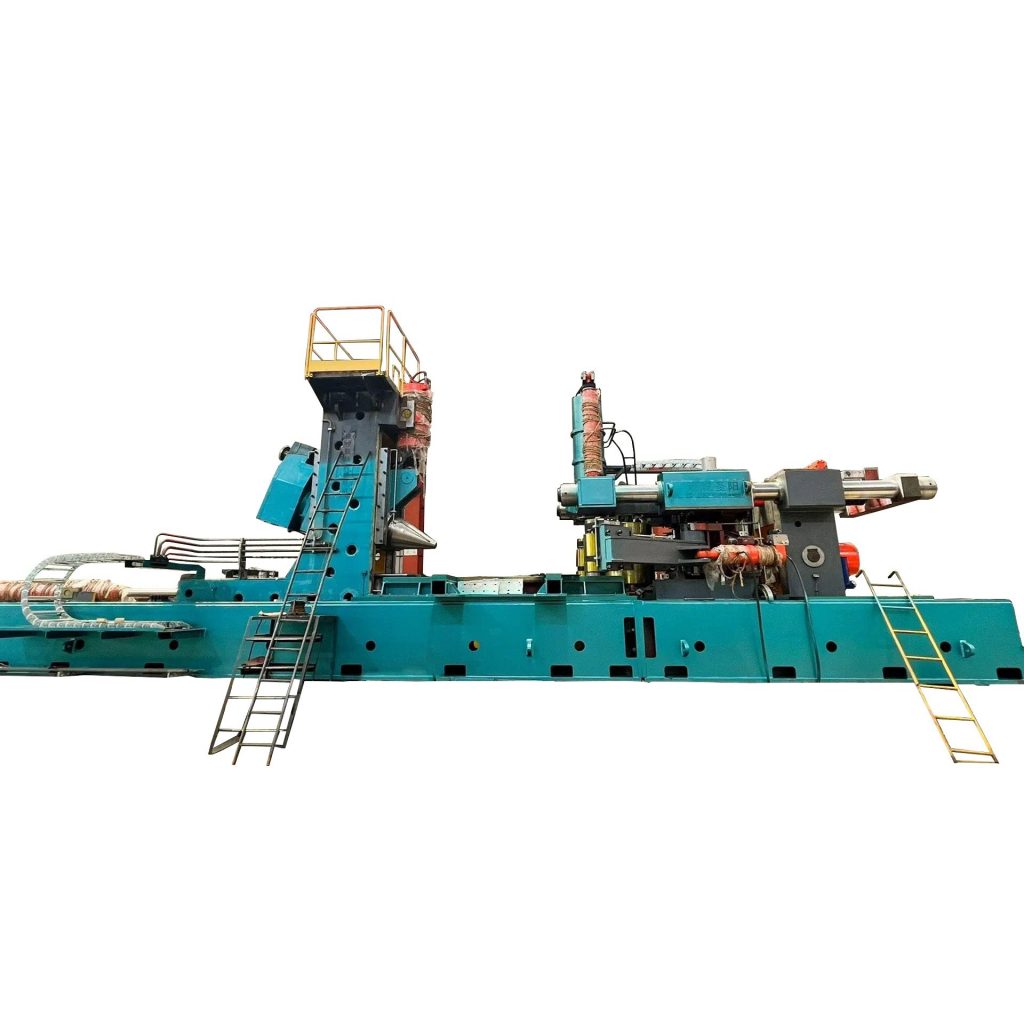

Pneumatic Forging Power Hammer Overview

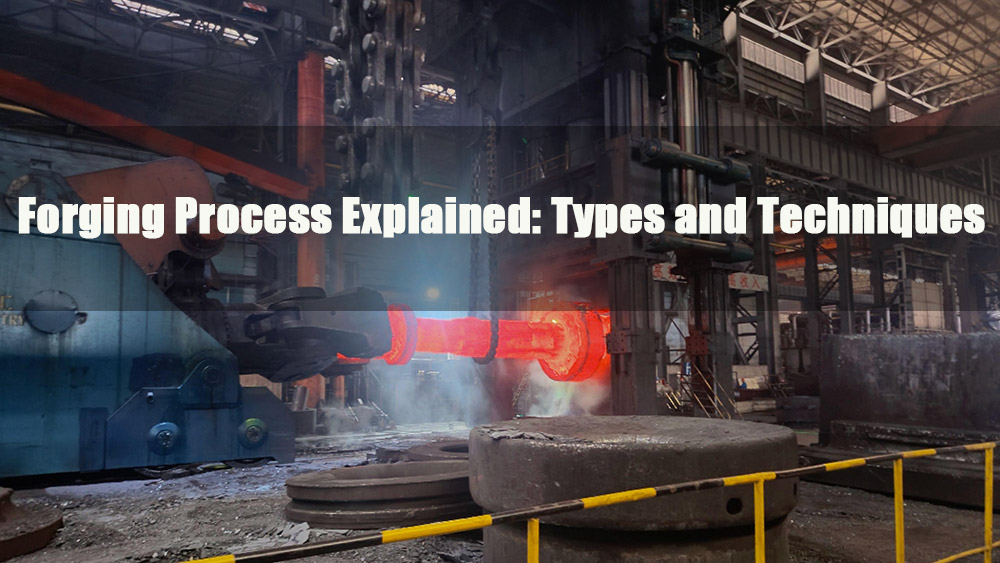

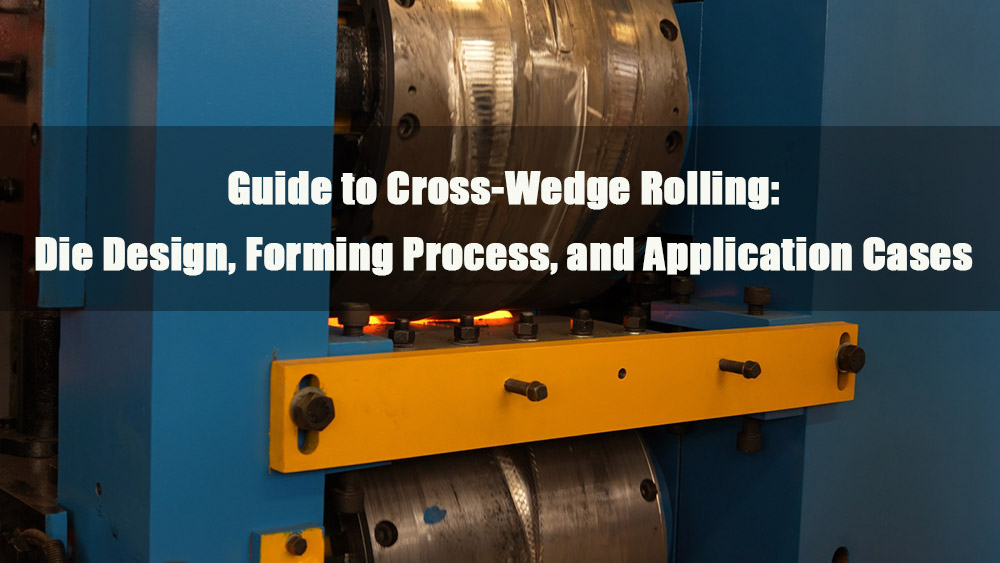

The pneumatic forging hammer uses compressed air as its power source, converting air pressure into hammer energy for high-frequency, controllable strikes. It enables plastic deformation of billets into shafts, gear blanks, connectors, and other precision or heavy-duty components.

Compared with traditional steam hammers, it is cleaner, more efficient, and requires no complex piping. Striking force is easily adjustable, making it suitable for both small-batch precision forging and large-scale heavy forging. With its efficiency, flexibility, and eco-friendly operation, the pneumatic forging hammer is a key equipment in modern metal forming.

Structure & Design

- Robust Frame: Machine body made of cast iron for excellent vibration resistance; large-capacity anvil blocks are made of cast steel for superior durability.

- Durable & Low Maintenance: Simple structure, easy to maintain, long service life, and high production efficiency.

- Core Components: Composed of the body frame, transmission mechanism, compression cylinder, working cylinder, compression piston, valve system, and anvil block.

Additional Features

- Self-contained Power System: Unlike steam hammers or compressor-fed hammers, the pneumatic hammer has its own cylinder system, requiring no external compressor or high-pressure hoses.

- Automatic Lubrication: Equipped with a self-priming oil pump, achieving automatic lubrication during operation.

- Easy Operation: By controlling the hand lever or foot pedal, all functions—idle run, top setting, pressing down, single blow, light blow, or full series blow—can be easily achieved.

- Built to Last: Frames are heavy cast iron for long-term stability; internal parts are forged steel and precision-machined; crankshaft uses large tapered roller bearings in a sealed grease case, ensuring decades of trouble-free operation.

Applications of Pneumatic Forging Power Hammer

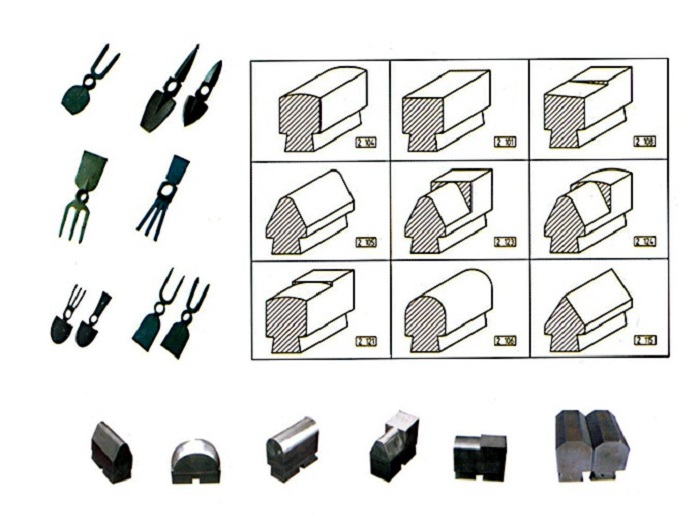

- Tool & Knife Forging: Forging blades, knives, hammers, chisels, and hand tools with strong impact energy and precise control, ensuring durable and consistent tool quality.

- Automotive & Machinery Parts: Producing shafts, gear blanks, connecting rods, and couplings, capable of handling large billets such as Φ320 mm round steel and 290×290 mm square steel.

- Hardware & Precision Components: Forging fasteners, rings, and small precision parts with high striking frequency (up to 258 blows/min) for efficient mass production.

- Industrial Open-Die Forging: Drawing-out, upsetting, bending, twisting, punching, chiseling, and forge welding of medium and large billets in open die forging workshops.

- Custom Forging Applications: Applied in mining, oil machinery, shipbuilding, aerospace, and other industries, designed for long-term reliable performance in harsh factory environments.

AEK Pneumatic Forging Power Hammer– Customizable Solutions

The AEK Series Pneumatic Forging Hammers are engineered for versatility and adaptability in modern forging. Beyond standard models, AEK offers a high degree of customization to meet diverse production needs.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.