Coil Line for Servo Presses – High-Performance Integrated Feeding Solutions

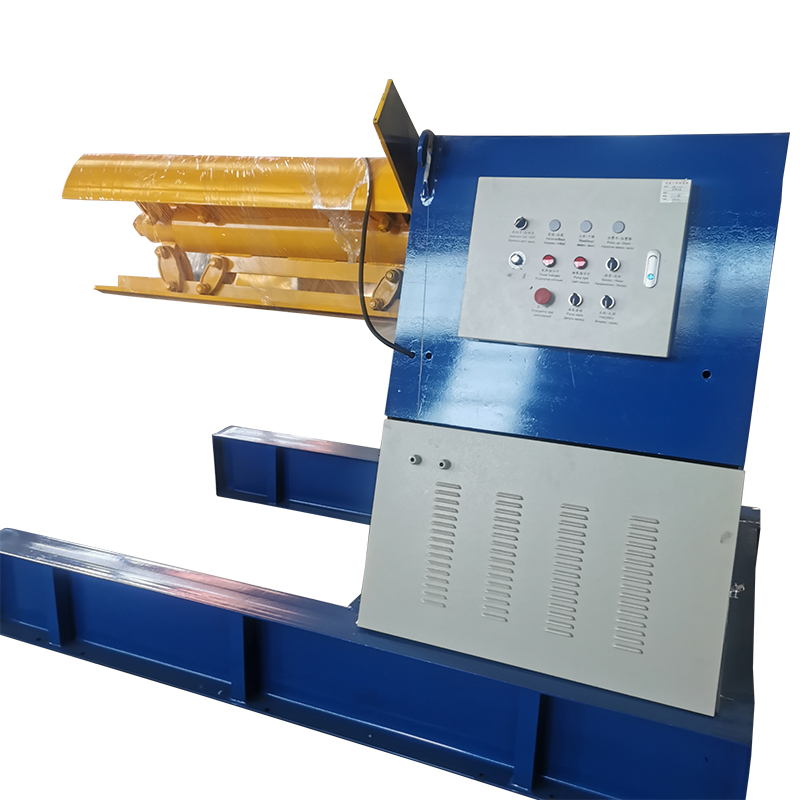

The ALEKVS Press Feeding Line is more than just a system that straightens coil material and feeds it into the press — it is the core link in a fully integrated metal forming production chain.

Designed to work in perfect harmony with front-end coil preparation, back-end processing, and cross-process integration, it enables a seamless flow from raw coil to finished product. From coil preparation and stamping to welding, painting, and assembly, every stage connects effortlessly for maximum efficiency, continuity, and quality.

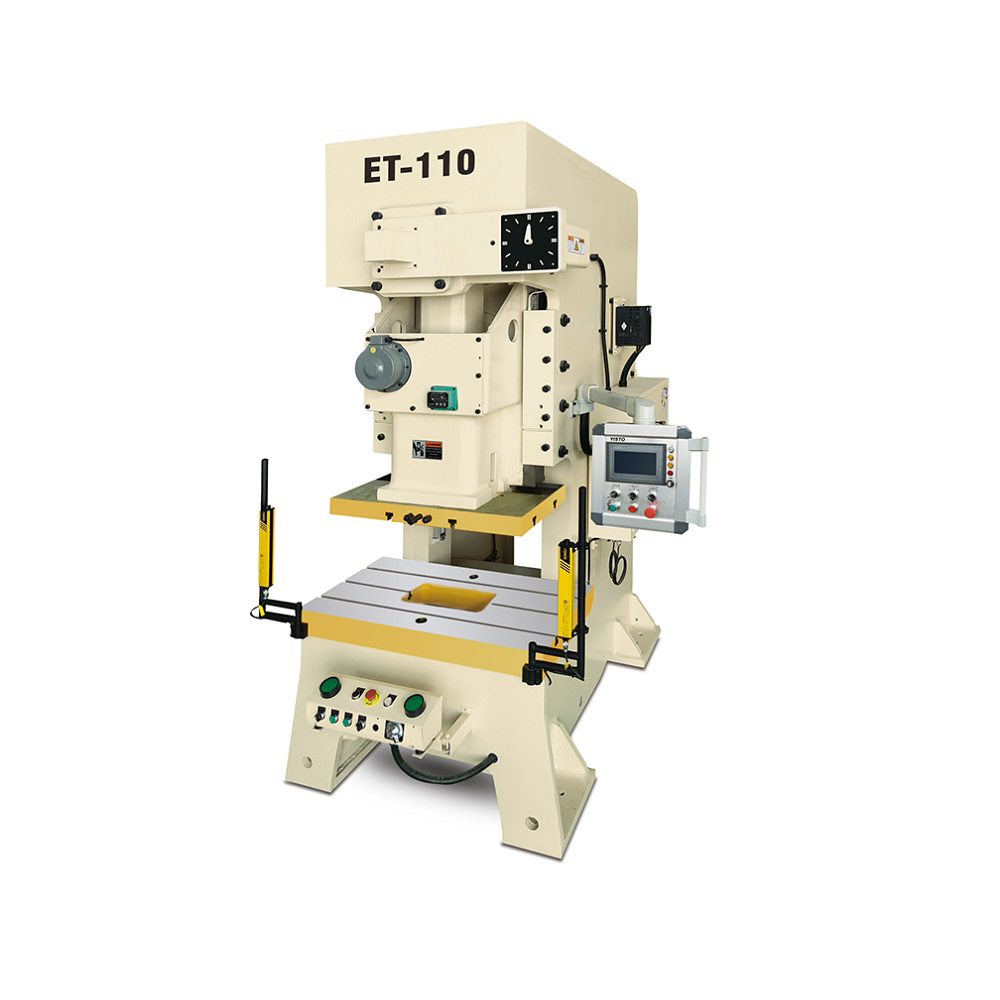

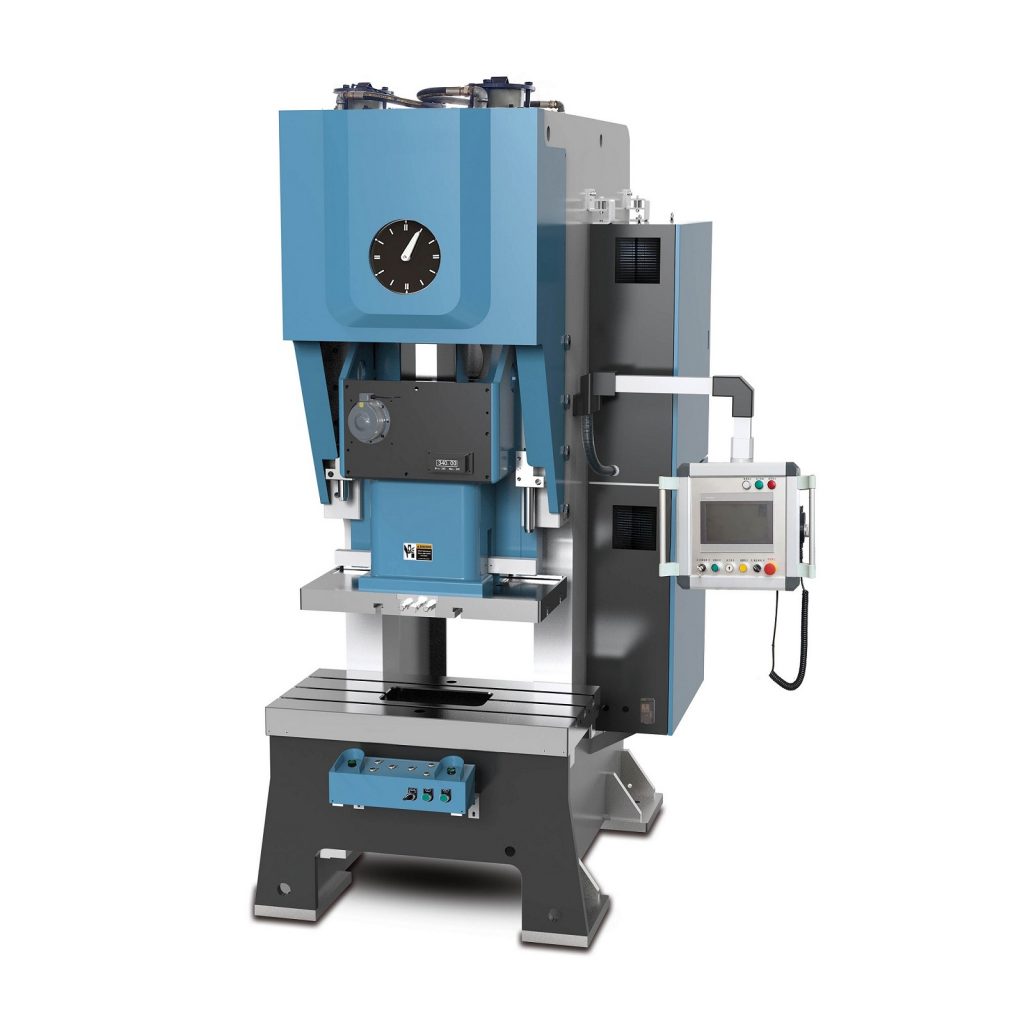

For servo press applications, ALEKVS offers long-form press feeding lines engineered for high-performance feeding even at high speeds. Thanks to the decoupled leveler and feeder design, connected via a loop, the system ensures continuous leveling without sacrificing throughput — ideal for demanding, high-volume production.