite que os usuários salvem e recuperem configurações facilmente, reduzindo o tempo de configuração durante as trocas de produção.

Aplicação do Servo Alimentador NC

- Alimentador servo NC para automação de linha de prensas elétricas

- Alimentador de rolo servo NC para linhas de corte longitudinal e endireitamento de bobinas

- Alimentador servo NC de alta velocidade para produção de estampagem de metal

- Servoalimentador NC multiestágio para matrizes progressivas

- Servoalimentador NC de precisão para componentes de alta tolerância

- Alimentador servo NC geral para linhas de processamento de bobinas e chapas metálicas

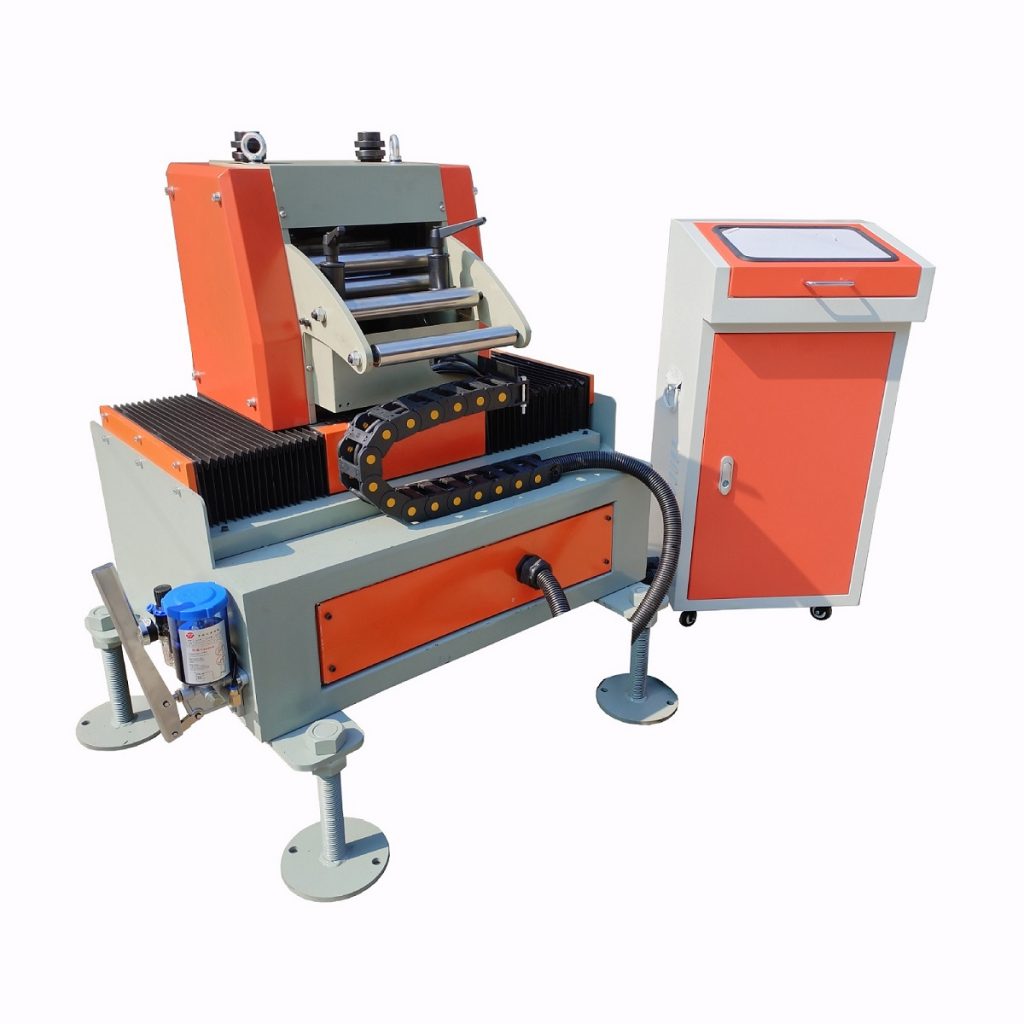

Imagem do alimentador servo NC

Estrutura e especificações técnicas:

- Sistema de servo acionamento: Acionado por um servo motor sem escovas de alta qualidade, garantindo resposta rápida e operação suave.

- Codificador de alta sensibilidade: Um preciso sistema de feedback garante controle de alimentação preciso e estável.

- Transmissão por correia síncrona: Substitui os sistemas de engrenagens tradicionais para eliminar folgas, reduzir o desgaste, operar silenciosamente e não exigir lubrificação, sendo seguro e ecológico.

- Projeto de motor integrado: O motor é integrado ao corpo da máquina, reduzindo o risco de danos durante o transporte ou manuseio.

- Rolos de alimentação do tipo oco: Leve, com baixa inércia rotacional, garantindo resposta rápida e maior precisão de alimentação.

- Material do rolo: Feito de aço de rolamento importado (HRC60°), tratado termicamente, cromado duro e retificado com precisão para longa vida útil e excelente acabamento de superfície.

- Corpo da máquina robusto: Estrutura de peça única e alta rigidez para durabilidade a longo prazo sob cargas pesadas, fácil de manter e altamente precisa.

- Sistema de engrenagens de precisão: As engrenagens são feitas de aço 20CrMnTi, cementado, temperado e retificado com precisão para garantir alta resistência ao desgaste e transmissão precisa.

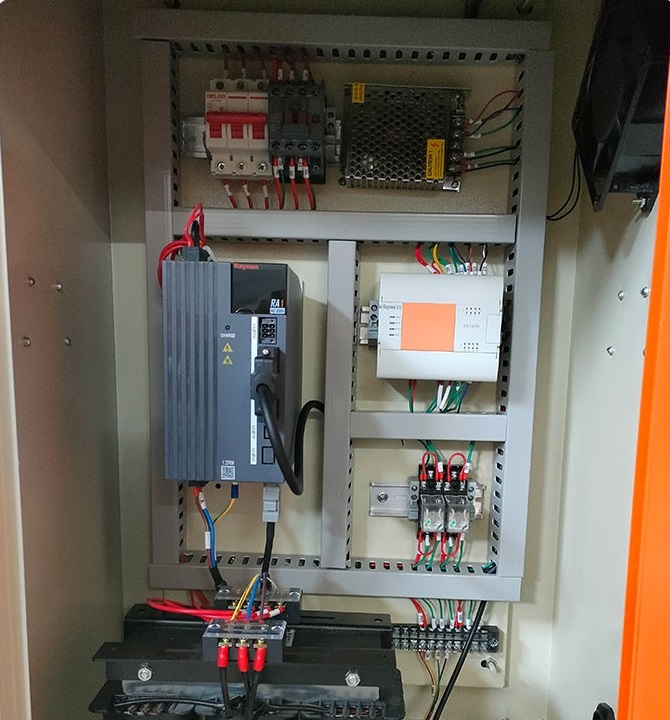

- Eletrônica de Controle Avançada: Os componentes elétricos são de marcas líderes globais, como Siemens, Yaskawa, Mitsubishi e Schneider, garantindo um desempenho confiável e eficiente.

- Integração Flexível: Isto pode Podem ser integrados em linhas de prensagem, linhas de corte longitudinal ou sistemas de alimentação automatizados. Soluções personalizadas estão disponíveis para atender a aplicações específicas.

Preencha este formulário para enviar uma solicitação de orçamento. Um membro da nossa equipe analisará os detalhes e entrará em contato em até 12 horas úteis.