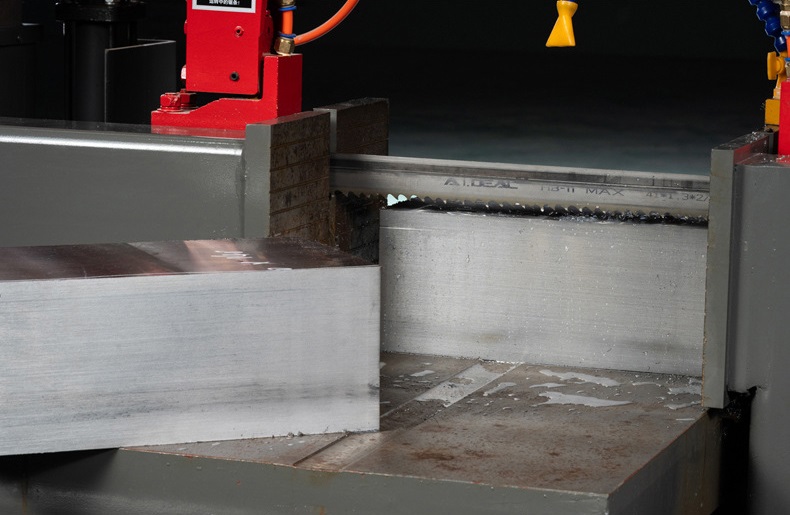

As serras de fita industriais para metal ALEKVS oferecem desempenho de corte excepcional, processando aço estrutural espesso e barras de liga resistente com precisão. Projetadas para precisão, velocidade e durabilidade, elas cortam com eficiência aço de baixo carbono, ligas endurecidas e peças metálicas complexas.

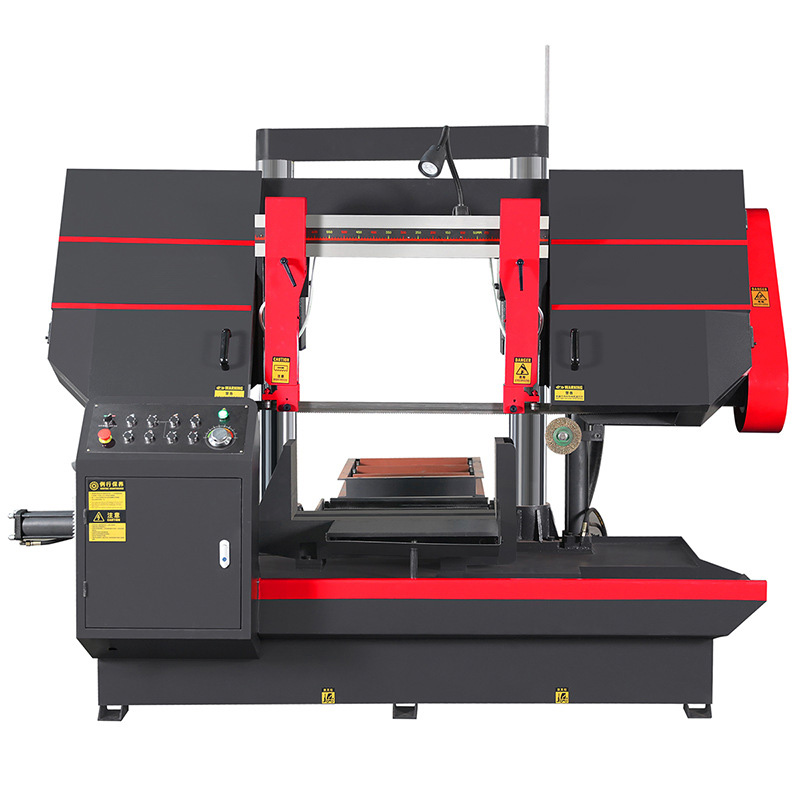

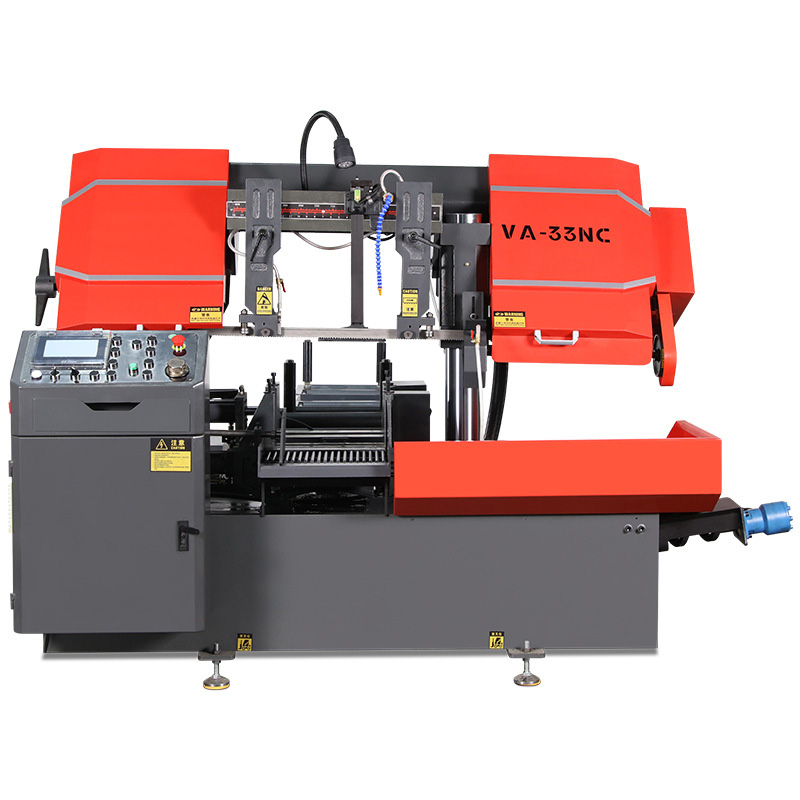

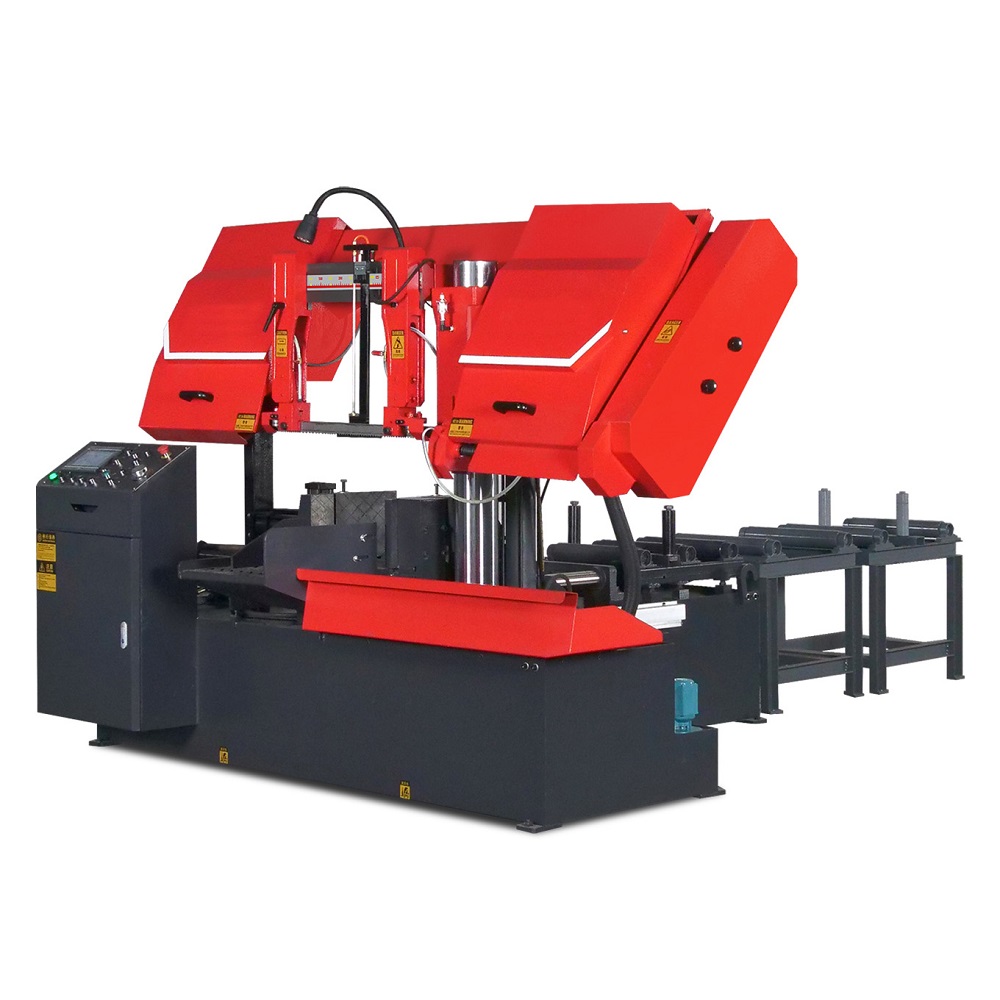

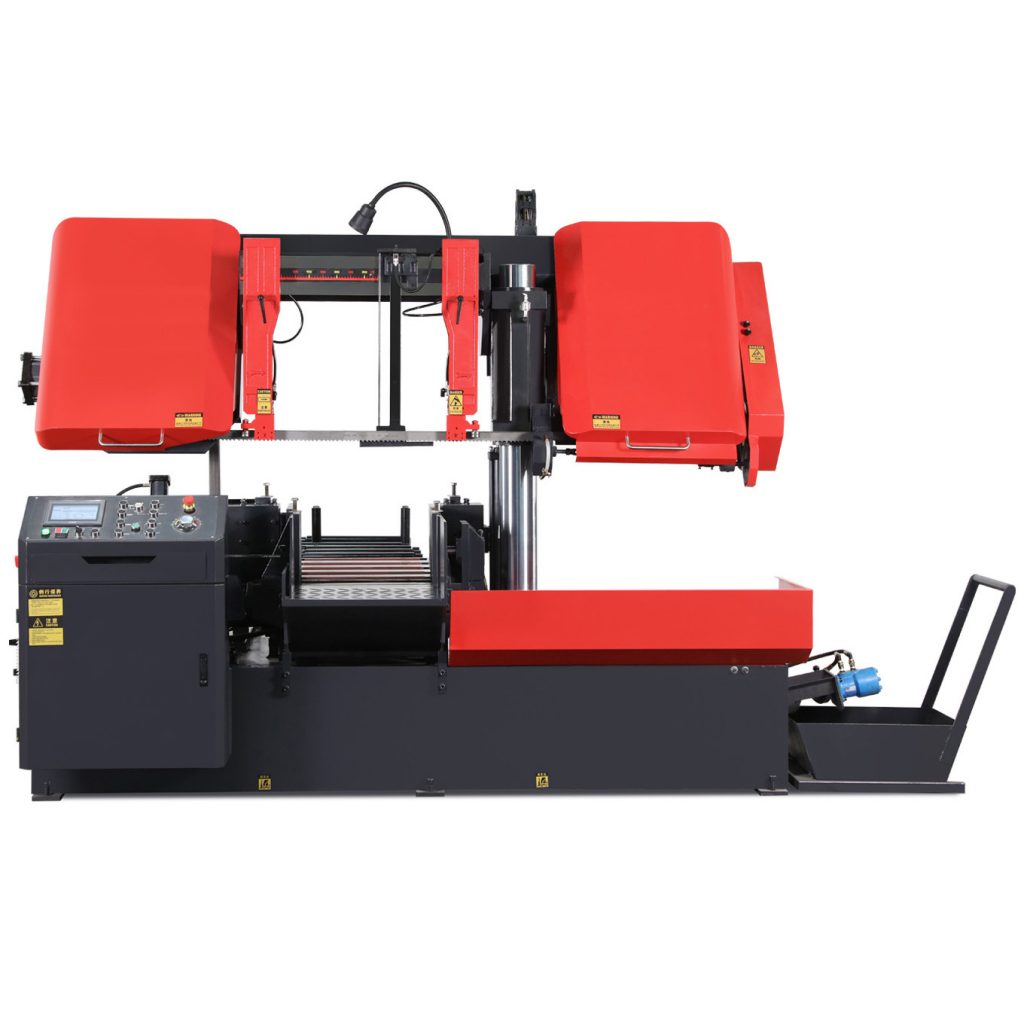

Nossa versátil série inclui serras verticais para usinagem fina, serras manuais para corte controlado e modelos semiautomáticos ou totalmente automáticos para produção em larga escala. As serras de fita ALEKVS oferecem soluções confiáveis e econômicas para oficinas de todos os tamanhos.

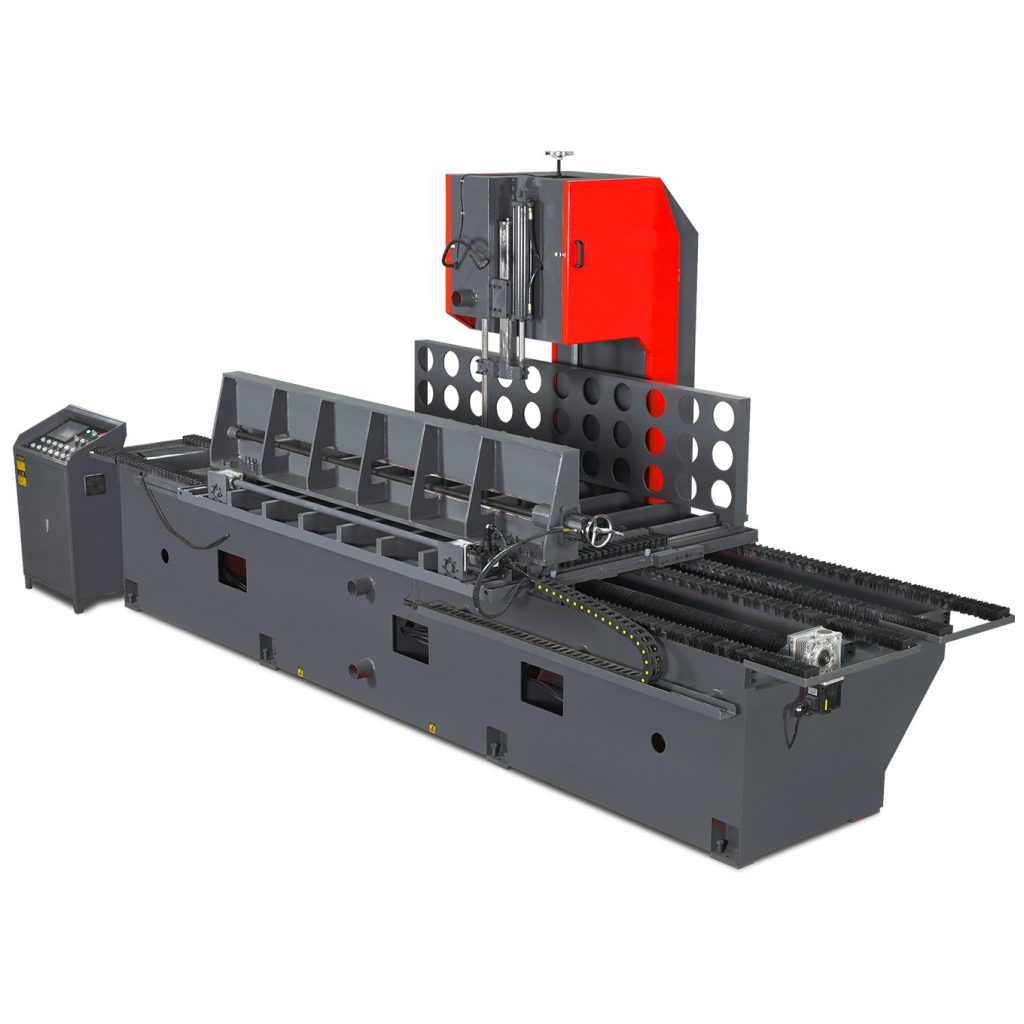

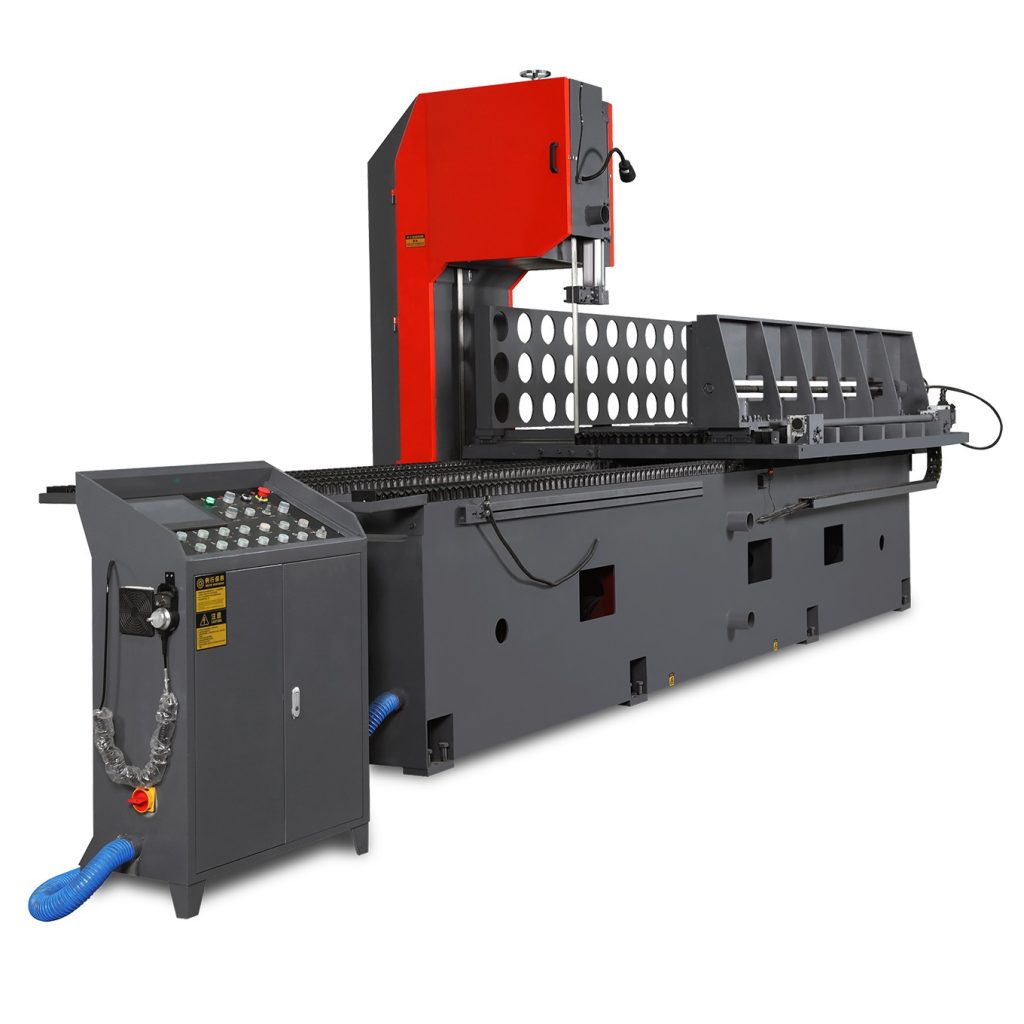

Serra de fita vertical – aplicações comuns

As serras de fita verticais são ideais para corte de curvas, usinagem de formas complexas e processamento de moldes, oferecendo alta precisão e operação flexível.

- Corte de aço para moldes (aço para moldes, blocos de aço para ferramentas)

- Curvas complexas em perfis de alumínio (Perfis de alumínio com curvas complexas)

- Corte de chapas de aço inoxidável (chapas de aço inoxidável)

- Corte de chapas de cobre e barras de latão (chapas de cobre, barras de latão)

- Corte de peças brutas de máquinas (Machine Part Blanks)

- Ranhuramento e corte de peças com formas especiais (Ranhuramento/Corte de Peças Especiais)

- Corte de padrões em chapas de aço grossas (Corte de padrões em chapas de aço grossas)

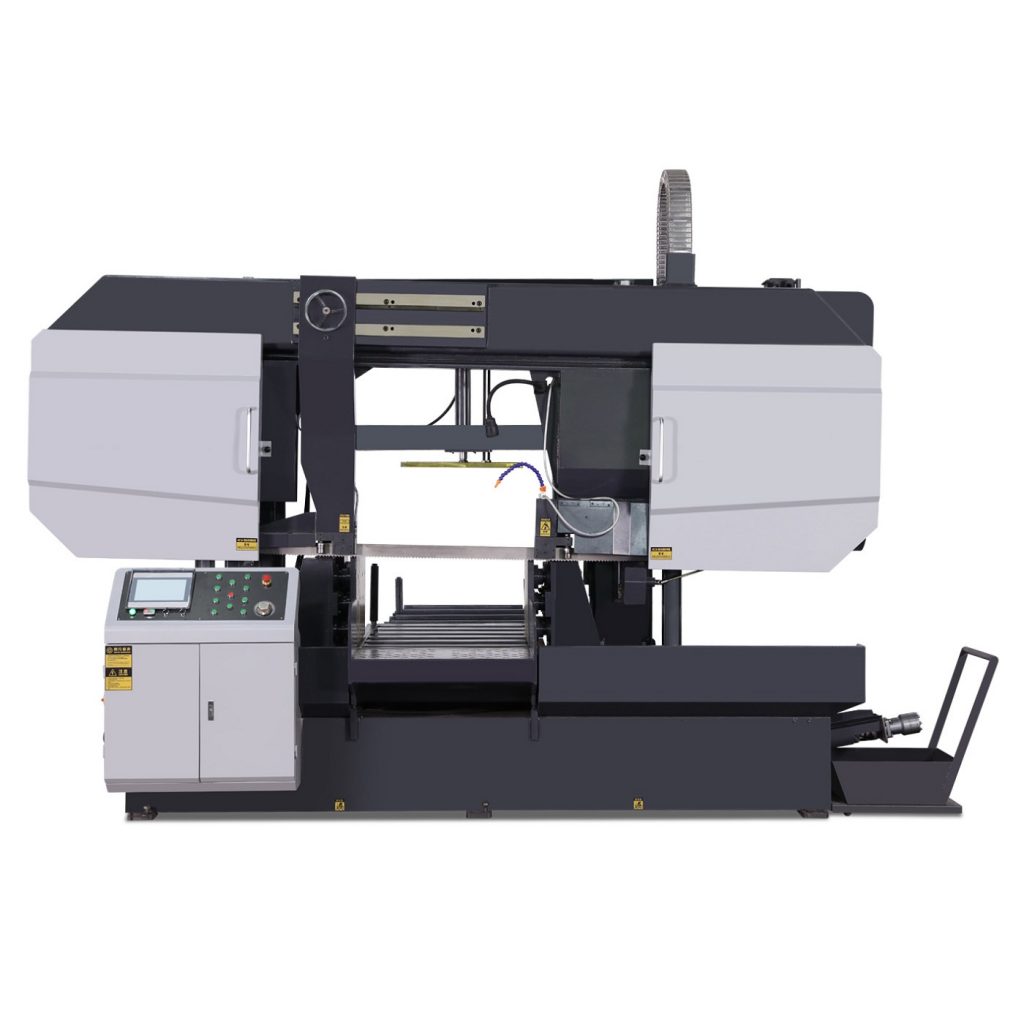

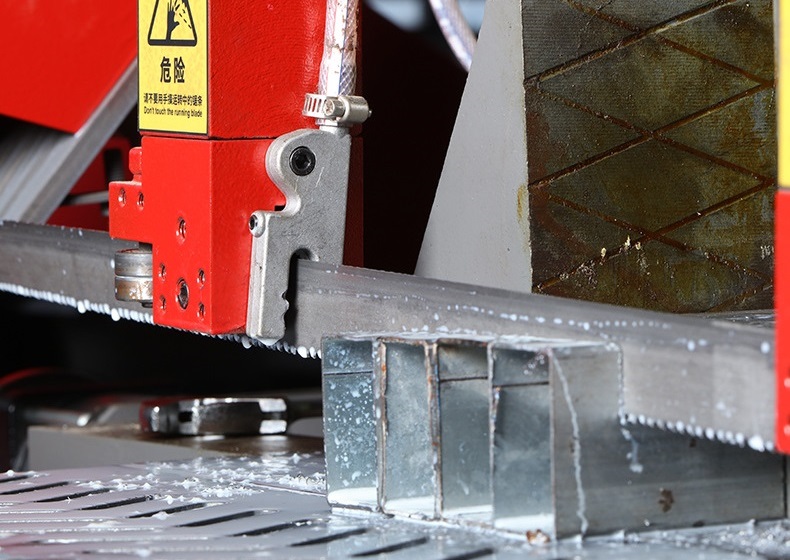

Serra de fita horizontal – Aplicações comuns

As serras de fita horizontais são mais adequadas para corte reto em lote, corte de barras e perfis, e oferecem alta eficiência para produção de alto volume.

- Corte de barras redondas sólidas (Barras redondas sólidas)

- Corte de barras quadradas (barras quadradas)

- Corte de tubos de aço e aço inoxidável (Tubos de aço, Tubos de aço inoxidável)

- Vigas H, vigas I, canais e barras angulares (vigas H, vigas I, canais, barras angulares)

- Barras, tubos e placas de alumínio (Barras, tubos e placas de alumínio)

- Corte em lote de aços ligados e carbono (aços ligados, aços carbono)

- Corte de blanks de eixo (Shaft Blanks)

- Corte de blanks de fundição pesada (blanks de fundição)